Simex SRD-N16 User manual

Assisting the automation

industry since 1986

User manual

DATA RECORDER

SRD- 16

•Firmware: v.3.40 b1 or higher

•Loggy Soft: v.1.10.0 or higher

•S-Toolkit: v.2.1.0 or higher

Read the user's manual carefully before starting to use the unit or software.

Producer reserves the right to implement changes without prior notice.

2019.0 .16 SRD-N16_INSSXEN_v.1.08.001

User manual - DATA RECORDER SRD-N16 and cooperating software

CONTENTS

1. BASIC REQUIREMENTS AND USER SAFETY........................................................................................4

2. GENERAL CHARACTERISTICS................................................................................................................5

3. TECHNICAL DATA......................................................................................................................................7

4. DEVICE INSTALLATION..........................................................................................................................12

4.1. UNPACKING....................................................................................................................................12

4.2. ASSEMBLY......................................................................................................................................12

4.3. CONNECTION METHOD.................................................................................................................16

4.3.1.Connection of current type input ( I ver ion ).......................................................................18

4.3.2.Connection of voltage type input ( U ver ion ).....................................................................19

4.3.3.Connection of temperature type input ( RTD ver ion ).......................................................20

4.3.4.Connection of thermocouple type input ( TC ver ion ).......................................................21

4.4. MAINTENANCE................................................................................................................................21

5. FRONT PANEL DESCRIPTION................................................................................................................23

6. PRINCIPLE OF OPERATION...................................................................................................................24

6.1. MEASUREMENT MODE..................................................................................................................24

6.1.1.Mea urement range definition of current input ( U/I ver ion ).............................................24

6.1.2.Mea urement range definition of RTD and TC input ( TC/RTD ver ion )............................25

6.1.3.Recording momentary and averaged data...............................................................................26

6.2. MODES OF RESULT PRESENTATION..........................................................................................27

6.2.1. "Single channel" mode............................................................................................................28

6.2.2."Mea urement li t" mode.......................................................................................................29

6.2.3.”Graph” mode...........................................................................................................................32

6.2.4.”Channel Li t” mode...............................................................................................................35

6.3. PRINCIPLE OF OUTPUTS OPERATION........................................................................................37

6.3.1.Alarm ......................................................................................................................................37

6.3.2.Output control.........................................................................................................................38

6.3.3.Example of output control........................................................................................................40

7. DEVICE PROGRAMMING.........................................................................................................................41

7.1. PARAMETERS EDITION.................................................................................................................43

7.1.1.Numeric and witching parameter ("LIST" - type)..................................................................43

7.1.2. Text parameter ......................................................................................................................44

7.1.3.“SLIDER” - type parameter .....................................................................................................45

7.2. DESCRIPTION OF RESULTS PRESENTATION MODES MENU.................................................46

7.2.1."Mea urement li t option " menu...........................................................................................46

7.2.2.”Graph option ” menu..............................................................................................................47

7.2.3.”Channel li t option ” menu....................................................................................................47

7.3. RESULTS PRESENTATION MODES MENU STRUCTURE..........................................................48

7.4. MAIN MENU DESCRIPTION...........................................................................................................49

7.4.1.”Device information” menu.......................................................................................................49

7.4.2.”Di play option ” menu............................................................................................................49

7.4.3.”Logging etup” menu..............................................................................................................50

7.4.4.“Temperature unit” parameter (RTD ver ion)..........................................................................52

7.4.5.”Input etting ” menu (common parameter )...........................................................................53

7.4.6.”Input etting ” menu ( I ver ion )............................................................................................54

7.4.7.”Input etting ” menu ( U ver ion )...........................................................................................55

7.4.8.”Input etting ” menu ( RTD ver ion )......................................................................................57

7.4.9.”Input etting ” menu ( TC ver ion )........................................................................................58

7.4.10.”Output etting ” menu.........................................................................................................59

7.4.11.”Date & time etting ” menu..................................................................................................61

7.4.12.”RS485 port etting ” menu...................................................................................................61

7.4.13.”Acce etup” menu.............................................................................................................62

7.4.14.”USB option ” menu...............................................................................................................63

User manual - DATA RECORDER SRD-N16 and cooperating software

7.4.15.”Language” menu...................................................................................................................64

7.4.16.”Default etting ” menu..........................................................................................................64

7.5. MAIN MENU STRUCTURE..............................................................................................................65

8. DO NLOADING DATA FROM DATA LOGGER.....................................................................................67

8.1. MODBUS (RS485) DATA DOWNLOAD..........................................................................................67

8.2. USB FLASH DRIVE (PENDRIVE) DATA DOWNLOAD..................................................................67

9. THE MODBUS PROTOCOL HANDLING.................................................................................................70

9.1. LIST OF REGISTERS......................................................................................................................70

9.2. TRANSMISSION ERRORS HANDLING..........................................................................................76

9.3. EXAMPLES OF QUERY/ANSWER FRAMES.................................................................................77

10. USER'S SETTINGS LIST........................................................................................................................80

1. GENERAL CHARACTERISTICS..............................................................................................................87

2. INSTALLATION AND STARTUP..............................................................................................................87

3. USING THE PROGRAM............................................................................................................................90

3.1. „CURRENT MEASUREMENT” MENU.............................................................................................91

3.2. „REPORTS” MENU..........................................................................................................................91

3.2.1.„Table” tab................................................................................................................................92

3.2.2.„Graph” tab...............................................................................................................................94

3.3. „CONFIGURATION” MENU.............................................................................................................99

3.3.1.„Device ” tab..........................................................................................................................100

3.3.2.„Group ” tab - group operation .............................................................................................104

3.3.3.„Setting ” tab..........................................................................................................................106

3.4. LIST OF ERRORS AND FAULT DIAGNOSTICS .........................................................................108

1. GENERAL CHARACTERISTICS............................................................................................................109

2. INSTALLATION AND STARTUP............................................................................................................109

3. USING PROGRAM..................................................................................................................................110

3.1. “INPUTS SETTINGS” TAB.............................................................................................................111

3.2. “OUTPUTS SETTINGS” TAB.........................................................................................................112

3.3. “LOGGING SETUP” TAB...............................................................................................................112

3.4. “INTERFACE OPTIONS” TAB......................................................................................................113

3.5. “DEVICE INFORMATION” TAB.....................................................................................................115

3.6. CONFIGURATION MODES...........................................................................................................116

3.6.1.Individual configuration of channel .......................................................................................116

3.6.2.Configuring elected channel ...............................................................................................116

3.6.3.Configuring all channel .........................................................................................................116

3.7. UPDATING DEVICE FIRMWARE..................................................................................................117

3

User manual - DATA RECORDER SRD-N16 and cooperating software

Explanation of symbols used in the manual:

- Thi ymbol denote e pecially important guideline concerning the in tallation and

operation of the device. Not complying with the guideline denoted by thi ymbol

may cau e an accident, damage or equipment de truction.

IF THE DEVICE IS NOT USED ACCORDING TO THE MANUAL THE USER IS

RESPONSIBLE FOR POSSIBLE DAMAGES.

- Thi ymbol denote e pecially important characteri tic of the unit.

Read any information regarding thi ymbol carefully

I. USER MANUAL FOR DATA RECORDER

1. BASIC REQUIREMENTS AND USER SAFETY

- !"# $%"&& '( !)% &(*)!('+, #)& !- . /( $ "(. +-

'! **&)*&' % '!(% ,, %')!0 !)% '!% '!'!/ % *&)*& !1'&)!!% ,

$)!.'%')!( !."('!/%"!'%$)!%& &-%)'%( (('/!!%

- Installation should be conducted by qualified personnel . During installation all

available safety requirements should be considered. The fitter is responsible for

executing the installation according to this manual, local safety and EMC

regulations.

- The unit must be properly set-up, according to the application. Incorrect

configuration can cause defective operation, which can lead to unit damage or

an accident.

- If the device is equipped with PE conntector, it should be connected to PE wire.

- #'!%$ ()# "!'% ,#"!$%')!%&'( &'(2)# (&')"(%& %%)%

( #%- )# *)*, )& *&)*&%- ..'%')! ,0 '!.*!.!% (-(%( !.

(),"%')!(%)*&1!%("$ %& %"(%+"(.

- "!'%"((. !/&)"(1),% /% %$ !$ "( ,% , $$'.!%"!'%

"(%+ (3'%$.)## !..'($)!!$%.#&)%*)3& ("**,-*&')&%)

(% &%'!/'!(% ,, %')!)#%&)"+,())%'!/4'!%$ ()# ,#"!$%')!5

- Neighbouring and connected equipment must meet the appropriate standards

and regulations concerning safety and be equipped with adequate overvoltage

and interference filters.

-)!)% %%*%%).'( ((+,0&* '&)&).'#-%"!'%-)"&(,#"!'%

(!)"(&(&1'$ +,* &%( #$%'1"!'%("(%+.'($)!!$%. !.

("+'%%.#)&&* '&( % ! "%)&'6.(&1'$$!%&

4

i

!

!

User manual - DATA RECORDER SRD-N16 and cooperating software

- Do not use the device in areas which are vulnerable to excessive quakes,

vibrations, corrosive gases and oils.

- Do not use the device in potentially explosive environments.

- Do not use the device in water vapor condensation and icing exposed places.

- Do not use the device in places which are exposed to direct sunlight.

- It is necessary to insure that temperature around the device does not exceed

recommended values. If so, take under consideration forced cooling of

the device (e.g. using fan).

"!'%'(.('/!. #)&)*& %')! '! !'!."(%&' ,!1'&)!!% !."(%

!)%+"(.'! )"(),.!1'&)!!%)&('', &

2. GENERAL CHARACTERISTICS

• Multifunctional

Deviceis designed for recording, displaying current or averaged values and

presentation of technological parameter trends in graphic form.

• Large data storage capacity

The registered measurement results are recorded in the unit's memory. The

capacity of installed memory allows to store over 2 000 000 measurements.

• Configurable measurement and control input

The unit has up to 8 measurement channels (depending on version) of

measurement signals and one digital voltage input with programmable functions,

e.g. control of the recording process. Each signal can be freely configured and

described. Depending on device version all measured parameters must be available

as current type signals (0-20 mA or -20 mA standards for I version), voltage type

signals (0-5 V, 1-5 V, 0-10 V or 2-10 V standards for U version or standards K, S, J,

T, N, R, B, E for TC version) or resistance (Pt100, Pt500 or Pt1000 standards for

RTD version). The internal analogue-digital converter has a 12 or 16 bit resolution

(depending on input type), which provides high measurement resolution results.

Additionally, individual alphanumeric description (text) of each of the recorded

channels is possible.

• Fast serial interface

The data logger is fitted with a galvanic isolation RS- 85 interface, programmed

with ModBus RTU transmission protocol. This enables the connection of a number

of data recorders into the network, remote collecting of data from each unit and also

remote configuration. The application of the RS- 85 interface instead of RS-232 is

due to the possibility of achieving high transmission speeds using transmission lines

of larger length than is possible with the RS-232 interface.

5

!

!

User manual - DATA RECORDER SRD-N16 and cooperating software

• Built-in USB Host interface

The device is equipped with built-in USB Host interface, allowing for data transfer to

popular USB Flash Drives (PenDrives). This method allows for significant

simplification of unit application: it is no longer necessary to connect PC and data

logger via RS- 85 interface.

Significant acceleration of data transfer is an additional advantage: data download

can be 10 times faster than using RS- 85 interface.

78 Device should work properly with any standard Flash Drives, but

manufacturer can not guarantee proper cooperation with non-standard devices, or

with devices developed after data logger release.

• ide range of power supply voltage and external sensor power supply

The built-in pulse power supply allows to power the device with 85...9:...260 V

AC/DC, 16...9...35 V AC, 19...9...50 V DC, 11...9...16 V DC, 10...9...13 V AC

(depending on version). Data recorder (version with current inputs only) is equipped

with output for powering the sensor and converters with 2 V DC ±5% and

max.current 50 mA for 11...9...16 V DC, 10...9...13 V AC power supply voltage

and max. 200 mA for other power supply voltage.

• Legible graphic display

The 128 x 6 points display with a backlight mounted on front of the unit is a big

advantage of the data recorder. It allows the display of trend graphs for each

channel separately. Different operation modes provide the possibility of selecting

and adjusting the method of data presentation depending on the user's

requirements. Data recording intervals are selected by the user from the menu

level. Additionally, it is possible to set the display to show one current value

measured for a selected channel.

• Easy configuration

There are 6 keys on the front of the data recorder that enable the configuration of

the unit. The menu assisted with full text descriptions makes the unit configuration

process quite easy. However, due to a significant number of configured parameters

it is advised to use the attached configuration software for PCs.

6

User manual - DATA RECORDER SRD-N16 and cooperating software

3. TECHNICAL DATA

Power supply voltage

(depending on version)

External Fuse (required)

Power consumption

85...9:...260 V AC/DC; 50 ÷ 60 Hz (separated),

19...9...50 V DC, 16 V...9...35 V AC (separated)

or 11...9...16 V DC, 10...9...13 V AC (separated)

T - type, max. 2 A

for power supply voltage: 12 V DC max. 5 W,

for other power supply voltage:

typically 3 VA; max. 5 VA

Measurement inputs

(depending on version)

I version:

U version:

RTD version:

TC version:

up to 8 inputs 0-20 mA or -20 mA, common ground,

overload protection, input current is limited to 50mA

(typical)

up to 8 inputs 0-5V, 1-5V, 0-10V, 2-10V, common ground

up to 8 inputs Pt100, Pt500 or Pt1000 type with

automatic connection recognition (2 or 3-wires)

up to 8 thermocouple inputs type K, S, J, T, N, R, B, E

Digital input 1 input 2 V DC, galvanic isolation

power consumption: 7,5 mA / 2 V,

isolation: 1min @ 500V AC.

Outputs 2 electromagnetic relays, NO type,

5A/250V AC (resistance)

3A/250V AC (reactance)

Recording cycle 1 sec./ 2 sec. / 5 sec. / 10 sec. / 15 sec. / 20 sec. /

30 sec. /1 min. / 2 min. / 5 min. / 10 min. / 15 min. /

20 min. / 30 min. / 60 min.

Communication interface

Baud rate

RS- 85, 8N1 / Modbus RTU, galvanic isolated:

1min @ 500V DC.

1200 bit/s ÷ 115200 bit/s

USB Host interface Cooperation with standard Flash Disks

Display

Backlight color

(depending on version)

LCD graphic display, 128 x 6 points, with backlight

white or amber

Data memory 8 MB

Protection level IP 65

7

User manual - DATA RECORDER SRD-N16 and cooperating software

Housing type

Housing material

Housing dimensions (L x H x D)

without glands

with glands

(depending on version)

version with 1 to inputs

version with 8 inputs

panel

ABS + polycarbonate

166 x 161 x 103 mm

166 x 189 x 103 mm

166 x 192 x 103 mm

Glands

power supply and relays

RS- 85 and digital input

measurement inputs

(depending on version)

version with 1 to 2 inputs

version with inputs

version with 8 inputs

1 x M20 with insert for cables 2 x 5mm

1 x M16 without insert

1 x M20 with insert for cables 2 x 5mm

2 x M20 with insert for cables 2 x 5mm

2 x M25 with insert for cables x 5mm

(inserts provide tight seal by filling spaces between the

wires)

Operating temperature

Storage temperature

Humidity

Altitude

0°C to +50°C (standard)

-20°C to +50°C (optional)

-10°C to +70°C (standard)

-20°C to +70°C (optional)

5 to 90% no condensation

up to 2000 meters above sea level

Screws tightening max. torque 0,5 Nm

Max. connection leads diameter 3 mm2

Safety requirements according to: PN-EN 61010-1

installation category: II

pollution degree: 2

voltage in relation to ground: 300V AC

insulation resistance: >20MW

isolation strength between power supply and input/output

terminal: 1min. @ 2300V (see '/:)

EMC PN-EN 61326-1

Device described in this manual is available in two versions differed by

measurement inputs type. This manual contain following short descriptions:

I version - means device with current type inputs (0..20mA, ..20mA)

U version - means device with voltage type inputs (0..5V, 1..5V, 0..10V,

2..10V)

RTD version - means device with RTD-type inputs (Pt100, Pt500, Pt1000)

TC version - means device with TC-type inputs (K, S, J, T, N, R, B, E)

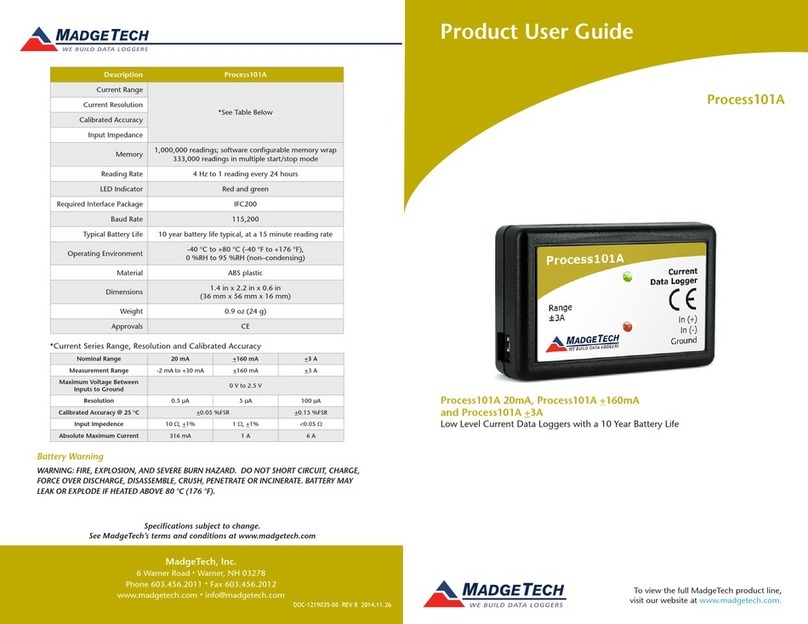

Parameters of current type inputs ( I version )

Input type 0-20 mA or -20 mA, common ground

Measurement range ± 9999 plus decimal point

8

i

User manual - DATA RECORDER SRD-N16 and cooperating software

Current measurement accuracy ± 0.1% @ 25°C; ± one digit (for 0-20 mA range)

Temperature stability 50 ppm / °C

Sampling rate 8 sps

Accepted prolonged input overload 20%

Measurement input resistance 120 W

Sensor power supply output 2 V DC ± 5% and max. current:

50 mA for power supply voltage 11...9...16 V DC,

10...9...13 V AC,

200 mA for other power supply voltage,

Uninsulated from measurement inputs

Parameters of voltage type inputs ( U version )

Input type 0-5V, 1-5V, 0-10V, 2-10V, common ground

Measurement range ± 9999 plus decimal point

Current measurement accuracy ± 0.1% @ 25°C; ± one digit (for 0-10 V range)

Temperature stability 50 ppm / °C

Sampling rate 8 sps

Accepted prolonged input overload 20%

Measurement input resistance 6 kW

Parameters of RTD type inputs ( RTD version )

Input type Pt100, Pt500 or Pt1000 type with automatic

connection recognition (2 or 3-wires)

Measurement range -100,0°C ÷ +600,0°C

-1 8,0°F ÷ +999,9°F

Measurement accuracy ± 0.15% @ 25°C; ± one digit

Temperature stability 100 ppm / °C

Sampling rate 1 sample per 2.5 sec

Measurement wires resistance max. 20 W (every wire)

Parameters of TC type inputs ( TC version )

Input type Thermocouple type K, S, J, T, N, R, B, E

Measurement range K:

S:

J:

T:

N:

R:

B:

E:

Voltage:

-200°C

-50°C

-210°C

-200°C

-200°C

-50°C

250°C

-200°C

-30mV

-50mV

÷

÷

÷

÷

÷

÷

÷

÷

÷

÷

1370°C

1768°C

1200°C

00°C

1300°C

1768°C

1820°C

1000°C

80mV

120mV

Measurement accuracy ± 0.1% @ 25°C; ± one digit

Accuracy of cold ends temperature

compensation ± 1°C

9

User manual - DATA RECORDER SRD-N16 and cooperating software

Temperature stability 50 ppm / °C

Sampling rate 2 sps

Accepted prolonged input overload 20,00%

Input impedance typ. 1MW

Measurement inputs should be connected with isolated signals (it is

recommended to use shielded cables)

Cables connected to RTD inputs can not be longer than 30 meters and must be

laid completely in building.

Software (Window environment)

•S-Toolkit, PC software for data logger easy configuring,

•Loggy Soft, PC software for moving, reporting, archiving and displaying recorded data.

'(;"'*!%'(!)%'!%!..#)&"('!&('.!%' ,!1'&)!!%( !. -

!)%*&)1'. .;" %*&)%$%')!%)& .')&$*%')!'!("$!1'&)!!%(

Carefully check that the isolation used with the unit ('/ :) meets the

expectations and if necessary use appropriate measures of overvoltage protection.

Additionally, insure the appropriate air and surface insulation gaps when installing

( + :).

Range of operating voltage Air gap [mm] Surface gap [mm]

Up to 50V RMS or DC 0,2 1,2

Up to 100V RMS or DC 0,2 1,

Up to 150V RMS or DC 0,5 1,6

Up to 300V RMS or DC 1,5 3,0

Tab. 3.1. Minimal in ulation gap according to EN 61010-1

10

!

!

!

User manual - DATA RECORDER SRD-N16 and cooperating software

Fig. 3.1. Schematic diagram howing the in ulation between individual circuit of the unit.

11

Internal circuits

("&!%

'!*"%(

<

*&)%$%')!

$'&$"'%

Relay 1

<)3&

("**,-

=

Relay 2

Reinforced insulation (2300V AC / 1 min)

Supplementary insulation (1350V AC / 1 min)

Basic insulation (500V AC / 1 min)

No insulation

USB

>

$'&$"'%

?%&! ,(!()&

("**,-)"%*"%

$'&$"'%

'/'% ,'!*"%

$'&$"'%

User manual - DATA RECORDER SRD-N16 and cooperating software

4. DEVICE INSTALLATION

The unit has been designed and manufactured in a way assuring a high level of user

safety and resistance to interference occurring in a typical industrial environment. In order to

take full advantage of these characteristics installation of the unit must be conducted correctly

and according to the local regulations.

- Read the basic safety requirements on page prior to starting the installation.

- Ensure that the power supply network voltage corresponds to the nominal

voltage stated on the unit’s identification label.

- The load must correspond to the requirements listed in the technical data.

- All installation works must be conducted with a disconnected power supply.

- Protecting the power supply connections against unauthorized persons must be

taken into consideration.

4.1. UNPACKING

After removing the unit from the protective packaging, check for transportation damage.

Any transportation damage must be immediately reported to the carrier. Also, write down the

unit serial number located on the housing and report the damage to the manufacturer.

4.2. ASSEMBLY

- Disconnect the power supply prior to starting assembly.

- Check the connections are wired correctly prior to switching the unit on.

Optionally, the insert with the key can be included to the device to reduce the risk of

tampering. To assembly the insert first remove the end cap then insert the insert (see '/

). Inserting the insert may require using force.

1

!

!

User manual - DATA RECORDER SRD-N16 and cooperating software

c) d)

Fig. 4.1. Method of the in ert a embling

In order to install the unit a mounting hole must be prepared as it is shown on

'/ 9. First drill central hole and mount a hook, bolt or screw and hang the

device. Then mark drill places for rest of the mounting holes, drill them and mount

the device. It is recommended to use f8 dowels and f screws. After assembling

the device, remove protective films from door and display.

14

!

Insert the insert

with the key

Turn and remove

the key

User manual - DATA RECORDER SRD-N16 and cooperating software

4.3. CONNECTION METHOD

Caution

- Installation should be conducted by qualified personnel. During installation all

available safety requirements should be considered. The fitter is responsible for

executing the installation according to this manual, local safety and EMC

regulations.

- The unit is not equipped with an internal fuse or power supply circuit breaker.

Because of this an external time-delay cut-out fuse with a small nominal current

value must be used (recommended bipolar, max. 2A) and a power supply circuit-

breaker located near the unit. In the case of using a monopolar fuse it must be

mounted on the phase cable (L).

- The power supply network cable diameter must be selected in such a way that in

the case of a short circuit of the cable from the side of the unit the cable shall be

protected against destruction with an electrical installation fuse.

- Wiring must meet appropriate standards and local regulations and laws.

- In order to secure against accidental short circuit the connection cables must be

terminated with appropriate insulated cable tips.

!"(. %&'! ,(4 &2. (!$5"(% !)%+"(.#)&$)!!$%'!/ !-

$)!!$%'!/$ +,(4/ (+&'./(50+$ "(%'($ !$ "(. /%)%

;"'*!%)&,$%&'$()$2

- If the unit is equipped with housing, covers and sealing to, protecting against

water intrusion, pay special attention to their correct tightening or clamping. In the

case of any doubt consider using additional preventive measures (covers, roofing,

seals, etc.). Carelessly executed assembly can increase the risk of electric shock.

- After the installation is completed do not touch the unit’s connections when it is

switched on, because it carries the risk of electrical shock.

"%)*)(('+,('/!'#'$ !%'!%&#&!$'!'!."(%&' ,'!(% ,, %')!( **&)*&' % ("&(

(("&'!/$)&&$%)*& %')!)#%"!'%"(%+ **,'. ) 1)'.%"!'%)#'*&)*&

'!.'$ %')!(2*&$)!. %')!(,'(%.+,)3

-Avoid running signal cables and transmission cables together with power supply cables

and cables controlling inductive loads (e.g. contactors). Such cables should cross at a

right angle.

-Contactor coils and inductive loads should be equipped with interference protection

systems, e.g. RC-type.

-Use of screened signal cables is recommended. Signal cable screens should be

connected to the earthing only at one of the ends of the screened cable.

-In the case of magnetically induced interference the use of twisted pair of signal cables is

recommended. Twisted pair (best if shielded) must be used with RS- 85 serial

transmission connections.

-In the case of measurement or control signals are longer than 30m or go outside of the

building then additional safety circuits are required.

16

!

User manual - DATA RECORDER SRD-N16 and cooperating software

-In the case of interference from the power supply side the use of appropriate interference

filters is recommended. Bear in mind that the connection between the filter and the unit

should be as short as possible and the metal housing of the filter must be connected to

the earth with the largest possible surface. The cables connected to the filter output must

not be run with cables with interference (e.g. circuits controlling relays or contactors).

Connections of power supply voltage and measurement signals are executed using the

clamping connections on the bottom of the unit’s housing.

Some glands have the inserts which allow to drag wires without losing tightness. They

have small range of clamping so wires diameter should be about the same size as holes in

glands (5 mm).

Recommended usage of glands (from right to left):

• M20 gland with insert for power supply and relays – one hole of the insert for supply cable,

second for relays in common cable,

• M16 gland without insert for RS- 85 and digital input – all in common cable,

• M20 or M25 glands with insert for measurement inputs – each channel has his own hole in

the insert,

Fig. 4.4. Method of cable in ulation replacing and cable terminal dimen ion

Fig. 4.5.Method of cable connecting

,,$)!!$%')!("(%+ .3',*)3&("**,-'(.'($)!!$%.8

17

!

6-7 mm

max. 2 mm

User manual - DATA RECORDER SRD-N16 and cooperating software

Fig. 4.6. Connection of power upply

Fig. 4.7. Connection of RS-485 tran mi ion ignal

Fig. 4.8. Connection of digital input (depending on data recorder configuration)

4.3.1.

Connections of current type inputs (

I version )

18

9

9@ recording enable

external switch

external

supply

A

konwerter

RS232/ 85

= >

A

9

Depending on ver ion:

85...230...260V AC/DC lub

19...24...50V DC; 16...24...35V AC

11...12...16 V DC, 10...12...13 V AC

User manual - DATA RECORDER SRD-N16 and cooperating software

Fig. 4.9. Terminal de cription ( I ver ion )

Fig. 4.10. Connection of current ignal of active en or

(current ignal 0-20 mA or 4-20 mA and ground)

Fig. 4.11. Connection of current ignal of 2-wire en or

( en or power upply voltage and 4-20 mA ignal)

4.3.2.

Connections of voltage type inputs (

U version )

19

'!

9

=

>

:

9

A9@

'!A

A

>

current inputs

sensor supply output

+2 V

Imax. 200mA

B

additional terminals

(internally connected)

<

99 9 9 = >

:9 : : 9 9 9 9= 9>

=>

9

:

9 9:

:

9

*)3&

("**,-

(depending

on version)

:9 : : 9 9 9 9= 9> 9 9:

99 9 9 = > :

A9@

input 1

-20 mA

input 8

-20 mA

C

&'! ,( !.9 &()&%.

&'! ,(#&)9:%):9 &)!*)%!%' ,

:9 : : 9 9 9 9= 9> 9 9:

99 9 9 = > :

A9@

input 1

-20 mA

input 8

-20 mA

A A

C

&'! ,(: !.9: &()&%.

&'! ,(#)&9:%):9 &)!A9@*)%!%' ,

User manual - DATA RECORDER SRD-N16 and cooperating software

Fig. 4.12. Terminal de cription ( U ver ion )

4.3.3.

Connections of temperature type inputs (

RTD version )

Fig. 4.13. Terminal de cription ( RTD ver ion )

The Pt100 / Pt500 / Pt1000 sensor can be connected to the device in typical 3-wire circuit

('/ a) or 2-wire circuit ('/b). Due to precision of measurement 3-wire circuit is

recommended.

If 2-wire circuit is used, the resistance of wires should be as small as possible, to

avoid measurement errors. Measured value can be corrected (constant correction)

using „B' (” parameter from menu „!*"%(%%'!/(”. Due to low precision 2-wire

connection is not recommended.

0

i

'!

9

'!A

A

>

B

<

= >

9

:

9

*)3&

("**,-

(depending

on version)

: =

> :

=

9 9

>

!$

!$

!$

:: :9 ::= :> :: : :

9 9: 99

9 9= 9>: 9 9

9

'!

9

=

>

:

9

A9@

'!A

A

>

voltage inputs

sensor supply output

+2 V

Imax. 200mA

B

additional terminals

(internally connected)

<

99 9 9 = >

:9 : : 9 9 9 9= 9>

= >

9

:

9 9:

:

9

*)3&

("**,-

(depending

on version)

!$

!$

Table of contents

Other Simex Data Logger manuals

Popular Data Logger manuals by other brands

DAVIS

DAVIS 6466 manual

National Instruments

National Instruments Isolated Analog Input Device NI PXI-4224 user manual

MadgeTech

MadgeTech RTDTemp2000 Product Information Card

ADAPT LOGGERS

ADAPT LOGGERS KELVIN M300 user manual

Microtronics

Microtronics myDatalogMUC xG/4G user manual

Omega

Omega OM-EL-USB Series user guide