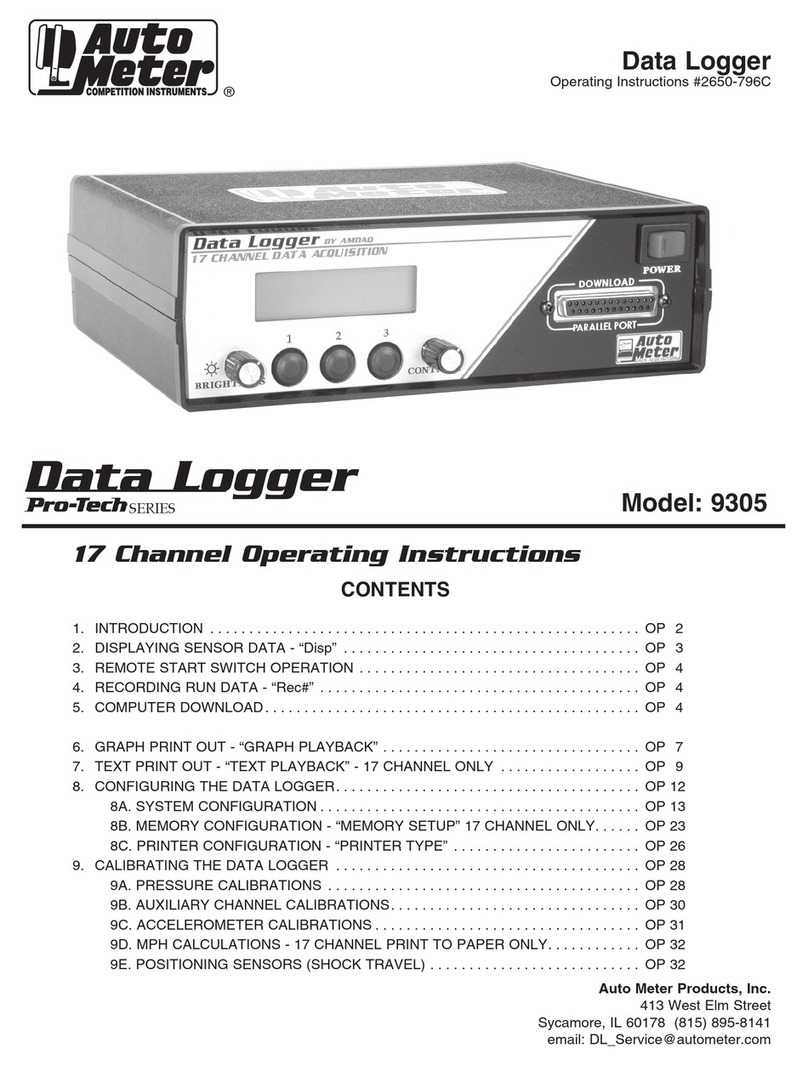

AutoMeter Pro-Tech Series User manual

Data Logger

34 Channel Operating Instructions

Auto Meter Products, Inc.

413 West Elm Street

Sycamore, IL 60178 (815) 895-8141

email: [email protected]

Data Logger

Operating Instructions #2650-627

®

Model: 9301

CONTENTS

1. INTRODUCTION ....................................................... OP 2

2. DISPLAYING SENSOR DATA - “Disp” . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 3

3. REMOTE START SWITCH OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 4

4. RECORDINGRUNDATA-“Rec#” ......................................... OP 4

5. COMPUTERDOWNLOAD................................................ OP 5

6. CONFIGURINGTHEDATALOGGER....................................... OP 6

6A.SYSTEMCONFIGURATION......................................... OP 6

7. CALIBRATINGTHEDATALOGGER ....................................... OP 7

7A.PRESSURECALIBRATIONS ........................................ OP 7

7B. AUXILIARY CHANNEL CALIBRATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 9

7C. ACCELEROMETER CALIBRATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 10

7D. POSITIONING SENSORS (SHOCK TRAVEL) . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 11

8. CALIBRATING AUX CHANNELS 5-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . OP 16

SERIES

1. INTRODUCTION

This manual explains how to operate the Data Logger. We have made the Data Logger as easy to use as possible.

The 34 channel computer is operated much the same as the 17 channel computer.

DISPALYING SENSOR DATA

Same as 17 channel, except pressing button #2 toggles through AUX 1-20. AUX 1-4 will be displayed in engineering

units, while AUX 5-20 will only display ADC numbers. You can still view AUX 5-20 to verify they are working, but you

will

be unable to read actual channel units until the recorded run is downloaded to the PC and calibrated.

MEMORY - RUN 1, RUN 2

The 34 channel computer has two runs available for recording. Run 1 and Run 2. The button on the front panel of the

data logger indicates which run is being used. If the switch is set to Run 1, each time a recording is started, the data is

recorded into the RUN 1 memory, and when a download is performed, RUN 1 is transferred to the PC.

To recoed RUN 2, simply press the button on the front panel once and it will toggle to RUN 2 for recording

and download.

COMPUTER DOWNLOAD

See page OP 5.

AUTO-DOWNLOAD

Display on Data Logger Brief Details

Press No

Press Enter

Press “Up” Once

Press Up

Press Enter

Press Yes

Press No

Press DNLD

Download will start at 0

Start from beginning of Memory.

Will display download End Time.

To desired Download End Time.

Identifies Download Time Bracket.

Store Settings.

No settings will be stored.

Sends data to computer.

3.

4.

5.

6.

7.

8.

9.

To Download from the Launch to the End of the RunTo Download from the Launch to the End of the Run

FIND LAUNCH

Start at Sec. 0

Stop at Sec. None

Stop at Sec. “X”

Stop at Sec. “Y”

Update Auto DL?

Playback Type

Display on Data Logger Brief Details

CHOOSE MODE Press Play Finds stored settings and sends data to computer.

10.

Set Up One Button DownloadSet Up One Button Download

One Button Download

To enable one button download, the computer must be ready to accept data and cables connected at both ends. (Download box must

be ser 0n “Receive” and be connected to Data Logger.

If you use the Data Logger to find the start of the race, and you know that your car consistently runs 8.90’s, you can set the Stop at Sec.

window to remove any extra time at the end of the run. This will drastically speed up the download process.

If you use the Data Logger to find the start of the race, and you know that your car consistently runs 8.90’s, you can set the Stop at Sec.

window to remove any extra time at the end of the run. This will drastically speed up the download process.

OP 2OP 2

CHOOSE MODE

Disp Rec# Play

1 2 3

Function

Choices Buttons

Display Brief

The following pages have diagrams and details to get you started. Don’t worry about accidentally pressing the wrong button

and loosing data or your calibrations. Any configuration or calibration can easily be re-entered, and data has to be manually

removed. If you find yourself lost in an operation, just turn the unit OFF and ON to reset to the main menu (“CHOOSE MODE”).

When an option is explained in this manual, you will only be told to press the buttons relating to the option. If other options are

available on the same screen, they will not be explained. For more details on those options, see the related section.

We hope you enjoy your Data Logger and hope it proves to be an asset to your racing program.

CALIBRATING AUX 1-4

Calibrated the same as the 17 channel computer.

CALIBRATING AUX 5-20

The calibration numbers for these channels are calibrated in the Data Facts Pro 34 Channel Software.

(See Software Channel Maintenance Section Page 23)

The LCD display on the front of the Data Logger guides you through the functions. It identifies the function on the top line, and up

to three choices on the bottom line. A function/option can be selected by pressing the button directly below the name.

To operate the system, select a function by pressing one of the three buttons, and following the menus to the task of your choice.

OP 3

2. DISPLAYING SENSOR DATA - “Disp”

Display (“Disp”) mode is selected from the “CHOOSE MODE” screen and allows you to display active sensor data. Use the three

buttons below the screen to select the data to be viewed. Display enables view of Engine and Driveshaft RPM, Accelerometer,

Pressure, EGT and Aux 1-4 only.

ER XXXX DR XXXX

XX.XXG XX.XXPSI

CHOOSE MODE

Disp Rec# Play

Press the “Disp” button to enter the “Disp” mode and display

sensor data.

Press “Disp”

Button 2

Display Aux. Channels

Button 3

Display EGT’s

The first screen in the “Disp” mode shows Engine RPM,

Drive shaft RPM, Acceleration and Fuel pressure.

• Pressing button 2 will display the Auxiliary channels

information.

• Pressing button 3 will display the EGT’s.

C1 X.XXX 2 X.XXX

3 X.XXX 4 X.XXX

Button 1

Return to prev. screen

Button 3

Display EGT’s

The Auxiliary channels are displayed as shown.

• Press button 1 to return to previous screen.

• Press button 3 to display the EGT’s.

• Pressing button 2 cycles through Aux 5-20.

TC5 XXXX 6 XXXX

7 XXXX 8 XXXX

Button 1

Return to first “Disp” screen

Button 2

Return to Auxiliary

channel display

Button 3

Alternate between Aux.

Channels 1-4 and 5-8

The EGT’s are displayed as shown.

• Press button 1 to return to the first screen in the “Disp” mode

with RPM’s, Acceleration and Fuel pressure.

• Press button 2 to return to the Auxiliary channels display.

• Press button 3 to alternate the display between EGT channels

1-4 and 5-8.

NOTE:

• To exit the “Disp” mode and return to the “CHOOSE MODE”, press and hold buttons 1 and 2 until the unit resets itself.

• The Display mode for AUX 5-20 does not show engineering units.

The number displayed is the ADC number for that channel.

Display Brief Details

1 2 3

1 2 3

1 2 3

1 2 3

OP 5

3. REMOTE START SWITCH OPERATION

The remote switch supplied with the Data Logger is a single throw, momentary switch. Pressing the switch is the same as pressing

the “Rec#” button in the “CHOOSE MODE”. The unit will continue recording until the memory for the run is full.

4. RECORDING RUN DATA - “Rec#”

The Record (“Rec#”) mode, selected from the “CHOOSE MODE”, allows you to begin recording run data.

The memory in the 9301 is split into 2 runs. The square run button on the front panel selects which run will be

recorded and/or downloaded.

CHOOSE MODE

Disp Rec# Play

There are three options to start recording data:

•Press “Rec#”, in the “CHOOSE MODE”.

• Activate the remote start switch

(works like pressing the “Rec#” button).

•Exceeding the configurable preset start engine or drive shaft

RPM value by pressing the “Rec#” button or activate the

remote start switch. If the system is configured for multiple

runs, the number of runs remaining will appear next to Rec.

Pressing and holding the “Rec#” button displays the preset

start engine or drive shaft RPM.

3 options to start recording.

• Press “Rec#” button

• Remote start switch

• Exceeding preset RPM

“EXIT”

Exit to “CHOOSE MODE”

Display Brief Details

1 2 3

ERPM Start XXXX

EXIT

1 2 3

* Optional screen *

This screen will be displayed only if an engine RPM (“START

RPM”) has been configured as the trigger. Data recording will

not begin until the configured RPM value has been exceeded.

Engine RPM will be displayed in place of “XXXX”.

• Press the “EXIT” button to return the “CHOOSE MODE”.

RECORDING DATA

1 2 3

This screen is displayed during recording. The computer

will continue receiving and recording data until the allocated

memory for that run is full.

“END”

Return to the

“CHOOSE MODE”

RECORD COMPLETE

END

1 2 3

Once the “Record” mode has been stopped, the unit will display

record complete.

•Press the “END” button to return to the “CHOOSE MODE”.

This screen selects the start point for the print out. If no run is

recorded the Data Logger returns to the “CHOOSE MODE”.

•Selecting “Yes “ allows the Data Logger to find the point of launch.

Approximately 1 second is subtracted from this point. This enables

1-2 seconds of data to be printed prior to the launch point. While the

unit is calculating the exact launch point “Searching XXX” will be

displayed with an “ABORT” option. “ABORT” will return you to the

main menu.

•Selecting “No” advances to the next screen to allow you to enter the

starting point manually.

OP 6

5. COMPUTER DOWNLOAD

Select which run you want to download with the square run select button on the front panel of the data logger.

9301 download is the same as the 9305.

CHOOSE MODE

Disp Rec# Play

Press the “Play” button to access all playback functions.

Press “Play”

Display Brief Details

1 2 3

Choose Function

Setup Cal Play

Press the “Play” button to enter the Play function.

Press “Play”

1 2 3

Find Launch ?

Yes No

“Yes”

Data Logger finds

point of launch

“No”

Advance to the next screen

and enter selection

1 2 3

Start at Sec. X

Up Down ENTER

The start point of the print out is selected from this screen. If you

chose “YES” on the previous screen, the calculated start point will be

displayed in place of the “X”.

•The “Up” button increases the start time.

•The “Down” button decreases the start time.

•After reaching the correct starting time, press the “ENTER” button

to make your selection. If no time is chosen, data will print from 0

seconds.

“Up”

Increase time

“Down”

Decrease time

“ENTER”

Make selection

1 2 3

Stop at Sec. X

Up Down ENTER

The stop point of the print out is selected from this screen.

•The “Up” button increases the stop time.

•The “Down” button decreases the stop time.

•After reaching the correct stop time, press the “ENTER” button to

make your selection.

“Up”

Increase time

“Down”

Decrease time

“ENTER”

Make selection

1 2 3

Update Auto DL ?

Yes No

Next time a file is downloaded, if the PC is ready to receive the file

and the Download cable is connected to the Data Logger,

pressing Play in the main screen will Download the settings you just

entered.

Select “Yes”

1 2 3

Playback type ?

DNLD GRAPH TEXT Press the “DNLD” button to Download the data to the PC.

Press “DNLD”

1 2 3

OP 7

6. CONFIGURING THE DATA LOGGER

The Data Logger software has several customizable options. These options allow you to tailor the system operation and

playback functions to your individual needs. The entire configuration process can be performed with menu selections on

the LCD screen.

This is a list of options provided by the configuration software. They are explained in more detail in the following

sections.

SYSTEM CONFIGURATION OPTIONS:

1. Data Recording

A) Manual start data recording

B) Delayed start data recording (activated by a selectable engine or drive shaft RPM)

2. Units for auxiliary channels

A) Auxiliary channel 1

B) Auxiliary channel 2

C) Auxiliary channel 3

D) Auxiliary channel 4

6A. SYSTEM CONFIGURATION

The following steps lead you through the System Configuration process.

CHOOSE MODE

Disp Rec# Play

Press the “Play” button. The configuration functions are

accessed through the Play mode.

Press “Play”

Display Brief Details

1 2 3

Choose Function

Setup Cal Play

Press the “Setup” button to enter the System Configuration mode.

Press “Setup”

1 2 3

Print SETUP ?

Yes No

The current configuration can be printed from this screen before

any changes are made. This is always a good idea. It gives

you a copy of your current configuration to return to incase an

error is occurs.

• Connect your printer and select “Yes” to print the file

• Select “No” to go directly to the “CHOOSE FOR SETUP”

screen.

“Yes”

Print current setup

“NO”

Do not print current setup

1 2 3

ER Pls/Rev 4

UP DOWN ENTER

1 2 3

This option allows you to change the number of pulses per

revolution for the Engine RPM channel. Use the up arrow to

change the number then press enter.

The starting device for recording is selected on this screen.

• Pressing the “MAN” button selects a manual start. Both the

“Rec#” button and the remote switch will start recording.

• Pressing the “DRPM” button selects drive shaft RPM as the

starting device. Recording will start when the drive shaft

exceeds 300 RPM. To ensure one second of data is saved

before launch, a second block of data will stored.

• Pressing the “ERPM” button selects engine RPM as the

starting device. Recording will start after a preset engine

RPM has been reached.

RECORD MODE

MAN DRPM ERPM

“MAN”

“Rec#” button or remote

start switch

“DRPM”

Driveshaft RPM

“ERPM”

Engine RPM

1 2 3

Display Brief Details

ENABLE RESTART ?

YES EXIT NO

The “ENABLE RESTART ?” screen allows you to instantly

restart a recording. This is used when the Data Logger is set

in manual start mode and a recording is started accidentally

or to early. If this option is OFF and a recording needs to

be restarted, it takes several steps to cancel and restart the

recording. With this option ON, it only takes the press of a

button. This is a big time saver when sitting on the starting line.

• Pressing the “YES” button turns “ENABLE RESTART ?” ON.

• Pressing the “EXIT” button exits to the “CHOOSE MODE”.

• Pressing the “NO” button turns “ENABLE RESTART ?” OFF.

“YES”

Use “ENABLE RESTART”

“EXIT”

Exit to “CHOOSE MODE”

“NO”

Do not use

“ENABLE RESTART”

1 2 3

OP 8

Setup CHNL X ?

YES EXIT NO

Auxiliary channels can be configured from this screen

• Pressing the “YES” button from this screen will allow you to

configure the auxiliary channel(s). The following screens

will allow you to choose the units and graph scale for the

displayed auxiliary channel. You will have the opportunity to

change each of the four auxiliary channels.

• Press the “EXIT” button to return to the “CHOOSE MODE”.

• Pressing the “NO” button increments up through the 4

channels.

“YES”

Configure auxiliary

channel selected

“EXIT”

Return to

“CHOOSE MODE”

“NO”

Increment through auxiliary

channels 1-4

1 2 3

CHX Units=(unit)

Change BAK ENTER

“Change”

Advance unit choice

“BAK”

Go back to previous screen

“ENTER”

Store your selection

1 2 3

* Optional *

This screen will appear if “YES” is selected from any of the

four “Setup CHNL X ?” screens. Here you can select the

measurement units to be used for the selected channel.

• Pressing the “Change” button advances through the unit

choices (VDC, %, U, PSI, DEGF, and INCH).

• Pressing the “BAK” button will go back to the previous screen.

• Press the “ENTER” button to select the displayed unit.

This screen will appear if “YES” is selected from any of the

four “Setup CHNL X ?” screens. Here you can select the

measurement units to be used for the selected channel.

• Pressing the “Change” button advances through the unit

choices (VDC, %, U, PSI, DEGF, and INCH).

• Pressing the “BAK” button will go back to the previous screen.

• Press the “ENTER” button to select the displayed unit.

Note: Use enable restart only in manual start mode. It is rarely if ever needed in drive shaft or

engine RPM start mode.

OP 9

7. CALIBRATING THE DATA LOGGER

Your system was fully calibrated before it was sent to you. The calibrations are stored in the systems permanent

memory, and those values are listed on the system data sheet. Calibration software is also provided with the system to

allow you to change the calibration if needed.

The calibration software is designed to provide maximum flexibility. The software will allow you to change the Data

Logger to fit your specific system to meet the changing needs of your racing program. For example, if you have a

shock travel sensor on your system to help you work out a chassis problem, once you get that problem worked out

you can change the calibration to use that channel for something else (without having to send the system back to be

reconfigured).

The calibration software in your system has two modes, Auto and Manual. In the “Auto” mode, you tell the Data Logger

what the measurement should read when it receives a signal from a sensor. Then you send the signal from the sensor.

The Data Logger then computes the calibration data point based on that given value. In the “Manual” mode, you tell the

Data Logger what the measurement should read when it receives a signal from a sensor, and then you manually enter

the signal (provided with the system) the Data Logger will receive. (If this sounds complicated, don’t give up, the actual

procedure is very easy.)

7A. PRESSURE CALIBRATIONS

The pressure channel in your system is set up for a two point calibration. We will calibrate the 0.0 PSI value and a high

pressure value. The high or upper calibration reading will depend on the sensor you have and the pressure you want to

Choose Function

Setup Cal Play

CHOOSE MODE

Disp Rec# Play

Press the “Play” button to enter the “Choose Function” screen.

“Play”

Selects the Play mode

“CAL”

Select Calibration Mode

This screen selects the Calibration Mode.

• Press the “Cal” button to enter Calibration.

Choose Sensor

PRES ACC CHNL

“PRES”

Selects pressure calibration

This screen selects the type of calibration you want to perform.

• Press the “PRES” button to select pressure calibration.

Calibration Type

MAN AUTO VIEW

“AUTO”

Select auto calibration

This screen selects the type of calibration you want to perform.

• Press “AUTO” for automatic calibration.

Display Brief Details

1 2 3

1 2 3

1 2 3

1 2 3

0.0PSI AD= ##

ENTER ABORT

“ENTER”

Stores the calibration

“ABORT”

Exits the calibration mode

Now we’re at the point where the system is going to calibrate

the 0.0 PSI reading. With your fuel pump off, and the pressure

bled down to zero, press ENTER. The computer will save that

reading as the 0.0 PSI calibration value.

• Press the “ENTER” button to save the zero calibration.

• Press the “ABORT” button to exit calibration.

1 2 3

OP 10

9.00 Set Dec Pt

<-- --> ENTER

This screen is asking you to select the number of decimal

places you want to view. Use the arrow buttons to move the

decimal point to the left or right (maximum pressure of 4 digits),

then press ENTER. In this example the pressure should not

exceed 10 PSI, (10.00) so set the display for 2 decimal places

(0.00). This also plays a part in setting the resolution of the

measurement.

• Press “<--” to display more decimal places and increase the

resolution.

• Press “-->” to display less decimal places and decrease the

resolution.

• Press “ENTER” to store your selection.

“<--”

Increase decimals places

“-->”

Decrease decimals places

“ENTER”

Enters selection

Display Brief Details

1 2 3

5.00PSI AD= ##

INC DEC ENTER

This screen is asking you to tell the system what pressure you

are going to apply to the sensor. Turn on the fuel pump, and

use the INCrement and DECrement buttons to set the display

equal to the pressure at the sensor. Hold down the INC or DEC

button to speed up the change. The longer you hold the button

the faster the change.When done, press ENTER. The computer

will save this as the upper calibration value.

• Press “INC” to increase the PSI.

• Press “DEC” to decrease the PSI

• Press “ENTER” to store your selection.

“INC”

Increase PSI

“DEC”

Decrease PSI

“ENTER”

Enters selection

1 2 3

Store Cals ?

YES NO

The calibration is now complete and the system is ready to

save it to permanent storage and display it for you to see.

• Press “YES” to store the calibrations you have entered.

• Press “NO” to erase the calibrations you have entered.

“YES”

Store calibration

“NO”

Do not store calibration

1 2 3

The Manual calibration mode is very similar except instead of reading the value from the sensor, the system allows you

to tell it what value to equate to what pressure. As you go through the manual calibrations screens, the computer will

recall the current calibrations values, and allow you to manually change them.

OP 11

7B. AUXILIARY CHANNEL (1-4) CALIBRATION

The calibration software for the auxiliary channels includes some additional features not required for the pressure

channel. Since some of the functions of the auxiliary channels include nonlinear measurements, the calibrations include

additional calibration points to better approximate the sensor response. In these channels you have the capability of

performing 2, 3 or 4 point calibrations. Also, the first calibration point does not need to be a 0.0 reading. For example,

when using a nonlinear shock travel sensor the sensor could be calibrated at 1.0”, 2.0” 3.0” and 4.0” of travel with very

little linearity error.

This calibration is very similar to the pressure calibration, and the menus will guide you through the process. The display

function is a little different, since there are more calibration points. As you step through the VIEW calibration displays,

the system will display the channel number as well as the calibration number with the reading and calibrated value. If

you continue to press the NEXT button, the system will step through all the calibrations for each of the channels built

into your system.

If you have any difficulty with these calibrations or any function of your system, just give us a call and we will gladly talk

you through it.

CHOOSE MODE

Disp Rec# Play

Press the “Play” button to enter the “Choose Function” screen.

“Play”

Selects the Play mode

Display Brief Details

1 2 3

Choose Function

Setup Cal Play

This screen selects the Calibration Mode.

• Press the “Cal” button to enter Calibration.

“CAL”

Select Calibration Mode

1 2 3

Choose Sensor

PRES ACC CHNL

This screen selects the type of calibration you want to perform.

• Press the “CHNL” button to select auxiliary channel calibration.

“CHNL”

Selects auxiliary

channel calibration

1 2 3

Channel # 1

Change ENTER

This screen selects the channel you want to calibrate.

• Press the “Change” button to scroll through the channels.

• Press the “ENTER” button to enter that channels calibration.

“Change”

Scrolls through channels

“ENTER”

Enters selection

1 2 3

7C. ACCELEROMETER CALIBRATIONS

The accelerometer, or “G Meter”, measures the G forces relative to its primary axis. This primary axis can be thought

of as a line, perpendicular to the front face of the accelerometer. (The side with the Data Logger logo is the front face.)

The unit can accurately measure positive and negative acceleration from +5 to -5 G, with a .01 G resolution. Proper

mounting and calibration is very important for accurate calibrations and measurements.

Over time, the accelerometer calibration should be checked. This is a very easy task. The software will direct you

through the calibration, and store the results to permanent memory. For an accurate calibration, the car needs to be

sitting on level ground.

CHOOSE MODE

Disp Rec# Play

Press the “Play” button to enter the “Choose Function” screen.

“Play”

Selects the Play mode

Display Brief Details

1 2 3

Choose Function

Setup Cal Play

This screen selects the Calibration Mode.

• Press the “Cal” button to enter Calibration.

“CAL”

Select Calibration Mode

1 2 3

Choose Sensor

PRES ACC CHNL

This screen selects the type of calibration you want to perform.

• Press the “ACC” button to select accelerometer calibration.

“ACC”

Selects Accelerometer

channel calibration

1 2 3

Calibrate ACCEL

00 +1G ENTER

This screen is asking you to position the accelerometer so it

can measure the force of gravity. To do this, rotate the unit so

that the front face is looking up, and carefully position it so that

you see the largest number attainable displayed on the screen.

While that number is displayed, press the “ENTER” button. The

computer will record the +1G calibration.

• Press the “ENTER” button to enter the calibration for +1G.

“ENTER”

Enters calibration

1 2 3

Calibrate -1.00G

00 ENTER

This screen is asking you to position the accelerometer for a

-1G calibration. To do this, rotate the unit so that the front face

is looking directly down, and the lowest number attainable is on

the screen. With the lowest number displayed, press “ENTER”.

The computer will store the -1G calibration.

• Press the “ENTER” button to enter the calibration for -1G.

“ENTER”

Enters calibration

1 2 3

SET 0.00G 00

00 DONE

The last step is to set the “ZERO” point and tighten the

mounting bolts. The computer is now displaying two numbers

on the screen. Rotate the accelerometer so that the front face,

is facing the front of the car and adjust its position so that the

two numbers displayed on the screen are equal. Maintain that

position, and tighten the mounting bolts.

• Press the “DONE” button to enter the calibration for 0G.

“DONE”

Enters calibration

1 2 3

SAVE MSTR CAL ?

YES NO

This screen allows you to store the calibration for the

accelerometer.

• Press the “YES” button to store the calibration.

• Press the “NO” button to erase the calibration.

“YES”

Stores calibration

“NO”

Erases calibration

1 2 3

The calibration can easily be checked by entering the “RUN” mode, loosening the mounting bolts and rotating the

accelerometer face up, to verify that +1.00G is the maximum attainable stable reading. Then reposition the unit for a

reading of 0.00G and retighten the mounting bolts.

OP 12OP 12

7D. POSITIONING SENSORS (SHOCK TRAVEL)

The software has a four point calibration to reduce the nonlinearity of the linkage arrangement. This also allows you to

calibrate your system in the field to meet your needs. The computer directs each step of the calibration.

The calibrated range of the sensor is 0 - 500. Depending on your application, this could be 0 - .500 inches, 0 - 5.00

inches, etc. Calibration can be performed in both “AUTO” or “MAN”ual modes. (If you are interested in relative travel

only, and don’t need calibrated inches in your measurement, simply leave the factory calibration.)

To calibrate shock travel

OP 13OP 13

# Cal Points=2

Change SELECT

This screen selects the number of calibration points (2, 3, or 4).

• Press the “Change” button to scroll through the number of

calibration points you need (depending on your application).

• Press the “SELECT” button to store your selection.

“Change”

Scrolls through channels

“SELECT”

Select calibration points

1 2 3

0.00 Set Dec Pt

<-- --> ENTER

This screen is asking you to select the number of decimal

places you want to view. Use the arrow buttons to move the

decimal point to the left or right (maximum 4 digits), then press

ENTER. In this example the length should not exceed 10”,

(10.00) so set the display for 2 decimal places (0.00). This also

plays a part in setting the resolution of the measurement.

• Press “<--” to display more decimal places and increase the

resolution.

• Press “-->” to display less decimal places and decrease the

resolution.

• Press “ENTER” to store your selection.

“<--”

Increase decimal places

“-->”

Decrease decimal places

“ENTER”

Enters selection

1 2 3

CHOOSE MODE

Disp Rec# Play

Press the “Play” button to enter the “Choose Function” screen.

“Play”

Selects the Play mode

Display Brief Details

1 2 3

Choose Function

Setup Cal Play

This screen selects the Calibration Mode.

• Press the “Cal” button to enter Calibration.

“CAL”

Select Calibration Mode

1 2 3

Choose Sensor

PRES ACC CHNL

This screen selects the type of calibration you want to perform.

• Press the “CHNL” button to select auxiliary channel calibration.

“CHNL”

Selects auxiliary

channel calibration

1 2 3

Channel # 1

Change ENTER

This screen selects the channel you want to calibrate.

• Press the “Change” button to scroll through the channels.

• Press the “ENTER” button to enter that channels calibration.

“Change”

Scrolls through channels

“ENTER”

Enters selection

1 2 3

Channel 1 Cal

MAN AUTO VIEW

This screen selects the calibration method you want to use.

“AUTO”

Selects auto calibration

1 2 3

OP 14

Display Brief Details

Store Cals ?

YES NO

The calibration is now complete and the system is ready to

save it to permanent storage and display it for you to see.

• Press “YES” to store the calibrations you have entered.

• Press “NO” to erase the calibrations you have entered.

“YES”

Store calibration

“NO”

Do not store calibration

1 2 3

To directly monitor the auxiliary channels, select Disp from the main menu, then press the button 2 to display the

auxiliary channels. To exit the RUN display, press the hold and button 1 & 2 until the the Data Logger resets itself

If you have any questions or are having difficulties calibrating your unit, give us a call and we will be glad to help.

CAL 1 INCH= 0.00

Up Down ENTER

The computer is now ready for you to input the distance in

inches that the shock is compressed for calibration point 1.

Set the display to 0.00 and press ENTER.

• Press the “Up” button to increase the distance.

• Press the “Down” button to decrease the distance.

• Press the “ENTER” button to store the distance.

“Up”

Increases the distance

“Down”

Decreases the distance

“ENTER”

Stores the distance

1 2 3

1: 0.00 INCH= #

ENTER

The computer is now reading the input from the sensor.

Press ENTER to store this value.

• Press the “ENTER” button to store the calibration.

“ENTER”

Enters selection

1 2 3

Cal 2 INCH= 1.67

Up Down ENTER

This screen is asking for the distance the shock is extended for

calibration point 2. Enter the distance in inches (1.67 for this

example) the shock is extended and press ENTER.

• Press the “Up” button to increase the distance.

• Press the “Down” button to decrease the distance.

• Press the “ENTER” button to store the distance.

“Up”

Increases the distance

“Down”

Decreases the distance

“ENTER”

Stores the distance

1 2 3

2: 1.67 INCH= #

ENTER

The computer is now reading the input from the sensor.

Extend the shock 1.67 inches and press ENTER to store the

reading.

• Press the “ENTER” button to store the calibration.

“ENTER”

Enters selection

1 2 3

8. Channel Maintenance

Follow the steps below to add, change or delete channel information:

1. Click on the File menu.

2. Click on Maintenance.

3. Click on Channel Maintenance.

RESULT: The Password dialog box appears.

4. No password is required. Click OK to logon as a user.

RESULT: The Channel Maintenance dialog box appears.

OP 15

12 MONTH LIMITED WARRANTY

Auto Meter warrants to the consumer that this product will be free from defects in materials and workmanship for a period of twelve (12) months from the date of the original purchase. Products that

fail within this 12 month warranty period will be repaired or replaced at the manufacturer’s option to the consumer, when determined by the manufacturer that the product failed because of defects

in material or workmanship. This warranty is limited to the repair or replacement of parts in the instrument and the necessary labor done by the manufacturer to affect the repair or replacement of

the instrument. In no event shall this warranty exceed the original purchase price of the instrument, nor shall the manufacturer be responsible for special, incidental or consequential damages or

costs incurred due to failure of this product. Warranty claims to the manufacturer must be transportation prepaid and accompanied with dated proof of purchase. This warranty applies only to the

original purchaser of product and is non-transferable. All implied warranties shall be limited in duration to the said 12 month warranty period. Breaking the meter seal, improper use or installation,

accident, water damage, abuse, unauthorized repairs or alterations voids this warranty. The manufacturer disclaims any liability for consequential damages due to breach of any written or implied

warranty on all products made by the manufacturer.

FOR SERVICE SEND TO:

AUTO METER PRODUCTS, INC.

413 W. Elm St., Sycamore, IL 60178

(815) 895-8141

email: [email protected]

SERVICE

For service send your product to Auto Meter in a well packed shipping carton. Please include a note explaining what the problem is along with your

phone number. Please specify when you need the product back. If you are sending product back for Warranty adjustment, you must include a copy (or

original) of your sales receipt from the place of purchase.

2650-627 7/3/03

9. CALIBRATING AUX CHANNELS 5-20

To calibrate any auxiliary channel 5-20 you will need the small channel calibration card

that came with the sensor. Make sure you have that card before proceeding with the remaining

steps.

1. Using the PREV & NEXT buttons, scroll through the list of channels until you find

the channel you would like to calibrate.

2. Once you have found the correct channel,

3. Select the CALIBRATION button

4. The Calibration Settings window will open.

5. Enter the calibrations as they appear on the calibration sheet that came with the sensor.

6. In the upper left box, enter the first unit number

7. In the box next to that, enter the ADC number for that reading

8. Repeat for each reading on the calibration sheet

They should appear similar to this:

9. When finished, select SAVE

10. Then select UPDATE

11. Make sure to click UPDATE before

exiting the channel calibration window otherwise your changes will not take effect.

12. When you are finished calibrating and updating the software, click EXIT

The channel calibrations are now entered into the software.

Each time you download a run from a 34 channel data logger, the channel calibration settings you

have entered on your computer will be applied to the corresponding channels in the data file. Once

a file has been downloaded, the raw data can not be re-calibrated. If you find an error in the channel

calibration data in the software, correct the calibration settings and download the run from the data

logger again.

OP 16

This manual suits for next models

1

Table of contents

Other AutoMeter Data Logger manuals