DINA DNSL-ZM User guide

Original Instruction Manual

we are safety.

Original instruction manual Date: 2017.08.28 Page 2 of 28

Original instruction manual Date: 2017.08.28 Page 3 of 28

The direct way to safe automation

Inhaltsver eichnis

1

SAFELINE Modules ........................................................................................................................................................................... 6

1.1

Intended purpose ............................................................................................................................................................................. 6

2

Safety regulations ............................................................................................................................................................................ 7

2.1

Important notes and validation ................................................................................................................................................... 7

3

Product description ......................................................................................................................................................................... 8

o

Behaviour with errors...................................................................................................................................................................... 8

4

Mounting ............................................................................................................................................................................................. 9

5

Central modules .............................................................................................................................................................................. 10

5.1

Schematic and display .................................................................................................................................................................. 10

5.2

Front view of the central modules ............................................................................................................................................ 11

6

Field busses and interfaces ......................................................................................................................................................... 11

7

Standstill and speed monitoring................................................................................................................................................ 12

7.1

Schematic, display and front view ............................................................................................................................................ 12

8

In-, output modules ........................................................................................................................................................................ 13

8.1

Schematic, display and front view ............................................................................................................................................ 13

9

Kaskadierung über DNSL-CI und DNSL-CM .......................................................................................................................... 14

10

Networking using DNSL-NI ......................................................................................................................................................... 15

11

Inputs for safety functions .......................................................................................................................................................... 16

11.1

Safe Shutdown mat functions using I16 – I20 at DNSL-ZMT ............................................................................................ 16

11.2

Input for function mode switch (FMSS) at the central module ....................................................................................... 16

11.3

Input for Tow-Hand functions according to EN 574: Type IIIC......................................................................................... 16

11.4

Eingänge für Sicherheitskreise (SK) mit manuellem Quitt ............................................................................................... 17

11.5

Inputs for safety circuit without quit input ............................................................................................................................ 17

11.6

Quit for safety circuits (SC) ......................................................................................................................................................... 18

12

Standstill and speed monitoring................................................................................................................................................ 18

12.1

Standstill and speed monitoring at DNSL-ZMB/ ZMR/ ZMT ............................................................................................ 18

12.2

Requirement at Proximity sensors ............................................................................................................................................ 18

12.3

Standstill and speed monitoring using DNSL-DS ................................................................................................................ 19

12.4

Requirement at the Measuring system ................................................................................................................................... 19

12.5

Standstill and speed monitoring using 2 Sensors for measuring system .................................................................... 19

12.6

Standstill and speed monitoring using DNSL-DR ................................................................................................................ 19

12.7

Standstill and speed monitoring using DNSL-SI ................................................................................................................. 20

12.8

Quit of the speed monitoring ..................................................................................................................................................... 20

12.9

Brake monitoring with DSV, DRV, SIV ..................................................................................................................................... 20

12.10

Direction monitoring with DNSL-DSV, DRV and SIV .......................................................................................................... 20

12.11

DNCO Function to monitor the Peripheral speed ............................................................................................................... 21

12.12

Analogue inputs for DNCO-function at DNSL-ZMA ........................................................................................................... 21

13

Cable adapter................................................................................................................................................................................... 21

14

Data in- and outputs at the field bus ....................................................................................................................................... 22

15

Outputs at SAFELINE ................................................................................................................................................................... 23

16

General technical data ................................................................................................................................................................ 24

Original instruction manual Date: 2017.08.28 Page 5 of 28

16.1 Electrical characteristics ............................................................................................................................................................ 24

16.2 Semiconductor outputs at the central module ................................................................................................................... 24

16.3 Semiconductor outputs at the function modules .............................................................................................................. 24

16.4 Contact outputs at at SAFELINE .............................................................................................................................................. 25

16.5 Electrical life of the contact outputs ...................................................................................................................................... 26

17 Dimension and installation .........................................................................................................................................................27

17.1 Rack variants ....................................................................................................................................................................................27

SAFELINE Modules

Original instruction manual Date: 2017.08.28 Page 6 of 28

1SAFELINE Modules

Central module

Speed monitoring

In-, output modules

Relay modules Field bus modules

Network modules

DNSL-ZM

DNSL-ZMA

DNSL-ZMB

DNSL-ZMK

DNSL-ZMR

DNSL-ZMT

DNSL

-

DS

DNSL-DR

DNSL-SI

DNSL-IN

DNSL-IO

DNSL-IO2

DNSL-RM

DNSL-KM

DNSL-RM

DNSL-KM

DNSL

-

CO

DNSL-DP

DNSL-EC et

DNSL-NI

1.1

Intended purpose

•Testing based on:

•EN 55011: 2009+A1 2010 (class B), EN 61326-1: 2006-05 SIL3, EN 61000-6-2: 2006-05,

EN 62061: 2005, EN 61326-3-1: 2008

•DIN EN 60947-5-1 (2010-4): Low-voltage switch gear and control gear;

part 5.1: Control circuit devises and switching elements - electromechanical control circuit devices

•EN ISO 13849-1 (2016-06): Safety-related parts of control systems;

Part 1: General principles for design (category 4, PL e, ET 16110 from 2016-08-012)

•DIN EN ISO 13849-2: Safety-related parts of control systems; Part 2: Validation

•DIN EN 574 (2008-12): two-hand control devices type III C using contact outputs type III A using

semi-conductor outputs

•GS-ET-20 (2014-10): Basic principles for testing and certification of safety switch devices

Authori ed person for the combination of the technical documents: Dirar Najib, CEO,

Esslinger Str. 84, D 72649 Wolfschlugen

Wolfschlugen, 2016-08-15Zertifi ierungsdaten

EN ISO 13849-1: Category 4, PLe

EN 574: two-hand function

MTTF

D

: 75 years

DC

awg

: ≥ 90%

PFH

D

: 6,24x10

-8

CCF: 85 points,

DIN EN 62061

CCF: 95 points,

T

M

: 20 years

R

1ZD7

US LISTED

IND.CONT.EQ

File E227037

Certificated by: (Fachausschuss für Elektrotechnik, Prüf- und Zertifi ierungsstelle Köln)

European notified institution, Identification-number 0340, EC-Type Test certificate (DGUV Test: ET 16110 from 12-08-2016)

EMC-directive certificated by “ELMAC GmbH Bondorf”, Reg. No.: DAT-P-206/05-00

CNL, USL: File E227037

QM System certificated according to DIN EN ISO 9001:2015 by “DQS, Frankfurt”, Reg.-No.: 67542 QM08

Certificate and declaration of conformity: See www.dina.de

Safety regulations

Original instruction manual Date: 2017.08.28 Page 7 of 28

2Safety regulations

•The device may only be installed and commissioned by an electrician or trained persons who are familiar with

these operating instructions and the applicable regulations regarding work safety and accident prevention.

•Observe the VDE, EN and local regulations, particularly with respect to the protective measures.

•Failure to observe the regulations may result in death, severe bodily injury or extensive property damage.

•For emergency-stop applications, either the integrated function for restart interlock must be used or

automatic restarting of the machine must be prevented by means of a higher-level control.

•During transport, storage and operation adhere to the conditions specified in EN 60068-2-1, 2-2!

•Unauthori ed modifications shall render any warranty null and void.

•Dangers may thereby arise that could result in severe injuries or even death.

•Install the device in a control cabinet with a protection class of at least IP54! Dust and moisture may

otherwise result in impaired functions.

•Installation in a control cabinet is mandatory.

•Ensure adequate protection circuits at output contacts for capacitive and inductive loads!

•The device is to be installed taking into account the distances required per DIN EN 50274, VDE 0660-514.

•During operation, switching devices carry dangerous voltage. Do not remove protective covers.

•Replace the device after the first malfunction!

•Properly dispose of the device at the end of its service life.

+

-

•If these regulations are not adhered to or in the event of improper use, DINA Elektronik GmbH accepts

absolutely no liability for the resulting property damages or personal injury.

•Save this product information!

2.1

Important notes and validation

•The product described here was developed to perform safety related functions as part of a complete system.

•The complete system consists of sensors, evaluation and message units as well as concepts for safe

shutdowns.

•It is the responsibility of the manufacturer of a system or machine to ensure the proper overall function.

•The manufacturer of the system is required to test and to document the effectiveness of the implemented

safety concept within the complete system.

•This verification is to be performed after every modification to the safety concept or to safety parameters.

•DINA Elektronik is not in the position to guarantee the properties a complete system that was not designed

by DINA.

•DINA Elektronik GmbH also accepts no liability for recommendations that are given or implied by the

following description.

•No new guarantee, warranty or liability claims that extend beyond DINA's general delivery conditions can be

derived on the basis of the following description.

•To avoid EMC disturbances, the physical environmental and operating conditions at the installation location

of the product must comply with section EMC of DIN EN 60204-1.

•The safety function must be required every month if there is performance level (e) and every year if there is

PLd is required by using contact outputs.

•The information in the general technical data at the end of the operating instructions must be adhered to.

Product description

Original instruction manual Date: 2017.08.28 Page 8 of 28

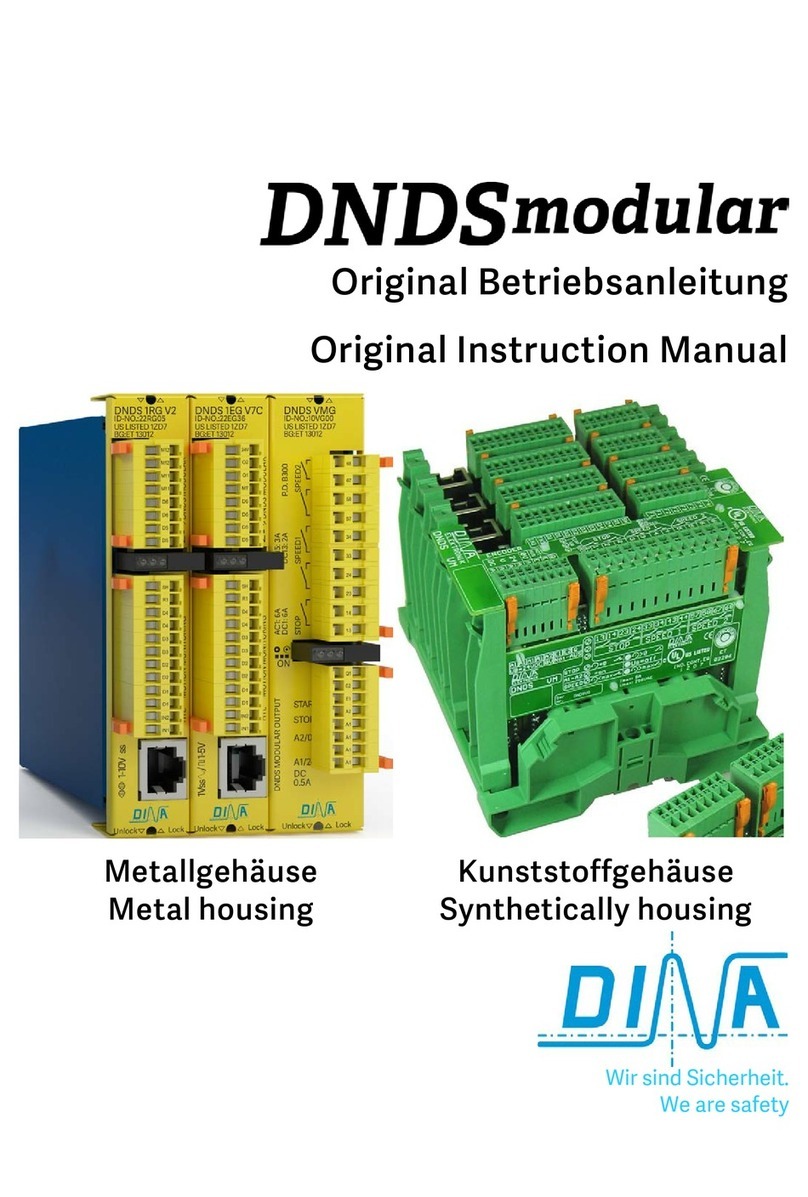

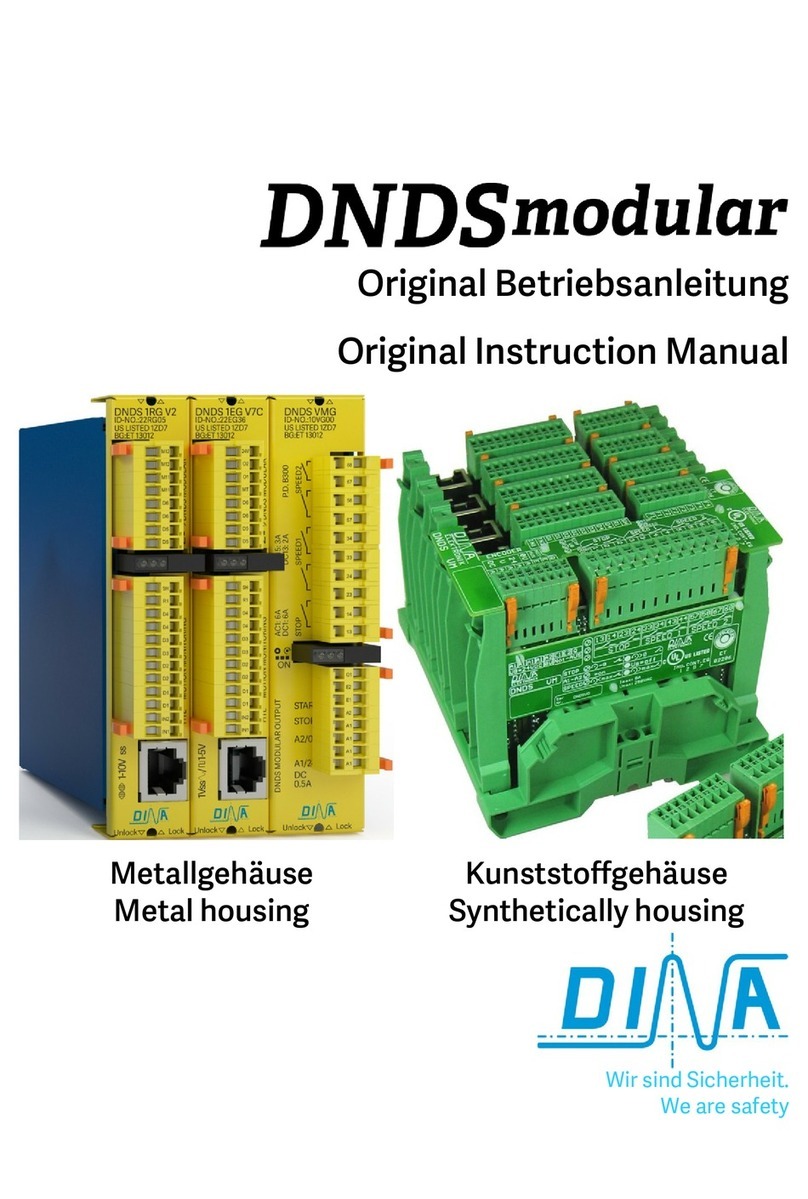

3Produ t des ription

•SAFELINE is appropriated to be used in machines and plants to protect the operator against potential

dangers and plants against destruction.

•SAFELINE is housed in a metal rack. It can be mounted by spring fasteners to a DIN rail.

•The individual modules are pluggable. The number of the used modules set the rack width. Up to 15 modules

can be used.

•Racks with 2, 3, 5, 7, 9, 13 and 15 slots are available.

•Unused slots are closed with a blind cover. ID-No.: 10BD00

•All modules are connected by 2 backplane bus system.

•To fulfil the requirements of the wide ranges of needs different modules with diverse functions are available.

•SAFELINE is deliverable with different field bus modules.

•A variety of safe functions are available such as logic modules, timers, safety circuits, mode selector,

generator, counters, comparators, feedback, restart interlock etc.

•A lot of safe digital and analogue inputs, safe semi-conductor outputs and contact outputs are available.

•Semi-conductor outputs are overload and short circuit proofed.

•The switching status of all I/O terminals and supply voltage are indicated by LED.

•The power supply (24V DC) is connected to the terminals A1/ A2 at the central module for all modules.

•To supply the semi-conductor outputs at the function modules with 24V DC the terminal P is designated.

•The user application is configurable with the SAFELINE Designer on a PC. The application is transferred by

the USB or V24 interface at the central module. The Designer is software developed by DINA.

•The user application, instruction manual, Designer and all other documents can be stored on a memory

medium, if a central module with an USB interface is used.

•The Medium is to use as a drive.

•The used connection cable with COM PORT interface is V24 (1:1). Pins 2, 3 and 5 are only important.

•Remark

•The function devices are tested safe and certificated as a part of the firmware.

•A modification of the certified function devices as part of the firmware is excluded.

oBehaviour with errors

•Output O1 at the central module is switching off.

•Correction Inspection of the wiring and assembly

•Switching off and on of the power clears the errors. See also diagnostics tool at the Designer

Mounting

Original instruction manual Date: 2017.08.28 Page 9 of 28

4Mounting

•A central module is necessary in an Application.

•The number of other modules is breath-responsive.

•The central module is always left in the rack.

•The field bus is in the next slot.

•The data interface is separately right mounted if ZMB, ZMT or ZMR are used.

•The data interface and the field bus are integrated at the same module if a field bus is used.

•The relay module DNSL-KM can be used only with the DNSL-ZMR and must be placed at the right side.

•All other modules may be placed in any order

DNSL

-

ZMR

DNSL

-

EC

DNSL

-

KM

DNSL

-

DR

DNSL

-

IN

DNSL

-

IO

DNSL

-

IO2

DNSL

-

RM

Frei

DNSL

-

DS

Central modules

Original instruction manual Date: 2017.08.28 Page 10 of 28

5Central modules

DNSL-

ID-No.:

ID-No.:

Terminals

Description

all A1/ A2 Power supply terminals 24V DC for all modules in the application

all I1-I6 Safe digital inputs for safety functions

ZMB

ZMR

24ZB40

24ZR40

24ZB40

24ZR40 I11-I20 Safe digital inputs for safety functions

ZMT 24ZT40 24ZT40 I11-I15 Safe digital inputs for safety functions

ZMT 24ZT40 24ZT40 I16-I20 Safe inputs for shut down mat

Co. Mayser type TS/W1 and TS/ BK1

ZMB

ZMR

ZMT

24ZB40

24ZR40

24ZT40

24ZB40

24ZR40

24ZT40

1: I11, I12

2: I13, I14

2 safe standstill and speed monitoring using sensors with 24V

signals

ZMA 24ZA20 24ZA30 UR,UA,0V Connector for potentiometer

all O1 Semi-conductor output, system OK

ZM

ZMR 24ZM20

24ZR40

24ZM30

24ZR40

O2-O5

O6, O7

Safe Semi-conductor output

Safe Semi-conductor output for clock or switch outputs

ZMA

ZMK

ZMB

ZMT

24ZA20

24ZK20

24ZB40

24ZT40

24ZA30

24ZK30

24ZB40

24ZT40

O2, O3 Safe Semi-conductor output

ZMB

ZMT

ZMK

24ZB40

24ZT40

24ZK20

24ZB40

24ZT40

24ZK30

13/14

24/24 Safe contact outputs

CP

24CP40

V24

interface for DNSL

-

ZMB, ZMR und ZMZ fo

r

d

at

a

t

ransfer

UP

24UP4

USB

interface for DNSL

-

ZMB, ZMR und ZMZ for data transfer

KM 40KM01

O1-O4

13/14 - 83/84

Ôutputs for aiagnostics

Safe contact outputs every with 2 contacts

5.1

S hemati and display

DNSL

-

ZM

DNSL

-

ZMA

DNSL

-

ZMK

DNSL

-

ZMB/T

DNSL

-

ZMR

DNSL

-

KM

I1-I6 Signal=0V Signal = 24V

24V

6A

0V A2

A1

24V

O1

O2

O3

O4

O5

O6

O7

I1

I2

I3

I4

I5

I6

DC

MP ON SP

Eingänge/ Inputs

USB

PORT

DNSL-ZM

24V

O1

O2

O3

UR

UA

0V

I1

I2

I3

I4

I5

I6

Eingänge/ Inputs

DNSL-ZMA

6A

A1

24V

DC

0V

MP ON SP

USB

PORT

13

14

23

24

USB

PORT

DNSL-ZMK

MP ON SP

Eingänge/ Inputs

I1

I2

I3

I4

I5

I6

O1

O2

O3

24V

6A

A1

24V

DC

0V

24V

6A

0V A2

A1

24V

O1

O2

O3

13

14

23

24

I1

I2

I3

I4

I5

I6

DC

MPON SP

Eingänge/ Inputs

I11

I12

I13

I14

I15

I16

I17

I18

I19

I20

Eingänge/ Inputs

DNSL-ZMB/ ZMT

O7

O3

O4

O5

O6

Eingänge/ InputsEingänge/ Inputs

DNSL-ZMR

I11

I12

I13

I14

I15

I16

I17

I18

I19

I20

MPON SP

I1

I2

I3

I4

I5

I6

24V

6A

24V

A1

DC

0V

O1

O2

O1

13

14

23

33

34

43

44

24

O2

24V

24V

O3

53

54

63

73

74

83

84

64

O4

24V

24V

PwrK1 K2

K3 K4Pwr

K4

K3

K2

K1

DNSL-KM

I11-I20 Signal=0V Signal = 24V

O1-O7 I=0 I > 0 ≤ max.

13—24

1 A1/A2: 0V 1 A1/A2: 24V

2 System OK 2 Data

3 Not valid 3 Valid

3 SLOK off

3 Data Diagnostic

Datentransfer

Data transfer

DNSL-KM

Pwr ON

K1 K2

K1 K2

Pwr ON

K1 K2

K1 K2

I21-I28 Signal=0V Signal = 24V

Field busses and interfaces

Original instruction manual Date: 2017.08.28 Page 11 of 28

5.2

Front view of the entral modules

DNSL-ZM DNSL-ZMA DNSL-ZMK DNSL-ZMB DNSL-ZMT DNSL-ZMR DNSL-KM

6Field busses and interfa es

•The field busses are for data transfer between SAFELINE and the field bus master.

•The field bus is also deliverable with 8 safe inputs for different safety functions.

•The power supply for the field bus is ensured via the terminal inputs A1 and A2 at the central module.

•The data transfer interface is available separate or with integrated field bus

COM PORT (DNSL-CP) and USP PORT (DNSL-UP) are available.

•These are for the central modules DNSL-ZMB/ ZMR and ZMT

•DNSL-ZM, ZMA and ZMK have the interface on board.

DNSL

-

CO

DNSL

-

CO

DNSL

-

EC

DNSL

-

EC

CANopen

USB PORT

EtherCA

T

I21

I22

I23

I24

I25

I26

I27

I28

DNSL

-

DP

DNSL

-

DP

USB PORT

I21

I22

I23

I24

I25

I26

I27

I28

PROFIBUS DP

DNSL

-

CP

DNSL

-

UP

I21-I28 Signal=0V Signal = 24V USB Pwr OFF

USB Pwr ON

Standstill and speed monitoring

Original instruction manual Date: 2017.08.28 Page 12 of 28

7Standstill and speed monitoring

DNSL- ID-No.: Terminals/ onne tors

Des ription

all

B11

-

B18

Safe digital inputs for safety functions

all

P1, P2

Terminal

f

o

r

24V DC

to supply the outputs

DS 24DS07

2 safe monitoring for standstill, speed, position, direction and

brake in different function modes

Sin/cos or TTL measuring systems, HTL signals via HTL cable

adapter

DR 24DR01

2 safe monitoring for standstill, speed, position, direction and

brake in different function modes

Resolver Measuring system

SI 24SI02

2 safe monitoring for standstill, speed, position, direction and

brake in different function modes

SSI interface Measuring system

DS/ SI O1-O4 Semi-conductor outputs configurable as safe or clock outputs

DR O1-O2 Semi-conductor outputs configurable as safe or clock outputs

7.1

S hemati , display and front view

Display DNSL-DS

DNSL-DR

DNSL-SI

B11-14 Signal=0V

Signal=24V

DNSL-DS

ON

P1 24VDC

P2 24VDC

O1

O2

O3

O4

B11

B12

B13

B14

B21

B22

B23

B24

1 2

oder/or

Eingänge/ Inputs

1

2

DNSL-DR

ON

P1 24VDC

P2

O1

O1

O2

O2

B11

B12

B13

B14

B21

B22

B23

B24

1 2

Eingänge/ Inputs

1

2

DNSL-SI

ON

P1 24VDC

P2 24VDC

O1

O2

O3

O4

B11

B12

B13

B14

B21

B22

B23

B24

1 2

Eingänge/ Inputs

1

2

SSI 1

SSI 2

B21-24 Signal=0V

Signal=24V

O1-4 I=0 I>0 ≤ max.

P1/P2 O-Pwr = 0V

Pwr = 24V

1 Pwr: 0V* 1 Pwr: 24V*

2 n>0 2 n=0

3 n>max. 3 n<max.

2 3

Measuring

system

OK

2 3

No

measuring system

See also Designer instruction manual.

In-, output modules

Original instruction manual Date: 2017.08.28 Page 13 of 28

8In-, output modules

DNSL-

ID-No.: Terminals Des ription

IN 24IN01

I1

-

I8 / I21

–

I28

Safe digital inputs for safety functions

IO 24IN01

I21

–

I28

Safe digital inputs for safety functions

IO2 24IO02

I15

–

I18/ I21

–

I28

Safe digital inputs for safety functions

IO/ IO2

P1, P2

Terminal for 24V DC to supply the outputs

IN O11, O12, O21, O22 Semi-conductor outputs configurable as safe or clock outputs

IO/ IO2

O21, O22 Semi-conductor outputs configurable as safe or clock outputs

IO O11 - O18 Semi-conductor outputs configurable as 4 safe outputs

IO2 O11 - O14 Safe semi-conductor outputs

8.1

S hemati , display and front view

DNSL-IN DNSL-IO DNSL-IO2 DNSL-RM230

O22

24V

24V

O11

O12

I11

I12

I13

I14

I15

I16

I17

I18

O21

I21

I22

I23

I24

I25

I26

I27

I28

SP MP

ON

DNSL-IN

Eingänge/ Inputs

Eingänge/ Inputs

DNSL-IO

24V

P1 24VDC

P2 24VDC

O11

O12

O13

O14

O15

O16

O17

O18

O21

O22

I21

I22

I23

I24

I25

I26

I27

I28

SP MP

ON

Eingänge/ Inputs

24V

P1 24VDC

P2 24VDC

O11

O12

O13

O14

I15

I16

I17

I18

O21

O22

I21

I22

I23

I24

I25

I26

I27

I28

SP MP

ON

DNSL-IO2

Eingänge/ Inputs

Eingänge/ Inputs

MP

K2

K1

K4

SP

K3

K 1

13

14

23

24

33

34

43

44

53

54

63

64

73

74

83

84

RM

K 2

K 3

K 4

DNSL-

RM

Display

DNS-IN

DNSL-RM230

DNSL-IO / DNSL-IO2

MP OK

I11-18 Signal=0V Signal=24V

K2 K1 K2/ K1

I21-28 Signal=0V Signal=24V

K2 K1 K2/ K1

O11-18 I=0 I>0 ≤ max.

SP OK

O11-22 I=0 I>0 ≤ max.

K4 K3 K4/ K3

1 Pwr OFF 1 Pwr ON

2 3 CAN internal OFF 2 3 CAN internal OK

K4 K3 K4/ K3

Kaskadierung über DNSL-CI und DNSL-CM

Original instruction manual Date: 2017.08.28 Page 14 of 28

9Kaskadierung über DNSL-CI und DNSL-CM

•Cascade installation is necessary if the SAFELINE Modules of an application have to be at different places of

the construction to avoid wiring.

•Depending of the need functions the Modules will be mounted in different racks.

•In the basis unit is the central module and the cascade modules DNSL-CI if needed a fieldbus, function

modules.

•In the periphery units PU the cascade module DNSL-CM is mounted for the central module and right of them

the needed function modules FM.

•Maximal 14 FM are possible in one application.

•The connections between the units happen via RJ45 patch cables type DNRJ-45/45 with the necessary

length.

•Serial or star shaped connection is possible.

•The power supply for the PU can be connected to CM. The DIP switches have to be adjusted EXTERN.

•With INTERN supplying is of the basis unit (I≤ 0.5A).

•An address has to be assigned for every FM in the PUs. This happen via DIP switches at the rack circuit board.

•Every slot is equipped with a DIP switch. See graphic.

Serial cascade

USB

PORT

BUS

DNSL-CIDNSL-DSDNSL-EC DNSL-CM DNSL-DS DNSL-CM DNSL-DSDNSL-ZMx

on

1

on

2

on

3on 4

on

5

on

6

on

7

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

on 8on 9on 10 on 11 on 12 on 13 on 14

1

23

4

5

6

7

8

1

2

3

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

1

23

4

5

6

7

8

External power supply connected to A1/ A2 at DNSL-CM

Internal power supply connected to A1/ A2 at central module

DNSL-CM

Power

supply

A2

INTERN

EXTERN

A1

24V

DC

4A

ON

EXT ON

INT

EXTERN

INTERN

DNSL-CM

Star shaped cascade

USB

PORT

BUS

DNSL-CIDNSL-DSDNSL-ECDNSL-ZMx

DNSL-CI

Networking using DNSL-NI

Original instruction manual Date: 2017.08.28 Page 15 of 28

10 Networking using DNSL-NI

•The data transfer happens via 4 RJ 45 sockets. The sockets can be local grounded via 4 internal jumpers.

•The connection happens via Patch cable.

•The connection can be starry or line shaped.

•

For every application a DNSL-NI is necessary.

•A manual quit via the quit symbol at the Designer is necessary after an interrupt of the data transfer.

•Signals of safety functions like emergency stop,

protection cover, timer etc. can be transferred between the application using the data inputs and outputs.

•

The configuration happens in the Designer.

•

The schematic down left is a serial right a starry shaped networking

Serial shaped network

USB

PORT

BUS

DNSL-NIDNSL-DSDNSL-EC DNSL-ZMx DNSL-DS DNSL-DSDNSL-ZMx DNSL-ZMxDNSL-NI DNSL-NI

Starry shaped network

USB

PORT

BUS

DNSL-NIDNSL-DSDNSL-ECDNSL-ZMx

DNSL-NI

Designer Symbols

Input

symbol

Output

symbol

Quit Symbol

See also Designer instruction manual.

Inputs for safety functions

Original instruction manual Date: 2017.08.28 Page 16 of 28

11 Inputs for safety fun tions

Modules Inputs

DNSL-ZM/ ZMA/ ZMK I1 I2 I3 I4 I5 I6

DNSL-ZMB/ ZMR/ ZMT I1 I2 I3 I4 I5 I6 I11 I12 I13 I14 I15 I16 I17 I18 I19 I20

DNSL-DS / DR / SI B11

B12

B13

B14

B21

B22

B23

B24

DNSL-IN I11 I12 I13 I14 I15 I16 I17 I18 I21 I22 I23 I24 I25 I26 I27 I28

DNSL-IO/ DNSL-FB I21 I22 I23 I24 I25 I26 I27 I28

DNSL-IO2 I15 I16 I17 I18 I21 I22 I23 I24 I25 I26 I27 I28

11.1

Safe Shutdown mat fun tions using I16 – I20 at DNSL-ZMT

Up to eight shutdown mats can be monitored.

After stepping on the mat the quit-function in the Designer can be

activated.

The configuration will be done with the Designer.

Input value < min value: SM

Input value > min < max value: SM

Input value > max value: SM

Designer Symbol Quit Symbol

11.2

Input for fun tion mode swit h (FMSS) at the entral module

Function mode

(

FM

)

FMSS

with 4

p

osition

s

FMSS

with 6

Position

s

3 Function modes

I1 I2 I3

2

4

5

6

1

24VDC

I2

I1

I3

I4

I5

I6

3

I2

I1 I3

123

2 3

I1

I2

1

Error

I4

4

I5

5

I6

6

FM1

FM2

FM3

6 Function modes

I1 I2 I3 I4 I5 I6

FM1

FM2

FM3

FM4

FM5

FM6

•Only one switching position has to be selected

•Error: None or more than one

11.3

Input for Tow-Hand fun tions a ording to EN 574: Type IIIC

Inputs Control Diagram Designer Symbol

Modules E1 Q1 E2 Q2

Q1 E1 Q2E2

Q2

E1

E2

2H

Q1

>500ms Q2

OK

<500ms

DNSL-ZM/ ZMA I1 I2 I3 I4

DNSL-ZMK/ ZMB I1 I2 I3 I4

DNSL-ZMR/ ZMT I1 I2 I3 I4

DNSL-DS / DR B11

B12

B13

B14

DNSL-IN I11 I12 I13

I14

DNSL-IO/ IO2 I21

I22

I23

I24

Start keys have to be activated during 500ms

1 2

3

24VDC

I1 I2

I3

4

I4

I2

I1 I3

123

2 3

I1

I2

1

Error

Inputs for safety functions

Original instruction manual Date: 2017.08.28 Page 17 of 28

11.4

Eingänge für Si herheitskreise (SK) mit manuellem Quitt

Safety circuit (SC) / input name (E/Q) / Input (I/B)

SK1

SK2

SK3

SK4

SK5

Modules E11 E12 Q1 E21 E22

Q2 E31 E32

Q3 E41 E42 Q4 E51 E52

Q5

DNSL-ZM/ ZMA/ ZMK I1 I2 I3 I4 I5 I6

DNSL-ZMB/ ZMR/ ZMT I1 I2 I3 I4 I5 I6 I11 I12 I13 I15 I16 I17 I18 I19 I20

DNSL-DS / DR B11 B12 B13

B21 B22

B23

DNSL-IN I11 I12 I13 I15 I16 I17 I21 I22 I23 I25 I26 I27

DNSL-IO/ IO2 I21 I22 I23 I25 I26 I27

•The control of the safety circuit happen parallel static, parallel using clock or static antivalent.

•

Start edge Qt is configurable only at the central module. See Designer

•

Start edge is constant (1s) at the function modules

Control Static parallel Clock Control Antivalent: central module only

Emergency

stop

Quit

E11

E12

Q1

Diagram

t

SK

E11

E12

Q1

t < Qt t

t > Qt

Diagram

E31

E32

Q3

SK

t

t < Qt

t

t > Qt

Emergency

stop

Quit

E21

E22

Q2

Diagram

Q2

E21

E22

SK

Static: Q1 connected to 24V DC

Permission

Zustimmung

Safety gate

Diagram

t

SK

E11

E12

Q1

t < Qt t

t > Qt

Diagram

E31

E32

Q3

SK

Safety cover

Diagram

SK

E11

E12

Q1

Clock: see SAFELINE outputs for clock.

11.5

Inputs for safety ir uit without quit input

8 safety circuits are possible.

At the Designer can be selected with or without quit.

Mixed is possible

Safety circuit (SC) / input name (E) / Input (I)

Modul SK1 SK2

SK3

SK4

SK5

SK6

SK7

SK8

E11 E12 E21 E22 E31 E32

E41 E42

E51 E52

E61 E62

E71 E72 E81 E82

DNSL-IN I11 I12 I13 I14 I15 I16 I17 I18 I21 I22 I23 I24 I25 I26 I27 I28

Q

E2

E1

E2

E1

E1

E2

Q

11

12

21 22

13

14

23 24

E1

E2

11

12

21 22

Standstill and speed monitoring

Original instruction manual Date: 2017.08.28 Page 18 of 28

11.6

Quit for safety ir uits (SC)

Central modules manual

•Quit via quit-terminal, RTDS symbol or FBI7 at fieldbus

•Quit signal change , independent from source

•Quit-time Qt is selectable 0, 1, 3 and 5S

•FBI7 is active, FBI7 as follow to use:

SK1: FBI7.1, SK2: FBI7.2, SK3: FBI7.3, SK4: FBI7.4, SK5:

FBI7.5

•Central module automatic

•Quit signal is constant on, not necessary if “Off”

selected.

•Terminal is free for another using

Fun tion modules

•Quit is only possible via the quit-terminals.

•Signal change is needed . Qt is fixed at 1s.

•Automatic: quit signal constantly on

•No quit-signal: select automatic, quit-terminal at

24V.

•Protection cover: connect quit-signal to quit-

terminal and select automatic.

•E1 and E2 controllable static or dynamic

•For dynamic arrange clock outputs at SL.

:

•The function is only important if SC1 via I1-I3 or SC2 via I4-I6 at the central module is used as an

emergency stop.

•With an external or internal error an emergency stop will be generated by SAFELINE.

•During the SLOK time SAFELINE works normally.

•After all outputs will be turned off. The plant stops.

•The SLOK Delay time has to be selected such as long, that the plant will be stopped safety.

: SC off/on is not need. : SC off/on is need

12 Standstill and speed monitoring

12.1

Standstill and speed monitoring at DNSL-ZMB/ ZMR/ ZMT

•2 safe monitoring for standstill and motion in different function modes for 2 axles

•Two sensors for every monitoring are required

•During standstill one sensor is active (24V signal).

•Sensors are constantly monitored

Symbol Function mode Designer Symbol

During standstill

I11/I13

I12/I14

In function

I11/I13

I12/I14

Standstill

Speed

SpeedSpeed

Speed

n

►

!

12.2

Requirement at Proximity sensors

•Two sensors for every monitoring

•At the cogwheel one sensor opposite to cog other to gap

•During standstill at least one sensor has 24V signal.

E1

E2

Zahnrad

Gear

2: I13 I14

Sensor

Sensor

1: I11 I12

Standstill and speed monitoring

Original instruction manual Date: 2017.08.28 Page 19 of 28

12.3

Standstill and speed monitoring using DNSL-DS

•Zwei Überwachungen sind möglich.

•Für jede Überwachung ist ein inkrementelles Messsystem erforderlich, Sinus/ Kosinus 1Vss oder TTL

Signale(≤ 500 KH ).

•Stillstand, Position, Richtung, Bremse und Dreh ahl in diversen Betriebsarten können überwacht werden.

•Für Bremsüberwachung siehe Designer Betriebsanleitung.

Measuring system connector Usage example Function mode

Designer Symbol

1 2

1Vss 1 - 5V

≤500KH

►

!

12.4

Requirement at the Measuring system

Sin / Cos or TTL measuring system

•Amplitude 1Vpp sinus / cosine or TTL, Frequency

≤ 500KH

•2 tracks, 90° phase offset, per track 2 signals, 180°

phase shifted

•A direct connection between motion monitoring

and measuring system is required

HTL measuring system

•Amplitude 18 to 26V square wave, Frequency

≤ 500KH

•2 tracks, 90° phase offset, per track 2 signals,180°

phase shifted

•A direct wire connection between motion

monitoring and measuring system is required.

•System without negated signals is possible.

12.5

Standstill and speed monitoring using 2 Sensors for measuring system

•For every monitoring 2 PNP sensors with antivalent signals.

•The sensors signals have to be connected to the RJ45 plugs the cable adapters type DNRJ45 HTL-SL.

•For direction monitoring a time difference between the impulse edges of both signals for the whole speed

range.

•Value of time difference and duty cycle are not relevant.

•After power-on The LR-signal is indefinite.

•Usage of sensors with one output is possible. Here is a Monitoring of the direction not possible

12.6

Standstill and speed monitoring using DNSL-DR

•2 safe monitoring for Standstill, position; direction; break and speed in different function modes

•For every monitoring a Resolver measuring system (1–10V / ≤ 1200H ) is necessary.

Measuring system connector

Usage example Function mode

Designer Symbol

1 2

1 – 10V, ≤1200H

►

!

Adjustment of the Resolver amplitude

Amplitude

1-2Vss 2-4Vss 4-8Vss 8-10Vss

Adjustment

on

1 2 3 4

on

1 2 3 4

on

1 2 3 4

on

1 2 3 4

on

1 2 3 4

on

1 2 3 4

on

1 2 3 4

on

1 2 3 4

+A

- A

+B

- B

+A

- A

+B

- B

+A

- A

+B

- B

Standstill and speed monitoring

Original instruction manual Date: 2017.08.28 Page 20 of 28

12.7

Standstill and speed monitoring using DNSL-SI

•2 safe monitoring for Standstill, position; direction; break and speed in different function modes

•For every monitoring a SSI interface measuring system is necessary.

Measuring system connector

Usage example Function mode

Designer Symbol

1 2

SSI Schnittstelle

►

!

12.8

Quit of the speed monitoring

•After a quit using the RTDS-symbol the output (SSM) has a High-signal if the measurement system is

error-free.

•SSM has Low-signal during movement if no function mode is selected via F--or MT-.

•Selection of function modes happens via hardware inputs.

•To control the terminals permission-switches can be used as inching mode contact, permission key contact

or safety cover contact

Priority: MTx > Fx3 > Fx2 > Fx1 > standstill

12.9

Brake monitoring with DNSL-DS, DR and SI

•The output (SAR

BRx

) at the symbol is to use for the ramp monitoring

of an axle.

•The speed of the drives will be recorded every 100ms during 500ms.

After the first value will be overwritten.

•During standstill, constant speed and acceleration the virtual output is

LOW.

•It changes to HIGH if the speed is reduced ≤ 5% during 500ms.

•The shortest reaction time is 100ms.

•Hardware output or virtual input can be triggered with this output

12.10

Dire tion monitoring with DNSL-DS, DR and SI

•During standstill and while sinus is advanced, the virtual output (SDI) has signal High.

•If cosine is advanced signal is Low.

•The preferred direction can be selected via hardware inputs and logic elements.

Symbolfunktionen

F11

Input for tool setting, symbol of the second monitoring is with F21 indicated.

F12

Input for semi-automatic mode, symbol of the second monitoring is with F22 indicated.

F13

Input for automatic mode, symbol of the second monitoring is with F23 indicated.

MT1

Mute input for the automatic function mode, symbol of the second monitoring is with MT2 indicated.

BR1

Output for the brake function (SAR), symbol of the second monitoring is with BR2 indicated.

Output for standstill, Safety gate enable/ disable

n

Output for over speed (SSM)

Output for the direction function (SDI)

RTDS

>5%

BR1, BR2 t/ms

V

t

100

200

300

400

500

600

700

800

900

1000

1100

This manual suits for next models

17

Table of contents

Other DINA Control Unit manuals

Popular Control Unit manuals by other brands

avintos

avintos 33 Series Operating and safety instructions

Conti

Conti A50 user manual

EOS

EOS KUSATEK K-Tec installation instructions

Brocade Communications Systems

Brocade Communications Systems 6542 Hardware reference manual

iWave

iWave iW-RainboW-G50M i.MX 93 Hardware user's guide

Water Specialist

Water Specialist CK Programming and Cover Drawing Manual

Paxton

Paxton BLU Expansion Controller installation guide

Rockwell Automation

Rockwell Automation Allen-Bradley 1718 Series user manual

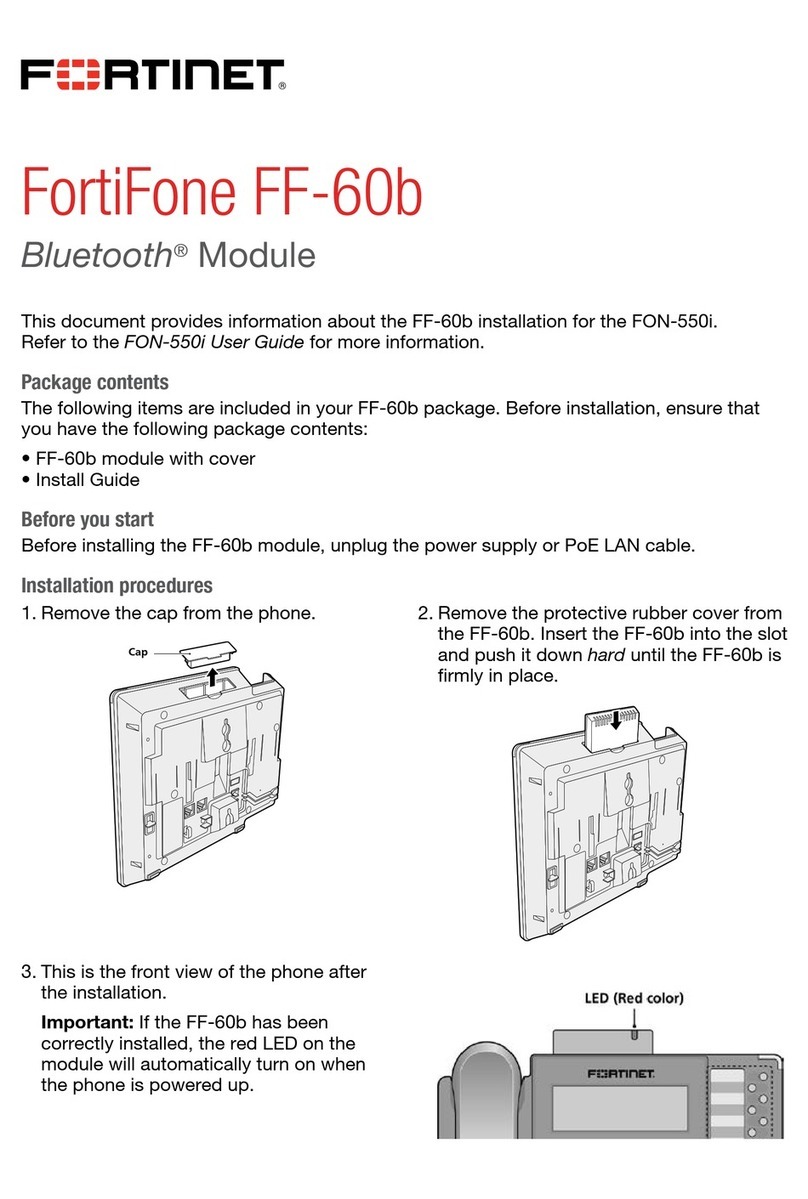

Fortinet

Fortinet FortiFone FF-60b user guide

HIMA

HIMA HIMax X-DO 32 51 manual

Aetina

Aetina DeviceEdge Orin Nano AIE-CO21 user manual

SeaSoft

SeaSoft MobilTherm-1c quick start guide