AutoTest BAMbino User manual

User Manual

Version 4.1

AUTO

Test

BAMbino

Bearing Acoustic Monitor

10242

Table of Contents

1. Unpacking and First Time Use.......................................................1

2. Background Information ................................................................1

2.1 Application............................................................................................1

2.2 Measurement Distance.........................................................................2

2.3 Modes of Operation..............................................................................2

2.4 What is BAMbino listening to? ...........................................................3

2.5 Hardware/Software..............................................................................4

3. Getting Started- A Quick Overview.................................................5

3.1 Conventions...........................................................................................6

3.2 Default Factory Settings.......................................................................6

3.3 A Quick Lesson.....................................................................................6

3.2 Starting Your Routine Inspection .....................................................10

4. BAMbino –A Complete Guide......................................................13

4.1 Set up locations, conveyors and roller speed (Conveyor Set-up).....13

4.2 Shift Key .............................................................................................17

4.3 Monitoring..........................................................................................17

4.4 Entering Notes....................................................................................20

4.5 Diagnose..............................................................................................20

4.6 Changing Location.............................................................................22

4.7 Checking the Battery Voltage............................................................23

4.8 Adjusting The Contrast......................................................................24

4.9 Using a Smart Card............................................................................24

4.10 Clearing the Memory .......................................................................27

4.11 Using a computer..............................................................................27

4.12 Setting the time and date..................................................................30

4.13 Connecting Microphone...................................................................31

4.14 Changing Battery .............................................................................32

6. Calibration and Service.................................................................33

6.1 Packaging............................................................................................33

6.2 Shipping ..............................................................................................33

8. SPECIFICATIONS.......................................................................34

9. Troubleshooting and FAQ ............................................................35

10. WARRANTY................................................................................40

11. WARRANTY REGISTRATION FORM .....................................40

12. SPARE PARTS............................................................................41

BAMbino User Manual, Model 915978, Version 4.1 Page 1of 45

1. UNPACKING AND FIRST TIME USE

Congratulations on your choice of the AUTOSTOP™ BAMbino. Please take

the time to read this User’s Manual before using the BAMbino in the field.

Incorrect or inappropriate use of this instrument may void the warranty.

Retain the packing materials for future shipping and transport of the unit for

periodic calibration.

The packing box containing your AUTOSTOP™ BAMbino contains:

•AUTOSTOP™ BAMbino, Model 915978

•Microphone

•240VAC to 12VDC power pack

•User manual.

•Serial Cable

•Software CD

•Smart Card

2. BACKGROUND INFORMATION

2.1 Application

The BAMbino is a hand-held, stand-alone portable instrument for the

remote detection and analysis of faulty conveyor idler bearings. It uses

advanced signal processing techniques to scan ambient conveyor noise to:

•Detect bearing faults

•Detect build-up on rollers

•Screen out extraneous noise to eliminate false alarms

The Fault Detection Technique uses Roller Speed to distinguish various

bearing fault types whilst detailed knowledge of the actual bearing type is

not required.

Input parameters Incorporating Roller speed can be pre-programmed for

up to 8 locations and 2 sub locations, thus eliminating the need to input data

into the instrument whilst scanning the conveyer.

Location is a database of stored parameters that can be pre-programmed,

from which the operator chooses the required set for his current testing

location. There are 8 locations and 2 sub locations enabled for use, all of

BAMbino User Manual, Model 915978, Version 4.1 Page 2of 45

which are user named. See Section 5 for how to set the individual location

parameters.

On “Power Up”, the operator is only required to select Monitoring and then

choose a Location.

By default BAMbino is programmed for the whole range of bearings used on

standard idlers in conveyors in the Australian mining industry. There will be

exceptions, in particular for older conveyors, but AUTOTEST can re-

program the unit to suit the application if the exact bearing details are

submitted with the order prior to shipment.

2.2 Measurement Distance

BAMbino only needs to “see” one side of the

conveyor to measure all bearings on the carry and

return idlers. It can detect faulty bearings within a

range of up to three metres. This is possible due to

the distinctive signature that faulty bearings emit

and can be discerned even in environments

possessing high-level ambient noise.

2.3 Modes of Operation

To achieve high execution speed and accuracy,

the instrument has three operational modes: A

Scan mode, both fast and slow and a Diagnosis

mode. The operator uses the Scan mode to

sample data as he walks along the conveyor. This

is a “quick look” mode of operation that is used for quickly indicating the

presence of a faulty bearing. When the instrument detects a noise that is

characteristic of a faulty roller, an alarm is set off and the operator would

then stop and mark the roller. There is a note pad facility to allow the user to

write a comment, and the operator also has the ability to enter the diagnosis

mode to display an instantaneous frequency spectrum of the faulty bearing.

The Bambino takes about 1.7 seconds to compute the noise data, and

signals the operator, it does this continuously, thus the operator can walk

along the conveyer at approximately 2 Km/H.

BAMbino User Manual, Model 915978, Version 4.1 Page 3of 45

2.4 What is BAMbino listening to?

In short EVERYTHING. BAMbino’s sensitive microphone accepts all

sounds from the environment. The software analysis program breaks the

sounds into components and tests these components for the characteristics

found in faulty bearings.

Sit quietly as you read this manual and listen to all those background

sounds. You can choose which ones to listen to and which ones to ignore.

BAMbino is trained to listen to them all and to search for certain

characteristics. BAMbino may find those characteristics in ordinary sounds

like -

Motorbike exhausts Tonal Harmonics

Diesel engines Tonal Harmonics

Voices Tonal Harmonics

Keyboard typing Repetitive Impulses

Note: BAMbino can discern acoustic signals that trigger the alarm even

when our own ears sometimes do not. Remember that BAMbino is not

searching for a sound of some loudness, but for one having the

characteristic signature of a bearing fault. If BAMbino finds such a sound

that has sufficiently distinctive character, then it will trigger its alarm. It is

possible to trigger BAMbino with some distinctive voice input.

BAMbino User Manual, Model 915978, Version 4.1 Page 4of 45

2.5 Hardware/Software

BAMbino relies entirely upon signal processing software embedded into the

instrument to carry out its functions. It provides an instant audible and/or

visual alarm as well as a visible ranking of fault severity. The degree of

severity of the characteristic sounds detected are listed on the screen

during operation, and continuously updated:

•Bearing OK No alarm Normal, no fault detected

•Bearing Faulty Alarm Fault level signal detected

•Overload Acoustic Signal To Large

Note: If a fault is found the user may record a note and save it to memory

for later retrieval on a computer.

BAMbino User Manual, Model 915978, Version 4.1 Page 5of 45

3. GETTING STARTED- A QUICK OVERVIEW

Keypad Functions

Alpha Keys A

through Z for

Entering Location

Names and data

during setup, also for

adding notes during

monitoring

Keys can be used

with either case by

pushing the shift key

D key used to

decrease the trigger

count in the

monitoring mode

Up arrow Key used

in menus to select

line items, also used

to adjust the gain in

monitor and

Diagnose.

Right arrow Key

Used to select

location or in

conjunction with the

shift key to adjust the

LCD contrast

Shift Key changes

the case of alpha

keys and allows

arrow keys to

change function

U key used to

increase the

trigger count in the

monitoring mode

Left arrow Key Used

to select location or

in conjunction with

the shift key to adjust

the LCD contrast

Down arrow Key

used in menus to

select line items,

also used to adjust

the gain in monitor

and Diagnose

E key used to

show the

extended signal

information

M key used to

select the monitor

mode Fast or Slow

BAMbino User Manual, Model 915978, Version 4.1 Page 6of 45

3.1 Conventions

In this manual the following symbol indicates a keypad function (push this

button):

Words in italics are menu list names.

To implement the instruction on the screen, or to go one more level down

the menu, touch

3.2 Default Factory Settings

The BAMbino is delivered with the following Default Factory Settings which

are identical for all 12 Locations:

•Location Name: Location 1

•Conveyer1: Conveyer 1

oAlarm Band: 6-30 Hz

•Trigger: 9.0dB

•Gain 80%

3.3 A Quick Lesson

Touch the button.

The unit will beep and the display brings up the ‘Logo screen:

After a few seconds the Start-up screen will be displayed:

ENTER

ON/OFF

BAMbino User Manual, Model 915978, Version 4.1 Page 7of 45

The software version is identified with the “Version No:”. The serial no of the

unit is also displayed. Wait approximately 5 seconds for all of the software

routines to load and to run a self-check.

The unit then goes straight into its menu Mode.

Selecting Monitor from the menu readies the BAMbino for use and defaults

to the Location that was active before the last power-off.

Within one second BAMbino will be scanning its acoustic environment,

listening for noises characteristic of bearing faults with the settings of the

Active Location.

BAMbino User Manual, Model 915978, Version 4.1 Page 8of 45

An example of operation mode screen display would appear as shown

below.

NOTE: The level bar indicates that the gain is to low, the user should

increase the gain setting by pressing the up arrow (2) to increase

the gain within the OK bands.

Press the button to increase the Gain.

Press the button to decrease the Gain.

The Gain numerical value will decrease in steps of 2, i.e. 94 down to 92.

As the Gain increases the BAMbino may trigger an alarm mode. If this

occurs decrease the gain by pressing the down arrow key. For optimal

performance the gain should be set within the ok band.

2

8

Location

Indicator

Alarm Light

Bearing

Fault

Indicator

Battery level

indicator

Gain and trigger

information and

MODE indicator

Extended

Signal

information

Level Bar,

signal should

be between the

‘OK’ markers

BAMbino User Manual, Model 915978, Version 4.1 Page 9of 45

To change to another location or conveyer press

By pressing the right arrow key the BAMbino will scroll through all 8

locations and all 16 conveyers allowing you to select the right setup. When

the BAMbino is powered up it will always return to the last used location.

During your scanning if the BAMbino alerts you of a faulty bearing then you

may be required to mark the location, if you press

The BAMbino will take you to a text entry screen.

This input screen allows you to make a note and save it with a date stamp

to memory for later retrieval on a computer.

Once you have entered your note, press

This will save the note and return you to

the main menu.

That’s all you will need to do during a routine inspection, i.e. using “ENTER”

to save a note in BAMbino upon alarm. No parameter entry and no gain

setting is required. BAMbino is able to accommodate a wide range of signal

levels, so generally you only have to set the gain once for each conveyor,

however if the distance changes significantly or the background noise

changes you may have to adjust the gain up or down accordingly.

Before you start using BAMbino you need to set it up to suit your needs.

BAMbino’s software architecture allows set-ups to be made 2 different

ways:

Method 1: the user can load the details of their locations and conveyers

from the smartcard. Autotest can supply pre-programmed Cards

according to the users specification.

Method 2: the user can enter the details directly into the BAMbino using

the setup Menu. This then allows the user to save this on a

smartcard for later retrieval.

6 >

ENTER

ENTER

BAMbino User Manual, Model 915978, Version 4.1 Page 10 of 45

3.2 Starting Your Routine Inspection

If BAMbino has already been set-up for your conveyors (i.e. Roller

speed and Location name), you can start your inspection straight

away, as no data input is required.

1. Switch ON instrument, wait for User Menu.

2. At the USER MENU screen touch the

button.

3. You can scroll through the 16

Conveyors by touching either

4. Start walking at normal pace pointing BAMbino toward the belt at a

distance of 1-2 m. When an alarm is triggered on BAMbino, stop

walking.

5. If the alarm stays ON, it means that a faulty bearing has been

detected within a 3m radius from this position.

Walk back one idler set and take another reading. If the alarm comes

ON, walk back another idler set and repeat as above. When the alarm

no longer comes ON, the faulty bearing is out of range. Pace 1 m from

your position and the idler with the faulty bearing is the farthest. Tag this

module and continue your inspection. If the alarm is still erratic you can

select Slow Mode by pressing

You must then wait for about 5 seconds for the BAMbino measure the

bearing. If the alarm is still active then you have found a faulty bearing

You can move closer to identify exactly which bearing or roller is causing

the alarm, and then press

A notation can then be entered detailing where and what the fault is, this

is automatically date stamped, and can be uploaded to a computer at a

later date and continue your inspection. Should you wish to add a note

press enter from the monitoring screen, the display will look like this:

ENTER

< 4

6 >

M

ENTER

BAMbino User Manual, Model 915978, Version 4.1 Page 11 of 45

The text note will be stored in the BAMbino’s internal memory, it is

stamped with the time and date in addition to the location and conveyor

name.

If BAMbino has not been set-up for your conveyors, you will need to

enter the roller speed before you start your inspection. Enter these

parameters as explained in Section 5 and then proceed as above.

Quick Notes (see FAQ for more details):

1. Belt speed must be accurate to within 5%. If not sure what it is,

measure it.

2. When an alarm is triggered but is not confirmed in a second

measurement ignore it. This may be due to:

a) the bearing fault being marginal and thus the severity level

being borderline between “Bearing OK” and “Bearing

Faulty”.

b) the alarm was triggered by a transient such as a belt splice

pass-by, a loud voice, a loud sound from an impact, etc.

c) the BAMbino’s gain is set too high and the overload

indicator is on.

Location to

which the

note is

attached

Remaining

internal memory

Text Body

BAMbino User Manual, Model 915978, Version 4.1 Page 12 of 45

3. Alternatively you can select slow mode and take a more accurate

measurement, in slow mode the Bambino takes measures a lot

more information and provides a more accurate reading, however it

takes a lot longer to measure (about 5 seconds) so you must

remain still will it measures the roller set.

4. You are near a noisy roller, which you think it’s faulty but BAMbino

is not picking it up. What do you do? BAMbino scans noise for

bearing faults and roller build-up only. The noise you are hearing is

probably not due to a faulty bearing. It could be looseness, a

squeaking seal, a worn shaft rattling in its support, etc. You should

still tag this module but use a different tag to differentiate it from

those with faulty bearings.

BAMbino User Manual, Model 915978, Version 4.1 Page 13 of 45

4. BAMbino –A COMPLETE GUIDE

The User Menu is accessible after switching the BAMbino on and allows the

user to do the following:

−Select Monitoring mode

−Diagnose a bearing

−Set up locations, conveyors and roller speed

−Upload to Computer

−Clear Memory

−Read from Smartcard

−Save to Smartcard

−Set date and time

To access this menu, Switch ON the instrument.

The unit will display:

Scroll through the menu using the

arrow buttons.

To select an item press

4.1 Set up locations, conveyors and roller speed

(Conveyor Set-up)

Access the User Menu and scroll down the list.

8

2

or

ENTER

BAMbino User Manual, Model 915978, Version 4.1 Page 14 of 45

At Settings press the button to select, and the unit will

indicate:

Scroll through the Locations using

the arrow buttons.

To select the Location press

Location is a database of stored parameters that can be pre programmed,

from which the operator chooses the required set for his current testing

location. There are 8 locations enabled for use each with 2 conveyers. All

are user named. See section 5 below for how to set the individual location

parameters.

Once a location has been selected the cursor will highlight the first

character of the location name. You can overtype the location name in this

space, to select an uppercase letter press the shift key,

An S will be displayed next to the battery indicator informing you that

shifted characters are enabled. To reselect lower case characters you will

ENTER

8

or

2

ENTER

SHIFT

BAMbino User Manual, Model 915978, Version 4.1 Page 15 of 45

need to press the shift key again. The location name is limited to 15

characters.

After you have entered the location name press

the unit will indicate:

Scroll through the Conveyers using the arrow buttons.

To select the Conveyer press

Once a conveyor has been selected the cursor will highlight the first

character of the conveyor name. You can overtype the location name in this

space, to select an uppercase letter press the shift key,

An S will be displayed next to the battery indicator informing you that

shifted characters are enabled. To reselect lower case characters you will

need to press the shift key again. The Conveyor name is limited to 15

characters.

After you have entered the Conveyor name

press

The unit will indicate:

ENTER

2

8

or

ENTER

SHIFT

ENTER

BAMbino User Manual, Model 915978, Version 4.1 Page 16 of 45

Scroll through the Alarm Bands using the arrow buttons.

Select an appropriate alarm band, to do this you will need to know the belt

speed and from that information calculate the band.

The formula is BELT SPEED (m/s)

3.14x Roller Diameter (m)

The lower alarm band threshold should be as close to the roller speed as

possible, for example a speed of 4 Hz would translate to a band setting of 6

- x, while a speed of 9 would require a band setting of 8 –x

The upper band limit should be set as close to three times the roller speed

as possible for example 6 Hz would give an upper band setting of 6 - 30

Once the alarm band has been determined press

You will be returned to the main user menu, to setup additional conveyers

repeat the steps above.

2

8

or

ENTER

BAMbino User Manual, Model 915978, Version 4.1 Page 17 of 45

4.2 Shift Key

The shift key allows the user to select upper case and lower case

alphabetic characters, it also allows the Screen contrast to be adjusted

when used in conjunction with the left and right arrow keys (see 4.3).

Pressing the

Key

Will activate the shift mode and is denoted on the display by an uppercase

S in the bottom left of the display. To deactivate the Shift mode press the

key again.

4.3 Monitoring

Selecting Monitor from the menu readies the BAMbino for use and defaults

to the Location that was active before the last power-off.

SHIFT

Uppercase

S denotes

shift mode

activated

Table of contents

Other AutoTest Measuring Instrument manuals

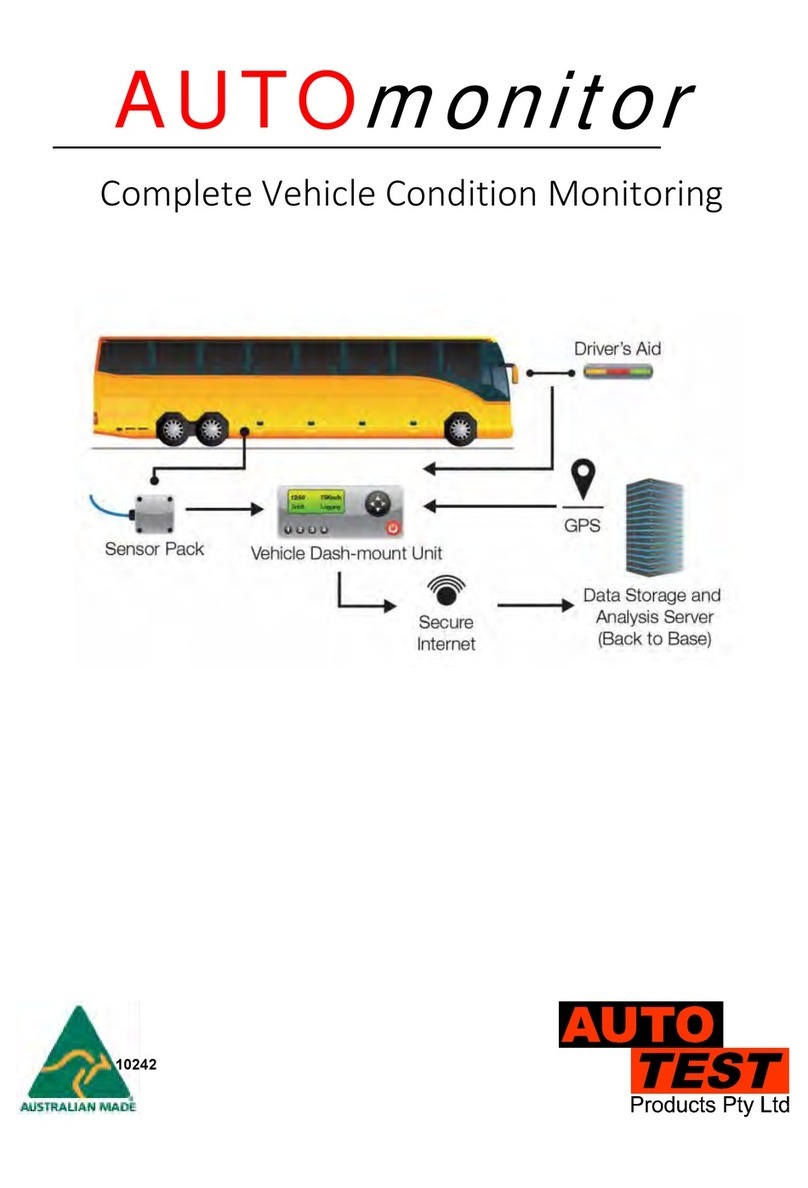

AutoTest

AutoTest AUTOmonitor User manual

AutoTest

AutoTest AutoLight User manual

AutoTest

AutoTest Battery Analyzer User manual

AutoTest

AutoTest AutoLight PLUS MAGNETIC User manual

AutoTest

AutoTest Brake Fluid Tester User manual

AutoTest

AutoTest AUTOSTOP User manual

AutoTest

AutoTest Digital Sound Level Meter User manual

AutoTest

AutoTest AUTOLIGHT PLUS User manual

Popular Measuring Instrument manuals by other brands

Konica Minolta

Konica Minolta bizhub C3100i user guide

Water I.D.

Water I.D. PoolLAB 1.0 user manual

Hanna Instruments

Hanna Instruments HI 96706C instruction manual

Somogyi Elektronic

Somogyi Elektronic home M 266AC instruction manual

Ultraflux

Ultraflux Minisonic_600-2 user manual

MULTISPAN

MULTISPAN AVF-19N manual