AutomationDirect P3-01AC User manual

Power Supplies

P3-01AC $147.00

There are two power supplies available;

both provide isolated 24VDC, 5VDC,

and 3.3 VDC to the Productivity3000

bases.

The P3-01AC input power supply requires

power from an external 100–240 VAC

source.

The P3-01DC input power supply

requires power from an external 24–48

VDC source.

No Power Budgeting

No power budgeting is required with

either power supply. Any combination of

I/O modules may be installed in any slots

without power budget considerations.

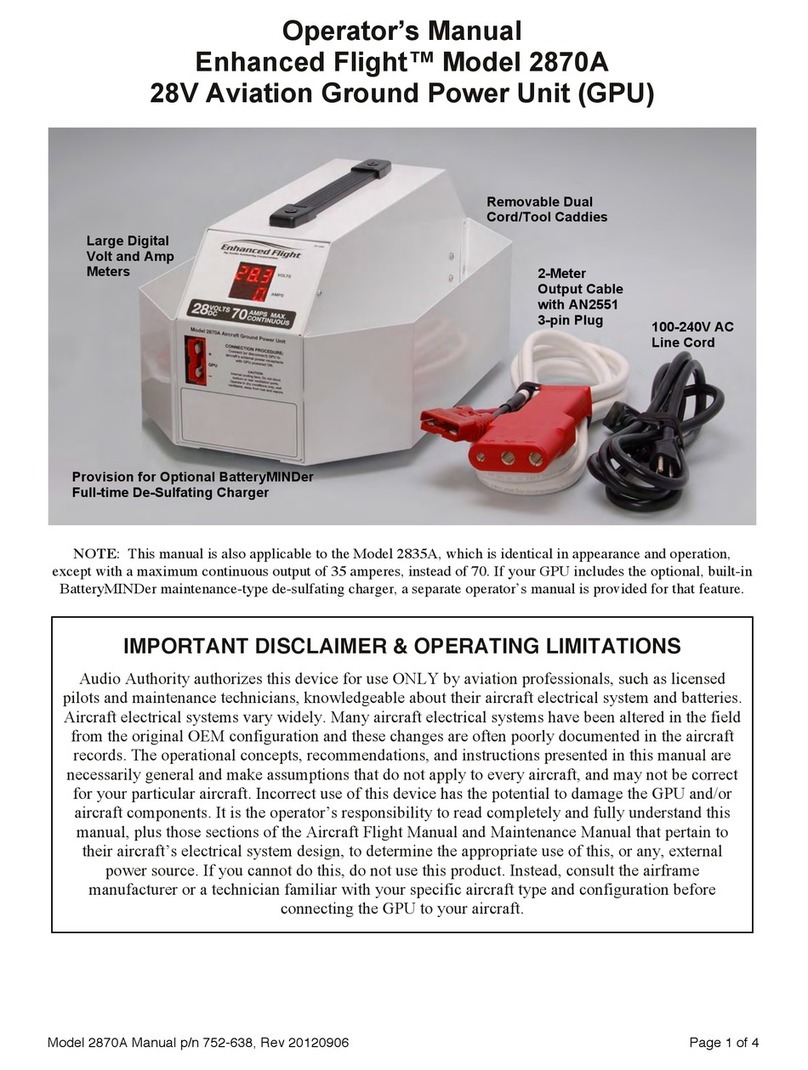

P3-01AC

Terminal Block Specifications

Number of Positions 4 Screw Terminals

Pitch 0.3 inch (7.62 mm)

Wire Range 22–14 AWG (0.324 to 2.08 sq. mm) Solid Conductor

22–14 AWG (0.324 to 2.08 sq. mm) Stranded Conductor

3/64 inch (1.2 mm) insulation maximum

Screw Driver Width 1/4 inch (6.5mm) maximum

Screw Size M3 size

Screw Torque 7–9 inch-pounds (0.882 - 1.02 N·m)

P3-01AC User Specifications

Input Voltage Range (Tolerance) 100 to 240 VAC (-15% / +10%)

Rated Operating Frequency 50 to 60 Hz with ± 5% tolerance

Maximum Input Power 72W

Cold Start Inrush Current 12A 3mS

Maximum Inrush Current (Hot Start) 12A 3mS

Input Fuse Protection (Internal) Micro fuse 250V, 2A, slow blow

Non-replaceable

Efficiency 83%

Output

24VDC @ 1.4 A (±10%)

5VDC @ 2.1 A (±5%)

3.3 VDC @ 6.1 A (±5%)

Maximum Output Power 57W Combined

Heat Dissipation 17W

Isolated User 24VDC Output None

Output Protection for Over Current,

Over Voltage, and Over Temperature

Self resetting for all three voltage outputs

to base

Under Input Voltage Lock-out 55–65 VAC

Over Input Voltage Lock-out 265–280 VAC

Input Transient Protection Varistor, plus input choke and filter

Operating Design Life 10 years at full load at 40°C ambient and

5 years at 60°C ambient

P3-01AC General Specifications

Operating Temperature 0°C– 60°C (32°F–140°F),

Storage Temperature -20ºC–70ºC (-4ºF–158ºF)

Humidity 5 to 95% (non-condensing)

Environmental Air No corrosive gases permitted

Vibration IEC60068-2-6 (Test Fc)

Shock IEC60068-2-27 (Test Ea)

Enclosure Type Open equipment

Voltage Withstand

(dielectric) 1900 VDC applied for 2s

Insulation Resistance >10MV@ 500VDC

Module Location Power supply slot in any local, expansion, or remote

base in a Productivity3000®System.

Weight 345g (12.1 oz)

Agency Approvals UL508 file E157382, Canada & USA

UL1604 file E200031, Canada & USA

CE (EN61131-2*)

This equipment is suitable for use in Class 1,

Division 2, Groups A, B, C and D or non-hazardous

locations only.

Hot-Swapping Information

Note: This device cannot be Hot Swapped.

IMPORTANT!

WARNING: Explosion hazard – Substitution of components may

impair suitability for Class I, Division 2.

*Meets EMC and Safety requirements. See the Declaration of Conformity for details.

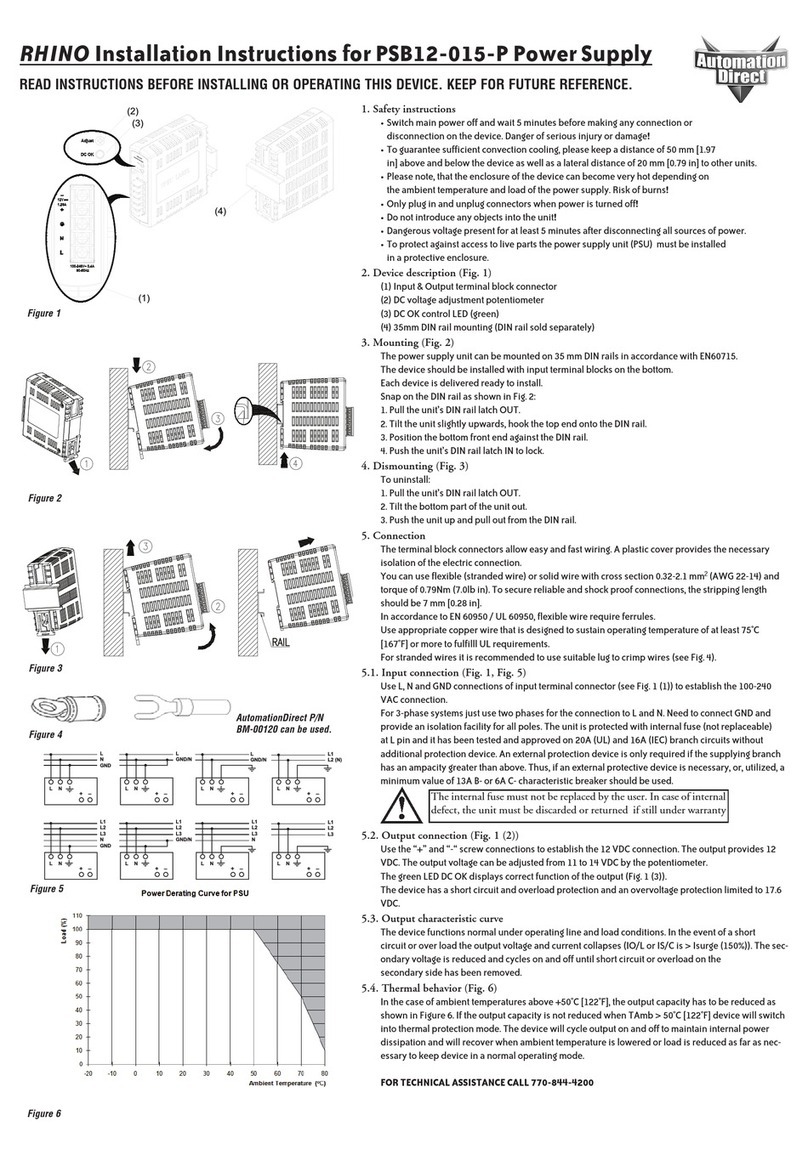

AC Input Power Supply

1-800-633-0405

tPR3-6 Productivity3000®Controllers

For the latest prices, please check AutomationDirect.com.

Power Supplies

+V

-V

GND

LOGIC

GND

P3-01DC

ACL

ACN

GND

LOGIC

GND

P3-01AC

Grounding

A good common ground reference (earth ground) is essential for

proper operation of the Productivity3000®system. One side of all

control circuits, power circuits and the ground lead must be properly

connected to earth ground by either installing a ground rod in close

proximity to the enclosure or by connecting to the incoming power

system ground. There must be a single-point ground (i.e. copper bus

bar) for all devices in the enclosure that require an earth ground.

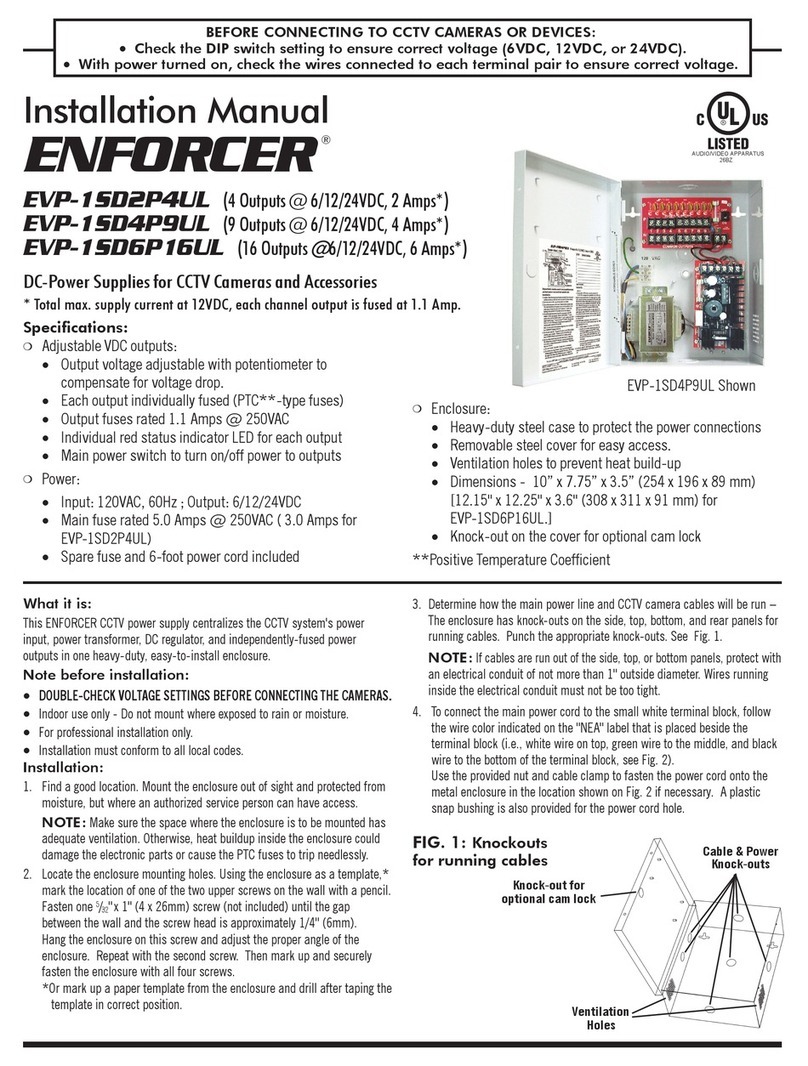

Power Connections

Power Supply Installation

Step Two:

Insert the Power

Supply at a 45° angle

into the notch located

at the top of the base

and rotate down until

seated in socket.

Step Three:

Snap the two retaining

tabs into the locked

position.

Step One:

Locate the left most

socket in the base.

WARNING: Explosion hazard – Do not connect or disconnect connec-

tors or operate switches while circuit is live unless the area is known to

be non-hazardous. Do not hot swap.

1-800-633-0405

tPR3-8 Productivity3000®Controllers

For the latest prices, please check AutomationDirect.com.

Dimensions and Installation

It is important to review and understand

the installation requirements for your

Productivity3000®system. Your knowl-

edge of these requirements will help

ensure that your system operates within

its environmental and electrical limits.

Plan for Safety

This catalog should never be used as a

replacement for the product inserts and

user manual. Each base, CPU, power

supply, I/O module, remote slave, and

expansion module comes with a product

insert. You can purchase, download for

free, or view online the Productivity3000

user manual (P3-USER-M). These docu-

ments, along with the software help files,

contain important safety information that

must be followed.

The system installation should comply

with all appropriate electrical codes and

standards.

Enclosures

Your selection of a proper enclosure is

important to ensure safe and proper

operation of your Productivity3000

system. Applications for the

Productivity3000 system vary and may

require additional hardware consider-

ations. The minimum considerations for

enclosures include:

• Conformance to electrical standards

• Protection from the elements in an

industrial environment

• Common ground reference

• Maintenance of specified ambient

temperature

• Access to the equipment

• Security or restricted access

• Sufficient space for proper installation

and maintenance of the equipment

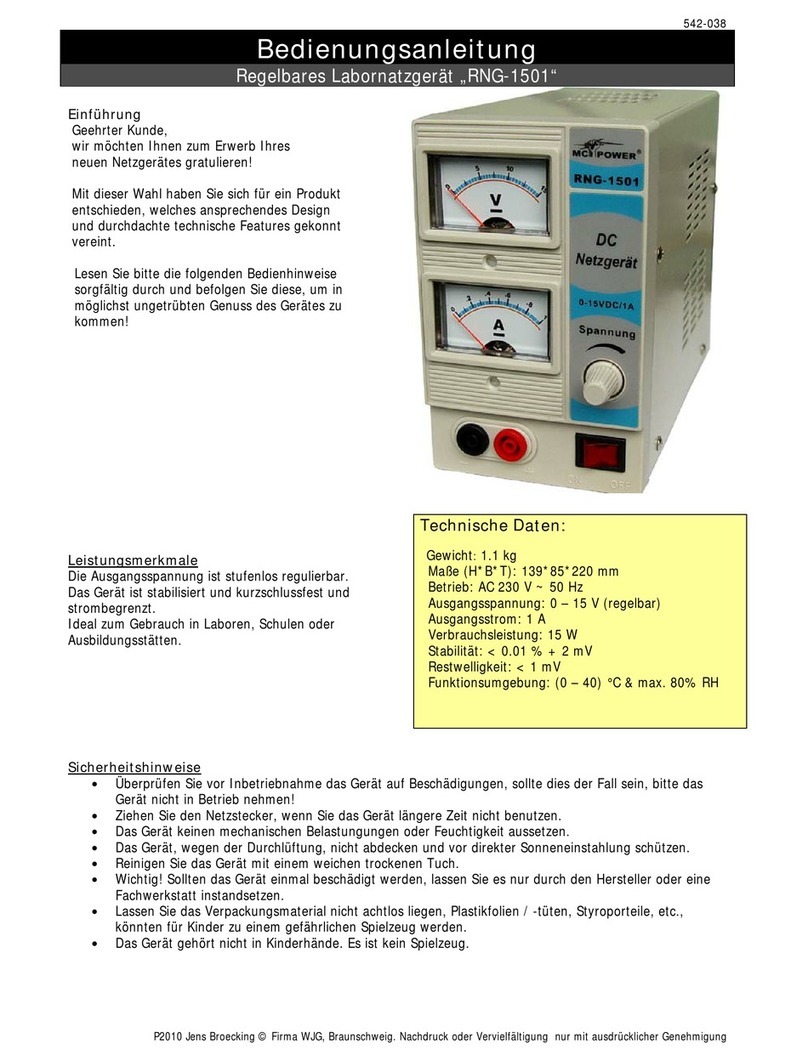

Mounting Position

Mount the bases horizontally, as shown in

the illustration, to provide proper ventila-

tion. Do not mount the bases vertically,

upside down, or on a flat horizontal

surface.

AIRFLOW

OK

3”

[76mm]

NOTE: Add 3 inches (76 mm)

to mounting depth when using

ZIPLink cable ZL-CBL40.

2”

50mm

min

2”

50mm

min

7.2”

183mm

min

3”

76mm

min

3”

76mm

min

7

2

”

2”

50mm

min

www.automationdirect.com/productivity3000 Productivity3000®Controllers tPR3-27

For the latest prices, please check AutomationDirect.com.

Dimensions and Installation

8.75”

inches

[mm]

4.75

[120.7]

8.50

[215.9]

8.75

[222.3]

9.88

[251.0]

19.56

[496.8]

14.50

[368.3]

15.44

[392.2]

10.31

[261.9]

6.00

[152.4]

6.00

[152.4]

6.00

[152.4]

6.00

[152.4]

7.56

[192.0]

11.25

[285.6]

5.59

[142.1]

P3-03B

P3-05B

P3-08B

P3-11B

P3-03B

P3-05B

P3-08B

P3-11B

5.59

[142.1]

5.59

[142.1]

5.59

[142.1]

Base Dimensions

Mounting Clearances

Provide a minimum clearance of 2 inches

(50mm) between the bases and all sides

of the enclosure. Allow extra door clear-

ance for operator panels and other

door mounted items. There should be a

minimum of 3 inches (76mm) clearance

between the base and any wire duct, and

a minimum of 7.2 inches (183mm) from

base to base in a multiple base installation.

Grounding

A good common ground reference (earth

ground) is essential for proper operation of

the Productivity3000®system. One side of

all control circuits, power circuits and the

ground lead must be properly connected to

earth ground by either installing a ground

rod in close proximity to the enclosure

or by connecting to the incoming power

system ground. There must be a single-

point ground (i.e. copper bus bar) for all

devices in the enclosure that require an

earth ground.

Temperature

Considerations

The Productivity3000 system should be

installed within the operating temperature

specifications as listed in this document. If

the temperature deviates above or below

the specification, measures such as cooling

or heating the enclosure should be taken to

maintain the specification.

Power Considerations

The Productivity3000 system is designed

to be powered by 110/220 VAC or 24/48

VDC via one of the Productivity3000

power supplies. The Productivity3000 has

achieved CE certification without requiring

EMF/RFI line noise filters on the AC power

supply. Please review the “EU Directives”

document, located in the User Manual

or at www.automationdirect.com/produc-

tivity/p3000, for applications which require

CE Compliance.

1-800-633-0405

tPR3-28 Productivity3000®Controllers

For the latest prices, please check AutomationDirect.com.

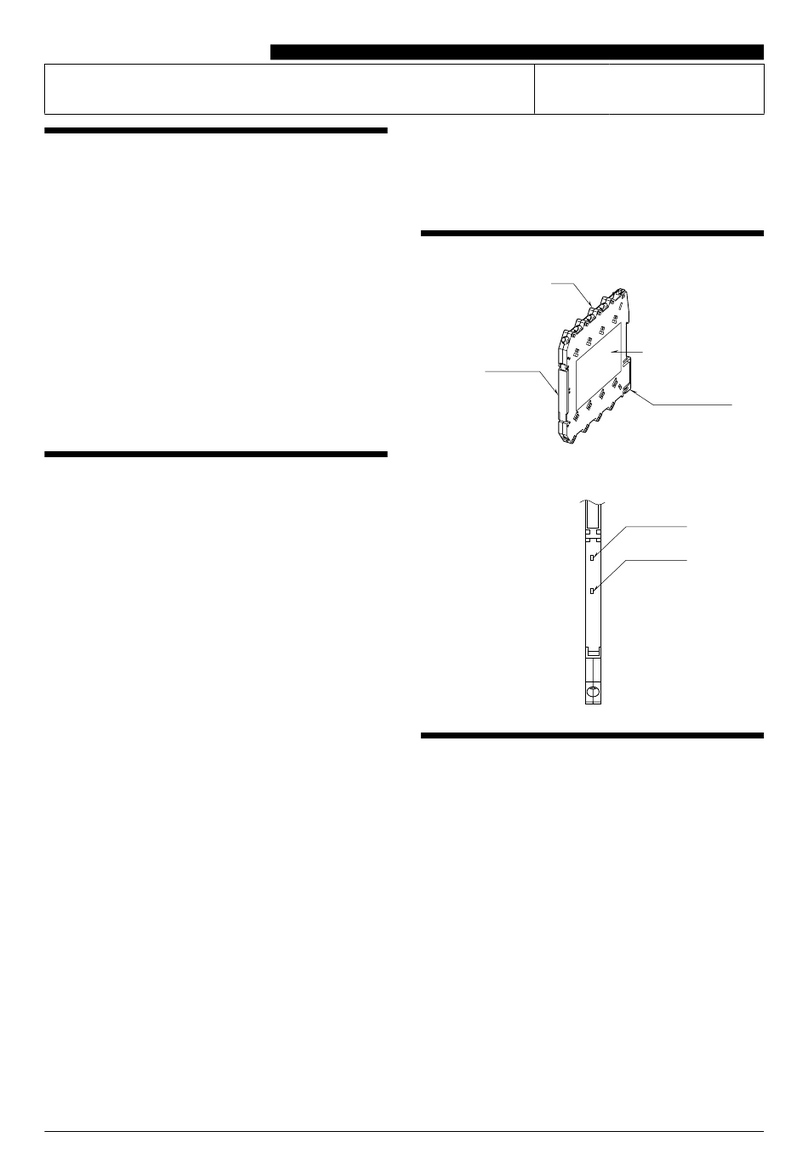

Base Installation

Using Mounting Rails

The Productivity3000®bases can be

secured to the cabinet using mounting

rails. You should use rails that conform

to DIN EN standard 50 022. We offer

a complete line of DIN rail, DINnectors

and DIN rail mounted apparatus. These

rails are approximately 35mm high, with

a depth of 7.5 mm. If you mount the

base on a rail, you should also consider

using end brackets on each side of the

base. The end brackets help keep the

base from sliding horizontally along the

rail. This helps minimize the possibility of

accidentally pulling the wiring loose.

If you examine the bottom of the base,

you’ll notice retaining clips. To secure

the base to a DIN rail, place the base

onto the rail and gently push up on the

retaining clips. The clips lock the base

onto the rail.

To remove the base, pull down on the

retaining clips, slightly lift up the base,

and pull it away from the rail.

DIN Rail

Dimensions

7.5 mm

35 mm

End Bracket (Part No. DN-EB35)

Rotate base

into position.

Hook base

onto DIN rail at

top of mount-

ing slot.

Gently push up

retaining clips.

1

2 3

Retaining Clips

DIN Rail (Part No. DN-R35S1)

www.automationdirect.com/productivity3000 Productivity3000®Controllers tPR3-29

For the latest prices, please check AutomationDirect.com.

Table of contents

Other AutomationDirect Power Supply manuals

Popular Power Supply manuals by other brands

Superior Electric

Superior Electric STABILINE Installation, operation and maintenance manual

Von Duprin

Von Duprin PS873 Installation instructions manual

National Instruments

National Instruments PS-17 user manual

Allied Telesis

Allied Telesis AT-PWR10 installation guide

RTS

RTS PS-20 user manual

TDK-Lambda

TDK-Lambda ZWS10C instruction manual