Movex Zero ATP Pro 5336 Series Installation and operation manual

working in partership with

ENGINEERING MANUAL

2

ENGINEERING MANUAL - ZERO ATP® PRO

APPLICATION CONSIDERATIONS.

The proper selection and application of Movex® products and components, including the related area of product safety, is the responsibility of the

customer. Operating and performance requirements and potential associated issues will vary appreciably depending upon the use and application

of such products and components. The scope of the technical and application information included in this publication is necessarily limited. Unu-

sual operating environments and conditions, lubrication requirements, loading supports, and other factors can materially aect the application

and operating results of the products and components and the customer should carefully review its requirements. Users of our products should

make their own tests to determine the suitability of any product for their particular purposes.

Any technical advice or review furnished by Movex® with respect to the use of products and components is given in good faith and without charge,

and Movex® assumes no obligation or liability for the advice given, or results obtained, all such advice and review being given and accepted at

customer’s risk.

For a copy of our Standard Terms and Conditions of Sale, Disclaimers of Warranty, Limitation of Liability and Remedy, please see our web site

www.movexii.com or contact our Customer Service.

These terms and conditions of sale, disclaimers and limitations of liability apply to any person who may buy, acquire, or use any Movex® product

referred to herein, including any person who buys from a licensed distributor of these branded products.

The applicable Movex® product catalogs and installation/maintenance bulletins must be used only by qualified individuals familiar with Movex®

products; these documents contain important precautions and other information intended to reduce the risk of bodily injury. Refer to these do-

cuments before specifying, installing, operating, or servicing equipment.

Incorrect and/or incomplete data could cause the selection of improper components, potentially resulting in bodily injury. Movex® makes no war-

ranties, express or implied, of merchantability or fitness for a particular purpose.

Movex® will not be liable for direct or indirect incidental, consequential, or punitive damages arising from the use or inability to use this any

of the information made available, including but not limited to product literature, selection programs, and interchange guides. Movex® reserves

the right to correct, modify, update and/or enhance these documents at any time without notice or penalty, including but not limited to pricing,

technical data, etc. Most updated documents can always be found on the website. For more technical information, contact our Technical Support.

© Copyright Movex S.p.A. 2022

The contents of this manual are the copyright of the publisher and may not be reproduced (even extracts) unless permission is granted.

Every care has been taken to ensure the accuracy of the information contained in this publication, but no liability can be accepted for any error

or omission. Catalogue N° M999584

3

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |Table of contents

INTRODUCTION ....................................................................................................................................................................................................................... 05

VERSIONS .................................................................................................................................................................................................................................... 06

SPEED CALCULATION

Mini motor version (standard) ........................................................................................................................................................................... 08

External motor version (power) ........................................................................................................................................................................ 09

Keyed shaft version .................................................................................................................................................................................................... 10

INSTALLATION ............................................................................................................................................................................................................................ 11

GENERAL TABLE WITH NOSEBARS / ROLLERS ............................................... ................................................................................................. 13

TRANSFER LENGTH WITH NOSEBARS / ROLLERS

520 FT with NoseBars Ø19 ................................................................................................................................................................................... 14

520 LBP with NoseBars Ø19 ................................................................................................................................................................................. 15

520 PRO LBP with NoseBars Ø19 ..................................................................................................................................................................... 16

525 FT with NoseBars Ø19 ..................................................................................................................................................................................... 17

530 PRO LBP with NoseBars Ø19 ..................................................................................................................................................................... 18

550 FT with Rollers Ø40 .......................................................................................................................................................................................... 19

551 FT with Rollers Ø40 .......................................................................................................................................................................................... 20

551 LBP with Rollers Ø40 ...................................................................................................................................................................................... 21

551 PRO LBP with Rollers Ø40 ........................................................................................................................................................................... 22

553 FLEXTOP with Rollers Ø50 .......................................................................................................................................................................... 23

556 FT with Rollers Ø50 ........................................................................................................................................................................................ 24

600 FT with Rollers Ø60 ........................................................................................................................................................................................ 25

GENERAL TABLE WITH SPROCKETS ................................................................................................................................................................. 26

TRANSFER LENGTH WITH SPROCKETS

520 FT with Sprockets .............................................................................................................................................................................................. 28

520 LBP with Sprockets ........................................................................................................................................................................................... 29

520 PRO LBP with Sprockets ............................................................................................................................................................................... 30

525 FT with Sprockets ............................................................................................................................................................................................... 31

530 PRO LBP with Sprockets ............................................................................................................................................................................... 32

550 FT with Sprockets ............................................................................................................................................................................................... 33

551 FT with Sprockets ................................................................................................................................................................................................ 34

551 LBP with Sprockets ............................................................................................................................................................................................ 35

551 PRO LBP with Sprockets ................................................................................................................................................................................ 36

553 FLEXTOP with Sprockets ............................................................................................................................................................................... 37

556 FT with Sprockets ............................................................................................................................................................................................... 38

600 FT with Sprockets .............................................................................................................................................................................................. 39

820 FT with Sprockets ............................................................................................................................................................................................... 40

821 LBP with Sprockets ......................................................................................................................................................................................... 41

4

ENGINEERING MANUAL - ZERO ATP® PRO

INSTALLATION WITH EXTERNAL TRANSMISSION ........................................................................................................................................ 42

PERSONAL PROTECTIVE EQUIPMENT .................................................................................................................................................................... 43

DO’S AND DON’TS ................................................................................................................................................................................................................ 44

MAINTENANCE

General maintenance instructions ............................................................................................................................................................. 45

Installation on the line ........................................................................................................................................................................................... 46

Inspection .......................................................................................................................................................................................................................... 47

CLEANING .................................................................................................................................................................................................................................... 48

TROUBLESHOOTING ........................................................................................................................................................................................................... 49

MATERIAL

LFA - LFB ............................................................................................................................................................................................................................. 50

MX ............................................................................................................................................................................................................................................ 51

FREQUENTLY ASKED QUESTION ................................................................................................................................................................................ 52

Zero ATP® PRO |Table of contents

5

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |Introduction

Mini-motor or

keyed shaft

Z16 drive sprockets

with incorporate key

Chrome steel

bearings

Compact

design

Smallest possible

transfer

ENSAT

M8 Side frame

AISI 304

Side frame

AISI 304

General products features Plug and play solution

• Self-tensioning

• Maintenance free

• Compact design

• Low voltage

• Easy installation

• Easy integration

Simultaneous transport of:

HIGH LOAD & BIG GOODSLIGHTWEIGHT & SMALL GOODS

CONVEYOR

A

CONVEYOR

B

CONVEYOR

A

CONVEYOR

B

Belt series 510 FT

Belt width 6inch ÷ 24inch

Transfer length 80 or 150 mm

Transmission Mini motor or Keyed shaft

Material LFA, MX or LFB

Max working load 3000 N/m

User-friendliness

Easy installation and interchangeability.

Minimized maintenance

Zero ATPTM Pro doesn’t require maintenance.

Short transfer connection

It works perfectly with small products.

Unique design

It solves traditional transfer plate issues.

Safer design

Minimized the possibility of injuries.

Saving (Energy, resources, time)

Fewer resources and time employed.

P

A

T

E

N

T

E

D

6

ENGINEERING MANUAL - ZERO ATP® PRO

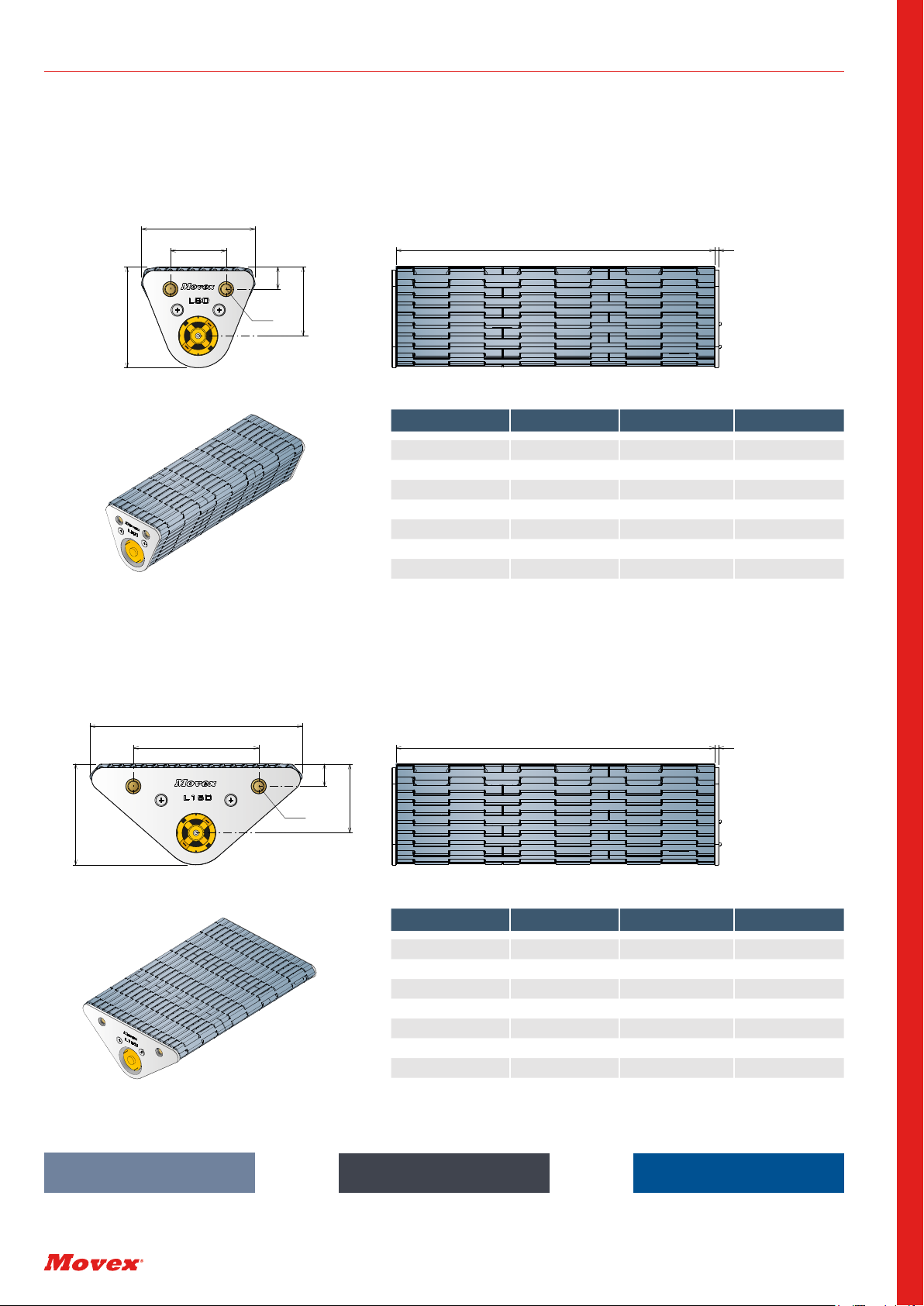

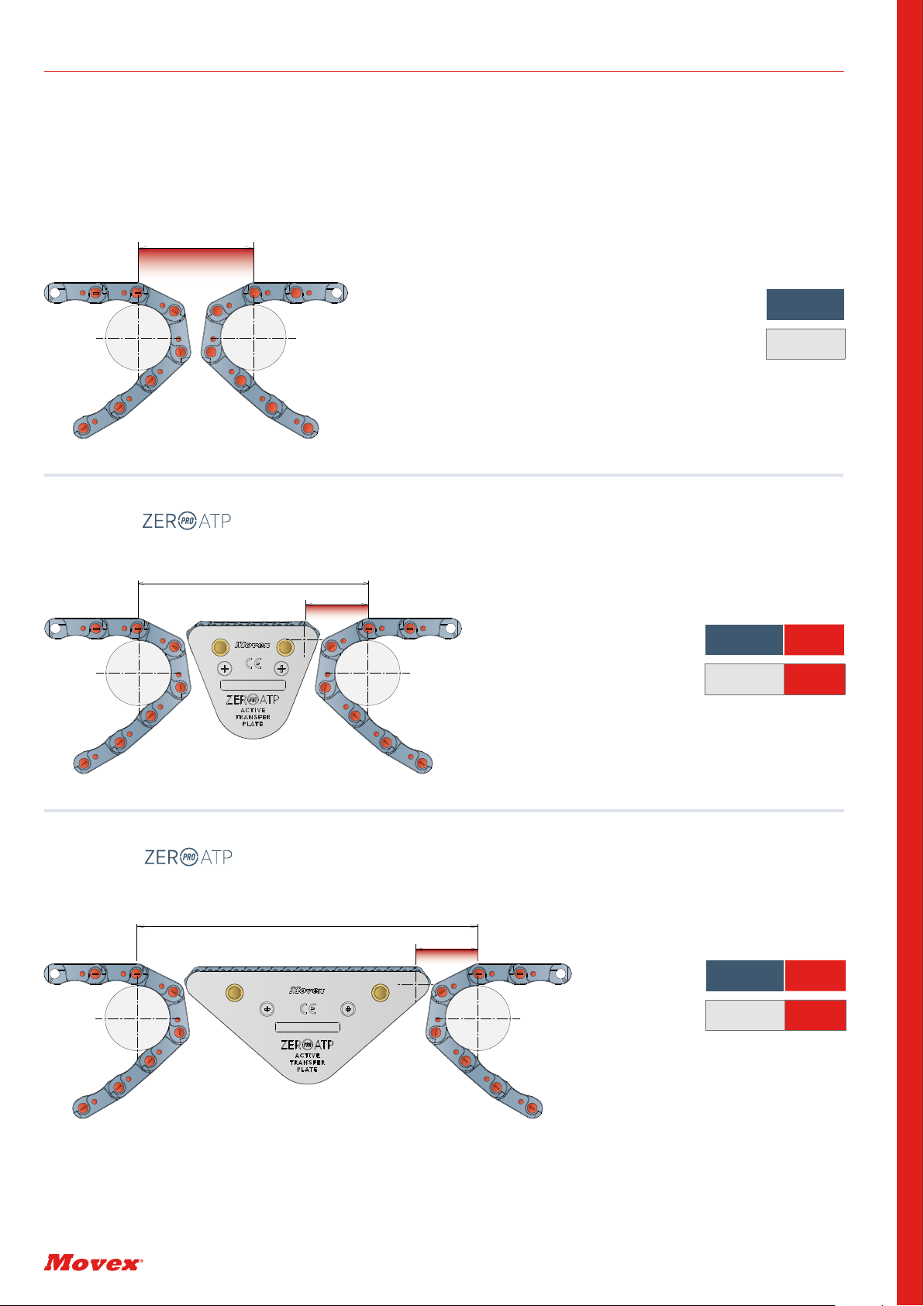

VERSION A - WITH MINI MOTOR

Zero ATP® PRO |Versions

Length 80 mm

49.5

90

150

40

80

16

49.5

16

Width 3

Width 3

M8

M8

72.5

72.5

Series *Material Width Version

5336 * 0006 A

5336 * 0009 A

5336 * 0012 A

5336 * 0015 A

5336 * 0018 A

5336 * 0021 A

5336 * 0024 A

Length 150 mm

Series *Material Width Version

5338 * 0006 A

5338 * 0009 A

5338 * 0012 A

5338 * 0015 A

5338 * 0018 A

5338 * 0021 A

5338 * 0024 A

LFA | Low friction Acetal LFB | Low friction Acetal

Material information, page 50

MX | Performance PBT

Material information, page 51 Material information, page 50

*Wider version on request

49.5

90

150

40

80

16

49.5

16

Width 3

Width 3

M8

M8

72.5

72.5

*Wider version on request

49.5

90

150

40

80

16

49.5

16

Width 3

Width 3

M8

M8

72.5

72.5

49.5

90

150

40

80

16

49.5

16

Width 3

Width 3

M8

M8

72.5

72.5

7

ENGINEERING MANUAL - ZERO ATP® PRO

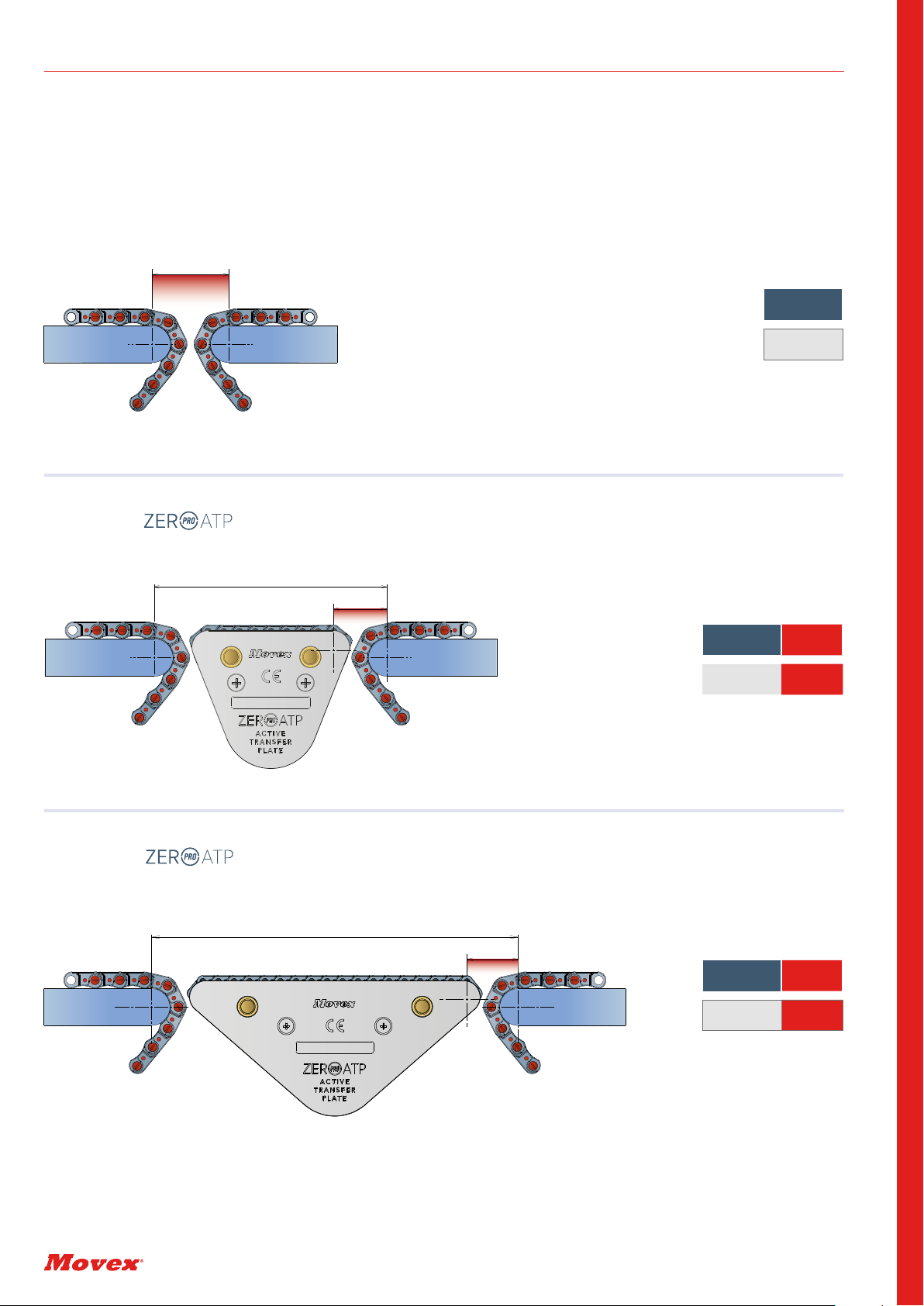

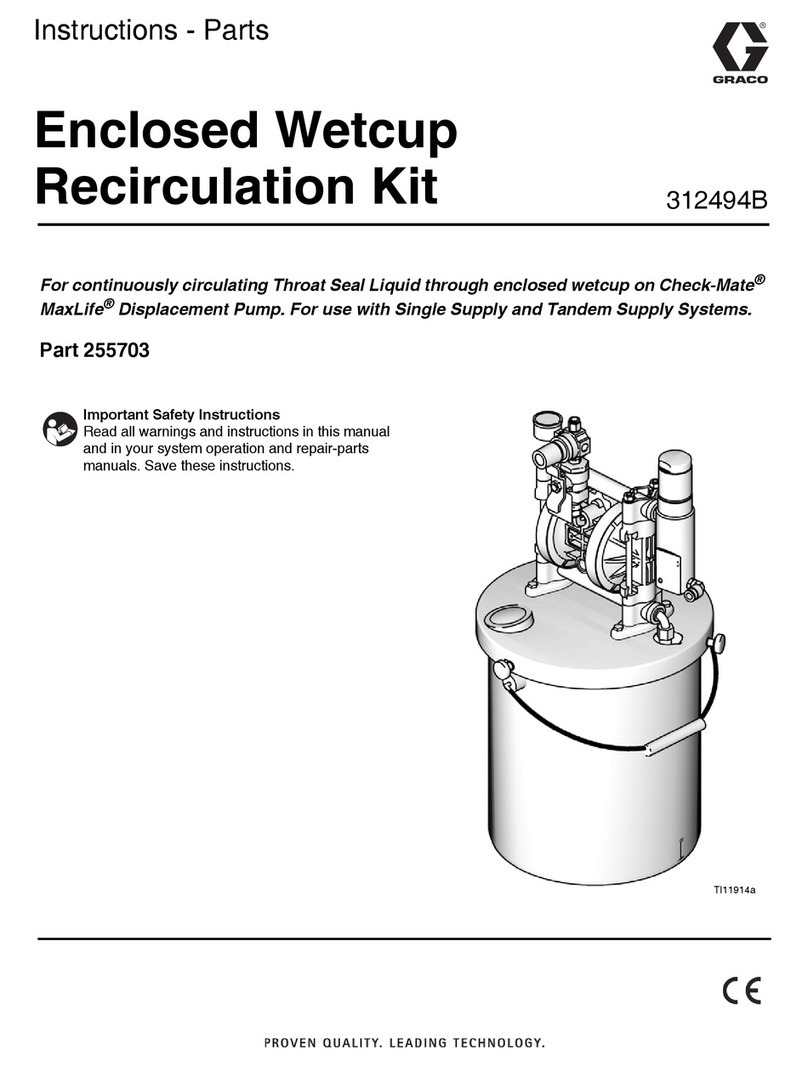

VERSION B - WITH KEYED SHAFT

Length 80 mm

49.5

90

150

40

80

16

49.5

16

Width 3

M8

M8

Width 3

75

60

Keyseat

5x5

Ø15

75

60

Keyseat

5x5

Ø15

72.5

72.5

Series *Material Width Version

5336 * 0006 B

5336 * 0009 B

5336 * 0012 B

5336 * 0015 B

5336 * 0018 B

5336 * 0021 B

5336 * 0024 B

Length 150 mm

Series *Material Width Version

5338 * 0006 B

5338 * 0009 B

5338 * 0012 B

5338 * 0015 B

5338 * 0018 B

5338 * 0021 B

5338 * 0024 B

*Wider version on request

Zero ATP® PRO |Versions

LFA | Low friction Acetal LFB | Low friction Acetal

Material information, page 49

MX | Performance PBT

Material information, page 50 Material information, page 49

49.5

90

150

40

80

16

49.5

16

Width 3

M8

M8

Width 3

75

60

Keyseat

5x5

Ø15

75

60

Keyseat

5x5

Ø15

72.5

72.5

49.5

90

150

40

80

16

49.5

16

Width 3

M8

M8

Width 3

75

60

Keyseat

5x5

Ø15

75

60

Keyseat

5x5

Ø15

72.5

72.5

49.5

90

150

40

80

16

49.5

16

Width 3

M8

M8

Width 3

75

60

Keyseat

5x5

Ø15

75

60

Keyseat

5x5

Ø15

72.5

72.5

*Wider version on request

8

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |Speed calculation

MINI MOTOR VERSION (STANDARD)

Voltage

m/min

RPM

0

40 60

080 100 120

2

44.5

6

8

10

12

14

16

20

15

8.6

12.9

4,4 m/min

(min speed)

14,7 m/min

(max speed)

Zero ATP® PRO version A is provided with the mini motor installed internally; this will make the Zero ATP® PRO

compact and easy to be installed into new or exiting lines.

Operating relative humidity 20% - 85%

Operating temperature range -10°C - +60°C

Optional cover for

motor connection

Article-Nr. 300601

Technical specifications

Output Speed 84 rpm

Supply Voltage 6 - 15 V dc

Maximum Output torque 6539 g.cm

DC Motor type Brushed

Shaft Diameter 6 mm

Power Rating 7.85 W

Gearhead Type Planetry

Length 73.9 mm

Width 32 (Dia.) mm

Current rating 990 mA

Weight 211g

NOTE: Motor speeds may vary by (+) or (-) 12.5% RPM - Revolutions per minute m/min - Meters per minute

m/min

0

10 15

020 25 30 35 40 45 50 55

10

20

30

40

50

60

70

5

db(A)

m/min

0

015

5 10

10

20

30

40

50

60

70

db(A)

Zero ATP® PRO noise level

The graphic on the right shows the noise

level of a 9-inch Zero ATP® PRO at dierent

speeds with the following conditions: 1m

distance, 1m height, 23°C room temperature.

9

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |Speed Calculation

EXTERNAL MOTOR VERSION (POWER)

m/min

RPM

100 150

0200 250 300 350 400

50

0

10

20

30

40

50

60

4,5

15

8,5

10,9

Voltage

16,4 m/min

(min speed)

54,5 m/min

(max speed)

In case standard internal motor doesn’t let your line achieving required speed, more powerful versions can be used.

Because of the small dimension of the Zero ATP® PRO, a dierent motor than the standard must be fixed externally,

by using a plate or directly at the conveyor frame.

The following motor is just an example of motors that can be used, able to achieve 55 m/min.

Also dierent/traditional motor scan be used by making the required adapter.

Operating relative humidity 20% - 85%

Operating temperature range -10°C - +60°C

Technical specifications

NOTE: Motor speeds may vary by (+) or (-) 12.5% RPM - Revolutions per minute m/min - Meters per minute

Output Speed 309 rpm

Supply Voltage 4.5 - 15 V dc

Maximum Output torque 3000 g.cm

DC Motor type Brushed

Shaft Diameter 6 mm

Power Rating 19.8 W

Gearhead Type Spur

Length 82.5 mm

Width 39.3 mm

Current rating 2810 mA

Weight 285 g

m/min

0

10 15

020 25 30 35 40 45 50 55

10

20

30

40

50

60

70

5

db(A)

m/min

0

015

5 10

10

20

30

40

50

60

70

db(A)

Zero ATP® PRO noise level

The graphic on the right shows the noise

level of a 9-inch Zero ATP® PRO at dierent

speeds with the following conditions: 1m

distance, 1m height, 23°C room temperature.

10

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |Speed calculation

KEYED SHAFT VERSION

Zero ATP® PRO version B is provided with keyed shaft, which can be connected by using a custom motor with an

adapter or with an external roller chain transmission.

By using this graphic, you can easily calculate

revolutions per minute based on the required speed.

Based on the selected transmission sprockets, speed

may vary more or less than established values.

0

100 1500 200 250 300 350 400

10

20

30

40

50

60

70

m/min

RPM

50 450 500

RPM - Revolutions per minute

m/min - Meters per minute

For more information about installation, please check page 42

Output speed can be easily calculated by using the pitch diameter of the

sprocket, d.45mm.

45

45

150

80

45

45

150

80

Keyed shaft version

Includes a 15 mm shaft

with standard key seat 5x5

for roller chain transmission.

Keyseat

5x5

Ø15

In case of a connection with roller chain

transmission, it is suggested to connect

the Zero ATP® PRO to the previous conveyor

(drive side) for a better stability.

DRIVE SIDEIDLER SIDE

11

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |Installation

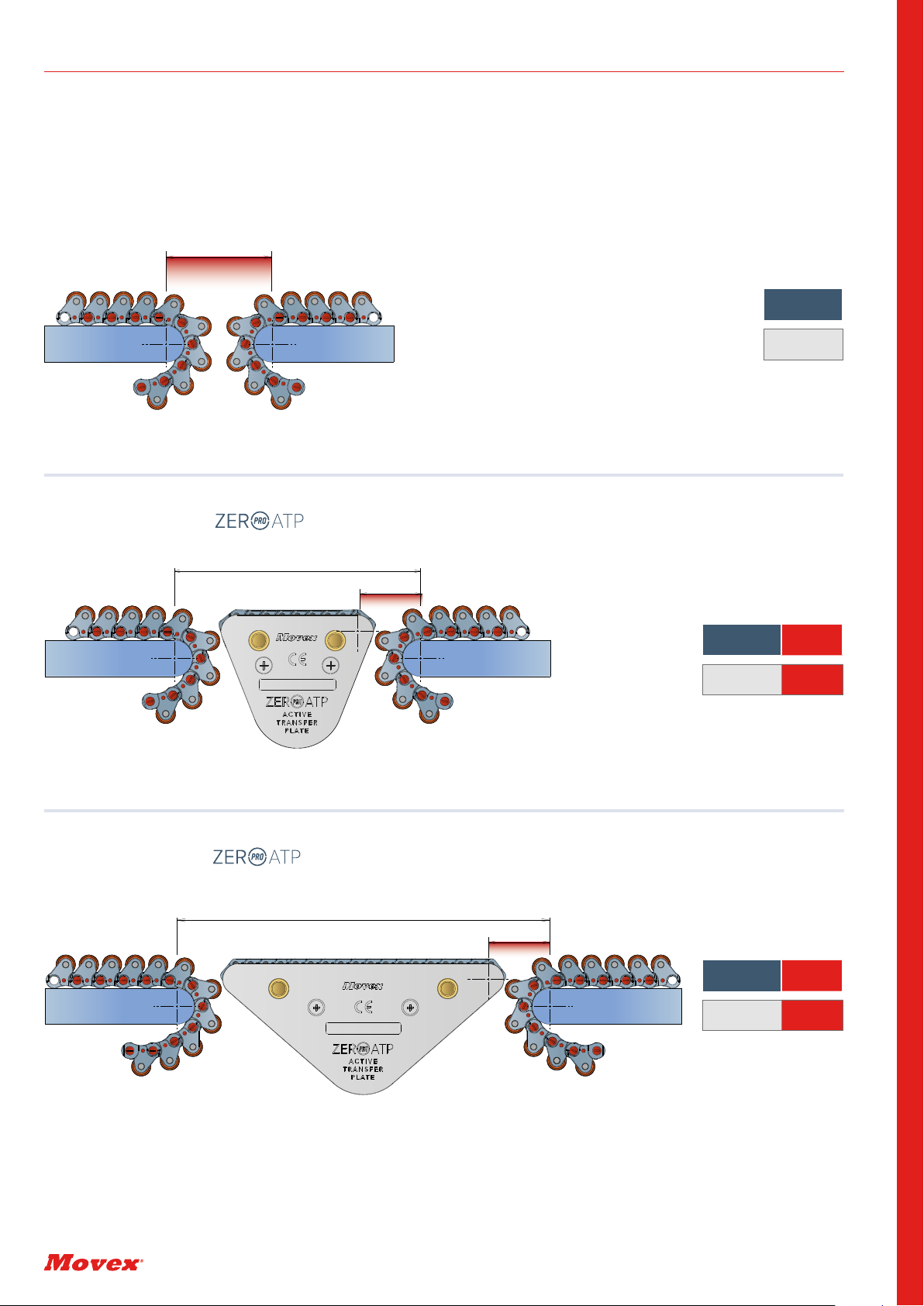

Ideal transfer for relative heavy products. The Zero ATP® PRO results in line with the infeed and outfeed belts.

The product is supported from the three belts and will leave the Zero ATP® PRO in a smooth way.

TRANSFER - ALIGNED

TRANSFER - LOWER

TRANSFER - UP & DOWN

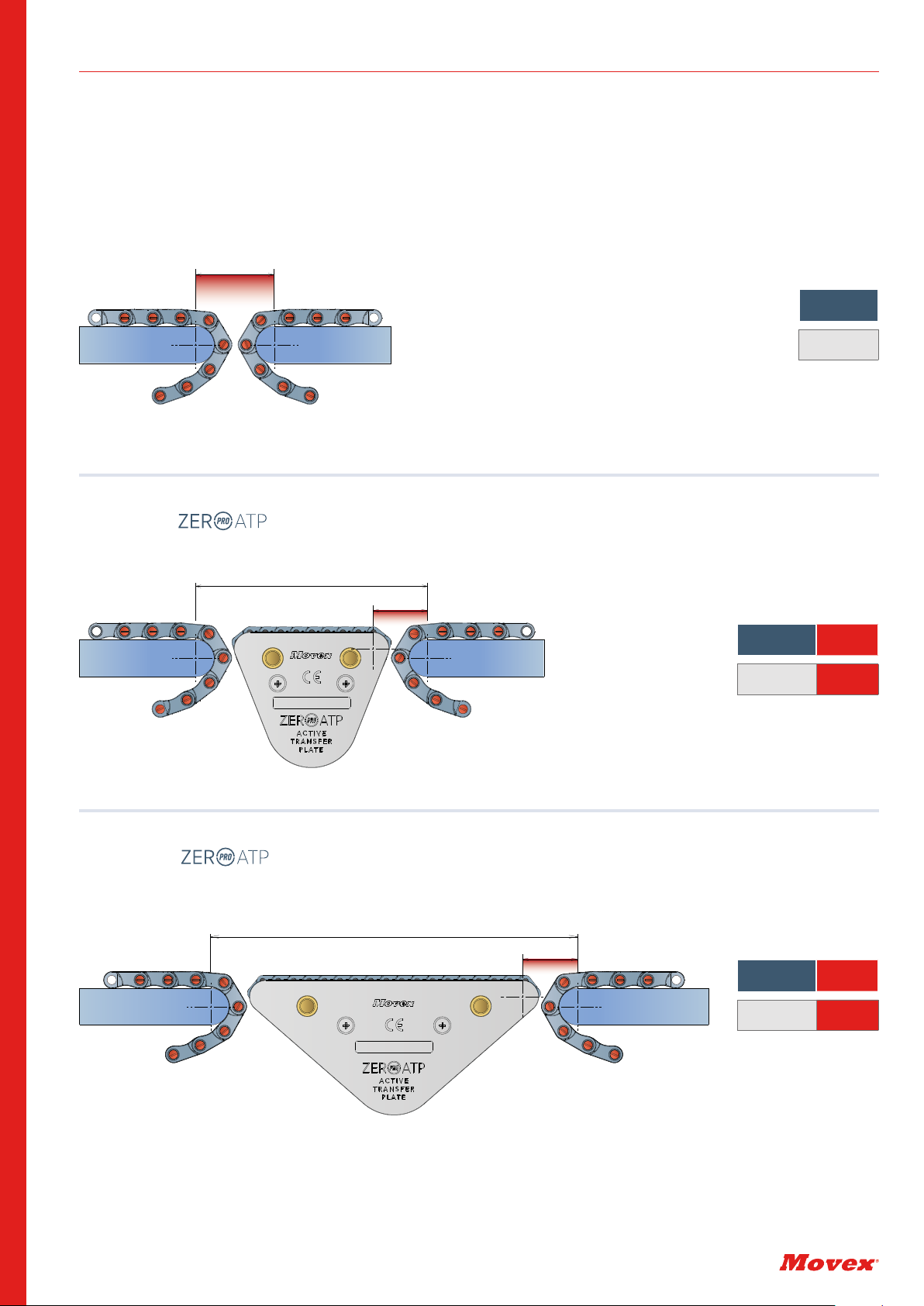

Ideal transfer for relative light products. The Zero ATP® PRO results lower than infeed and outfeed belts. The product will

fall from the first belt and climb to the second belt. This transfer is ideal to give more grip to the product.

Ideal transfer when the product results particularly small and light. The Zero ATP® PRO results lower than the infe-

ed belt and higher than the outfeed belt but it’s installed slightly inclined. The product will fall from the first belt to

the second belt while climbing on the Zero ATP® PRO. This transfer is ideal to avoid gaps on the outfeed, especially

when used with Zero ATP® PRO 80.

12

ENGINEERING MANUAL - ZERO ATP® PRO

Special transfer head to side usually developed with FTT belts can be now created with Zero ATP® PRO.

Products will have to be launched on the outfeed.

TRANSFER - PACKFALL

TRANSFER - INCLINED/DECLINED

Zero ATP® PRO |Installation

TRANSFER - HEAD TO SIDE

Ideal transfer when there is a mix of small and big products. . The Zero ATP® PRO results lower than the infeed belt

and higher than the outfeed belt and it’s installed completely straight. The product will fall from the first belt to the

Zero ATP® PRO and from the Zero ATP® PRO to the second belt.

Ideal transfer to connect a straight infeed belt and an inclined outfeed belt. The Zero ATP® PRO is following the inclination

of the outfeed belt. Attention: if the coecient of friction is too low, the product may slide back, in this case it is requied

to reduce the inclination of the Zero ATP® PRO.

13

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |General table with NoseBars / Rollers

TABLE TRANSFER LENGTH WITH NOSEBARS / ROLLERS

MODULAR BELTS UoM TRADITIONAL

510 FT (mm) 22,0 22,0 22,0

520 FT

520 HD FT

520 FG

520 M

521 FT

522 HD FT

(mm) 40,0 27,5 26,5

525 HD FT

525 HD FG

530 FT (mm) 40,0 29,0 28,5

520 GT (mm) 44,0 31,5 30,5

525 HD GT (mm) 44,0 33,0 32,5

530 GT (mm) 44,0 33,0 32,5

530 LBP (mm) 44,0 30,0 30,0

530 PRO LBP (mm) 44,0 30,0 30,0

520 PRO LBP (mm) 55,0 33,0 33,0

520 LBP (mm) 61,0 34,0 35,0

550 FT

550 FG

550 PRO FT

550 PRO M

(mm) 63,5 36,5 36,0

550 GT (mm) 67,5 40,5 40,0

551 FT (mm) 71,0 39,0 39,0

551 GT (mm) 75,0 43,0 43,0

553 FLEX TOP (mm) 74,5 41,0 41,0

551 PRO LBP (mm) 81,0 42,0 41,0

556 FT (mm) 82,0 43,0 42,0

556 GT (mm) 86,0 47,0 46,0

600 FT (mm) 90,5 46,0 44,0

551 LBP (mm) 94,0 46,0 43,0

Type of transfer

LT

LT= Transfer length between

Zero ATP® PRO 150 and NoseBars.

LT= Transfer length between

Zero ATP® PRO 80 and NoseBars.

LT

LT= Transfer length

between NoseBars.

LT

80 150

14

ENGINEERING MANUAL - ZERO ATP® PRO

520 FT - - 520 FT

Zero ATP® PRO |520 FT - with NoseBars Ø19

520 FT -520 FT

520 FT - - 520 FT

LT Δ%:

26,5 mm - 34%

LT Δ%:

27,5 mm - 31%

LT

40,0 mm

Valid also for: 520 HD FT; 520 FTT; 520 FG; 520 M; 521 FT, 522 HD FT.

40

118

27,5

190

26,5

LT: Transfer length center to center (see page 12)

Δ%:Refers to the comparison between transfer with NoseBars and transfer with Zero ATP® PRO.

150

80

15

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |520 LBP- with NoseBars Ø19

520 LBP -520 LBP

520 LBP - - 520 LBP

520 LBP - - 520 LBP

LT: Transfer length center to center (see page 12)

Δ%:Refers to the comparison between transfer with NoseBars and transfer with Zero ATP® PRO.

LT Δ%:

35,0 mm - 43%

LT Δ%:

34,0 mm - 44%

LT

61,0 mm

61

203

35

132,5

34

150

80

16

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |520 PRO LBP- with NoseBars Ø19

520 PRO LBP -520 PRO LBP

520 PRO LBP - - 520 PRO LBP

520 PRO LBP - - 520 PRO LBP

LT: Transfer length center to center (see page 12)

Δ%:Refers to the comparison between transfer with NoseBars and transfer with Zero ATP® PRO.

LT Δ%:

33,0 mm - 40%

LT Δ%:

33,0 mm - 40%

LT

55,0 mm

55

129

33

199

33

150

80

17

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |525 FT - with NoseBars Ø19

525 FT -525 FT

525 FT --525 FT

525 FT --525 FT

LT Δ%:

28,5 mm - 29%

LT Δ%:

29,0 mm - 28%

LT

40,0 mm

Valid also for: 525 FTT; 525 FG; 530 FT; 530 FTT.

119,5

29

40

190

28,5

LT: Transfer length center to center (see page 12)

Δ%:Refers to the comparison between transfer with NoseBars and transfer with Zero ATP® PRO.

150

80

18

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |530 PRO LBP - with NoseBars Ø19

530 PRO LBP -530 PRO LBP

530 PRO LBP --530 PRO LBP

530 PRO LBP --530 PRO LBP

LT Δ%:

30,0 mm - 32%

LT Δ%:

30,0 mm - 32%

LT

44,0 mm

Valid also for: 530 LBP.

44

122

30

192,5

30

LT: Transfer length center to center (see page 12)

Δ%:Refers to the comparison between transfer with NoseBars and transfer with Zero ATP® PRO.

150

80

19

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |550 FT - with Rollers Ø40

550 FT -550 FT

550 FT --550 FT

550 FT --550 FT

LT Δ%:

36,0 mm - 43%

LT Δ%:

36,5 mm - 42%

LT

63,5 mm

Valid also for: 550 FTT; 550 FG; 550 PRO FT; 550 PRO M.

136

36,5

63,5

206

36

LT: Transfer length center to center (see page 12)

Δ%:Refers to the comparison between transfer with NoseBars and transfer with Zero ATP® PRO.

150

80

20

ENGINEERING MANUAL - ZERO ATP® PRO

Zero ATP® PRO |551 FT - with Rollers Ø40

551 FT -551 FT

551 FT --551 FT

551 FT --551 FT

LT Δ%:

39,0 mm - 45%

LT Δ%:

39,0 mm - 45%

LT

71,0 mm

Valid also for: 551 FTT.

39

210

141

39

71

LT: Transfer length center to center (see page 12)

Δ%:Refers to the comparison between transfer with NoseBars and transfer with Zero ATP® PRO.

150

80

Table of contents

Other Movex Industrial Equipment manuals

Popular Industrial Equipment manuals by other brands

Graco

Graco 255703 Instructions and parts

Siemens

Siemens SIPLUS HCS4200 PROFINET Compact operating instructions

Elsamec

Elsamec UNIKO-1M EVOLUTION Series quick start guide

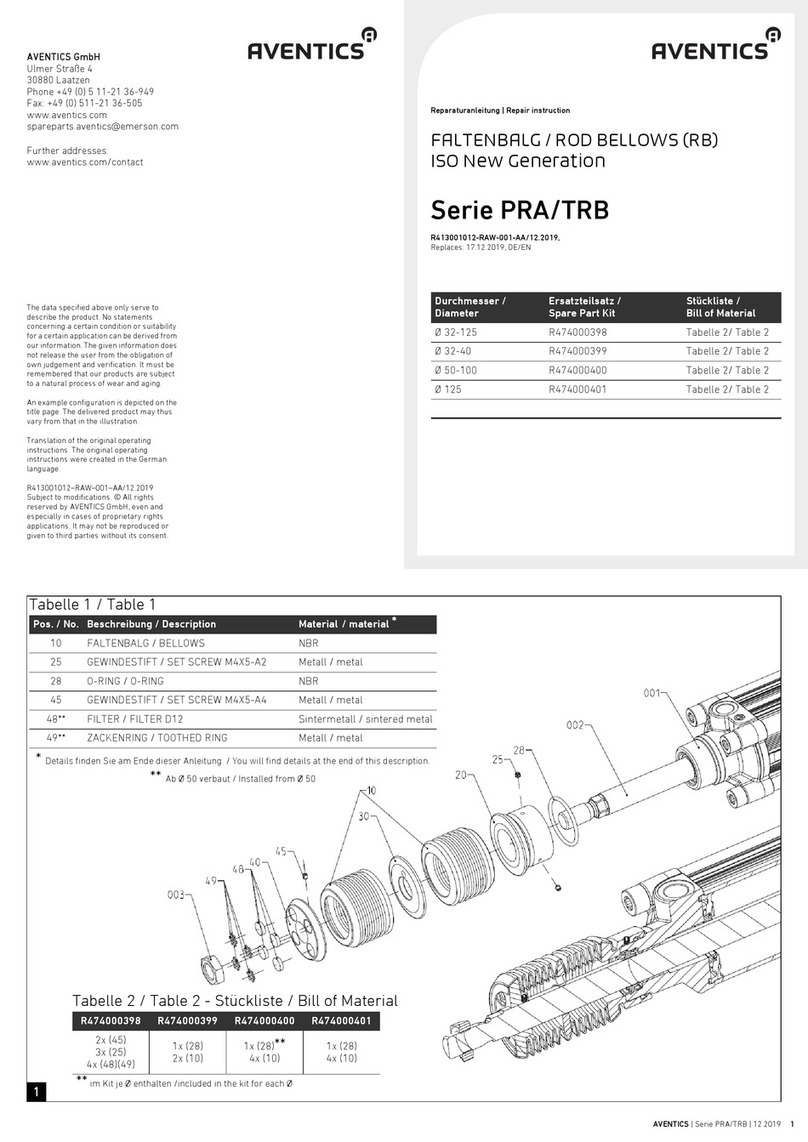

Aventics

Aventics TRB Series Repair instructions

Shaver

Shaver HD-10 Operator's manual

XYZ Machine Tools

XYZ Machine Tools ProTURN SLX 1630 Safety, installation, maintenance, service & parts list manual

BLOCK AND ROLL

BLOCK AND ROLL Multi Form 700 instruction manual

NIKA

NIKA NL-UHV / DX3 Operation manual

Aventics

Aventics EBS-ET-VE Series operating instructions

jost

jost JSK 39 Installation and Operating Instrucitons

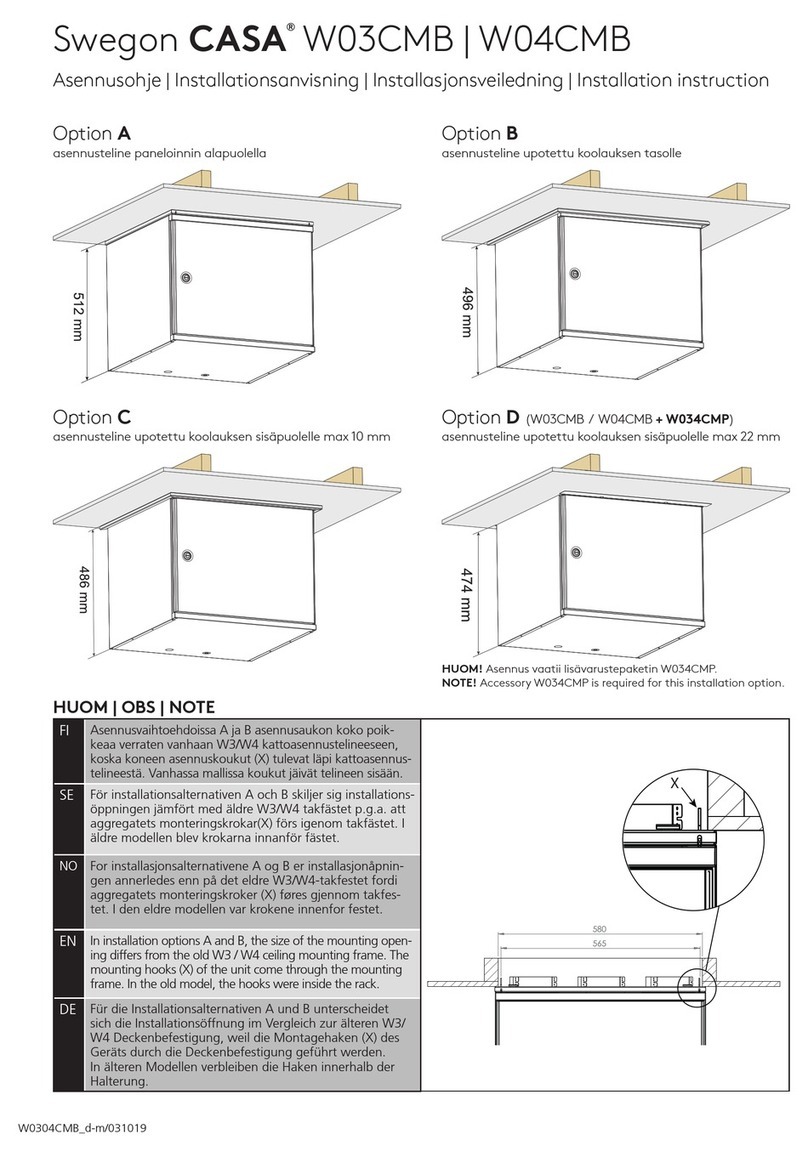

Swegon

Swegon CASA W03CMB Installation instruction

Vega

Vega VEGAMET 308 Technical information & operating instructions