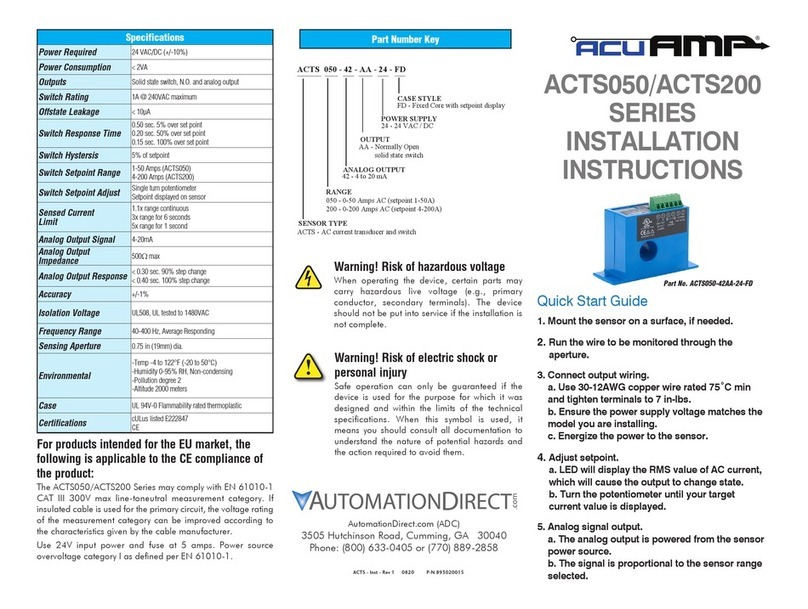

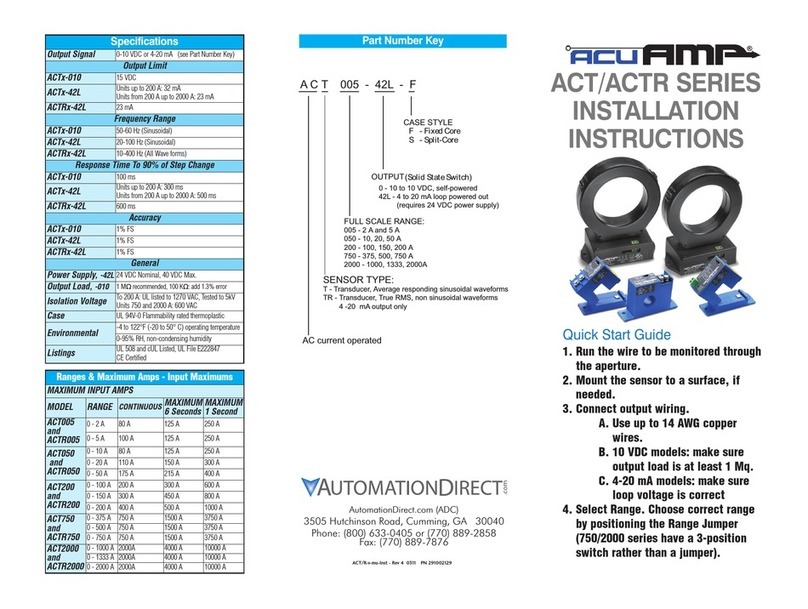

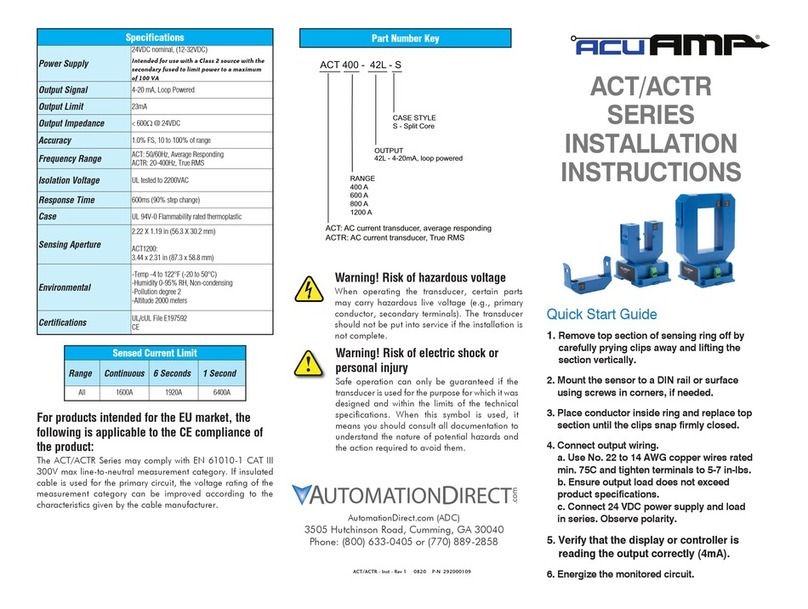

Part Number Key

AutomationDirect.com (ADC)

3505 Hutchinson Road, Cumming, GA 30040

Phone: (800) 633-0405 or (770) 889-2858

3ACT/3ACTR

SERIES

INSTALLATION

INSTRUCTIONS

Quick Start Guide

1. Mount the 3ACT/3ACTR Current Transducer to a

DIN rail or panel in a suitable enclosure.

2. With monitored load off, install each phase

through the sensing windows. Designate one

phase as A, B, and C.

3. Select the current range using the slide

switch.

4. Connect output terminals + and - using 22-14

AWG copper wires rated 75/90°C. Tighten to 5-7

inch-pounds torque.

5. Connect power supply voltage to terminals 9-10.

6. The output will be proportional to the current in

each phase, plus one which is the average of the

three.

7. Any of the four analog signals can be used

independently, or all four can be used at the same

time.

3ACT: 3-phase AC current transducer, average responding

3ACTR: 3-phase AC current transducer, True RMS

OUTPUT SIGNAL

HOUSING TYPE

CURRENT RANGES

030 - 0-10, 0-15 and 0-30A

100 - 0-30, 0-50, and 0-100A

200 - 0-100, 0-150 and 0-200A

F - Fixed Core

42 - 4-20mA

POWER SUPPLY

24 - 24 VAC/DC (non-isolated)

3ACT/3ACTR - Inst - Rev 1 0820 P-N 292000612

Specifications

Power Supply

24 VAC/DC ( +/- 10%), Intended for use with a Class

2 source with the secondary fused to limit power to a

maximum of 100 VA

Note: Power Supply and output signal ARE NOT

isolated. Do not connect the negative terminals

to a common point.

Power Consumption < 6.0 VA

Output Signals 4-20mA

Four outputs, three proportional to the current in that

phase, one an average of all three.

Output Limit 20.8 mA

Output Impedance 500Ωmaximum

Accuracy 1.0% FS

Response Time 220ms (90% step change)

Frequency Range 3ACT: 50/60Hz, Average Responding

3ACTR: 30-100Hz, True RMS

Sensed Current Limit

1.1x range continuous

3x range for 6 seconds

6x range for 1 second

Isolation Voltage UL tested to 1240VAC

Sensing Apertures 0.74 in (18.8 mm) dia.

Case UL 94V-0 Flammability rated thermoplastic

Environmental

-Temp -4 to 122°F (-20 to 50°C)

-Humidity 0-95% RH, Non-condensing

-Pollution degree 2

-Altitude 2000 meters

Certifications cULus listed E197592

CE

Warning! Risk of electric shock or

personal injury

Safe operation can only be guaranteed if

the transducer is used for the purpose for

which it was designed and within the limits

of the technical specifications. When this

symbol is used, it means you should consult

all documentation to understand the nature

of potential hazards and the action required

to avoid them.

Warning! Risk of hazardous voltage

When operating the transducer, certain parts

may carry hazardous live voltage (e.g., primary

conductor, secondary terminals). The transducer

should not be put into service if the installation is

not complete.

For products intended for the EU market, the

following is applicable to the CE compliance of

the product:

The 3ACT/3ACTR Series may comply with EN 61010-1 CAT III

300V max line-to-neutral measurement category. If insulated

cable is used for the primary circuit, the voltage rating of the

measurement category can be improved according to the

characteristics given by the cable manufacturer.

Part No. 3ACT030-42-24-F