AutoPulse 4100-3113AR User manual

Cautions, Warnings, and Regulatory Information

READ AND SAVE THESE INSTRUCTIONS Follow the instructions in this installation manual. These instructions must be followed to avoid damage to

this product and associated equipment. Product operation and reliability depend upon proper installation.

DO NOT INSTALL ANY AUTOPULSE™ PRODUCT THAT APPEARS DAMAGED Upon unpacking your Autopulse product, inspect the

contents of the carton for shipping damage. If damage is apparent, immediately file a claim with the carrier and notify an authorized

Autopulse product supplier.

ELECTRICAL HAZARD Disconnect electrical field power when making any internal adjustments or repairs. All repairs should be

performed by a representative or an authorized agent of your local Autopulse product supplier.

STATIC HAZARD Static electricity can damage components. Handle as follows:

• Ground yourself before opening or installing components.

• Prior to installation, keep components wrapped in anti-static material at all times.

EYE SAFETY HAZARD Under certain fiber optic application conditions, the optical output of this device may exceed eye safety limits. Do

not use magnification (such as a microscope or other focusing equipment) when viewing the output of this device.

SULFURIC ACID WARNING Battery contains sulfuric acid, which can cause severe burns to the skin and eyes and can destroy fabric.

Replace any leaking or damaged battery while wearing appropriate protective gear. If you come in contact with sulfuric acid, immediately

flush skin or eyes with water for 15 minutes and seek immediate medical attention.

FCC RULES AND REGULATIONS – PART 15. This equipment has been tested and found to comply with the limits for a Class A digital device,

pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a commercial environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in

accordance with the instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is

likely to cause harmful interference in which case the user will be required to correct the interference at his own expense.

Introduction

Using the sprinkler card you can provide one isolated IDNet signaling line circuit (SLC), or channel, with up to four isolated loop outputs, to the

sprinkler control panel. With this card, the system CPU can communicate with up to 250 devices, such as the 4098-9748AR Sprinkler Control Heat

Sensor. Isolated IDNet communications provide overall operation improvement and isolated output loops mean that a short circuit on one loop does

not impact the others.

Note: You can purchase the 4100-3111 IDNet Loop Card separately, and pre-install it on a sprinkler card.

Note: For ULC operation, you can only use one loop.

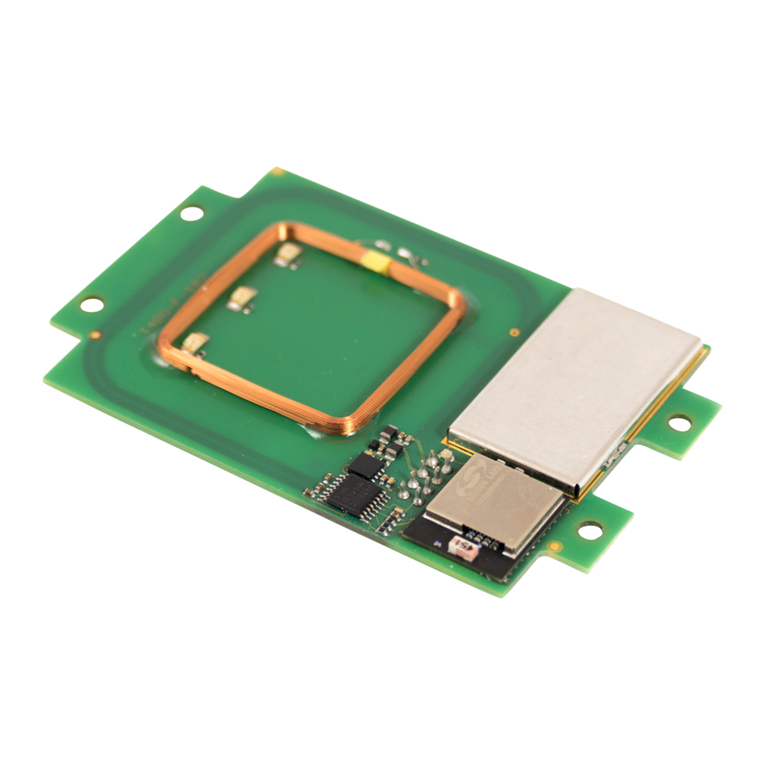

Figure 1: IDNet 2 Sprinkler Card Figure 2: IDNet Loop Card

With the 4100-3113AR IDNet 2 Sprinkler card you can enable the sprinkler control panel with two Class A / DCLA or Class B / DCLB loop outputs that

are isolated from each other.

Important: Verify the sprinkler control panel system programmer, executive, and slave software compatibility when installing or replacing system

components. For information about compatibility, refer to the Software Downloads page under Water Based Fire Protection on the Johnson Controls

Inc. training portal https://www.onlinetechxchange.com/.

579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

*05791214ARB*

Compatibility

Device compatibility:

4098-9748AR Sprinkler Control Heat Sensor

Hardware compatibility:

IDNet 2 Sprinkler Card: EAS-1 bays and ES-PS modules.

Card Layout

The sprinkler card is a standard 4 x 5 card. The sprinkler card can fit two IDNet Loop Cards, see Figure 3.

Figure 3: Card layout

LED definitions

The sprinkler card has 8 LEDs that report the card troubles. Table 1 describes the LEDs.

Table 1: LED definition

LED Name LED Description LED Map

Loop A

Loop B

Loop C

Loop D

When a trouble occurs on a loop, the LED

corresponding to that loop illuminates.

Earth- Normally off. Illuminates to indicate a negative earth

fault.

Earth+ Normally off. Illuminates to indicate a negative earth

fault.

IDNet Normally off. Illuminates to indicate a problem with

the IDNet channel. Steady on indicates channel

failure.

Comms Normally off. Turns on steady if the card is not

communicating with the sprinkler control panel CPU.

Figure 4: LED Map

page 2 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

Setting the address

The DIP switch SW1 is used to set the sprinkler card address as defined in the Autopulse Panel Programmer job, for more information, see

Programming. From left to right, these switches are SW1-1 through SW1-8:

• SW1-1. This switch sets the baud rate for the internal 4100 communications line running between the card and the 4100 CPU. Set this switch

to ON.

• SW1-2 through SW1-8. These switches set the card address within the sprinkler control panel. See Figure 6 for a complete list of the switch

settings for all of the possible card addresses.

You must set these switches to the address that the Autopulse Panel Programmer assigns to the card.

Figure 5: DIP Switch SW1

page 3 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

Figure 6: Sprinkler card addresses

page 4 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

Mounting

The IDNet 2 Sprinkler Card mounts onto the power distribution interface (PDI) in a sprinkler control panel expansion cabinet. You can also install the

sprinkler card in the expansion slot of an ES-PS card.

To mount the IDNet 2 Sprinkler Card Sprinkler Card, complete the following steps:

1. Select an empty PDI connector. Insert the washer and the metal standoffs into the corresponding installation holes.

2. Insert the PDI connector on the back of the card into the PDI connector.

3. Use the provided hardware to secure the card.

Figure 7: Mounting the IDNet 2 Sprinkler Card

To add an IDNet Loop card to a sprinkler card, complete the following steps:

1. Remove the screws that attach the sprinkler card to the panel.

2. Insert the metal standoffs and the plastic standoffs into the corresponding installation holes.

3. Insert the connector on the back of the IDNet loop card into the connector on the sprinkler card, and snap it into place with the plastic

standoff.

4. Use the provided hardware to secure the card.

Note: When adding IDNet Loop Cards to a pre-installed sprinkler card, it is important to update the properties of the sprinkler card in the sprinkler

control panel using the Autopulse Panel Programmer.

Figure 8: Adding IDNet Loop Cards to a sprinkler card

page 5 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

Wiring

You can wire each IDNet output from the sprinkler card, or IDNet Loop Card as either an isolated Class A circuit, or as two isolated Class B circuits.

Class A / DCLA wiring provides an alternate communication path that maintains communication to all devices when a single open circuit fault occurs.

Class A wiring requires two wires routed from the primary terminals (B+, B-) to each device, and then back to the secondary terminals (A+, A-). The

wiring is in/out. T-tapping is not permitted.

Class B / DCLB wiring permits T-tapping. IDNet wiring is inherently supervised due to individual device level communications. End-of-line resistors are

not required.

Ferrite beads

You need to use ferrite beads for field wiring.

1. Install a ferrite bead close to any IDNet field wiring terminals in use (terminals B+/B-, terminals A+/A-) for lowest radiated emissions. Install the

ferrite bead before wires leave the enclosure.

2. Loop both wires (+/-) through the bead as shown in Figure 9.

Figure 9: Ferrite bead installation

Wiring parameters

Table 2 identifies the card wiring parameters that you must consider when installing these cards.

Table 2: Card wiring parameters

Wiring capacitance parameters

Parameter Value

Maximum supported channel capacitance: total of all four

isolated outputs.

The sum of line-to-line capacitance, plus the capacitance of either line-to-shield

(if shield is present) = 0.6 μF (600 nF).

Capacitance between IDNet SLC wiring between wires of the same

polarity: plus to plus, minus to minus.

1 μF maximum (this is for multiple IDNet loops).

Wiring distance limits, see the note below.

Class B wiring, total channel wiring parameters,

including T-Taps

Class A wiring, total channel wiring parametersChannel loading

Up to 125 devices 126 to 250

devices

Up to 125 devices 126 to 250

devices

Total loop resistance 50 Ω maximum 35 Ω maximum 50 Ω maximum 35 Ω maximum

18 AWG (0.82 mm2) 4000 ft (1219 m)

per run, 12,500 ft (3810 m)

total

2500 ft (762 m) per

run, 10,000 ft

(3048 m) total

4000 ft (1219 m)

per loop, 12,500 ft (3810

m) total

2500 ft (762 m)

per loop, 10,000

ft (3048 m) total

16 AWG (1.31 mm2)

14 AWG (2.08 mm2)

12 AWG (3.31mm2)

5000 ft (1524 m)

per run, 12,500 ft (3810 m)

total

2500 ft (762 m) per

run, 10,000 ft

(3048 m) total

5000 ft (1524 m)

per loop, 12,500 ft (3810

m) total

2500 ft (762 m)

per loop, 10,000 ft (3048

m) total

Note: The maximum wiring distance is determined by either reaching the maximum resistance, the maximum capacitance, or the stated maximum

distance, whichever occurs first. Class A maximum distances are to the farthest device on the loop from either B or A terminals. For Class B wiring, the

maximum distance to the farthest device is limited to the stated Class A wiring distances.

Note: External wiring must be shielded for lightning suppression, and 2081-9044 Overvoltage Protectors

must be installed at building exit and entrance locations.

Capacitance: Each protector adds 0.006 μF across the connected line.

Resistance: Each protector adds 3 Ω per line of series resistance: both IDNet lines are protected, 6 Ω per

protector will be added to total loop resistance.

Maximum distance of a single protected wiring run is 3270 ft (1 km).

Wiring considerations using the

2081-9044 Overvoltage Protectors.

2081-9044 is UL listed to Standard

1459, standard for telephone

equipment.

For additional information, refer to 2081-9044 Overvoltage Protector Installation Instructions, 574-832.

page 6 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

Class A / DCLA wiring

To wire the loop terminals as a Class A circuit, complete the following steps:

1. Set the jumper assigned to the loop to the A position, see Figure 10.

- Loop A = Jumper P1 on the Sprinkler Card

- Loop B = Jumper P2 on the Sprinkler Card

- Loop C = Jumper P1 on the first IDNet Loop card

- Loop D = Jumper P1 on the second IDNet Loop card

Figure 10: Class A jumper setting

2. Shielded wire is not recommended. If shielded wires are present, cut and tape off the shield to prevent it coming in contact with other

components.

3. Route the wiring from the primary terminals (B+, B-) to the corresponding inputs on the first device.

4. Route the wiring from the first device to the next device as in/out. See Figure 6. Repeat this step for each device.

5. Route the wiring from the last device to the panel.

6. Connect the wiring to the corresponding secondary terminals (A+, A-).

Figure 11: IDNet loop Class A wiring

Class A wiring notes:

• If there are remote isolators or isolator bases on the loops, you must begin addressing the devices on the B side and assign each successive

isolator a higher address than the isolator that it precedes.

• If there are no remote isolators or isolator bases on the loops, you can assign the device addresses in any sequence.

Class B / DCLB wiring

When wiring the loop for Class B circuits, both the B+, B- and A+, A- terminals are available for parallel connections. In the IDNet circuitry, A+ is

connected to B+, and A- is connected to B- so circuits can stem from either one. In addition, two wires can be connected to each screw terminal.

To wire the loop terminals as a Class B circuit, complete the following steps:

1. Set the jumper assigned to the loop to the B position, see Figure 12.

- Loop 1 = Jumper P1 on the sprinkler card

- Loop 2 = Jumper P2 on the sprinkler card

- Loop 3 = Jumper P1 on the left IDNet Loop Card

page 7 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

- Loop 4 = Jumper P1 on the right IDNet Loop Card

Figure 12: Class B jumper setting

2. Route the wiring from the primary terminals (B+, B-) to the corresponding inputs on the first device.

Note: When using Class B wiring, you can add up to four circuits for each IDNet loop on the terminal block, see Figure 13.

3. Route the wiring from the first device to the next as in/out, see Figure 13. Repeat this step for each device.

Figure 13: IDNet loop Class B wiring

Class B wiring notes:

• If there are remote isolators or isolator bases on the loops, you must begin addressing the devices on the output and assign each successive

isolator a higher address than the isolator it precedes. For Class B wiring only, the A output and B output of a loop are connected in parallel for

wiring convenience.

• If there are no remote isolators or isolator bases on the loops, you can assign the device addresses in any sequence.

Programming

Adding the sprinkler card using the

Add the sprinkler card to the sprinkler control panel using the Panel Programmer.

To add the sprinkler card using the Panel Programmer, complete the following steps:

1. Launch the Panel Programmer software.

2. Create a job, or open an existing job.

3. Click the Hardware tab.

4. In the Hardware Configuration area, expand the Unit, Box and Bay configuration where you want to add the card.

5. In the Available Hardware area, expand the INTERFACE option. Drag the 4100-3113AR IDNet 2 Sprinkler card to the bay in the Hardware

Configuration area.

page 8 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

6. Double-click the 4100-3113AR IDNet 2 Sprinkler card in the Hardware Configuration area to open the Card Properties, Point Editing

and Loop Editing tabs. See Configuring the Card Properties tab for more information.

Configuring the Card Properties tab

Double-click the 4100-3113AR IDNet 2 Sprinkler card in the Hardware Configuration area to open the Card Properties tab.

Enter the appropriate information in the following fields:

• Card Address.*

• Card Description.

• Card Default label.

• Card Custom Label: Use this field to describe the card function, location, or other descriptive information.

• Card Alternate Custom Label: Use this field to enter an alternative description of the card.

• Annunciator: This field indicates which annunciator the card is associated with.

• Unit, Bay, and Box.*

• Location.*

• 24 V Alarm and Standby current (Amps).

* You can modify the default data manually. To avoid an error, ensure that the information you enter matches the data programmed in the sprinkler

control panel.

Configuring the Point Editing tab

Use the Point Editing tab to manage and edit the point types that correspond to the devices on the IDNet loop. Configure the Sprinkler Heat Sensors

at the desired addresses by selecting the SPRNKLR device type. The point type defaults to SUPV and cannot be changed.

Configuring the Loop Editing tab

When you add the sprinkler card to the sprinkler control panel, the Autopulse Panel Programmer programmer automatically reserves four addresses

for the four potential loops:

• Loop 1: Point 251

• Loop 2: Point 252

• Loop 3: Point 253

• Loop 4: Point 254

The device type for both Loop 1 and Loop 2 is set to ISO, you cannot edit this.

The device type for Loop 3 and Loop 4 is set to UNUSED by default. You must set this to ISO to activated these loops.

When the device is determined, complete the entries for the Custom Label, Alternate Custom Label, Primary Action Message, and Trouble

Action Message fields.

Troubleshooting

See the following tables for a list of error messages that can appear on the sprinkler control panel display when using the sprinkler card:

Table 3: Trouble messages

Trouble message Possible cause

Extra Device This message appears when one or more extra devices, or devices that have not been configured for the IDNet

channel, are found on the system. This message also appears when a device is at the incorrect address.

Note: An extra device on address 253 or 254 indicates that a loop module has been detected but not programmed.

Only one trouble message appears, regardless of the number of extra devices in the system. View the trouble log to

see the extra device address. LEDs on devices illuminate steady to indicate the trouble, as long as there are no alarms

in the system.

Wrong Device This message appears when the device detected at the address does not match the device type that is programmed in

the system.

Earth Fault Search This message appears when the sprinkler card is searching for earth faults on the IDNet channel. When this message

displays, the IDNet 2 Sprinkler Card cannot show any alarms or other statuses.

Channel Fail This message appears when the devices are configured, but none of the devices are communicating on the channel.

This message does not appear if there are no configured devices on the IDNet channel.

No Answer This message appears when a device is missing, damaged, or improperly configured, or when duplicate devices are

present.

Note: A No Answer trouble on address 253 or 254 indicates that a loop module has been programmed but not

detected.

Bad Answer This message appears when there is a faulty device, a noisy communications channel, or duplicate devices present.

Output Abnormal This message appears during any of the following conditions:

• When 24 V is not present on IDNet devices, MBZAM and MAZAM devices for example.

• When TrueAlarm sensor bases with relay driver outputs are not supervised.

• When isolator devices are in isolation mode.

See the panel diagnostics for additional troubleshooting information about duplicate devices, weak answers, and other problems.

page 9 579-1214AR Rev. B

4100-3113AR IDNet 2 Sprinkler Card, and 4100-3111 IDNet Loop Card Installation Instructions

Table 4: Loop troubles

All loop statuses report on the isolator points, unlike the IDNet 2 Sprinkler Card where card status points are used to report the short and open

statuses of the loops.

Supported loop statuses: • Loop connected OFF

• Loop isolated ON

• Break in loop wiring OPEN CKT TROUBLE

• Short circuit SHORT CKT TROUBLE

You can make isolator devices public on the network, so that the loop status is available at external nodes, instead of reporting in the common trouble

point.

• If expansion loop cards are programmed but not connected, No Answer troubles indicate for those devices.

• If the loop card is present but not programmed, an Extra Device card status trouble indicates for the card, and the appropriate address is

logged in the trouble log: 253, 254, or both.

Card specifications

Table 5: Sprinkler card specifications

Operating conditions:

Operating temperature range 32°F - 120°F (0°C - 49°C).

Operating humidity range Up to 93% relative humidity at 90°F (32°C), non-condensing.

Electrical specifications:

Channel voltage to remote devices 30 VDC (normal): 35 VDC maximum.

During an alarm or when activating large quantity of device outputs, the channel output voltage is

increased to 35 VDC. The data rate is 3333 bps.

Output circuits are supervised and power-limited.

Earth detection threshold 10k ohms minimum from either positive or negative terminals.

Card supply requirements 19.5 V - 32 V / 350 mA maximum. 100 mA for the first device,

0.8 mA for each additional IDNet device.

Comm wiring distance See Table 2.

Table 6: IDNet loop card specifications

Operating conditions:

Operating temperature range 32°F - 120°F (0°C - 49°C).

Operating humidity range Up to 93% relative humidity at 90°F (32°C), non-condensing.

Electrical specifications:

Channel voltage to remote devices 30 VDC (normal): 35 VDC maximum.

During an alarm or when activating large quantity of device outputs, the channel output voltage is

increased to 35 VDC.

The data rate is 3333 bps.

Output circuits are supervised and power-limited.

Earth detection threshold 10k ohms minimum from either positive or negative terminals.

Card supply requirements 19.5 V - 32 V.

Comm wiring distance See Table 2.

579-1214AR Rev. B

© 2021 Johnson Controls. All rights reserved. All specifications and other information shown were current as of document revision and are subject to change without notice. Additional listings may be applicable, contact your local

AUTOPULSE® product supplier for the latest status. Listings and approvals and the product names listed in this material are marks and/or registered marks. Unauthorized use is strictly prohibited. NFPA 72 and National Fire Alarm Code are

registered trademarks of the National Fire Protection Association (NFPA).

This manual suits for next models

1

Table of contents

Popular Control Unit manuals by other brands

Greystone Energy Systems

Greystone Energy Systems GT-ARES Series installation instructions

Siemens

Siemens SIMOTION D4 Series Equipment manual

Motion Control Engineering

Motion Control Engineering Nidec Element Series manual

Pneumax

Pneumax 2 SAFELI 412/2 Series Installation, Use and Maintenance Instruction

KLINGER

KLINGER KVN Series Standard Operation Manual

Toshiba

Toshiba RBM-PMV0363E, RBM-PMV0903E installation manual