Alarm[

AL-1/ AL-2

] Functions

Error

Caution During Use

Set both alarm operation and alarm option by combining.

Each alarm operates individually in two alarm output models.

When the current temperature is out of alarm range, alarm

clears automatically. If alarm option is alarm latch or alarm latch

and standby sequence 1/2, press digital input key( + 3 sec.,

digital input key[DI-K] of parameter 2 group set as AlRE), or

turn OFF the power and turn ON to clear alarm.

1. Input correction[IN-B]

Controller itself does not have errors but there may be error by external input temperature sensor. This function

is for correcting this error.

Ex) If actual temperature is 80℃ but controller displays 78℃, set input correction value [IN-B] as '2' and

controller displays 80℃.

※ As the result of input correction, if current temperature value (PV) is over each temperature range of input

sensor, it displays HHHH or LLLL.

2. Input digital lter[MAvF]

If current temperature (PV) is uctuating repeatedly by rapid change of input signal, it reects to MV and

stable control is impossible. Therefore, digital lter function stabilizes current temperature value.

For example, set input digital lter value as 0.4 sec, and it applies digital lter to input values during 0.4 sec

and displays these values. Current temperature may be different by actual input value.

4. Current output range[oMA]

In case of selectable current output or SSR drive output model(TX4S- 4C), when control output [OUT]

parameter 2 group is set as [CURR], you can select high/low-limit range, 4-20mA [4-20] or 0-20mA [0-20] of

current output.

8. Control output MV for input break[ErMV]

When input sensor is break, set control output MV.

When control method[C-MD] of parameter 2 group is set as ONOF, set control output MV as )0(OFF)

or10)0(ON). When control method[C-MD] is set as PID, setting range for control output MV is )0 to 10)0.

Alarm option

Sensor break alarm

The function that alarm output will be ON when sensor is not connected or when sensor's disconnection is

detected during temperature controlling. You can check whether the sensor is connected with buzzer or other

units using alarm output contact. It is selectable between standard alarm [SBaA] or alarm latch [SBaB].

Loop break alarm(LBA)

It checks control loop and outputs alarm by temperature change of the subject. For heating control(cooling

control), when control output MV is 100%(0% for cooling control) and PV is not increased over than LBA

detection band [LBaB] during LBA monitoring time [LBaT], or when control output MV is 0%(100% for cooling

control) and PV is not decreased below than LBA detection band [LBaB] during LBA monitoring time [LBaT],

alarm output turns ON.

Alarm

option

Alarm

operation

Alarm operation

AM!A

5. Hysteresis[HYS]

Set interval between ON and OFF of control output for ON/OFF

control.

●

If hysteresis is too narrow, hunting(oscillation, chattering) could

occur due to external noise.

●

In case of ON / OFF control mode, even if PV reaches stable

status, there still occurs hunting. It could be due to hysteresis

[HYS] setting value, load’s response characteristics or sensor’s

location. In order to reduce hunting to a minimum, it is required

to take into following factors consideration when designing temp.

controlling; proper Hysteresis [HYS], heater’s capacity, thermal

characteristics, sensor’s response and location.

6. Manual reset[REST]

When selecting P/PD control mode, certain temperature difference

exists even after PV reaches stable status because heater's rising and

falling time is inconsistent due to thermal characteristics of controlled

objects, such as heat capacity, heater capacity. This temperature

difference is called offset and manual reset [REST] function is to set/

correct offset.

When PV and SV are equal, reset value is 50.0%. After control is

stable, PV is lower than SV, reset value is over 50.0% or PV is higher

than SV, reset value is below 50.0%.

Heating operation

Hysteresis

[HYS]

ON OFF

SV

Control

output

Temp.

Major Products

Mode Name Alarm operation Description

AM)_

- -

No alarm output

AM!

Deviation

high-limit

alarm

SV

100℃

PV

110℃

OFF ONH

PV

90℃

SV

100℃

OFF ONHIf deviation between PV and SV as

high-limit is higher than set value

of deviation temperature, the alarm

output will be ON.

High-limit deviation: Set as 10℃High-limit deviation: Set as -10℃

AM@

Deviation

low-limit

alarm

PV

90℃

SV

100℃

OFFON H

SV

100℃

PV

110℃

OFFON HIf deviation between PV and SV as

low-limit is higher than set value of

deviation temperature, the alarm

output will be ON.

Low-limit deviation: Set as 10℃Low-limit deviation: Set as -10℃

AM#

Deviation

high/low-

limit

alarm

PV

90℃

PV

110℃

SV

100℃

OFFON ONH H If deviation between PV and SV

as high/low-limit is higher than set

value of deviation temperature, the

alarm output will be ON.

High, Low-limit deviation: Set as 10℃

AM$

Deviation

high/low-

limit

reserve

alarm

PV

90℃

PV

110℃

SV

100℃

OFF OFFONH H If deviation between PV and SV

as high/low-limit is higher than set

value of deviation temperature, the

alarm output will be OFF.

High, Low-limit deviation: Set as 10℃

AM%

Absolute

value high

limit alarm

PV

90℃

SV

100℃

OFF ONH

SV

100℃

PV

110℃

OFF ONH

If PV is higher than the absolute

value, the output will be ON.

Alarm absolute-value: Set as 90℃Alarm absolute-value: Set as 110℃

AM^

Absolute

value low

limit alarm PV

90℃

SV

100℃

OFFON H

SV

100℃

PV

110℃

OFFON H

If PV is lower than the absolute

value, the output will be ON.

Alarm absolute-value: Set as 90℃ Alarm absolute-value: Set as 110℃

SBa Sensor

break alarm

-

It will be ON when it detects sensor

disconnection.

LBa Loop break

alarm

-

It will be ON when it detects loop

break.

※ H: Alarm output hysteresis [AHYS]

※Condition of re-applied standby sequence for standby sequence 1, alarm latch and standby sequence 1: Power ON

Condition of re-applied standby sequence for standby sequence 2, alarm latch and standby sequence 2: Power ON,

changing set temperature, alarm temperature [AL1, AL2] or alarm operation [AL-1, AL-2], switching STOP mode

to RUN mode.

※

When executing auto-tuning, LBA detection band[LBaB] and LBA monitoring time are automatically set based

on auto tuning value. When alarm operation mode [AL-1, AL-2] is set as loop break alarm(LBA)[LBa ], LBA

detection band [LBaB] and LBA monitoring time [LBaT] parameter is displayed.

Display Description Troubleshooting

OPEN Flashes when input sensor is disconnected or sensor is not connected. Check input sensor status.

HHHH Flashes when measured value is higher than input range. When input is within the

rated input range, this display

disappears.

LLLL Flashes when measured value is lower than input range.

1. Please separate the unit wiring from high voltage lines or power lines to prevent inductive noise.

2. For crimp terminal, select following shaped terminal (M3).

3. Install a power switch or circuit breaker to control the power supply.

4. The power switch or circuit breaker should be installed where it is easily accessible by the user.

5. The unit is for temperature controller. Do not use the unit as volt-meter or ampere-meter.

6. When using RTD temperature sensor, must wire it as 3-wire type. If cable is extended, use 3 wires which are

same thickness as the line. It might cause the deviation of temperature when line resistance is different.

7. If power line and input signal line are close each other, install line lter for noise protection at

power line and use shielded input signal line.

8. Keep away from the high frequency instruments.(High frequency welding machine & sewing machine, large

capacity SCR controller).

9. When supplying the measured input, the unit displays HHHH or LLLL, the measured input may have problem.

Turn OFF the power to the unit and check the line. .

10. This unit may be used in the following environments.

①It shall be used indoor. ②Altitude up to 2,000m.

③Pollution degree 2. ④Installation category II.

Max. 5.8mm Max. 5.8mm

RS485 Communication Output

Applicable for models with RS485 communication output through option output(TX4S-B4 ).

Please refer to ' Ordering Information'.

1. Communication Specications

Com. protocol Modbus RTU Com. speed 2400, 4800, 9600, 19200,

38400 bps

Applied standard EIA RS485

Max. connections 31 units(address: 1 to 99) Start-bit 1-bit xed

Com. method 2-wire half duplex Data-bit 8-bit xed

Synchronization method

Asynchronous Parity-bit None, Even, Odd

Com. distance Within 800m Stop-bit 1, 2Bit

Com. response time 5 to 99ms

2. Modbus Mapping Table

2-1. Read Coil Status (Func 01) / Force Single Coil (Func 05) [Func: 01/05, R/W: R/W]

No.(Address) Type Description Setting/Display

range Unit Default

000001(0000) RUN/STOP Related

coil,

variable

Control output run/stop

0: RUN 1: STOP -STOP

000002(0001) AT Auto-tuning run/stop 0: OFF 1: ON -OFF

000003(0003) Alarm Reset Alarm output clear 0: OFF 1: ON -OFF

000004 to 000050 Reserved

No.(Address) Type Description Setting/Display

range Unit Default

100001(0000) ℃ indicator

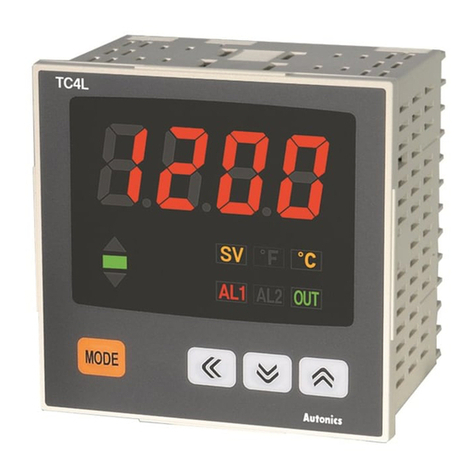

Front

indicator

Unit indicator 0: OFF 1: ON - -

100002(0001) ℉ indicator Unit indicator 0: OFF 1: ON - -

100003(0002) OUT indicator Control output indicator 0: OFF 1: ON - -

100004(0003) AT indicator Auto-tuning indicator 0: OFF 1: ON - -

100005(0004) AL1 indicator Alarm output 1 indicator 0: OFF 1: ON - -

100006(0005) AL2 indicator Alarm output 2 indicator 0: OFF 1: ON - -

100006 to 100050 Reserved

No.(Address) Type Description Setting/Display

range Unit Default

300001 to 300100 Reserved

300101(0064) - Product number H - - Dedicated

model

number

300102(0065) - Product number L - -

300103(0066) - Hardware version - -

300104(0067) - Software version - -

300105(0068) - Model 1 - - "TX"

300106(0069) - Model 2 - - " 4"

300107(006A) - Model 3 - - "S "

300108(006B) - Model 4 - - "14"

300109(006C) - Model 5 - - "R "

300110(006D) - Model 6 - - " "

300111(006E) - Model 7 - - " "

300112(006F) - Model 8 - - " "

300113(0070) - Model 9 - - " "

300114(0071) - Model 10 - - " "

300115(0072) - Reserved - - -

300116(0073) - Reserved - - -

300117(0074) - Reserved - - -

300118(0075) - Coil status start address - - 0000

300119(0076) - Coil status quantity - - 0

300120(0077) - Input status start address - - 0000

300121(0078) - Input status quantity - - 0

300122(0079) - Holding register start address - - 0000

300123(007A) - Holding register quantity - - 0

300124(007B) - Input register start address - - 0000

300125(007C) - Input register quantity - - 0

300127 to 300200 Reserved

301001(03E8) PV Present value -1999 to 9999 ℃/℉-

301002(03E9) DOT Decimal point location 0:0, 1:)0,

2:)00, 3:)000 - -

301003(03EA) UNIT Display unit 0: ?C, 1: ?F - -

301004(03EB) SV Setting value

Within L-SV to H-SV

℃/℉0

301005(03EC)

℃ indicator

Front

indicator

Unit indicator 0: OFF 1: ON - -

℉ indicator

Unit indicator 0: OFF 1: ON - -

OUT indicator

Control output indicator 0: OFF 1: ON - -

AT indicator

Auto-tuning indicator 0: OFF 1: ON - -

AL1 indicator

Alarm output 1 indicator 0: OFF 1: ON - -

AL2 indicator

Alarm output 2 indicator 0: OFF 1: ON - -

310006 to 310050 Reserved

2-2. Read Discrete Inputs(Func 02) [Func: 02, R/W: R]

2-3. Read Input Registers (Func 04) [Func:02, R/W : R]

2-4. Read Holding Register (Func 03)/Preset Single Register (Func 06)/

Preset Multiple Registers (Func 16)[Func:03/06/16, R/W : R/W]

2-4-1. SV setting

SV setting

Parameter 2 group

Parameter Factory default

-0

Parameter Factory default

AL1 1250

AL2

AT OFF

P 1)0

I0

D

REST 5)0

HYS 2

Parameter 1 group

Factory Default

No.(Address) Parameter Description Setting/Display range Unit Default

400001(0000) Set value SV setting value Within L-SV to H-SV ℃/℉0

400002 to 400050 Reserved

No.(Address) Parameter Description Setting/Display range Unit Default

400051(0032) AL1 AL1 temperature Deviation temperature: -F.S. to F.S.

Absolute value alarm: Temperature range

℃/℉1250

400052(0033) AL2 AL2 temperature

400053(0034) AT Auto-tuning 0: OFF 1: ON -OFF

400054(0035) PProportional band 1 to 9999: )1 to 99(9 ℃/℉1)0

400055(0036) IIntegral time 0 to 9999: 0 to 9999 Sec. 0

400056(0037) DDerivative time 0 to 9999: 0 to 9999 Sec. 0

400057(0038) REST Manual reset 0 to 1000: )0 to 10)0 %5)0

400058(0039) HYS Hysteresis 1 to 100(1 to 500):

1 to 100()1 to 5)0)-2

400059 to 400100 Reserved

2-4-2. Parameter 1 group [PAR1]

No.(Address)

Parameter

Description Setting/Display range Unit Default

400101(0064) IN-T Input sensor Refer to '▣ Input Type And Range' - KCaH

400102(0065) UNIT Temperature unit 0: ?C, 1: ?F -?C

400103(0066) IN-B Input correction -999 to 999(-1999 to 9999):

-999 to 999(`9(9 to 99(9)-0

400104(0067) MAvF Input digital lter 1 to 1200: )1 to 12)0 Sec. )1

400105(0068) L-SV SV low-limit value Refer to '▣ Input Type And Range' ℃/℉

-50

400106(0069) H-SV SV high-limit value 1200

400107(006A) O-FT Control output mode 0: HEAT, 1: COOL -HEAT

400108(006B) C-MD control method 0: PID, 1: ONOF -PID

400109(006C) OUT

Control output selection

0: SSR, 1: CURR -CURR

400110(006D) SSrM

SSR drive output method

0: STND, 1: CYCL, 2: PHAS -STND

400111(006E) oMA Current output range 0: 4-20, 1: 0-20 -4-20

400112(006F) TControl cycle 5 to 1200: )5 to 12)0 Sec. 2)0

@0

400113(0070) AL-1 AL1 operation 00: AM)_, 10 to 15: AM!A to AM!F, ...

60 to 65: AM^A to AM^F,

70: SBaA, 71: SBaB, 80: LBaA, 81: LBaB

-

AM!A

400114(0071) AL-2 AL2 operation AM@A

400115(0072) AHYS

Alarm output hysteresis

1 to 100(1 to 500): 1 to 100()1 to 5)0) - 1

400116(0073) LBaT LBA detection time 0 to 9999: 0 to 9999 Sec. 0

400117(0074) LBaB LBA detection band

0 to 999(0 to 9999): 0 to 999()0 to 99(9)

℃/℉2

400118(0075) FS-L Trans. output low-

limit value Refer to '▣ Input Type And Range'.

--50

400119(0076) FS-H Trans. output high-

limit value -1200

400120(0077) ADRS Com. address 1 to 127: 1 to 127 -1

400121(0078) BPS Com. speed 0: 24, 1: 48, 2: 96, 3: 192, 4: 384 -96

400122(0079) PRTY Com. parity bit 0: NONE, 1: EVEN, 2: ODD -NONE

400123(007A) STP Com. stop bit 0: 1, 1: 2-2

400124(007B) RSwT Com. response

waiting time 5 to 99: 5 to 99 ms 20

400125(007C) COMW Com. write 0: EnA, 1: DIsA -EnA

400126(007D) DI-K Digital input key 0: OFF, 1: STOP, 2: AlRE, 3: AT -STOP

400127(007E) ErMV Control output MV

for input break 0 to 1000: )0(OFF) to 10)0(ON) % )0

400128(007F) LOC Lock 0: OFF, 1: LOC1, 2: LOC2, 3: LOC3 -OFF

400129 to 400150

Reserved

2-4-3. Parameter 2 group [PAR2]

50 Cycle 50 Cycle

50% 80%

AC

OUT

ON ONOFF OFF

AC

OUT

10% 50%

AC

OUT

Temperature controller

(TX4S Series)

SSR voltage output

(12VDC) Load

Power

100-240VAC

50/60Hz

SSR module

Parameter Factory default Parameter Factory default

IN-T KCaH AHYS 1

UNIT ?C LBaT 0

IN-B 0 LBaB 2

MAvF )1 FS-L -50

L-SV -50 FS-H 1200

H-SV 1200 ADRS 1

O-FT HEAT BPS 96

C-MD PID PRTY NONE

OUT CURR STP 2

SSrM STND RSwT 20

oMA 4-20 COMW EnA

T2)0 DI-K STOP

@0 ErMV )0

AL-1 AM!A LOC OFF

AL-2 AM@A

(Relay)

(SSR drive)

Comprehensive Device Management Program[DAQMaster]

DAQMaster is a comprehensive device management software for setting parameters and monitoring

processes. DAQMaster can be downloaded from our web site at www.autonics.com.

Item Minimum specications

System IBM PC compatible computer with Pentium Ⅲ or above

Operations Windows 98/NT/XP/Vista/7/8/10

Memory 256MB+

Hard disk 1GB+ of available hard disk space

VGA Resolution: 1024×768 or higher

Others RS232C serial port (9-pin), USB port

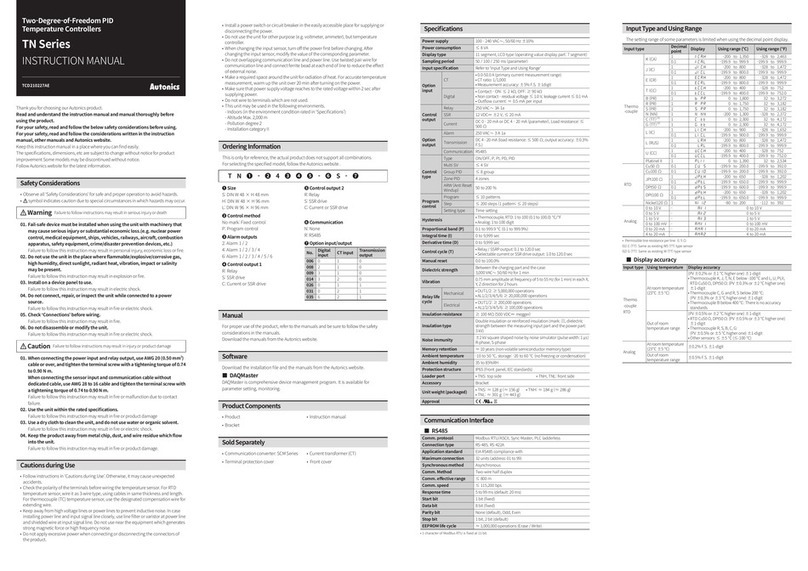

Photoelectric Sensors Temperature Controllers

Fiber Optic Sensors Temperature/Humidity Transducers

Door Sensors SSR/Power Controllers

Door Side Sensors Counters

Area Sensors Timers

Proximity Sensors Panel Meters

Pressure Sensors Tachometer/Pulse(Rate)Meters

Rotary Encoders Display Units

Connector/Sockets Sensor Controllers

Switching Mode Power Supplies

Control Switches/Lamps/Buzzers

I/O Terminal Blocks & Cables

Stepper Motors/Drivers/Motion Controllers

Graphic/Logic Panels

Field Network Devices

Laser Marking System(Fiber, Co₂, Nd:yag)

Laser Welding/Cutting System

http://www.autonics.com

Trusted Partner In Industrial Automation

HEADQUARTERS:

18, Bansong-ro 513beon-gil, Haeundae-gu, Busan, South

Korea, 48002

OVERSEAS SALES:

#402-303, Bucheon Techno Park, 655, Pyeongcheon-ro,

Wonmi-gu, Bucheon, Gyeonggi-do, South Korea, 14502

TEL: 82-32-610-2730 / FAX: 82-32-329-0728

EP-KE-03-0400B

※

Failure to follow these instructions may result in product damage.

Option Name Description

AM .A Standard

alarm

If it is an alarm condition, alarm output is ON. If it is a clear alarm condition, alarm output

is OFF.

AM .B Alarm latch If it is an alarm condition, alarm output is ON and maintains ON status.

(Alarm output HOLD)

AM .C Standby

sequence 1

First alarm condition is ignored and from second alarm condition, standard alarm

operates. When power is supplied and it is an alarm condition, this rst alarm condition is

ignored and from the second alarm condition, standard alarm operates.

AM .D

Alarm latch

and standby

sequence 1

If it is an alarm condition, it operates both alarm latch and standby sequence. When

power is supplied and it is an alarm condition, this rst alarm condition is ignored and

from the second alarm condition, alarm latch operates.

AM .E Standby

sequence 2

First alarm condition is ignored and from second alarm condition, standard alarm

operates. When re-applied standby sequence and if it is alarm condition, alarm output

does not turn ON. After clearing alarm condition, standard alarm operates.

AM .F

Alarm latch

and standby

sequence 2

Basic operation is same as alarm latch and standby sequence1. It operates not only by

power ON/OFF, but also alarm setting value, or alarm option changing. When re-applied

standby sequence and if it is alarm condition, alarm output does not turn ON. After

clearing alarm condition, alarm latch operates.

Start control

to

When control output MV is 100%, PV is increased over than LBA detection band [LBaB] during

LBA monitoring time [LBaT].

to The status of changing control output MV (LBA monitoring time is reset.)

to When control output MV is 0% and PV is not decreased below than LBA detection band [LBaB]

during LBA monitoring time [LBaT], loop break alarm (LBA) turns ON after LBA monitoring time.

to Control output MV is 0% and loop break alarm (LBA) turns and maintains ON.

to The status of changing control output MV (LBA monitoring time is reset.)

to When control output MV is 100% and PV is not increased over than LBA detection band [LBaB]

during LBA monitoring time [LBaT], loop break alarm (LBA) turns ON after LBA monitoring time.

to When control output MV is 100% and PV is increased over than LBA detection band [LBaB]

during LBA monitoring time [LBaT], loop break alarm (LBA) turns OFF after LBA monitoring time.

to The status of changing control output MV (LBA monitoring time is reset.)

Time

Set below 50.0 as reset value

Set over 50.0 as reset value

Offset

Offset

SV

●Manual reset [REST] by control result

Parameter

Operation

OFF OFF It does not use digital input key function.

RUN/STOP STOP

Pauses control output. Auxiliary output (except loop break alarm, sensor break alarm)

except Control output operates as setting. Hold the digital input keys for 3 sec. to restart.

RUN RUN

t t tt

STOP STOP RUN

Digital input key

(t: over 3 sec.)

Clear alarm AlRE

Clears alarm output by force.

(only when alarm option is alarm latch, or alarm latch and standby sequence 1/2 .)

This function is applied when present value is out of alarm operation range but alarm

output is ON. Alarm operates normally right after clearing alarm.

Auto-tuning AT

Starts/Stops auto-tuning. This function is same as auto-tuning[AT] of parameter 1

group. (You can start auto-tuning [AT] of parameter 1 group and stop it by digital input

key.)

※

This parameter AT appears only when control method [C-MD] parameter 2 group

is set as PID. When control method [C-MD] parameter 2 group is set as ONOF, this

parameter is changed as OFF.

3. SSR drive output method (SSRP function)[SSrM]

ㆍ

SSRP function is selectable one of standard ON/OFF control, cycle control, phase control by

utilizing standard SSR drive output.

ㆍThis function parameter appears only in SSR drive output model (TX4S- 4S).

ㆍ

Realizing high accuracy and cost effective temperature control with both current output (4-20mA)

and linear output(cycle control and phase control)

ㆍ

Select one of standard ON/OFF control [STND], cycle control [CYCL] , phase control [PHAS] at SSrM

parameter of parameter 2 group. For cycle control, connect a zero cross turn-on SSR or random

turn-on SSR. For phase control, connect random turn-on SSR.

3)Phase control [PHAS]

Controls the load by controlling the

phase within AC half cycle. Serial

control is available.

Must use random turn-on SSR for

this mode.

※

When selecting cycle or phase control mode, the power supply for a load and a temperature

controller must be the same.

※

Control cycle[T] is able to set only when control method[C-MD]of parameter group 2 is set as PID and SSR

drive output method [SSrM] is set as STND.

※

In case of selectable current output or SSR drive output model(TX4S- 4C), this parameter does not appear.

Standard ON/OFF control by SSR is only available.

1)Standard ON/OFF control [STND]

Controls ON (100% output)/OFF

(0% output) as same as standard

relay output.

2)Cycle control [CYCL]

Controls the load by repeating

output ON / OFF according to the

rate of output within setting cycle

based on certain period (50-cycle).

Control accuracy is almost the

same with phase control’s.

This control has improved ON/

OFF noise than phase control’s

due to zero cross type which turns

ON/OFF at zero point of AC.

7. Digital input key( + 3 sec.)[DI-K]

(Relay)

(SSR drive)