AutoPatch 8Y-XL Assembly instructions

8Y-3000 Documentation Set

q8Y-3000 New Features

q8Y-3000 Installation and Setup Guide

q8Y-3000 User’s Operation Manual

8Y-3000 New Features

This manual contains information for the 8Y-3000 Distribution Matrix, an

advanced 8Y-XL system with the following additional features:

q32-bit processor

qLink to other AutoPatch products with an XNNet network compatible

interface

qLink to a larger line of XNNet AutoPatch control accessories

– Next Generation SBCs (with real-time status update)

– SDU

– CP-32

– CP-20

–CP-10

– Precis Remote Panel

qControllable via Ethernet, Neuron, RS-232/RS-422, and a variety of

XNNet-based control panels

– 10 Base-2 Ethernet interface

– Neuron Control network @ 76 Kbps, free topology

– Software selectable RS-232 or RS-422

– Serial port BAUD rate up to 57600

– Serial port Hardware/Software Handshaking

qNew, more powerful, virtual matrix structure and easy configuration

via XNConnect software

qIndividual crosspoint disconnect capability

qField upgradeable software

qLiteral switch does not invalidate status

qPreset request does not invalidate status

Note: The 8Y-3000 processor does not link and communicate with older

8Y-XL processors.

8Y-XL

Installation

andSetup

Guide

VersionA0

VersionB0905197

CAUTION

To avoid ESD (Electrostatic Discharge) damage to sensitive components, make

sure you are properly grounded before touching any internal materials.

When working with any equipment manufactured with electronic devices,

proper ESD grounding procedures must be followed to ensure people, products,

and tools are as free of static charges as possible. Grounding straps, conductive

smocks, and conductive work mats are specifically designed for this purpose.

Anyone performing field maintenance on AutoPatch equipment should utilize an

appropriate ESD field service kit complete with at least a dissipative work mat

with a ground cord and a UL listed adjustable wrist strap with another ground

cord. These items should not be manufactured locally, since they are generally

composed of highly resistive conductive materials to safely drain static charges,

without increasing an electrocution risk in the event of an accident. ESD

protective equipment can be obtained from 3M™, Desco®, Richmond

Technology®, Plastic Systems®, and other such vendors.

Installation and Setup Guide

Important Safety Information

and Instructions

When using and installing your AutoPatch product, adhere to the following basic safety

precautions. For more information about operating, installing, or servicing your

AutoPatch product see your product documentation.

äRead and understand all instructions before using and installing AutoPatch products.

äUse the correct voltage range for your AutoPatch product.

äThere are no user serviceable parts inside an AutoPatch product; service should only

be done by qualified personnel.

äIf you see smoke or smell a strange odor coming from your AutoPatch product, turn

it off immediately and call AutoAssist.

äTurn off and unplug an enclosure before adding or removing boards, unless otherwise

specified in that product’s documentation.

äTo avoid shock or potential ESD (Electrostatic Discharge) damage to equipment,

make sure you are properly grounded before touching components inside an

AutoPatch product.

äFor products with multiple power supplies in each unit, make sure all power supplies

are turned on simultaneously.

äUse surge protectors and/or AC line conditioners when powering AutoPatch

products.

äOnly use a fuse(s) with the correct fuse rating in your enclosure.

äMake sure the power outlet is close to the product and easily accessible.

äMake sure the product is on or attached to a stable surface.

äTurn off equipment before linking pieces together, unless otherwise specified in that

product’s documentation.

äFor safety and signal integrity, use a grounded external power source and a grounded

power connector.

Installation and Setup Guide

Information et directives

de sécurité importantes

Veuillez vous conformer aux directives de sécurité ci-dessous lorsque vous installez et

utilisez votre appareil AutoPatch. Pour de plus amples renseignements au sujet de

l’installation, du fonctionnement ou de la réparation de votre appareil AutoPatch, veuillez

consulter la documentation accompagnant l’appareil.

äLisez attentivement toutes les directives avant d’installer et d’utiliser les appareils

AutoPatch.

äLe voltage doit être approprié à l’appareil AutoPatch.

äLes appareils AutoPatch ne contiennent aucune pièce réparable par l’usager; la

réparation ne doit être effectuée que par du personnel qualifié.

äSi de la fumée ou une odeur étrange se dégagent d’un appareil AutoPatch, fermez-le

immédiatement et appelez le Service de soutien technique (AutoAssist).

äFermez et débranchez le boîtier avant d’ajouter ou d’enlever des plaquettes, à moins

d’indication contraire fournie dans la documentation du appareil.

äPour éviter les chocs ou les dommages éventuels causés à l’équipement par une

décharge électrostatique, veillez à ce le dispositif oit bien relié à la terre avant de

toucher les composantes se trouvant à l’intérieur d’un appareil AutoPatch.

äVeillez à ce que tous les blocs d’alimentation des appareils dotés de blocs

d’alimentation multiples dans chaque unité soient allumés simultanément.

äServez-vous de protecteurs de surtension ou de conditionneurs de lignes à courant

alternatif lorsque vous mettez les appareils AutoPatch sous tension.

äPlacez uniquement des fusibles de calibre exact dans les boîtiers.

äVeillez à ce que la prise de courant soit proche de l’appareil et facile d’accès.

äVeillez à ce que votre appareil AutoPatch soit installé sur une surface stable ou qu’il

y soit fermement maintenu.

äFermez toutes les composantes de l’équipement avant de relier des pièces, à moins

d’indication contraire fournie dans la documentation de l’appareil.

äPar mesure de sécurité et pour la qualité des signaux, servez-vous d’une source

d’alimentation externe mise à la terre et d’un connect d’alimentation mis à la terre.

Installation and Setup Guide

Notices

AutoPatch©2001, all rights reserved. No part of this publication may be reproduced,

stored in a retrieval system, or transmitted, in any form or by any means, electronic,

mechanical, photocopying, recording, or otherwise, without the prior written permission

of AutoPatch. Copyright protection claimed extends to AutoPatch hardware and software

and includes all forms and matters copyrightable material and information now allowed

by statutory or judicial law or here in after granted, including without limitation, material

generated from the software programs which are displayed on the screen such as icons,

screen display looks, etc. Reproduction or disassembly of embodied computer programs

or algorithms is expressly prohibited.

No patent liability is assumed with respect to the use of information contained herein.

While every precaution has been taken in the preparation of this publication, AutoPatch

assumes no responsibility for error or omissions. No liability is assumed for damages

resulting from the use of the information contained herein.

Further, this publication and features described herein are subject to change without

notice. The United States Federal Communications Commission (in 47CFR 15.838) has

specified that the following notice be brought to the attention of the users of this product.

Federal Communication Commission Radio Frequency Interference Statement:

“This equipment generates and uses radio frequency energy and if not installed and used

properly, that is, in strict accordance with the manufacturers instructions, may cause

interference to radio and television reception. It has been type-tested and found to

comply with the limits for a Class B computing device in accordance with the

specifications in Subpart J of Part 15 of FCC Rules, which are designed to provide

reasonable protection against such interference in a residential installation. However

there is no guarantee that interference will not occur in a particular installation. If this

equipment causes interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

äReorient the receiving antenna

äRelocate the matrix with respect to the receiver

äMove the matrix away from the receiver

äPlug the matrix into a different outlet so that computer and receiver are on different

branch circuits

Installation and Setup Guide

If necessary, the user should consult the dealer or an experienced radio/television

technician for additional suggestions. The user may find the booklet, How to Identify and

Resolve Radio-TV Interference Problems, prepared by the Federal Communications

Commission to be helpful.”

This booklet is available from the U.S. Government Printing Office, Washington, D.C.

20402, Stock N. 004-000-00345-4.

8Y-XL™,X

NNet™, and XNConnect™are trademarks of XNTechnologies, Inc.

Use shielded cables. To comply with FCC Class B requirement, all external data

interface cables and adapters must be shielded.

MS-DOS, Windows, and Windows95 are registered trademarks of Microsoft

Corporation.

3M, Desco, Richmond Technology, and Plastic Systems are all registered trademarks.

Neuron®and LonTalk®are registered trademarks of Echelon.

Installation and Setup Guide

AutoPatch

Statement of Warranty

AutoPatch, a division of XNTechnologies, Inc., Cheney, Washington,

warrantees that the products manufactured by AutoPatch will be free of defects

in materials and workmanship for the lifetime of the product, subject to the

following terms and conditions.

Terms and Conditions

1. AutoPatch products are under warranty for a period of five (5) years

following the original sales invoice date. The warranty period may be

extended to the life of the product provided the warranty card is filled out

and returned to AutoPatch. TO VALIDATE THE LIFETIME

WARRANTY: THE AutoPatch WARRANTY CARD MUST BE FILLED

OUT BY THE DEALER AND RECEIVED BY AutoPatch WITHIN

THIRTY (30) DAYS OF THE INSTALLATION OF EQUIPMENT BUT

NO LATER THAN ONE (1) YEAR FROM THE ORIGINAL SALES

INVOICE DATE. A warranty certificate will be returned to the dealer to

verify the warranty period.

2. This Limited Lifetime warranty covers AutoPatch products shipped on or

after October 1, 1997. The Limited Lifetime warranty applies to products

in the original installation only. If the product is moved to a different

installation, the Limited Lifetime warranty will no longer apply and the

product warranty will revert to the original warranty which covers a period

of five (5) years following the original sales invoice date.

3. The product lifetime is defined as the period of time from the original sales

invoice date to ten (10) years after AutoPatch ceases manufacturing the

product model.

4. Warranty repairs are accomplished by returning the subassembly to

AutoPatch for repair. If conditions do not permit this procedure, AutoPatch

will invoice new or reconditioned (at AutoPatch’s option) replacement parts

and ship them to the dealer or to the customer if so directed by written order

from the dealer. In that case the replacement will be billed to the customer

and the customer may return the failed subassembly within 30 days for

credit. See “AutoPatch Returns Policy” in this manual for replacement

policies and procedures.

Installation and Setup Guide

Warranty

5. AutoPatch’s liability and Buyer’s remedies under this warranty shall

be limited solely to repair, replacement, or credit, at AutoPatch’s

option.

6. The AutoPatch warranty does not apply to any AutoPatch product that has

been modified, repaired by an unauthorized agent, or improperly installed,

used, or maintained. AutoPatch shall not be liable under any circumstances

for consequential or incidental damages including, but not limited to, labor

costs or loss of profits arising in connection with the use of or inability to

use AutoPatch products.

7. AutoPatch will not be responsible for items damaged during shipment to or

from AutoPatch. The shipping carrier is responsible for items damaged

during shipment.

8. This warranty is exclusive and in lieu of any other warranty, expressed or

implied, including but not limited to any implied merchantability or fitness

for a particular purpose. The terms of this warranty are governed by the

laws of the state of Washington; certain other states restrict warranty

limitations. You may have rights that are not defined herein.

9. This warranty may not be modified except in writing by an authorized

AutoPatch officer.

Installation and Setup Guide

Warranty

Contents

Welcome

Installer’s Product Notes ........................................ii

Meet the Manual...............................................iii

Terms to Know ................................................iv

Technical Support ..............................................v

Chapter 1 – Unpacking the 8Y-XL

Front of the Enclosure ........................................1-2

CP-10 Control Panel......................................1-3

Rear of the Enclosure ........................................1-6

Chapter 2 – Placing the Enclosure(s)

Chapter 3 – Linking Enclosures

Chapter 4 – Attaching Inputs and Outputs

Attaching Input and Output Cables .............................4-2

Paralleling Inputs.............................................4-4

Chapter 5 – Attaching an External Controller

Chapter 6 – Applying Power and the Startup Sequence

Applying Power ..............................................6-2

Startup from the CP-10 Control Panel..........................6-2

Startup from a Control Device .................................6-3

Chapter 7 – Executing a Test Switch

Executing a Test Switch Using CP-10 Control Panel..............7-2

Executing a Test Switch Using BCS Commands .................7-4

Installation and Setup Guide

Chapter 8 – Managing Configuration Files

Conceptual Overview .........................................8-2

Installing and Launching ......................................8-2

Panes, Views, and Dialog Boxes................................8-3

Opening and Downloading a Configuration File...................8-4

Modifying Configuration Files ..................................8-5

Configuring Local Presets.................................8-5

Modifying Groupings......................................8-8

Chapter 9 – Adjusting Gain

Chapter 10 – Adding Hardware

Adding Boards .............................................10-2

Input and Output Boards ................................10-2

Vertical Interval Timing Board ............................10-3

Adding Enclosures ..........................................10-5

Appendix A – AutoPatch Service and Returns Policy

Service......................................................A-1

Return Authorizations ....................................A-1

Claims for Shipping Damages .............................A-1

Replacement Policies and Procedures .........................A-2

Special Notice ...............................................A-3

Appendix B – Product Specifications

General .....................................................B-1

Analog Audio ................................................B-2

Standard Audio Boards ...................................B-2

Analog Video ................................................B-3

Standard Video Boards ...................................B-3

Wideband Video Boards ..................................B-4

Ultra-wideband Video Boards..............................B-5

Appendix C – BCS (Basic Control Structure) Commands

Glossary

Index

Installation and Setup Guide

Welcome

Welcome to the 8Y-XL Installation and Setup Guide. This book is the

first part of a three document set:

Installation and Setup Guide – compiled for the technician installing

the system.

User’s Operation Manual – created for the end-user who operates the

system.

Quick Reference Guide – a companion to the User’s Operation Manual.

The 8Y-XL Installation and Setup Guide is designed to provide the

installation technician with quick, easy-to-follow instructions for

installing an 8Y-XL and preparing it for operation.

The 8Y-XL User’s Operation Manual does not include any detailed

information about SBCs (Single Bus Controllers) for the 8Y-XL. Call

AutoAssist for more information about this controller type (see Technical

Support,p.v).

Installation and Setup Guide i

Welcome

Installer’s Product Notes

An 8Y-XL Distribution Matrix can stand alone or comprise a virtually

unlimited number of linked enclosures, including any other AutoPatch

products with an XNNet network compatible interface. Each 8Y-XL

enclosure can hold up to 8 input and 8 output boards and each board can

have up to 8 connectors, for a total capacity of 64 inputs and 64 outputs

per enclosure.

8Y-XL Distribution Matrices fit in a broad range of audio/video

environments and are controllable from a variety of sources, including a

CP-10 Control Panel, a CP-10 Remote Control Panel, any control device

that can send ASCII characters through an RS232 or RS422 serial cable,

a third party serial controller*, a PC, or a Single Bus Controller*.

Tools for Installation:

qA laptop computer with an RS232 or RS422 null modem cable

(communication with the 8Y-XL via a serial port for programming

and fault isolation)

qThe AutoPatch Configuration Software set (which includes copy of

the configuration file) shipped with the system

qThe full set of user documentation shipped with the system

*These control devices are not covered in this document.

ii Installation and Setup Guide

Welcome

Welcome

Meet the Manual

This manual contains 10 chapters and 3 appendices. The information in

this manual progresses from unpacking the 8Y-XL in Chapter 1 to BCS

(Basic Control Structure) commands in Appendix C. Use the following

chapter descriptions to guide you through the manual.

Title Description

Chapter 1

Unpacking the 8Y-XL

äItems included in shipping and unpacking tips

äDescription of the enclosure’s physical features

Chapter 2

Placing the Enclosure(s)

äList of tools needed for installation

äSteps for placing the enclosure(s)

Chapter 3

Linking Enclosures

äInformation on linking enclosures

Chapter 4

Attaching Inputs and Outputs

äDirections for attaching input and output cables

äDirections for paralleling inputs

Chapter 5

Attaching an External Controller

äDirections for attaching an external control

device to an enclosure

Chapter 6

Applying Power and

the Startup Sequence

äDirections for applying power

äStartup sequence from the CP-10 Control Panel

äStartup sequence from a serial control device

Chapter 7

Executing a Test Switch

äDirections for executing a test switch from the

CP-10 Control Panel

äDirections for executing and disconnecting a

test switch using BCS commands

Chapter 8

Managing Configuration Files

äConceptual overview and screen description of

XNConnect

äDirections for installing and launching

XNConnect

äDirections for opening and downloading

configuration files

äDirections for modifying configuration files

Chapter 9

Adjusting Gain

äDirections for adjusting gain

Chapter 10

Adding Hardware

äDirections for adding boards and enclosures to

expand system switching capabilities

Appendix A

AutoPatch Service and

Returns Policy

äDetails regarding AutoPatch Service and

Returns policies

Appendix B

Product Specifications

äTechnical specifications and performance

information

Appendix C

BCS (Basic Control Structure)

Commands

äBCS characters, functions, and descriptions in

chart format

Glossary äDefinitions of terms as they are used in this

manual

Index äIndex of subjects by features and tasks

Installation and Setup Guide iii

Meet the Manual

Welcome

Terms to Know

Before jumping into the technical details of this manual, you should be

familiar with the following terms:

Basic Control Structure (BCS)

BCS is a set of alphanumeric characters that combine to form command

lines. Use BCS to control a system from any serial device that allows you

to enter characters, such as a PC (personal computer).

Configuration File

A configuration file is a text file containing system configuration

information referenced by each enclosure’s CPU during any type of

switch operation. If a system has multiple enclosures linked together,

configuration information uploaded to any 8Y-XL enclosure is

automatically shared with the rest of the linked enclosures in the system.

CP-10 Control Panel

The CP-10 Control Panel is attached to each enclosure and is designed

for system control of the 8Y-XL Distribution Matrix.

ESD

Electrostatic Discharge (ESD) refers to electrical charges (such as static

electricity) that can damage sensitive components inside an enclosure.

The graphic to the left of this definition precedes every procedure where

ESD damage could occur if you are not properly grounded and not

handling components correctly (see the Caution page inside the front

cover of this guide for more details about ESD).

Input and Output Connectors

Input and output connectors are on the rear of an enclosure. Input and

output signal cables attach to the input and output connectors. Standard

8Y-XL audio and data connectors are 3-position terminal block; video

and sync connectors are BNC.

Level

A level is a set of input and output signals that are grouped and,

therefore, switch together. In a configuration file, a level is referred to as

a “virtual matrix.”

iv Installation and Setup Guide

Welcome

Welcome

Signal

A signal can be analog audio, analog video, serial digital, sync

information, or other types. A signal (also called an input or output

signal) comprises of a set of connectors whose signals switch together,

such as an “RGB” signal. To route a specific input (source) signal to a

specific output (destination) device, the input and output signals must be

of the same signal type and share the same level designation.

Switch

A switch is an active connection between an input (source) signal and

one or more output (destination) devices.

XNConnect

XNConnect is graphical software program that displays your most recent

configuration and allows easy addition of local presets and modification

of other configuration information (see the XNConnect Help file for

assistance).

XNNet

XNNet is an internal communication protocol that requires software

driver support for Ethernet and Neuron®interfaces.

Technical Support

AutoPatch provides technical support 24 hours a day, 7 days a week

(except for U.S. holidays). Before calling with a question, please consult

the 8Y-XL documentation. If these manuals cannot fully answer your

question, have your serial number (located on the plate between the

input and output connectors on the rear of the enclosure) ready and call

your authorized AutoPatch dealer or call AutoPatch AutoAssist at: (toll

free for U.S. and Canada) 800-622-0246 or (international) 509-235-2636.

You can also reach us through our web site: www.autopatch.com,or

e-mail our AutoPatch Technical Support Specialists at:

Installation and Setup Guide v

Technical Support

Welcome

Unpacking the 8Y-XL

The 8Y-XL is shipped with one enclosure in each shipping box. Each

box contains one of each of the following items (invoices are sent

separately):

qPower cords (one per enclosure)

qEnclosure

The shipping boxes are marked as “Box #_of_,” where the first blank is

the box number and the second blank is the total number of boxes in the

shipment. Box #1 contains several additional items:

qPacking list

qInstallation and Setup Guide

qUser’s Operation Manual

qQuick Reference Guide (inside binder)

qAutoPatch 8Y-XL Connector and Groupings Guide

qAutoPatch Configuration Software set

qLink cable (included with multi-enclosure systems)

qOther enclosure products

Installation and Setup Guide 1-1

Unpacking

Unpacking Tips

qBefore fully unpacking the enclosure(s), examine the shipping

box(es) for any signs of damage. If a box is partially crushed or any

sides have been broken open, notify the shipping agency

immediately and contact your AutoPatch Salesperson or

Representative.

qOnce unpacking is complete, closely check the physical condition of

the enclosure(s).

qCollect all documentation and envelopes.

Note: AutoPatch is not responsible for damage caused by insufficient

packing during return shipment to the factory. Upon request, AutoPatch

will supply new shipping boxes at cost.

1.1 Front of the Enclosure

Enclosures are the structural basis of an 8Y-XL Distribution Matrix.

Since AutoPatch matrix switchers are custom-built for each installation,

factors such as control method, signal type, and potential switches affect

the appearance and weight of each enclosure.

An enclosure can have a blank front panel or a CP-10 Control Panel (a

front panel that is produced by AutoPatch and has an LCD screen and

keys for entering commands). Although a CP-10 Control Panel is

optional, we recommend one on at least one enclosure in the system for

system verification, redundant control, and troubleshooting. The CP-10

Control Panel can be attached or removed as needed.

1-2 Installation and Setup Guide

Unpacking the 8Y-XL

Unpacking

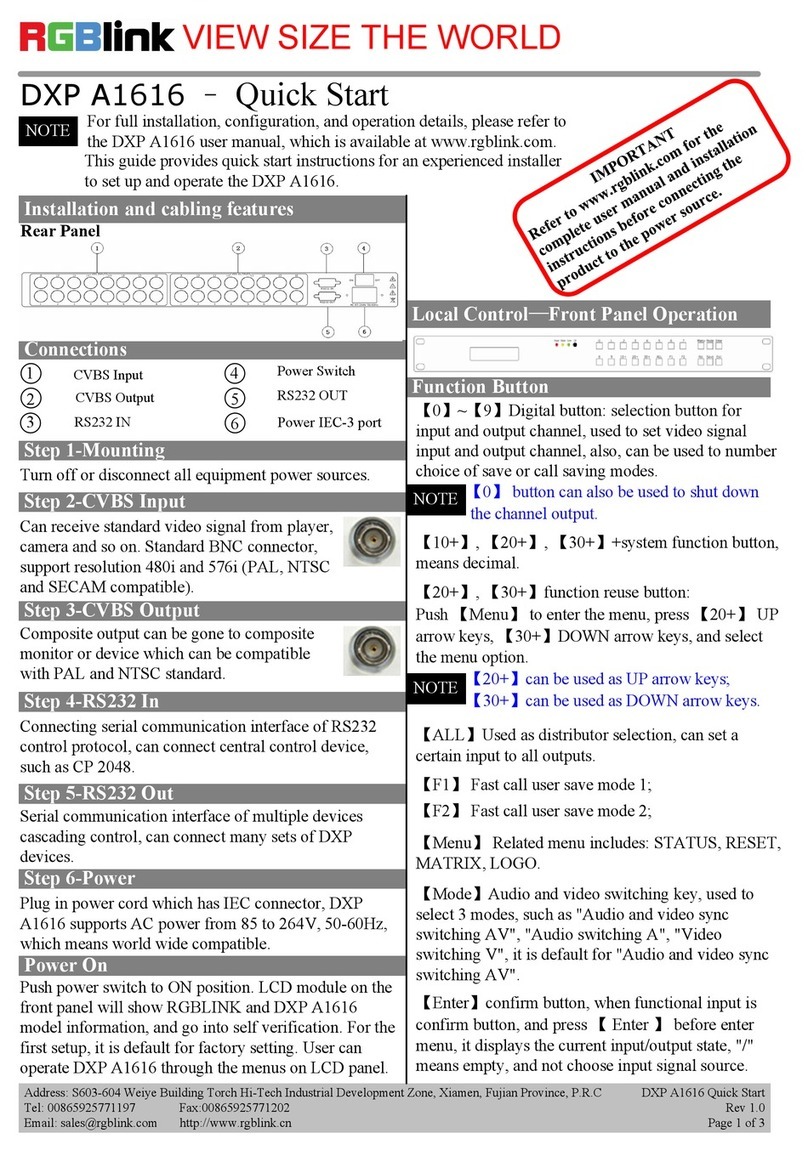

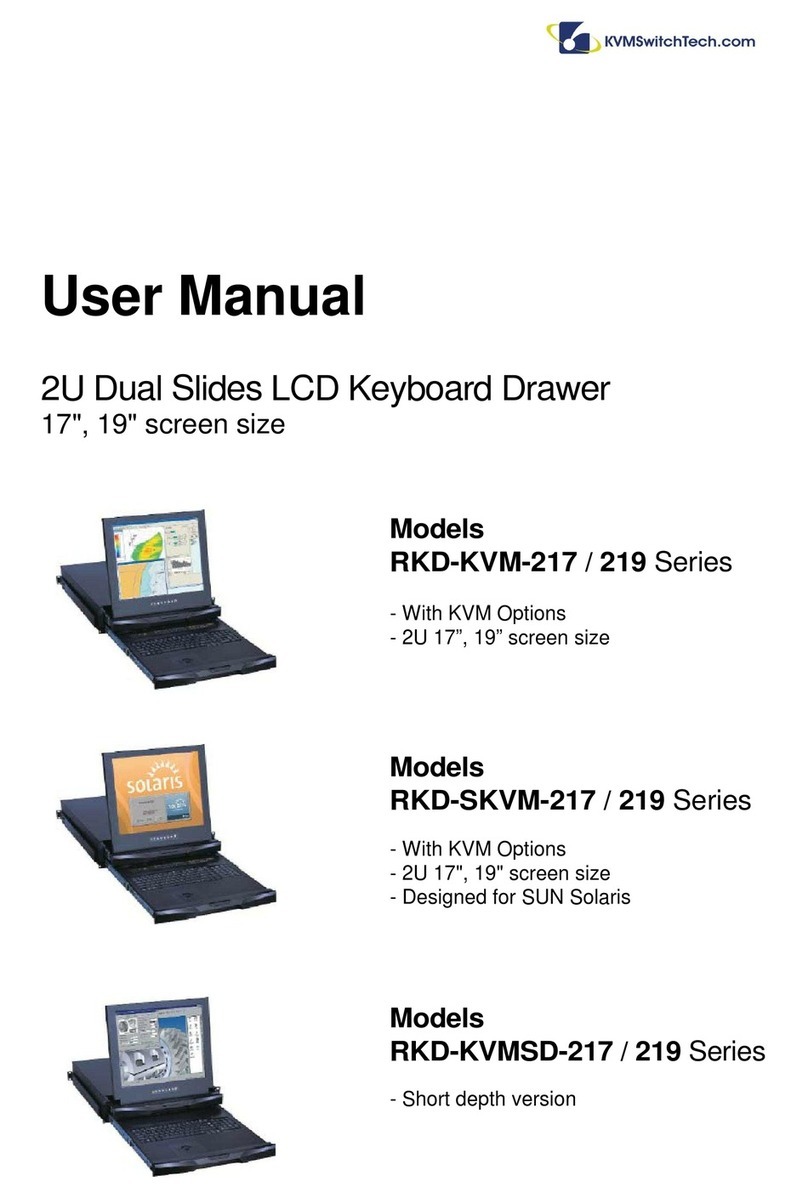

CP-10 Control Panel

A CP-10 Control Panel has 29 keys – 10 number keys for entering digits,

4 directional arrow keys, and 1 each of the following: Cancel, Take,

Status, Level, Change, Input, Output, Preset, Program, Backlight, Space,

Special, Undo, Comma, and Period (the last four are not implemented).

To use the CP-10 Control Panel, use the keys to choose commands and

values from the Command Screen.

To choose a command, push the key that corresponds with the one you

want to choose.

To select values for fields (such as Level, Source, Destination, and

Preset values), use the number keys.

Number Keys (0-9)

Use the number keys to enter digits when choosing front panel menu

items (instead of scrolling down the lists), entering input, output, and

local preset numbers, and entering digits for any other functions that may

require numbers.

Arrow Keys

Use the arrow keys to scroll left and right through long lists of outputs.

The arrow keys are required only when an arrow graphic is displayed on

the front panel’s LCD screen.

Installation and Setup Guide 1-3

Front of the Enclosure

Unpacking

SPECI AL PRESET PROGRAM BACKLI GHT UNDO

TAKE

CA N CEL

SPACE

123

6

54

789

INPUT OUTPUT

STATUS LEVEL CH AN GE

power

Front view of an 8Y-XL enclosure with a CP-10 Control Panel

LCD Screen

Arrow Keys

This manual suits for next models

1

Table of contents

Other AutoPatch Matrix Switcher manuals