AutomationDirect igus XYZ Gantry User manual

Page 1igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

Page 2igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

CONTENTS

Getting Started � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Unpacking � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

Adjusting Carriage Block Clearance � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 3

T-Slot Nuts � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 4

Linear Actuator Mounting � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Actuator Clamps� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 5

Gantry Accessories � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Mounting Clamps � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Carriage Plate Adapter � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Angle Brackets � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 6

Motor Bracket Assembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

SAW Series (Lead Screw Driven) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 7

ZLW Series (Belt Driven) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 8

Sensor Attachment � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � 9

SAW Series Assembly/Disassembly� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �10

SAW Lead Nut Replacement� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �12

ZLW Series Assembly/Disassembly � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �13

ZLW Series Belt Tensioning � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �16

Bearing Block Alignment Procedure (All Models) � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �17

Bearing Block Liner Replacement (All Models)� � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �18

ZLW Dual X Connecting Shaft � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � � �19

Page 3igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

Getting Started

Unpacking

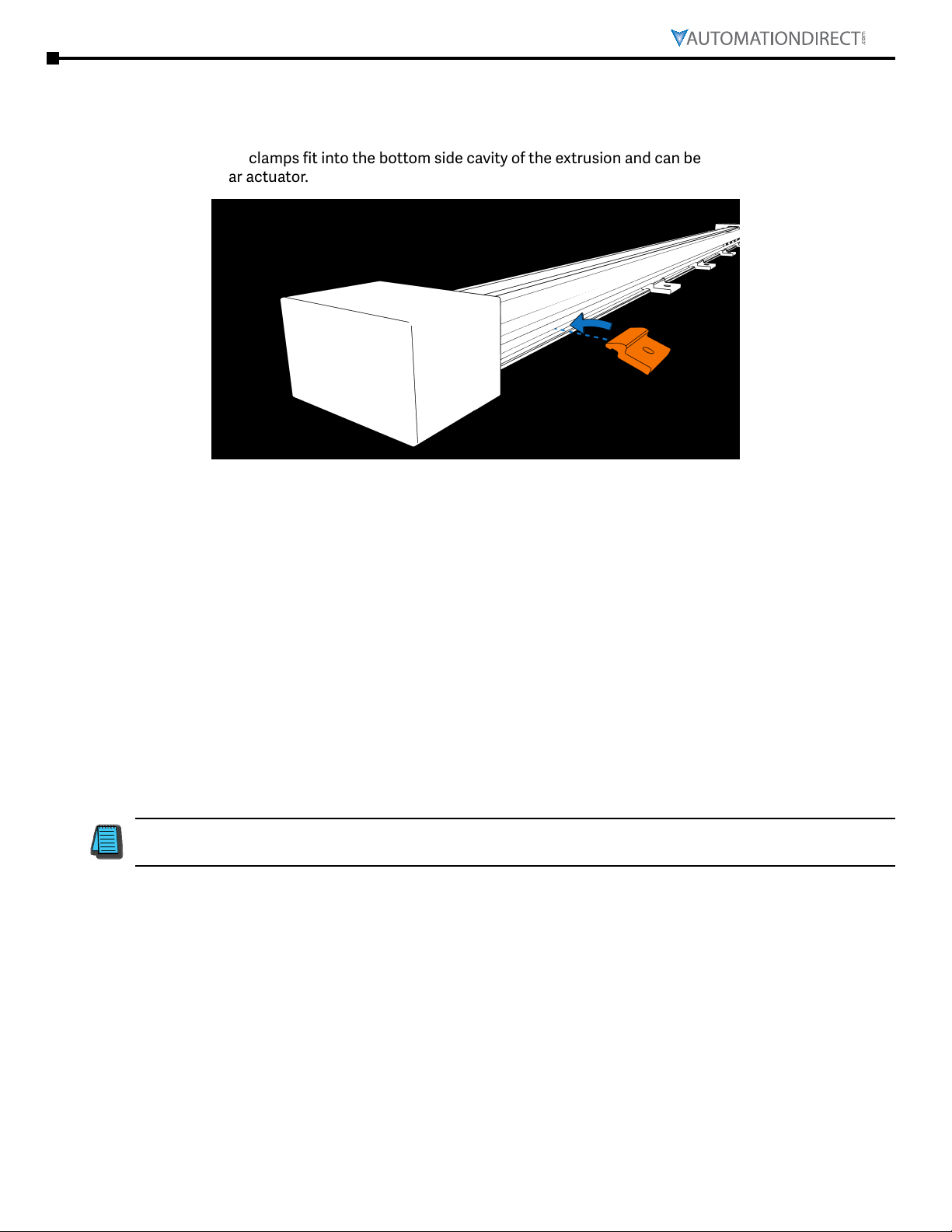

All linear actuators have mounting clamps included in the box. These can be used to secure the linear actuator

to a frame. Ensure the clamps are found and removed from the packaging before disposal of the box and packing

materials. There are 10 clamps included with each actuator (shown below).

Remove the orange quality inspection tag before using. Handle the linear actuator on the ends to avoid damage to

the bearing rails and carriage drive components.

The carriage of the ZLW series will have a slight stiffness to movement due to the storage of the belt in a fixed

position. This is normal and will diminish as the carriage is stroked back and forth exercising the belt.

Adjusting Carriage Block Clearance

All igus linear actuators are assembled with Adjustable Carriage Blocks to optimize side-to-side movement of the

Carriage. As the 4 adjustment screws are tightened the clearance between the bearing material and the guide rails

is reduced. The amount of adjustment depends on the application needs. Lower clearances give better holding

position when external loads are applied. But as the clearance decreases so does the resistance to linear travel,

therefore requiring more applied torque from the drive system. Typical clearance adjustment is a balance between

the two affects and becomes more of a judgement call rather than a calculated/measured value.

The adjustment is made by turning the brass set screw on each of the 4 bearing blocks.

• Use 1.5mm Allen wrench

• Clockwise = LESS Clearance

• Counter-Clockwise = MORE Clearance

• Turn 1 ‘click’ at a time, on each of the 4 bearing blocks, for best results

• Stroke the carriage assembly after each ‘click’ of adjustment and note the carriage travel resistance as well as

side-to-side movement.

NOTE: The adjustment set screw is brass. Do apply excessive torque or damage may occur to its threads or hex

socket.

Page 4igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

T-Slot Nuts

All igus linear actuators have 8 pre-installed t-slot nuts, M5-0.8, 4 each side. Remove the shipping set screws for

freedom of movement along the T-slot.

Page 5igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

Linear Actuator Mounting

Actuator Clamps

The included mounting clamps fit into the bottom side cavity of the extrusion and can be positioned anywhere along

the length of the linear actuator.

NOTE: Not all included mounting clamps may be needed.

Page 6igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

Gantry Accessories

Mounting Clamps

A-ZSY-104026 kit includes:

• 2 Mounting Clamps

• 6 SHCS M6-1.0 x 12mm

Carriage Plate Adapter

A-SWY108003150 kit includes:

• 2 Plate Adapters

• 8 Low Profile SHCS M6-1.0 x 20mm

Angle Brackets

A-AK-0026 kit includes:

• 2 Angle Brackets

• 4 SHCS M6-1.0 x 20mm

• 8 SHCS M5-0.8 x 10mm

• 8 T-slot nuts M5-0.8

Page 7igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

Motor Bracket Assembly

The motor brackets are designed to mount specific motor sizes. They include all of the necessary mounting

hardware for the particular motor. The drive coupling is not part of the motor bracket kit and must be purchased

separately. It is best practice to assemble the motor to the linear actuator with it in the vertical orientation.

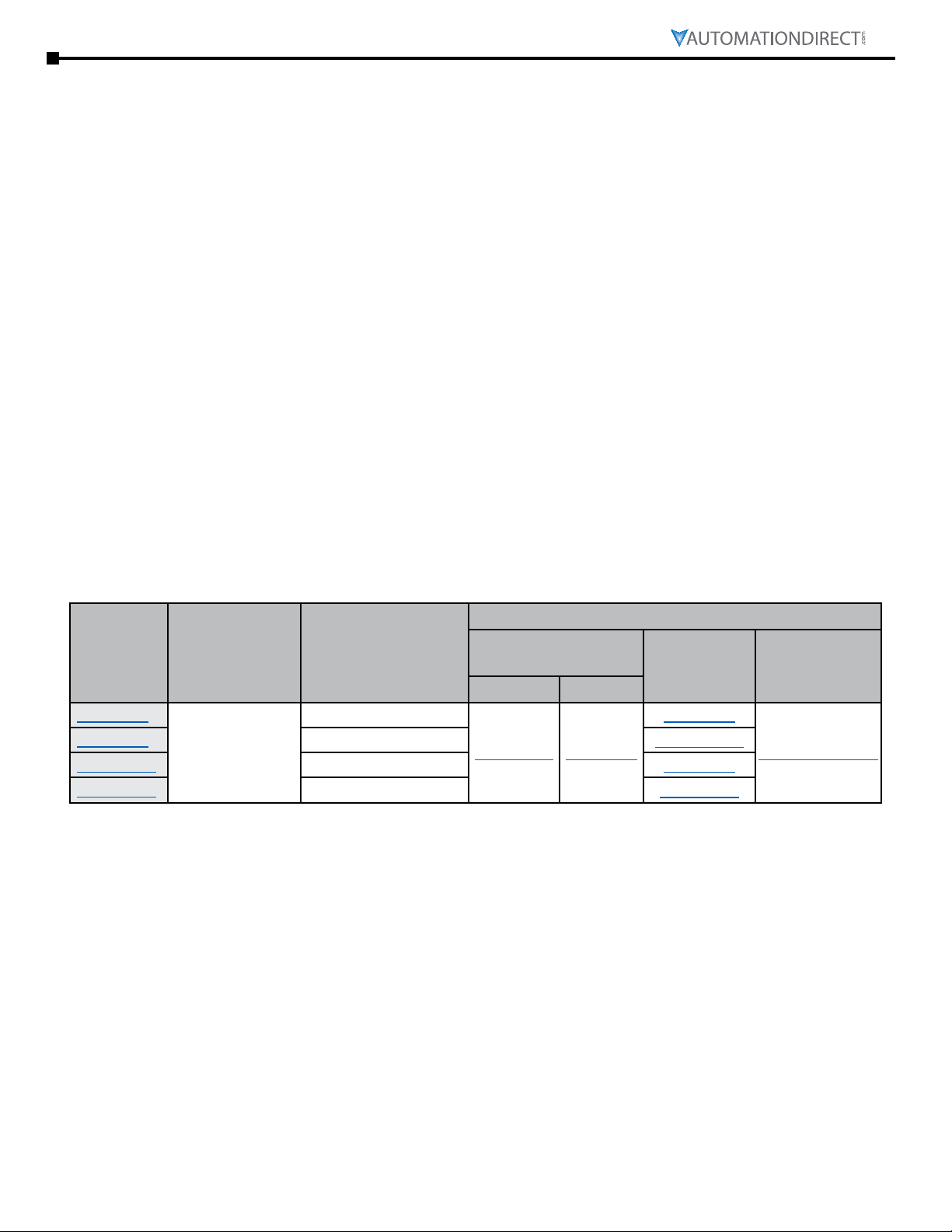

SAW Series (Lead Screw Driven)

Motor

Bracket PN

Bracket to

Actuator Fastener

Motor to Bracket

Fastener

Recommended ADC Drive Couplings

Coupling Jaw for

Actuator Coupling Jaw

for Motor Coupling Spider

1040 1080

STP17-SAW

SHCS M4-0.7 x 8mm

(x4)

SHCS M3-0.5 x 6mm (x4)

SJCA-30C-10 SJCA-30C-8

SJCA-30C-5

SJC-30-RD-SLEEVE

STP23-SAW SHCS M5-0.8 x 10mm (x4) SJCA-30C-6.35

SVL201-SAW SHCS M4-0.7 x 8mm (x2) SJCA-30C-8

SVL202-SAW SHCS M5-0.8 x 12mm (x4) SJCA-30C-14

Page 8igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

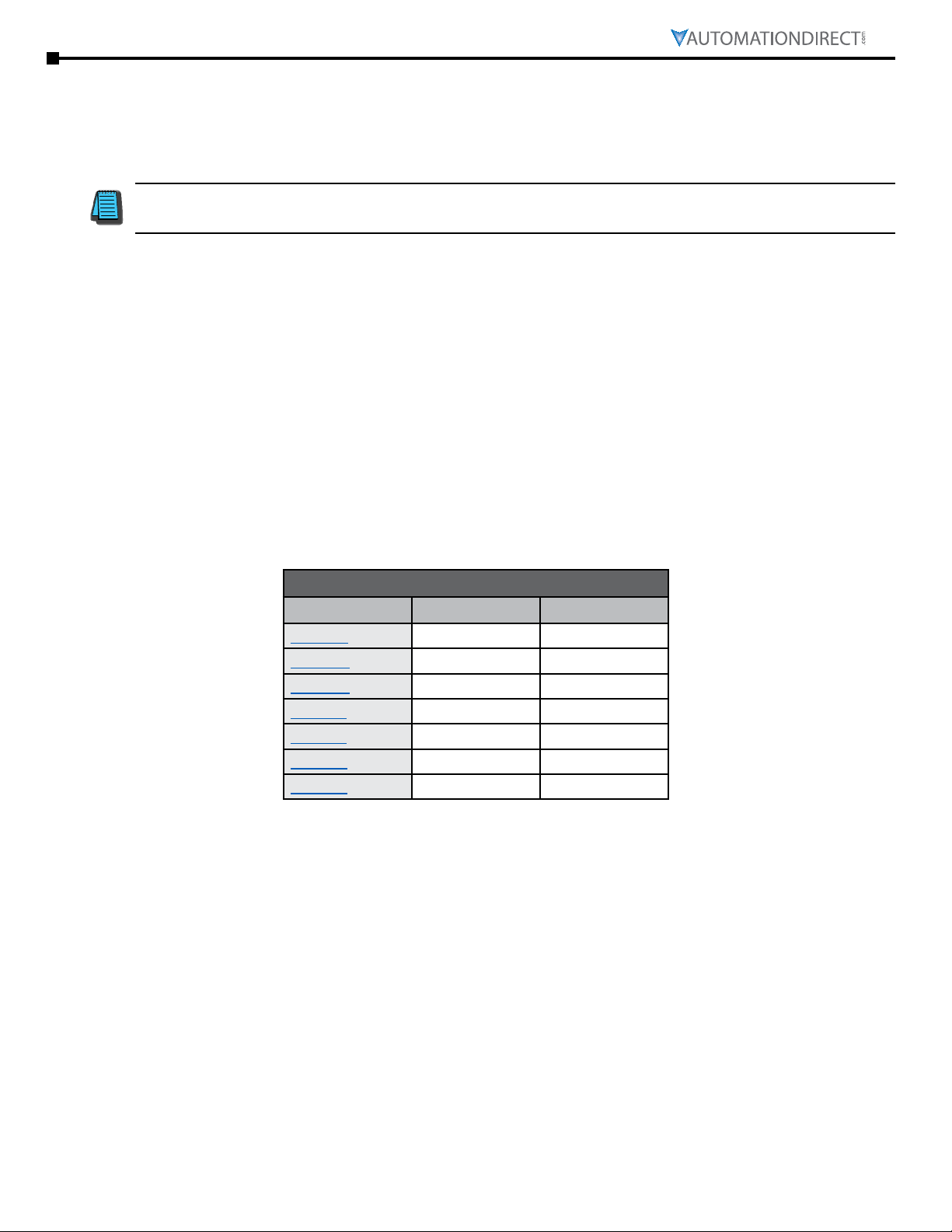

ZLW Series (Belt Driven)

Motor

Bracket PN

Bracket to Actuator

Fastener

Motor to Bracket

Fastener

Recommended ADC Drive Couplings

Coupling Jaw

for Actuator

Coupling Jaw

for Motor Coupling Spider

STP17-ZLW

Shoulder Screw

Ø6 x M5-0.8 x 20mm (x4)

SHCS M3-0.5 x 14mm (x4)

SJCA-30C-10

SJCA-30C-5

SJC-30-RD-SLEEVE

STP23-ZLW SHCS M5-0.8 x 10mm (x4) SJCA-30C-6.35

SVL201-ZLW SHCS M4-0.7 x 8mm (x2) SJCA-30C-8

SVL202-ZLW SHCS M5-0.8 x 10mm (x4) SJCA-30C-14

Page 9igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

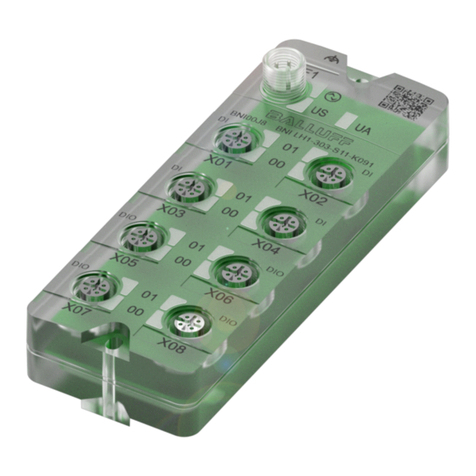

Sensor Attachment

Sensors can be attached to the side T-slots of the linear actuator using the pre-installed T-slot nuts. The carriage

block will act as the flag when an ADC proximity sensor is mounted on the sensor bracket. Mounting hardware is

included with the sensor bracket kit.

NOTE: The linear actuator end blocks should not be used as hard stops. Sensors should be mounted at both

ends of stroke for a controlled stop. Best control practice is to use Normally Closed (NC) for this purpose.

RECOMMENDED ADC INDUCTIVE PROX SENSORS

Sensor PN Switch Normal State

P8-AN-1F NPN N.O.

P8-AN-2A NPN N.O.

P8-CN-1A NPN N.C.

P8-AP-1F PNP N.O.

P8-AP-2F PNP N.O.

P8-CP-1F PNP N.C.

P8-CP-2F PNP N.C.

Page 10igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

SAW Series Assembly/Disassembly

The following assembly steps can be followed in the reverse order for disassembly.

NOTE: Steps shown below are the same for both ends of the Actuator.

1. Loosen 4 screws on Carriage Plate.

2. Install Carriage Plate subassembly by aligning the Bearing Liners with the top rails and Lead Nut with the Lead

Screw. Lead Nut should be opposite side from the input shaft. Turn Lead Screw to engage with Lead Nut. This

will pull the Carriage Plate fully onto rails.

3. Gently install O-ring onto Lead Screw until seated into notch (SAW1040 only).

4. Install end block.

Page 11igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

5. Apply blue thread locking compound to the screws (x2 set screws for SAW1040 / x4 SHCS for SAW1080) and

install to secure end block.

6. Install shaft collar onto Lead Screw...

i. SAW1040–...turning clockwise with a flat blade screwdriver. Install the shaft collar such that the Lead Screw

turns freely with no lengthwise movement of the Lead screw drive subassembly. Turn Lead Screw to access

shaft collar screw and tighten.

ii. SAW1080–... until bearing is fully seated. Turn Lead Screw to access 1 shaft collar screw (socket head) and

slightly tighten. Rotate the Lead Screw 180° to access the 2nd shaft collar screw and slightly tighten. Check to

ensure Lead Screw turns freely with no lengthwise movement of the Lead screw drive subassembly. Alternate

tightening of the shaft collar screws until fully tightened. Finally, rotate lead screw to access shaft collar set

screw and tighten.

Page 12igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

SAW Lead Nut Replacement

1. SAW1040

i. Press down to remove old Lead Nut.

ii. Press new Lead Nut into hole in the Carriage Plate until fully seated.

2. SAW1080

i. Remove 4 M5-0.8 x 12mm SHCS to release Lead Nut and Retainer.

ii. Remove old Lead Nut and press in new Lead Nut with groove facing down.

iii. Replace Retainer and re-install screws.

Page 13igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

ZLW Series Assembly/Disassembly

The following assembly steps can be followed in the reverse order for disassembly.

NOTE: Steps shown below are the same for both ends of the Actuator.

1. Loosen 4 screws on the Carriage Plate.

2. Slide the Carriage Plate onto the Rails.

3. Install the End Stop onto the rails using 2 screws (Low Profile SHCS M4-0.7 x 10mm).

4. Insert Drive Pulley subassembly into the End Stop.

Page 14igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

5. Prepare the Idler Pulley by loosening the 4 Locking Set Screws by a few turns and tightening the Jack Screws all

the way in. If the Jack Screws don’t go all the way in, loosen the Locking Set screws further.

6. Insert the Idler Pulley subassembly into the End Stop with the Jack Screw going in first.

7. Insert the timing belt through the lower channel of both End Stops and wrap it around both pulleys.

8. Attach the timing belt to both ends of the Carriage Plate using the belt clamps and screws.

Actuator Part Number Replacement Belt

Length (mm)

ZLW1040S-2 / ZLW1080S-2 775

ZLW1040S-3 / ZLW1080S-3 975

ZLW1040S-4 / ZLW1080S-4 1175

ZLW1040S-5 / ZLW1080S-5 1375

ZLW1040S-6 / ZLW1080S-6 1575

ZLW1040S-8 / ZLW1080S-8 1975

ZLW1040S-10 / ZLW1080S-10 2375

Timing Belt Information

Material: Polyurethane with Steel Cords

Tooth Profile: AT5

Belt Width: 16mm

Belt Mass: 0.059 kg/m

Color: White

Page 15igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

9. Install the End Stop covers

Page 16igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

ZLW Series Belt Tensioning

1. Using a ‘Belt Tensioning Meter’ to measure belt tension, turn the 4 Jack Screws counter-clockwise to increase

belt tension. Turn the Jack Screws evenly in a crisscross pattern. To reduce belt tension turn the Jack Screws

clockwise.

i. Belt mass property = 0.059 kg/m

ii. Proper Belt Tension should be 200N

2. Once the proper belt tension is achieved, install 4 Locking Set Screws

3. Verify Belt Tension. If adjustment is needed, loosen the Locking Set Screws and repeat the above steps.

4. Install plastic End Caps

Page 17igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

Bearing Block Alignment Procedure (All Models)

1. Loosen 4 Screws on the Carriage Plate

2. Loosely install 4 M6-1.0 screws in open holes of Carriage Plate. These are temporary to ensure thread access for

attaching future parts to the Carriage Plate.

3. While applying a downward force on the center of the Carriage Plate, slightly tighten the 4 Carriage Plate screws

in a crisscross pattern.

4. Move and stroke the Carriage checking for smooth movement.

5. Repeat steps 3 and 4 until movement is as desired.

6. Remove the 4 M6-1.0 temporary screws.

7. With a rubber hammer, sharply hit the center of the Carriage Plate. This fully seats the Bearing Liner. This step

can be done any time, after installation or use, when the carriage seems to have resistance to motion.

Page 18igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

Bearing Block Liner Replacement (All Models)

The following assembly steps are performed after the Carriage Plate is removed from the Linear Actuator. For

reinstalling the Carriage Plate, please refer to the SAW or ZLW Assembly Steps.

NOTE: Follow the “Bearing Block Alignment Procedure (All Models)” on page 17 after the Linear Actuator is

fully assembled to ensure the new Bearing Block Liners are fully seated.

Important:

1. Gently turn each of the 4 Clearance adjustment set screws fully counter-clockwise

2. To remove Bearing Liner, push down on the tab and roll.

3. To install new Bearing Liner, drop in and roll until seated

Page 19igus XYZ Gantry User Manual – 1st Ed – 09/14/2022

igus XYZ gantrY user Manual

ZLW Dual X Connecting Shaft

1. When the 2 linear actuators are mounted, measure the distance between shaft ends (D)

2. The length of the connecting shaft (L) may need to be cut to accommodate the proper spacing for the Drive

Couplings. Use the following formula to calculate L.

i. (metric) L = D – 38 mm

ii. (imperial) L = D- 1.5”

NOTE: This formula is for AutomationDirect Drive Coupling SRBA-39C-10-10 only.

3. Cut Connecting Shaft, A-AWM-10-xxx to the proper length (L). If the Connecting Shaft is greater than 500mm,

use Pillow Block Support A-KSTM-10 midway along Connecting Shaft to minimize shaft whipping during high

speeds.

4. Slide 2 Drive couplings, and optional Pillow Block Supprt, onto the Connecting Shaft. Align this subassembly

with linear actuator drive shafts.

5. Slide the couplings onto the 2 drive shafts and tighten coupling clamp screws.

6. If the Connecting Shaft is out of alignment, adjust the mounting of the Linear Actuators to correct.

7. Slide the Connecting Shaft into position of 1 Drive Coupling and tighten clamp screw onto the drive shafts.

8. Move Carriages of both actuators to same end of stroke and tighten 2nd Drive Coupling clamp screw to

Connecting Shaft.

Table of contents

Other AutomationDirect Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Siemens

Siemens Simatic Net Scalance M812 operating instructions

Shibuya Hoppmann

Shibuya Hoppmann Cap Star FCCPSTLDSA Installation & maintenance manual

Tecnosystemi

Tecnosystemi GALAXY STAR POINT user manual

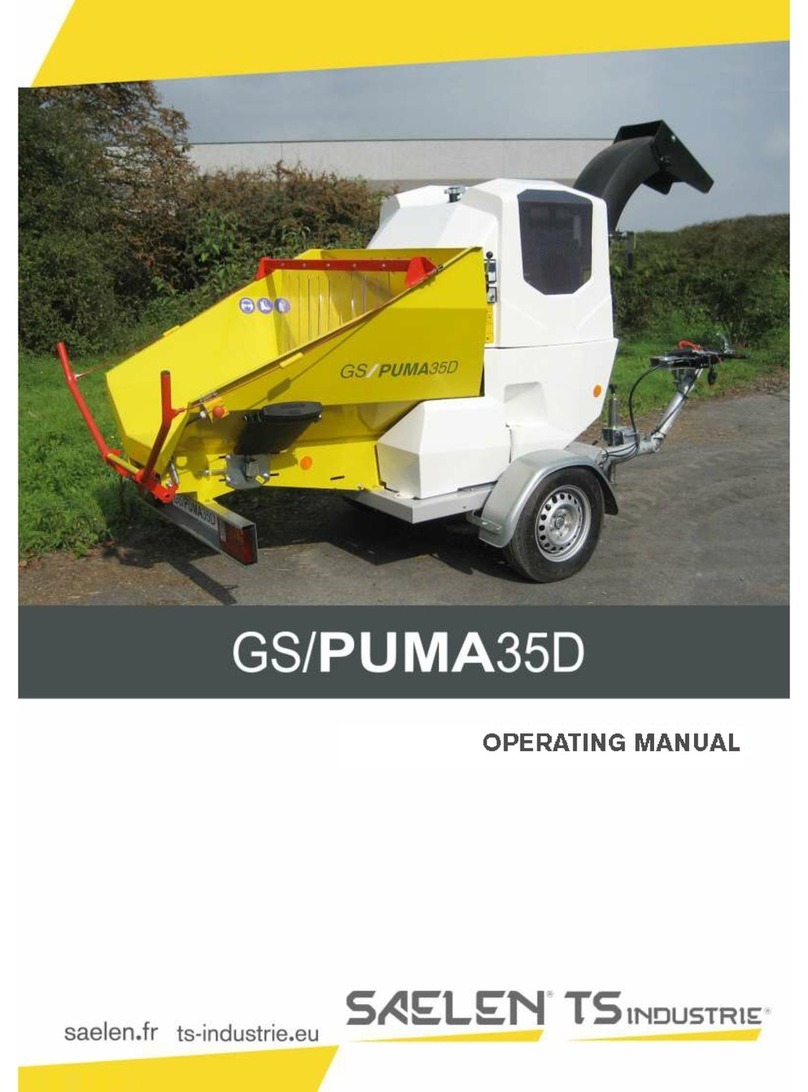

SAelen TS

SAelen TS GS/PUMA 35D operating manual

Pulsar

Pulsar AWO200K Assembly instruction

Dover

Dover Civacon LM1051 ADJUSTMENT PROCEDURE