AutomationDirect CLICK PLUS C2-01CPU Series User manual

1

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Before You Begin...

This guide provides a quick overview of installation and setup of your

CLICK PLUS CPU. It assumes some familiarity with the installation

and operation of industrial control equipment.

Please read and understand the information in this guide prior to

installation, operation, or servicing this equipment.

The CLICK PLUS User Manual provides full specifications and more

in-depth information on installation, setup,

programming and operation of the device. The

User Manual (C2-USER-M) is available in PDF

format by scanning this QR code or from https://

www.automationdirect.com/pn/doc/manual/

C2-USER-M. Extensive online help is also

available from within the CLICK software or at

https://www.automationdirect.com/clickplcs/free-software/

software-help.

What You’ll Need

CLICK PLUS CPU

PC with Click Software ver. 3.20 or later

24VDC power supply (SELV and Limited Energy)

(CLICK power supply C0-00AC or C0-01AC is recommended.)

Appropriate enclosure with vertical surface for DIN rail or surface mount

M4 screws, spring washers and flat washers if surface mounting

Ferrules and crimping tool for wire terminations (recommended)

Option Slot cover(s) (part #C2-FILL) are recommended if you are not

planning to use an Option Slot module. (Sold separately.)

Basic tools (screwdriver, wire stripper, etc.)

PLEASE REVIEW THE SAFETY WARNINGS ON THE

NEXT PAGE!

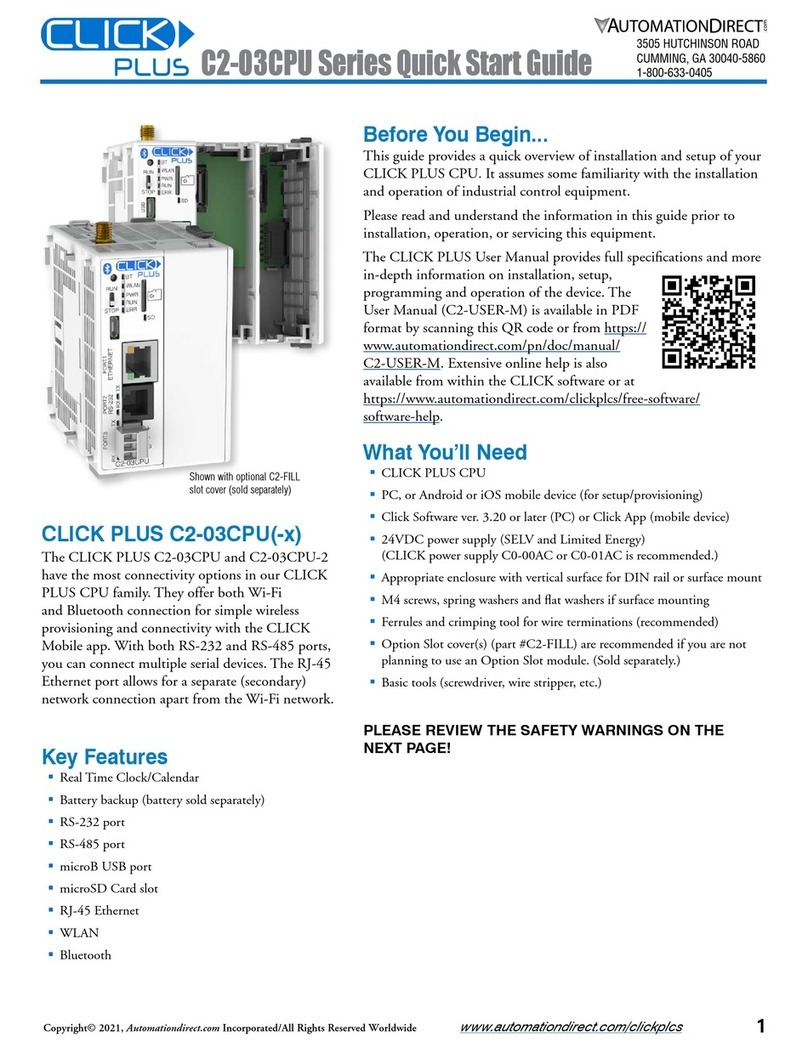

CLICK PLUS C2-01CPU(-x)

The CLICK PLUS C2-01CPU and

C2-01CPU-2 offer the lowest-cost entry

into our CLICK PLUS CPU family. They

provide all the computing power of the

CLICK PLUS line, and have USB, Ethernet

and RS-232 connectivity built in. The CPUs

are compatible with the full line of CLICK

PLUS Option Slot modules and CLICK

Stackable modules.

Key Features

Real Time Clock/Calendar

Battery backup (battery sold separately)

RS-232 port

microB USB port

RJ-45 Ethernet

Shown with optional C2-FILL

slot cover (sold separately)

2

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Safety Warnings

Please follow these instructions for personal and operational safety.

WARNING Assumes that incorrect handling may cause hazardous

conditions, resulting in severe injury or death.

CAUTION Assumes that incorrect handling may cause hazardous

conditions, resulting in medium or slight injury, or

may cause equipment damage.

WARNING

Don’t use this equipment in a flammable or explosive

environment in order to avoid accidental injury or fire.

You should use external electromechanical devices that are

independent of the PLC (Programmable Logic Controller)

system to provide protection for any part of the system;

otherwise malfunction or output failures may result in a

hazardous accident.

24VDC power is required from a secondary circuit or a specific

power supply unit only.

Ensure the Ground Terminal of the Power Supply (C0-00AC/

C0-01AC) for the CLICK PLUS CPU is connected to Earth

Ground to avoid electric shock or equipment damage during a

short circuit.

Don’t operate the equipment with a nonconforming external

power supply to avoid electric shock, equipment damage or fire.

Don’t intentionally fault the wiring; this may cause equipment

damage or fire.

To avoid electric shock or malfunctions which might result in an

accident, don’t touch any terminal while the PLC power is on.

Don’t put metals (e.g. screwdriver) into vent holes, or drop trash

or foreign objects (e.g. wire cut-offs) into the device, in order to

avoid electric shock or equipment damage.

If the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be

invalidated.

CAUTION

For use in Pollution Degree 2 Environment. Use and store the

equipment in an environment described in the specifications

(regarding temperature, humidity, vibrations, shock, etc.) in

order to avoid equipment damage or fire.

Ensure all wiring has strain reliefs in order to avoid damage to

insulation that might result in electric shock or fire.

Ensure secondary external power circuits are only live after PLC

control program is started; otherwise a malfunction or output

failure may result in a hazardous accident.

Don’t block the vent holes. This may cause an increase of inter-

nal temperature resulting in equipment damage or fire.

Don’t disassemble or modify equipment so as to avoid electric

shock, equipment damage, or fire.

Cut off all phases of the external power source before mainte-

nance work, thus avoiding electric shock or equipment damage.

Hardware Installation

ENCLOSURES

It is important to select the appropriate enclosure to ensure

safe and proper operation of your CLICK PLUS PLC

system. Please use this product in a metal enclosure/cabinet.

Control applications vary and yours may require additional

considerations. At a minimum your enclosure should include:

Conformance to electrical standards

Protection from the elements in an industrial environment

Common ground reference

Maintenance of specified ambient temperature

Access to equipment

Security or restricted access

Sufficient space for proper installation and maintenance of

equipment

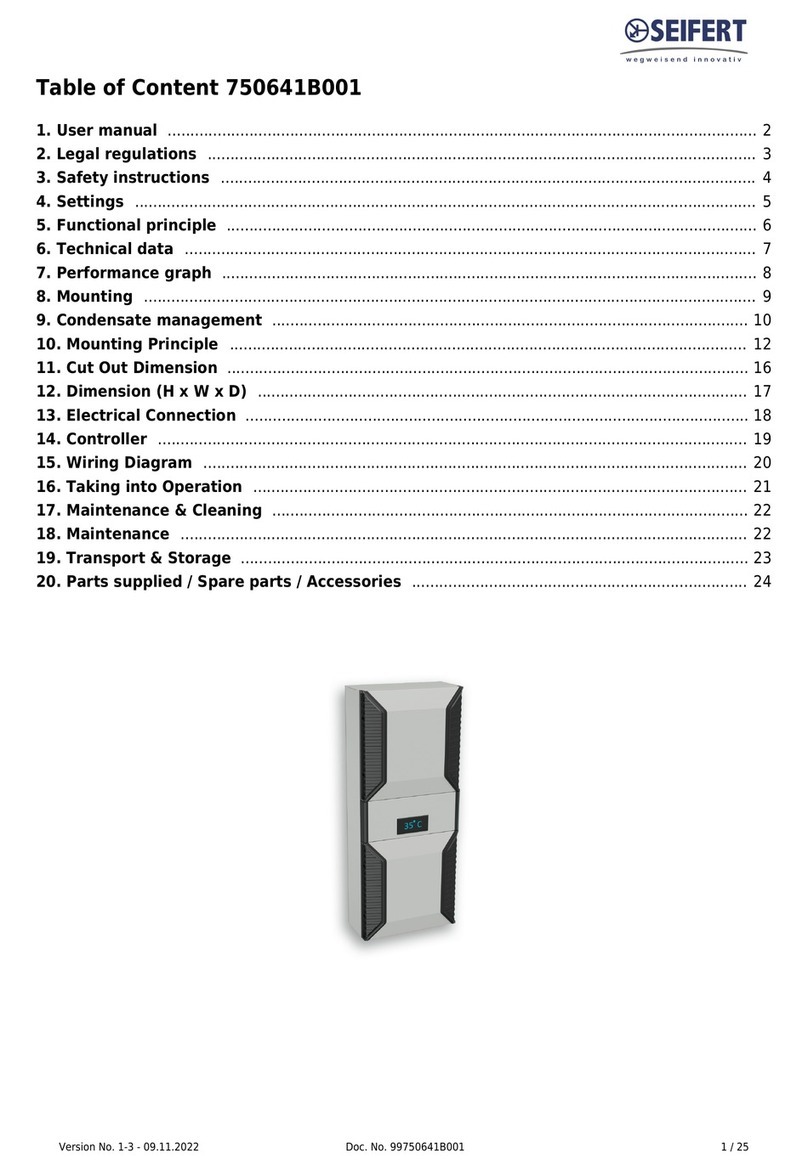

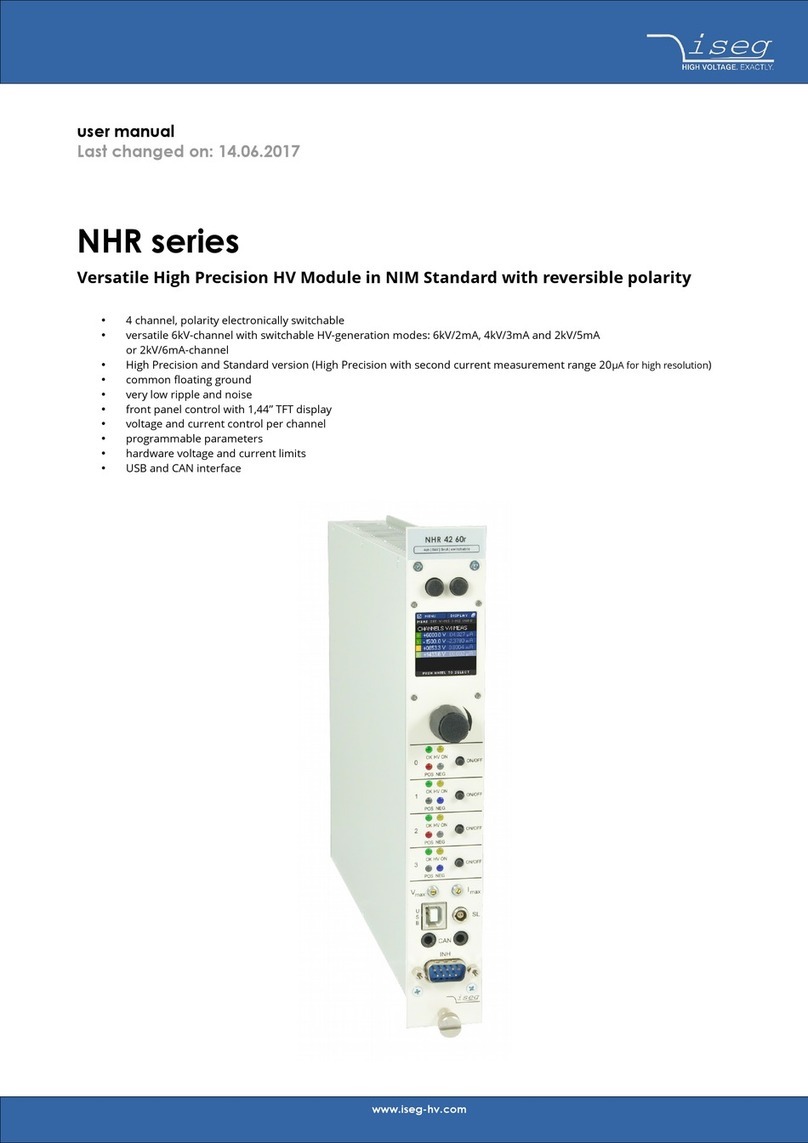

CLEARANCES AND ORIENTATION

Mount the unit horizontally to

provide proper ventilation.

There is a minimum clearance

requirement of 2in. (51mm)

from all sides of the cabinet and

the equipment.

There is a minimum clearance

requirement of 1.5 in. (38mm)

from the wiring ducts and the

equipment

Do not mount the unit upside down, on a horizontal surface, or

in a vertical arrangement.

Minimum clearance requirement

of 51mm for A, B, and C.

Air

Flow

TX2

PORT2

PORT1

RX2

RX1

TX1

PWR

ERR

RUN

STOP

RUN

Air

Flow

TX2

PORT2

PORT1

RX2

RX1

TX1

PWR

ERR

RUN

STOP

RUN

3

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Hardware Installation, continued

CAUTION

Discharge static electricity before installation or

wiring in order to avoid electric equipment damage.

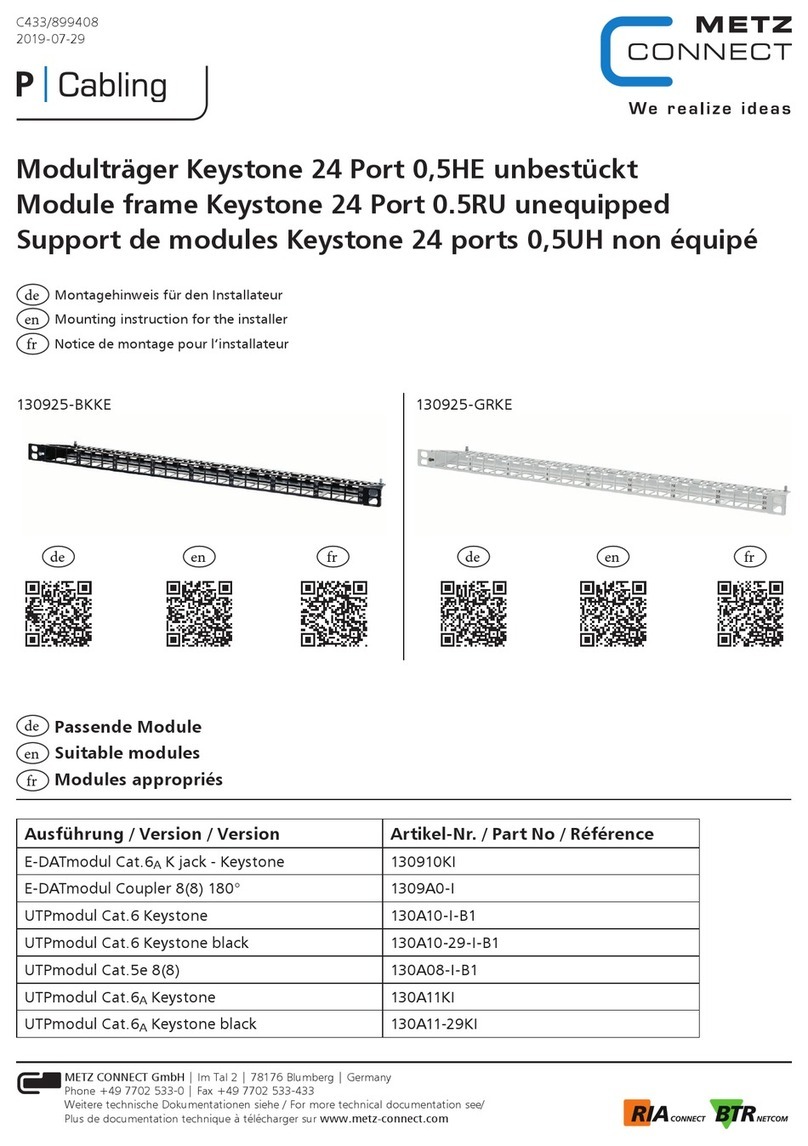

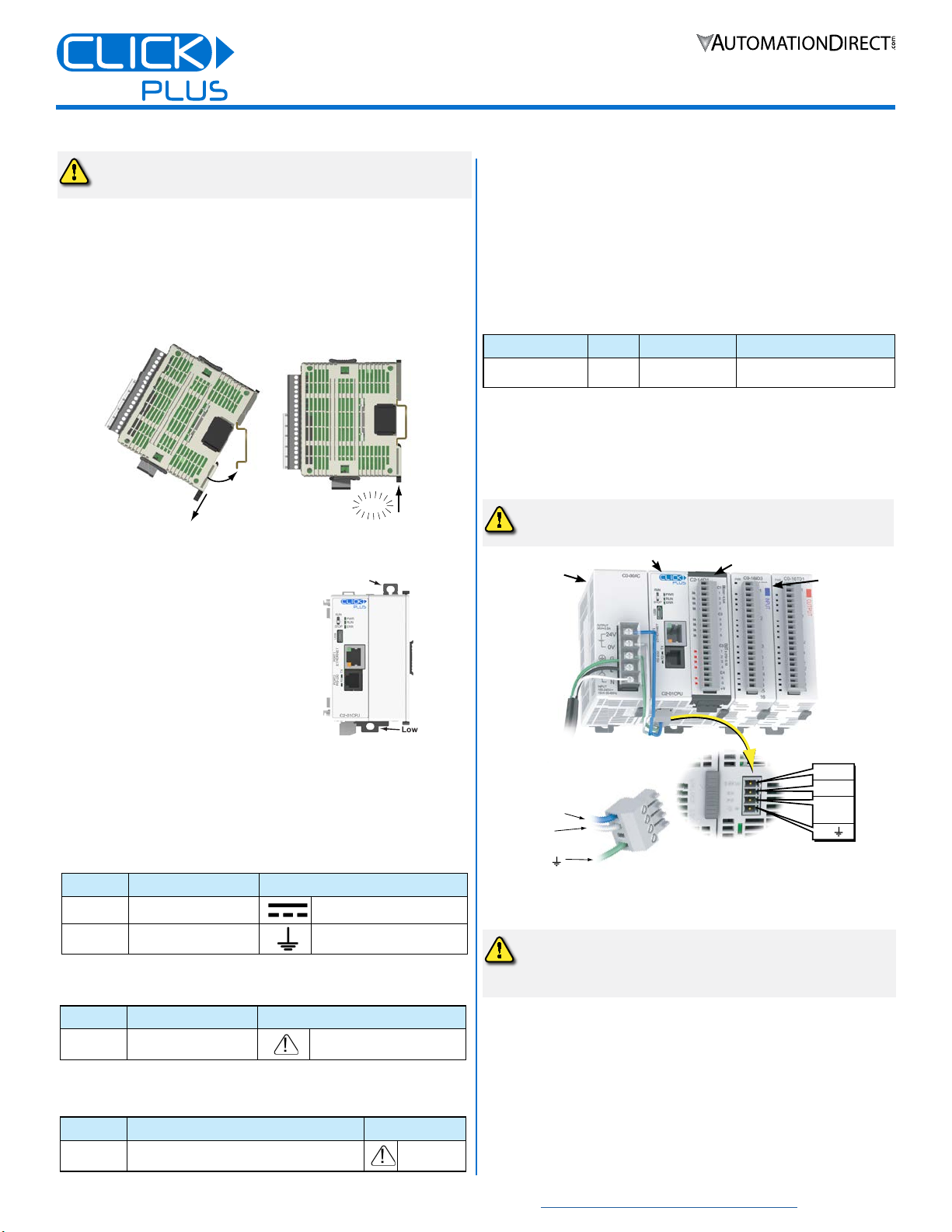

MOUNTING

The CLICK PLUS can be mounted on DIN rail or surface

mounted using built-in mounting tabs.

When installing on DIN

rails, always use end brackets

on both ends of assembly.

(AutomationDirect p/n DN-EB35)

Use 35mm width DIN Rails.

Use M4 size screws when you

surface mount.

Tighten the screws with a spring

washer and a small round washer

and torque 0.5 to 0.6 N·m.

Click

Pull tab

down.

Push tab

up until...

DIN Rail Mounting

Upper

Mounting Tab

Lower

Mounting Tab

Surface Mounting

WIRING

24VDC power is supplied to the CLICK PLUS CPU through

wiring connected from the power supply output to the 4-pin

connector located on the bottom of the CPU unit.

16–28 AWG wiring is supported. We recommend using

crimping ferrules on all wire terminations for a more secure

connection. The following crimping ferrules are recommend-

ed for the 24VDC power terminals.

Company

Type Model No. Compliant Wire

AutomationDirect

Ferrule V30AE000009

V30AE000041 0.2–0.5 mm2(22–26AWG)

* Maximum tightening torque is 0.22 to 0.25 N·m.

Take care not to contact adjacent terminal.

Please use SELV (as defined by UL61010-2-201) and Limited

Energy (as defined by UL61010-1, 9.4) power supply.

CLICK power supply C0-00AC or C0-01AC is recommended.

CAUTION

Do not operate without first installing safety

cover over power supply

leads.

CAUTION

DO NOT USE the PF connector. Leave this terminal

unconnected. Connecting the PF terminal to another

device may cause damage to the CLICK PLUS CPU.

24VDC

0V

PF

(future)

G

24VDC

0V

G

CLICK PLUS CPU

CLICK Power Supply

24VDC power is supplied to the CPU unit through wiring connected from

the power supply output to the 4-pin 24VDC input connector located on the

bottom of the CPU unit.

OPTION SLOT MODULE (OPTIONAL)

STACKABLE MODULES

(OPTIONAL)

I/O wiring is discussed in each module’s documentation.

Name

Description Symbol

DC

Direct current IEC6047 No. 5031

G

Functional earthing IEC6047 No. 5017

Name

Description Symbol

CAUTION

Safety instruction for

battery replacement ISO 7000 No.0434B

The symbol near the battery holder is indicated by the

following symbol.

Name

Description Symbol

CAUTION

• Refer to QR code link for product handling

• Use Copper Conductor Only

ISO 7000

No.0434B

The symbol on the product label is indicated by the

following symbol.

Power supply symbols listed on the equipment are indicated

by the symbols shown below.

4

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

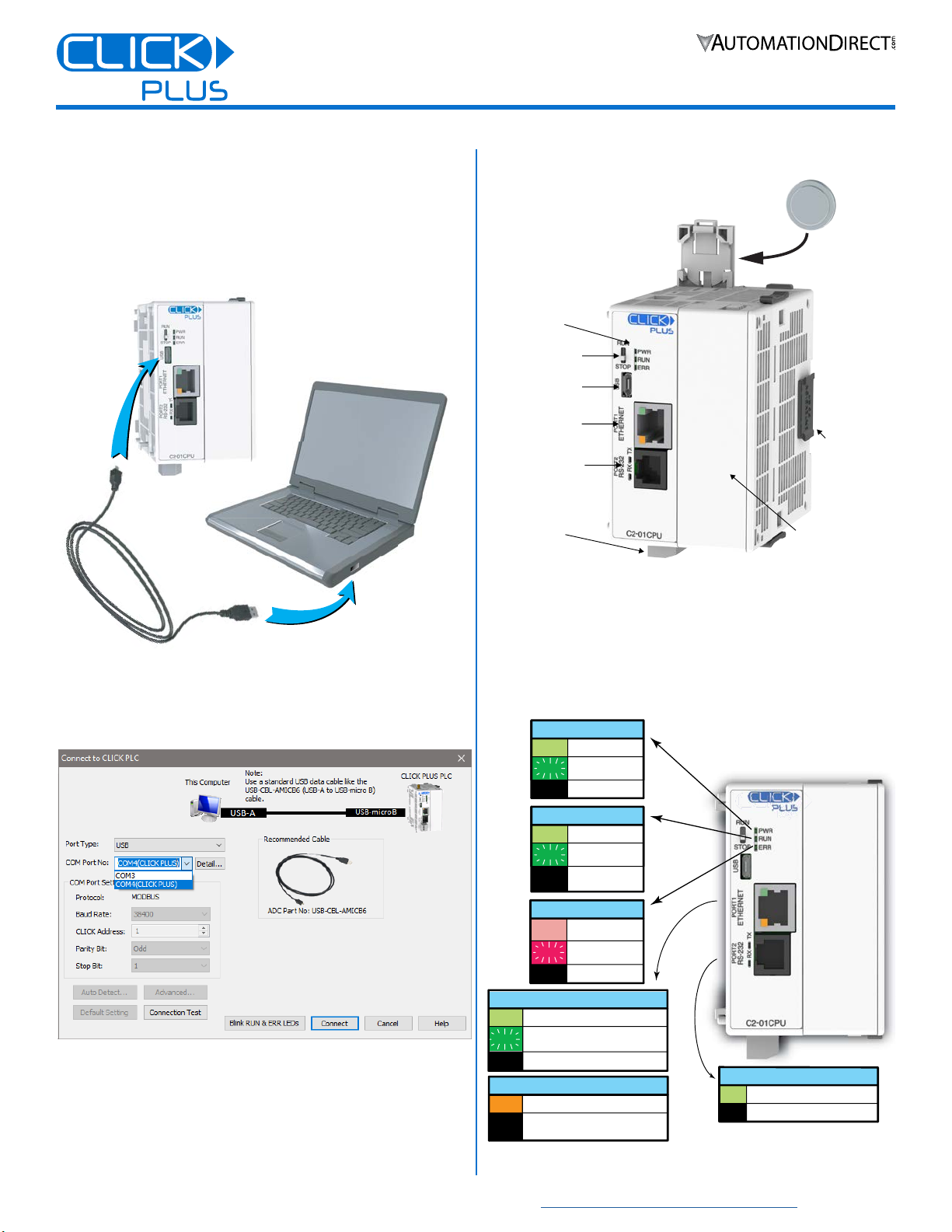

INSTALL OR REMOVE THE OPTION SLOT MODULE INSTALL OR REMOVE STACKABLE MODULES

1. Slide the expansion port LOCK lever to “UNLOCK” and

remove bus cover.

2. Align I/O module with right hand side of CPU, engaging bus

connector so that modules are flush.

3. Slide the “LOCK” lever firmly towards rear of modules, locking

them together.

1

2

3

To remove a module, work the installation steps in reverse.

INSTALL OR REPLACE THE BATTERY

(Lithium CR2032 battery, Part # D0-MC-BAT, not included)

1. Power up the CPU for at least 10 minutes to charge the CPU’s

capacitor prior to removing the

battery. This will retain function

memories. We recommend you

backup data memory before

replacing the battery.

2. Power off the CPU.

3. Pull out the battery holder. (This

may require a small screwdriver to

push in the tab and lift it when the

unit is mounted.)

4. Put in a new battery, with the

positive (+) polarity side facing the

battery holder.

5. Insert the battery holder into the

CPU and push it all the way in.

6. Power on the CPU.

Battery life is about 3 years. Replace

battery within 10 minutes of power off.

Hardware Installation, continued

1 Remove the Option Slot Cover (#C2-FILL)

if it was installed in the CPU, by grasping its

top and bottom front corners, squeezing and

pulling it forward.

2 Hold the

Option Slot

Module by the

top and bottom front

corners, align the PCB card

edge with the guide slots in the

CPU, and slide the module into

its slot. Press the module into place until it is

fully seated

3 Push the top and bottom locking clips

backward until they click into place.

Lift slightly on the locking clips until they

release, then slide each clip forward.

Reverse the procedure.

To install an Option Slot ModuleTo install an Option Slot Module

To remove an Option Slot Module

To remove an Option Slot Module

1 Remove the Option Slot Cover (#C2-FILL)

if it was installed in the CPU, by grasping its

top and bottom front corners, squeezing and

pulling it forward.

2 Hold the

Option Slot

Module by the

top and bottom front

corners, align the PCB card

edge with the guide slots in the

CPU, and slide the module into

its slot. Press the module into place until it is

fully seated

3 Push the top and bottom locking clips

backward until they click into place.

Lift slightly on the locking clips until they

release, then slide each clip forward.

Reverse the procedure.

To install an Option Slot ModuleTo install an Option Slot Module

To remove an Option Slot Module

To remove an Option Slot Module

1 Remove the Option Slot Cover (#C2-FILL)

if it was installed in the CPU, by grasping its

top and bottom front corners, squeezing and

pulling it forward.

2 Hold the

Option Slot

Module by the

top and bottom front

corners, align the PCB card

edge with the guide slots in the

CPU, and slide the module into

its slot. Press the module into place until it is

fully seated

3 Push the top and bottom locking clips

backward until they click into place.

Lift slightly on the locking clips until they

release, then slide each clip forward.

Reverse the procedure.

To install an Option Slot ModuleTo install an Option Slot Module

To remove an Option Slot Module

To remove an Option Slot Module

1 Remove the Option Slot Cover (#C2-FILL)

if it was installed in the CPU, by grasping its

top and bottom front corners, squeezing and

pulling it forward.

2 Hold the

Option Slot

Module by the

top and bottom front

corners, align the PCB card

edge with the guide slots in the

CPU, and slide the module into

its slot. Press the module into place until it is

fully seated

3 Push the top and bottom locking clips

backward until they click into place.

Lift slightly on the locking clips until they

release, then slide each clip forward.

Reverse the procedure.

To install an Option Slot ModuleTo install an Option Slot Module

To remove an Option Slot Module

To remove an Option Slot Module

CAUTION

Cut off all phases of the power source externally and wait 5 seconds before installing or removing the Option Slot

module or Stackable I/O of a running system.

1

3

Power 10+ minutes

2Remove Power

4

5

CAUTION

Battery may explode if mistreated.

Do not recharge, disassemble, or dispose of in fire.

5

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

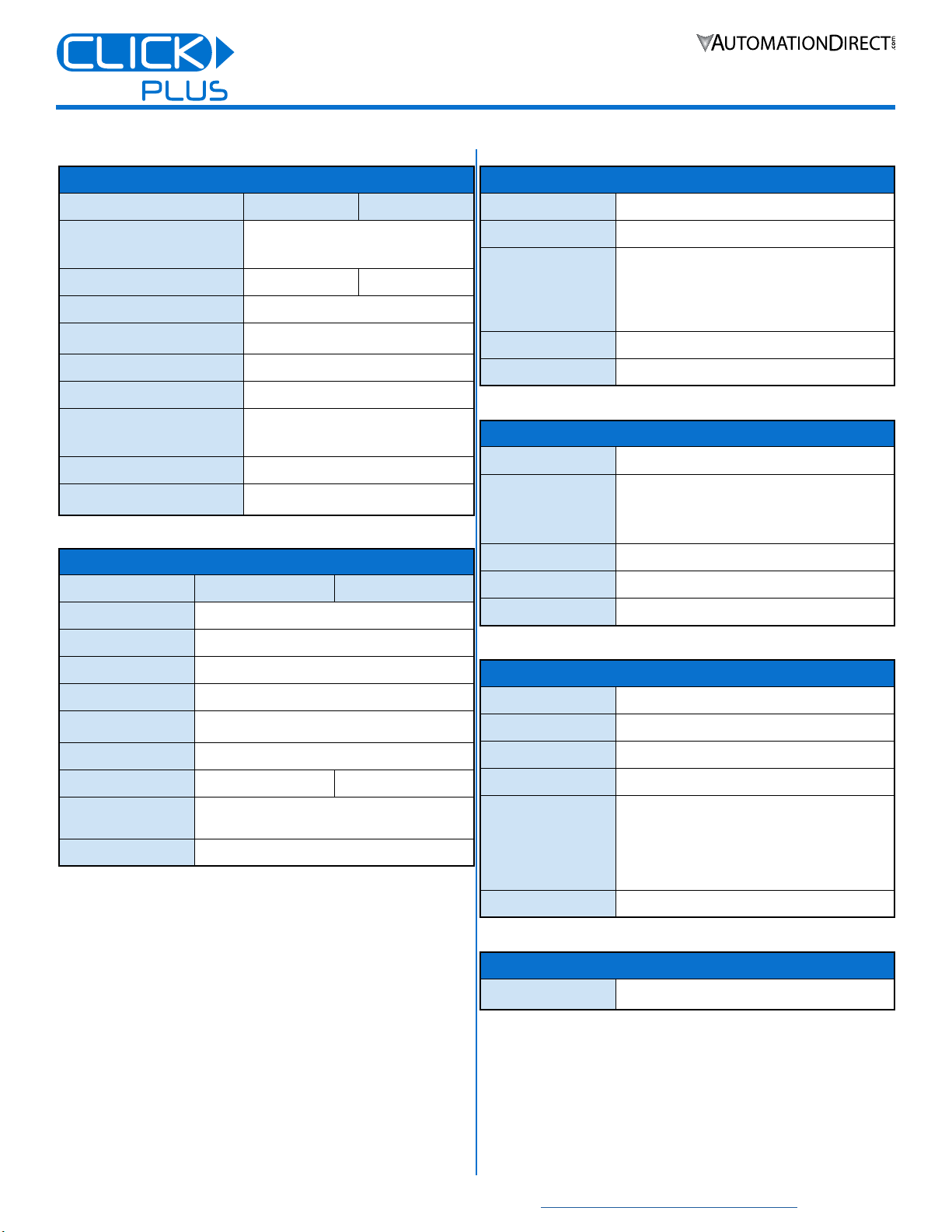

Connecting via USB

To connect the CLICK PLUS CPU to a PC, use a USB A

to USB microB cable, such as the AutomationDirect

USB-CBL-AMICB6 cable.

1. Connect the cable between the CPU microB port and an

available USB port on your PC.

USB Cable

ADC Part #

USB-CBL-AMICB6

PC with

USB A Port

USB

microB

Port

CLICK Plus

PLC

2. Once connected open the Software and select the PLC Menu

and Connect.

3. In the Connect to PLC Window, select USB for Port Type.

4. For Com Port No., select the COMX (CLICK PLUS).

LOAD A PROJECT

The CLICK PLUS CPU is now ready to continue

configuration using the CLICK software and load a project.

External Features

W

tts

micB

pn ot

(fpot)

(10/100)

tt

Pt

R

pnsion

Connto

Pow

Tmin

By

(p)

C2-01CPU(-x)

Blink

LNK/ACT LED (Green)

On Connected to the network

Communicating

Disconnected from the network

Off

100MBIT LED (Orange)

On Communicating at 100Mbps

Communicating at 10Mbps or

disconnected from the network

Off

TX & RX LED (Green)

On Com Port Data Active

No CommunicationOff

ERROR LED (RED)

On Self Diagnostic

Error

Self Diagnostic

Warning

No ErrorOff

Blink

POWER LED (Green)

On Power Good

USB Low

Power Mode

Power Failure

Off

Blink

RUN LED (Green)

On CPU Run Mode

Initializing

Modules

CPU Program

Mode

Off

Blink

LED Status Indicators

6

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Technical Specifications

Power Specifications

C2-01CPU C2-01CPU-2

Power Input Voltage Range

20–28 VDC Class 2

or SELV(Safety Extra-Low Voltage)

or Limited Energy Circuit power supply

Maximum Power Consumption

20W 22W

Maximum Inrush Current

30A @ 1ms

Acceptable External Power Drop

Max 10ms (AC Power Failure with

C0-00AC or C0-01AC)

Wire Range

16–28 AWG

Wire Strip Length

7.0 mm

Wire Specication

Lead-free, heat resistant,

polyvinyl chloride insulated copper wire,

rated over 80°C

Screw Torque

2.0–2.2 lb-in [0.22–0.25 N·m]

24VDC Power Terminal Block

Replacement

AutomationDirect p/n C0-4TB

General Specifications

C2-01CPU C2-01CPU-2

Operating Temperature

32°F to 131°F [0°C to 55°C]

Storage Temperature

–4°F to 158°F [–20°C to 70°C]

Ambient Humidity

30% to 95% relative humidity (non–condensing)

Altitude

Up to 2,000m

Environmental Air

No corrosive gases

Pollution Degree 2 (UL840)

Environment

For Indoor Use Only

Weight

99g [3.5 oz] 114g [4.0 oz]

Agency Approvals

UL61010 (File No. E157382, E316037);

CE (EN61131-2);

CUL Canadian C22.2

Other

RoHS 2011/65/EU Amendment (EU)2015/863

USB Programming Port Specifications

Communications Ratings

USB 2.0 Full Speed (12Mbps)

Connector

MicroB USB

Bus Power

USB Low power Mode: Max. 500mA USB power

supplied when USB cable is connected.

Disabled Functions:

Stackable I/O BUS

RUN Mode

Recommended Cable

AutomationDirect p/n USB-CBL-AMICB6

USB Cable Length

Max 15 ft.

Ethernet Port Specifications

Communications Ratings

10/100 Base-T

Cable Specications

Category 5

Auto MDI/MDI-X

Yes

Connector

RJ45

Default Settings

IP address assigned by DHCP

àFallback on DHCP failure: 169.254.x.x (APIPA)

Default Fixed Address:

àIP Address: 192.168.0.10

àSubnet Mask: 255.255.0.0

àDefault Gateway: 0.0.0.0

Manually congured Fixed Address

Status Lamp

LINK/ACT, 10/100

Backup Battery Specifications

Type

CR-2032

(AutomationDirect #D0-MC-BAT recommended)

RS-232 Port Specifications

Communications Ratings

RS-232

Port Settings

Baud rate: 2400, 4800, 9600, 19200, 38400,

57600, 115.2k bps

Data bits: 7 bit, 8 bit

Parity: None, Odd, Even

Stop bits: 1 bit, 2 bits

Connector

RJ12 phone jack

Power Supply to HMI

Supply 5V 200mA

Status Lamp

RX, TX

7

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

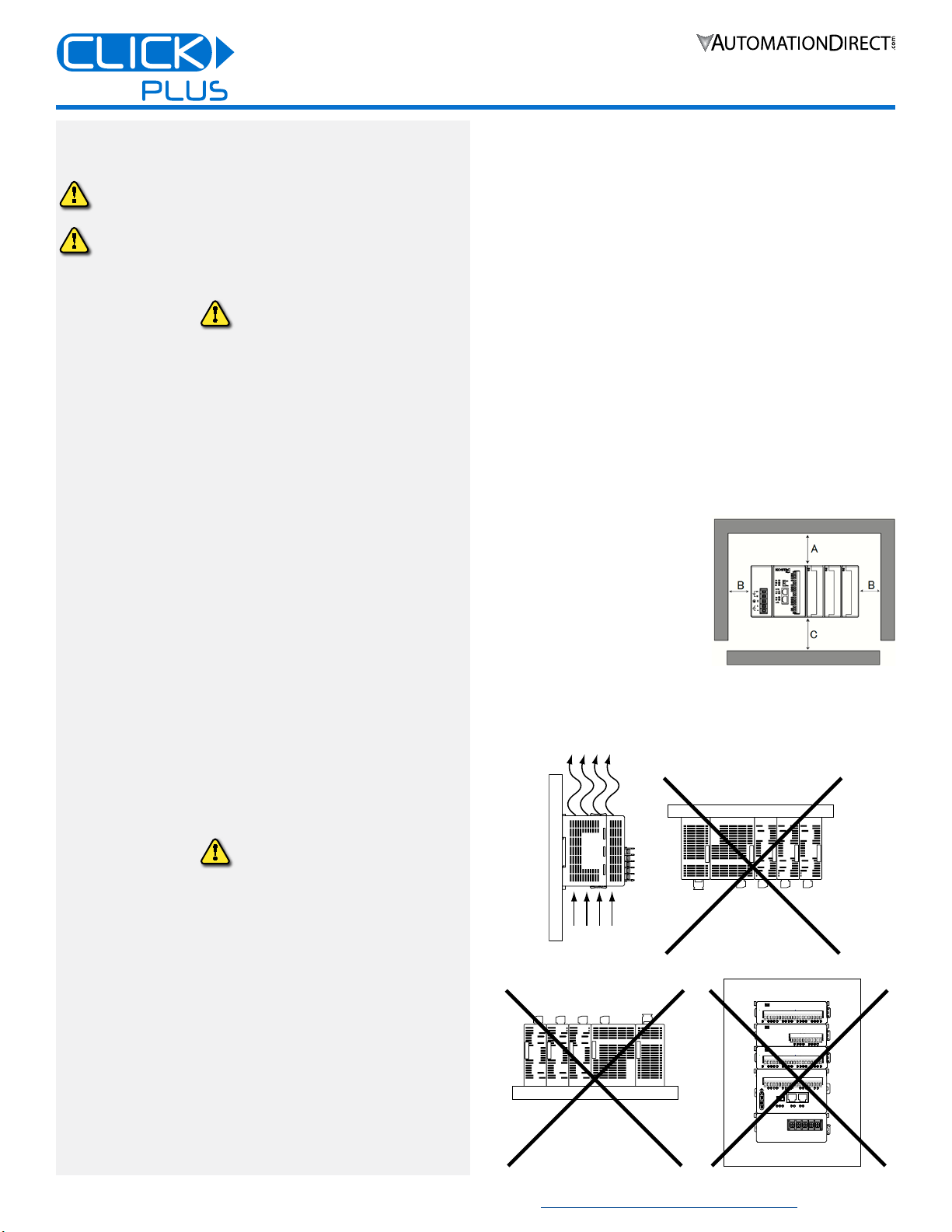

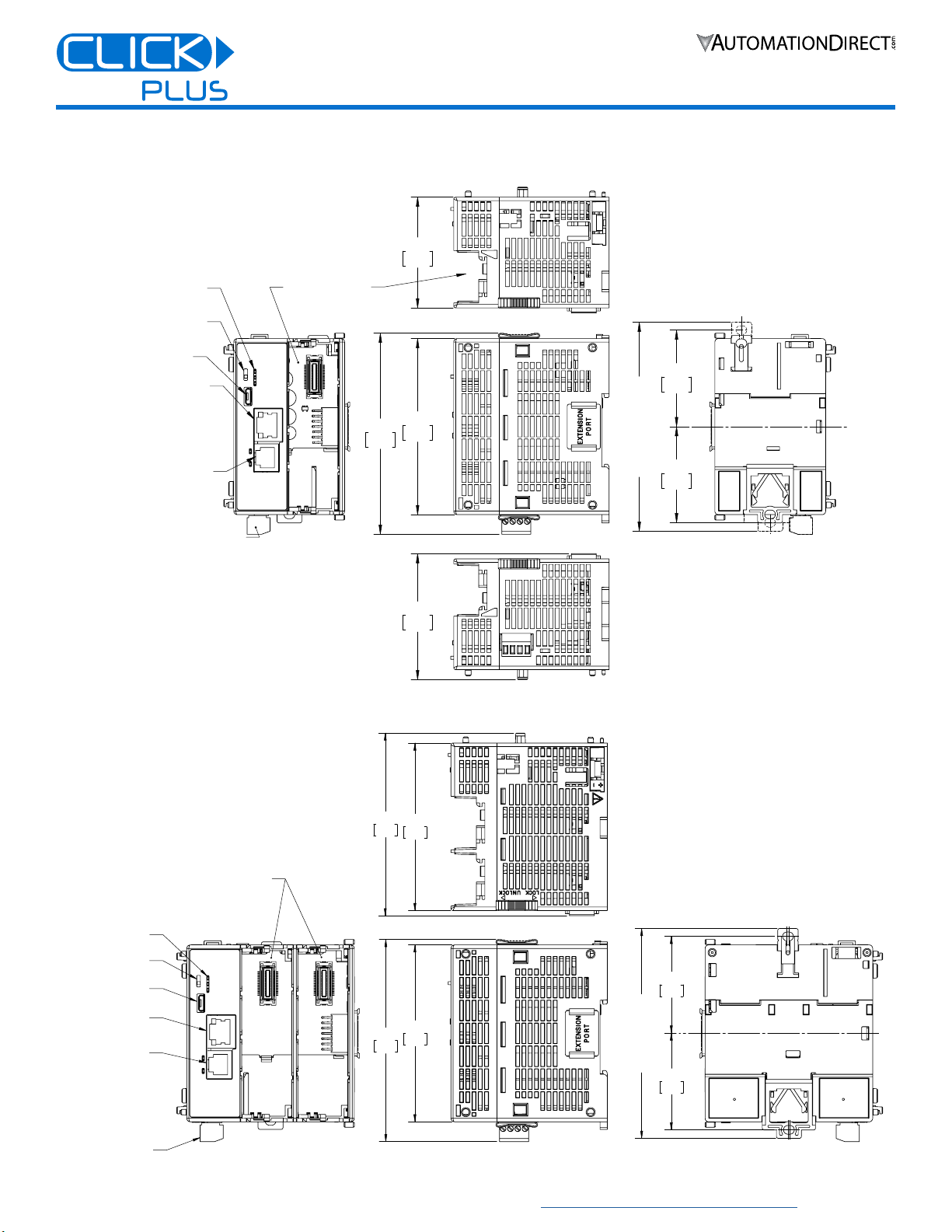

Mechanical Drawings

Unit Dimensions: mm [in]

MODE SWITCH

MICRO USB

ETHERNET 10/100

SERIAL PORT RS-232

STATUS LED's

POWER TERMINAL BLOCK

OPTIONAL

MODULE SLOT

85.0

3.35

97.1

3.82

53.5

2.11

60.8

2.39

46.6

1.83

46.4

1.83

FULLY EXTENDED

( OVERALL )

MODE SWITCH

MICRO USB

STATUS LED's

ETHERNET 10/100

SERIAL PORT RS-232

POWER TERMINAL

BLOCK

EXPANSION SLOTS

85.0

3.35

97.1

3.82

80.5

3.17

87.8

3.46

FULLY EXTENDED

(OVERALL)

46.4

1.83

46.6

1.83

C2-01CPU

C2-01CPU-2

8

3505 HUTCHINSON ROAD

CUMMING, GA 30040-5860

1-800-633-0405

C2-01CPU Series Quick Start Guide

www.automationdirect.com/clickplcs

Copyright© 2021, Automationdirect.com Incorporated/All Rights Reserved Worldwide

Accessories

C2-FILL

Snap-on CPU Option

Slot cover for applications

without an Option Slot

module present.

C0-4TB

Replacement terminal

block for the 24VDC

power connection.

Sold in packs of 2.

D0-MC-BAT

Replacement battery for

CLICK PLUS CPU units.

This manual suits for next models

2

Table of contents

Other AutomationDirect Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

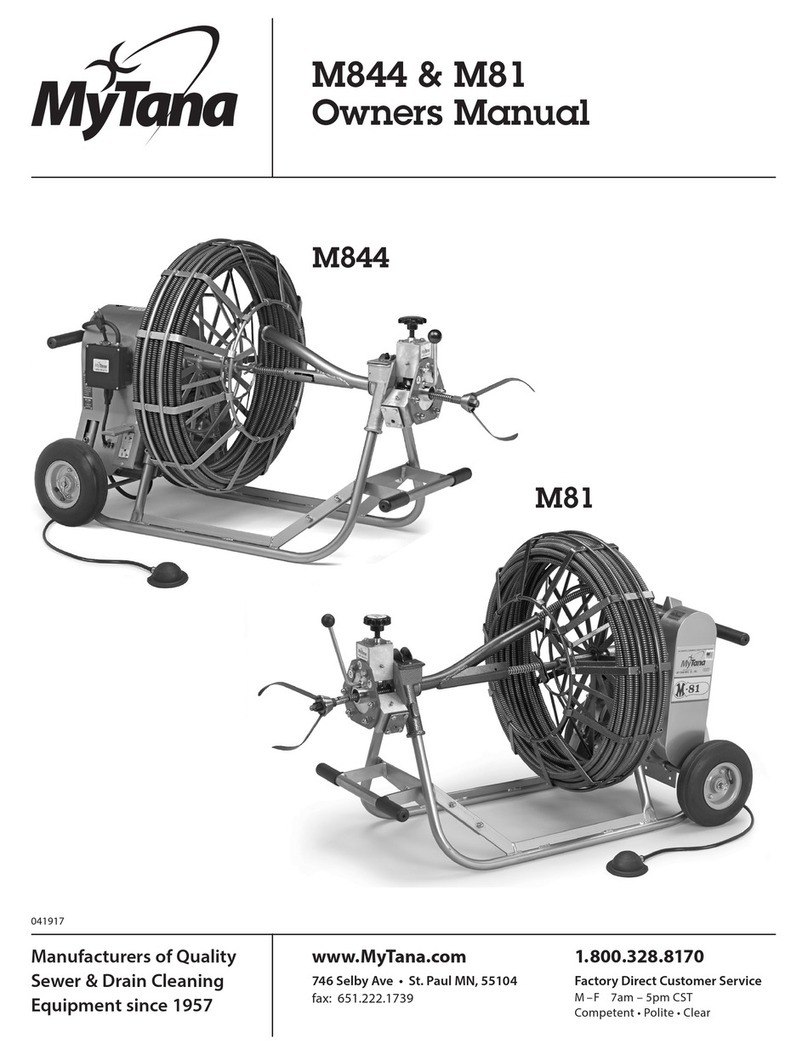

MyTana

MyTana M844 owner's manual

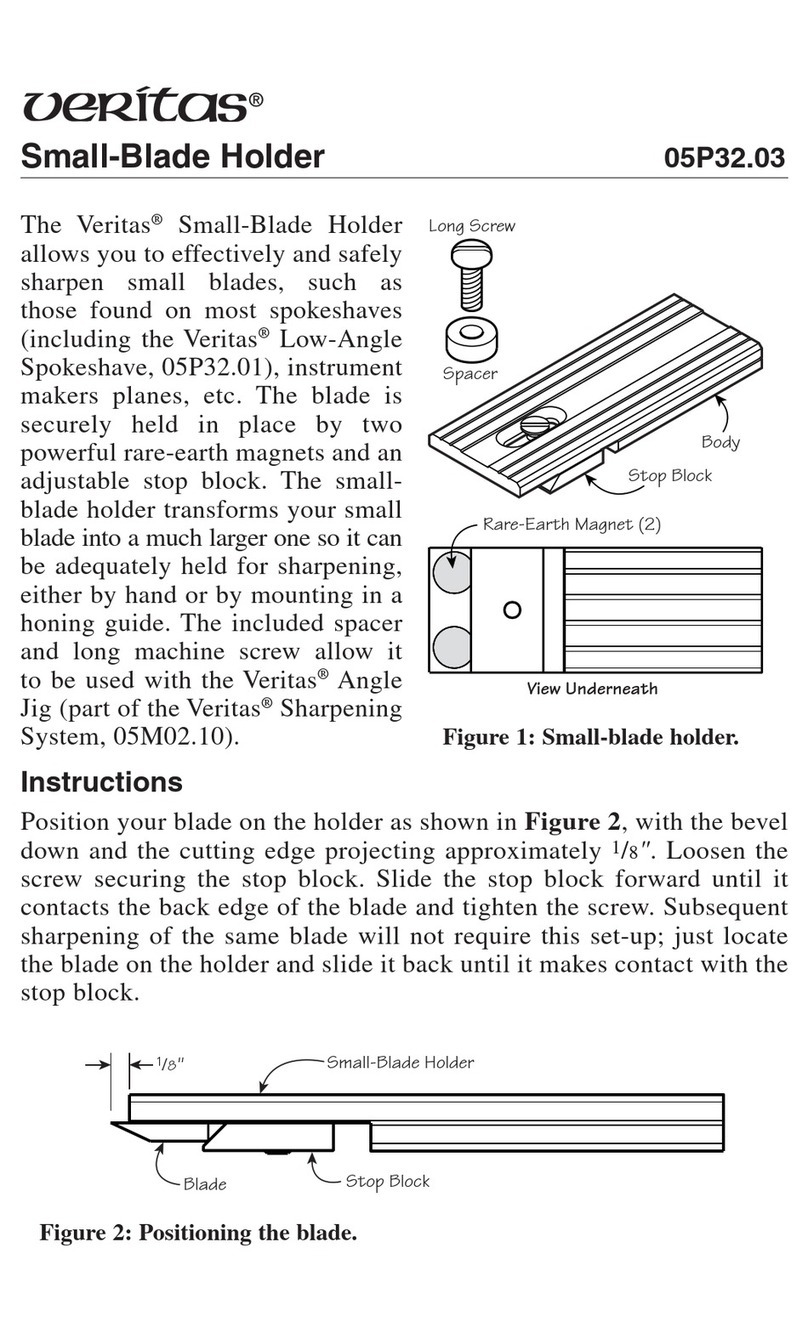

VERITAS

VERITAS 05P32.03 quick start guide

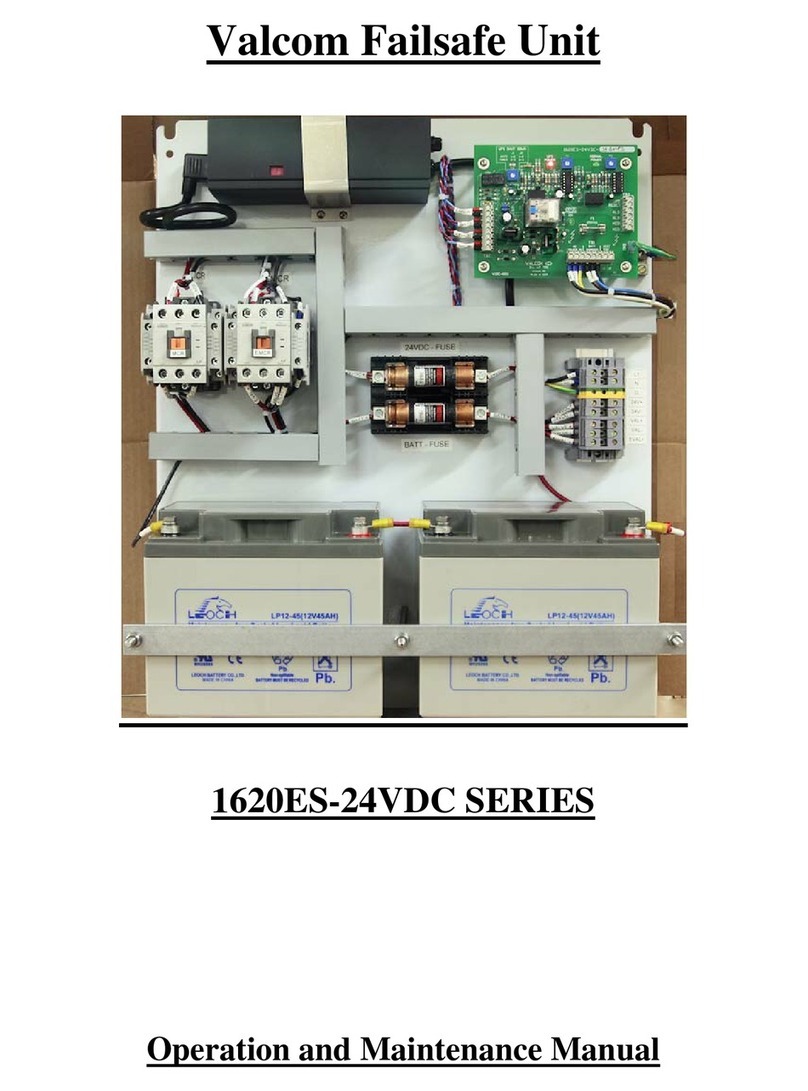

Valcom

Valcom 1620ES-24VDC Series Operation and maintenance manual

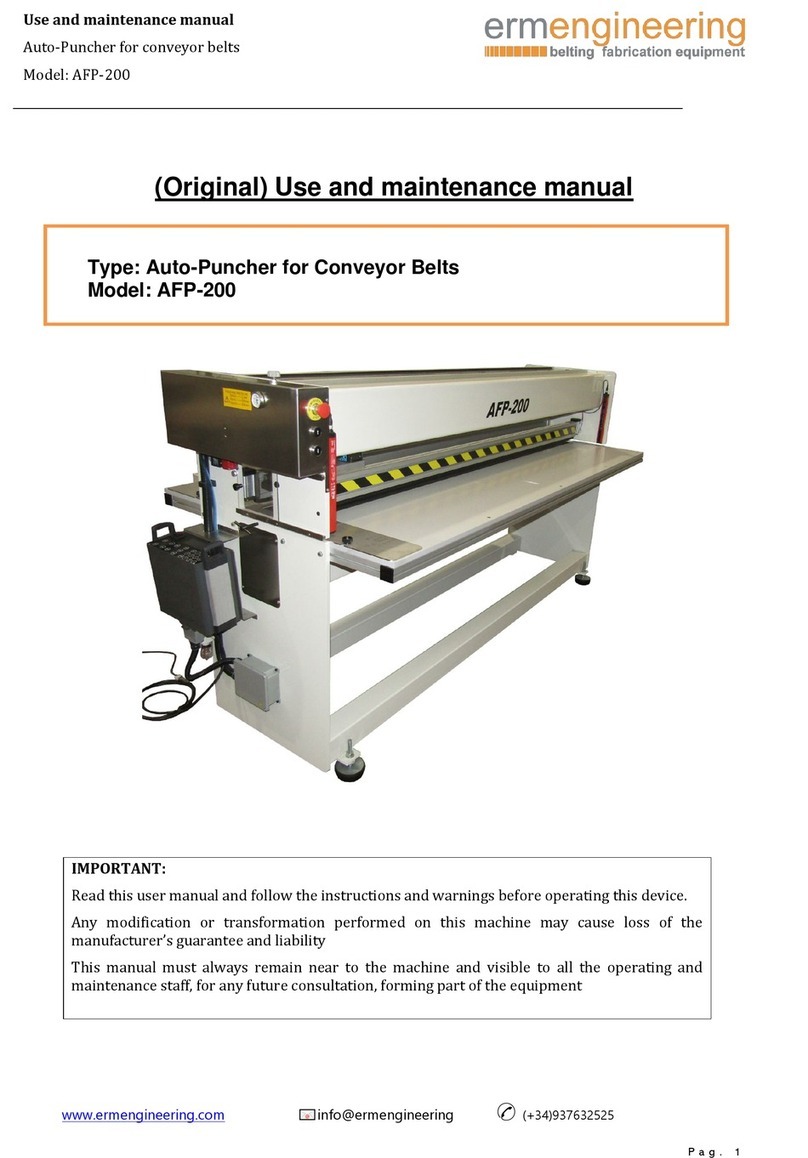

ermengineering

ermengineering AFP-200 Use and maintenance manual

Loveshaw

Loveshaw LITTLE DAVID LD7D/3 Parts and instruction manual

Siemens

Siemens SIRIUS 3RK1105-1AE04-0CA0 Original operating instructions