AutoTwirler Pro Rotisserie User manual

FRONT

REAR

STRAP STRAP

DO NOT STRAP

THIS WAY!

DO NOT STRAP

THIS WAY!

STRAP STRAP

STRAP

TRAILER TIEDOWN INSTRUCTIONS

1. POSITION THE ROTISSERIE CENTERED ON THE TRAILER AND SET THE CASTER WHEEL LOCKS.

2. ATTACH TIE DOWN STRAP TO THE BASE OF THE ROTISSERIE UPRIGHT THAT IS ON THE REAR END OF THE TRAILER.

CONNECT THE OPPOSITE END OF THE STRAP TO THE FRONT OF THE TRAILER.

3. ATTACH TIE DOWN STRAP TO THE BASE OF THE ROTISSERIE UPRIGHT THAT IS ON THE FRONT END OF THE TRAILER.

CONNECT THE OPPOSITE END OF THE STRAP TO THE REAR OF THE TRAILER.

4. WITH BOTH STRAPS ATTACHED AND PULLING THE ROTISSERIE INTO ITSELF, TIGHTEN THE STRAPS AND

MAKE SURE THE STRAPS ARE SUCURE FOR SAFE TRANSPORTATION OF THE ROTISSERIE.

5. AFTER SECURING THE ROTISSERIE BY THE FRONT AND REAR, STRAP BASE OF ROTISSERIE FROM SIDE TO SIDE ON

TRAILER SO THE ROTISSERIE CAN NOT MOVE IN ANY DIRECTION.

675 N 600 W STE 2 LOGAN UT. 84321

email: [email protected] website: www.autotwirler.com

phone #: 1 (435) 752-3921

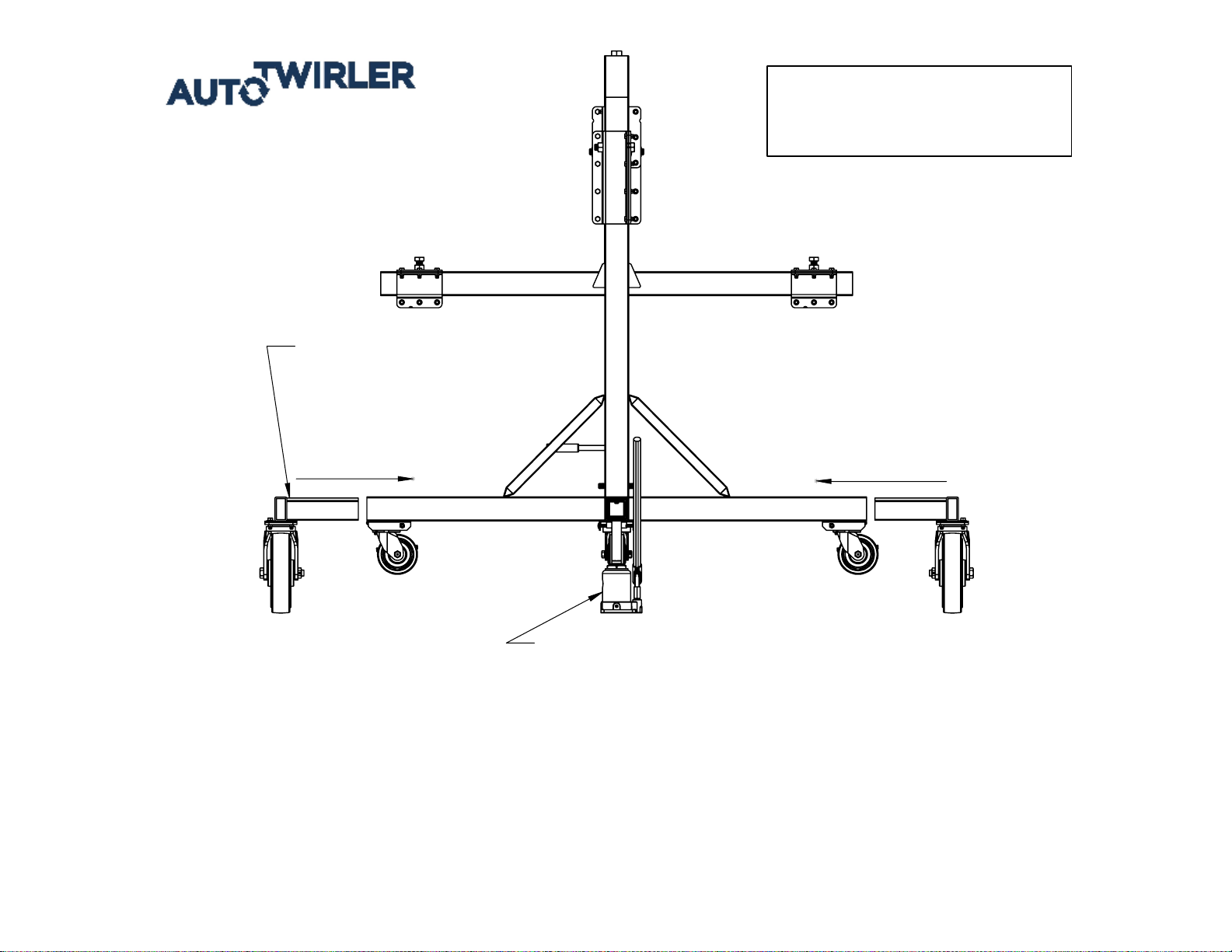

ATTENTION WITH WHEEL

KIT INSTALLED WEIGHT

LIMIT IS 1650LB

SEE DETAIL A

SEE DETAIL B

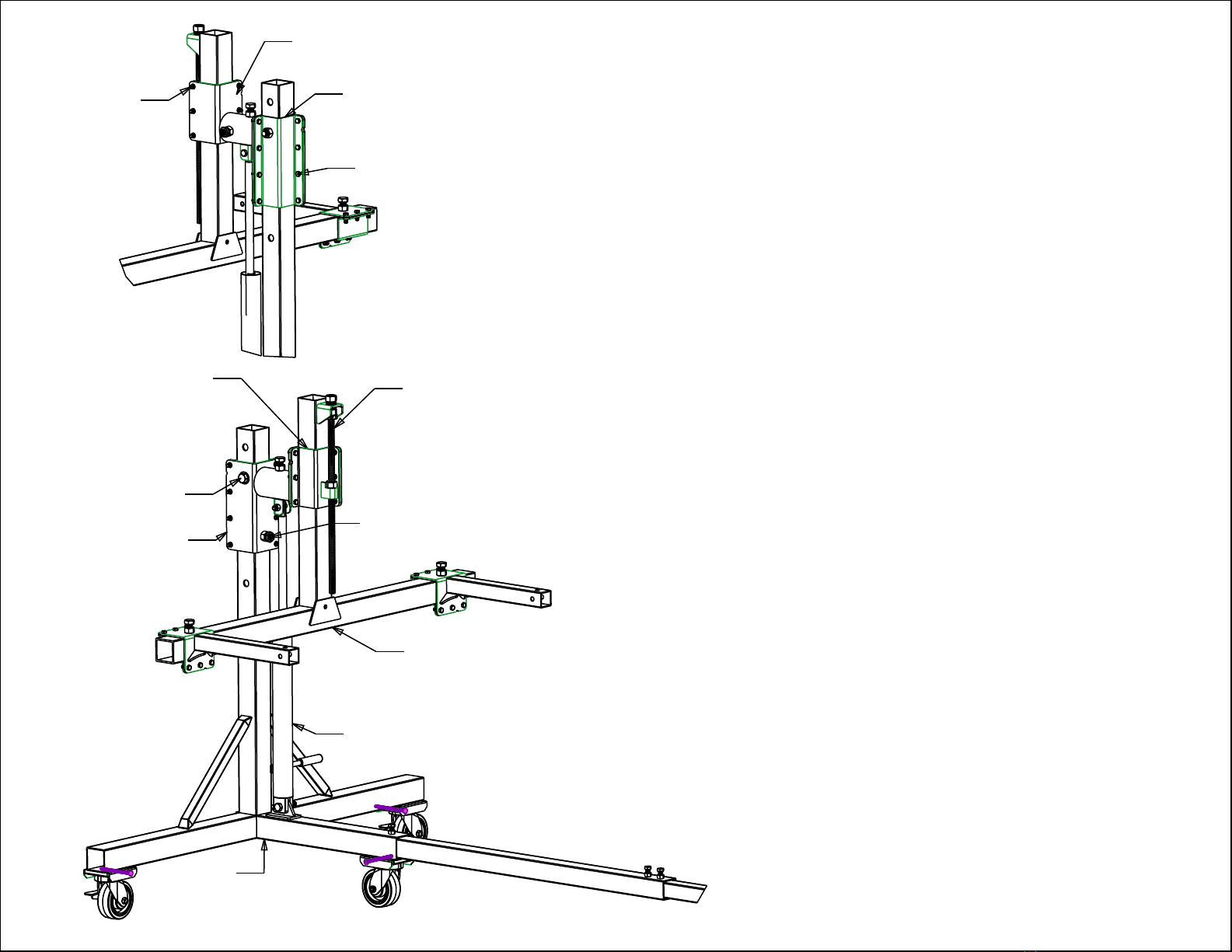

STAND

T-ARM

STAND HYDRAULIC JACK

T-ARM BALANCER

"W" BRACKET

STAND HEIGHT TRAVEL BEARING

3/4" X 4 1/2" BOLT

ACME THREADED ROD JACK

STAND OUTER PIVOT

L-BRACKET

STAND OUTER PIVOT

"W" BRACKET

3/8" X 1" BOLT

3/8" x 1" BOLT

T-ARM BALANCER

L-BRACKET Auto Twirler Jack Instructions

Adjusting the Stand Hydraulic Jack

1. Before you raise or lower the Auto Twirler Pro or

Elite you need to remove the 3/4” x 4 1/2” bolt with

accompanying nut and washer.

2. Loosen all eight 3/8” x 1” bolt and nuts located on the

L & W bracket clamp. Loosen them just enough to

allow the jack to be able to raise or lower.

3. Adjust the rotisserie to the height desired. Reinsert the

3/4” x 4 1/2” bolt with accompanying nut and washer,

make sure it is securely tightened.

4. Re-tighten all eight of the 3/8” x 1” bolts and nuts to

cause the L & W bracket to clamp down securely to the

Stand.

5. Readjust the Height Travel Bearing by snugging it up

and then backing it off ¼ turn and locking the bolt

down with the lock nut.

Adjusting the T-Arm Jack

1. Loosen all six 3/8” x 1” bolt and nuts located on the L & W

bracket clamp. Loosen them just enough to allow the jack to be

able to raise or lower.

2. To move the jack turn the Acme nut that is welded to the top of

the Acme threaded rod jack. Adjust the T-Arm to the desired

height.

3. Re-tighten all six of the 3/8” x 1” bolts and nuts to cause the

L & W bracket to clamp down securely to the T-Arm.

Reassemble of a pivot on a Pro Rotisserie

1. If the T arm is attached to the inner pivot it will need to be removed.

2. Make sure the O ring is seated in the Groove closets to the bracket on the Inner Pivot Piece.

3. Using a very stiff grease place 24 of the 3/8” bearings in the groove next to the O-ring and 24 of the 3/8”

bearings in the groove farthest from the Bracket.

4. Gently slide the inner pivot, with the 3/8” bearings into the outer pivot.

5. Line up the empty groove on the inner pivot with the hole on the side of the outer pivot part.

6. Drop in a 5/8” bearing.

7. Tighten down the set screw until it is snug up against the 5/8” bearing.

8. Back the set screw off about ¼ turn.

9. Tighten the Set/Lock nut down on the Set screw. This will hold the 5/8” Bearing in the groove. Which

will keep the pivot intact.

10. Remount the T arm to the Inner pivot.

PLACE JACK BENEATH ROTISSERIE AS SHOWN

DIRECTLY BELOW THE UPRIGHT.

INSERT OFF ROAD WHEEL KIT

COMPLETLY INTO THE ENDS

OF THE ROTISSERIE.

INSERT INSERT

OFF ROAD WHEEL KIT INSTRUCTIONS

Chock wheels on the opposite end of the rotisserie that you are jacking up.

1.

Place jack directly under rotissierie stand. (See picture)

2.

Raise jack high enough to easily insert the Off Road Wheel Kit.

3.

Position wheels to extend inside of the rotisserie so they don't extend the length of the rotisserie.

4.

Insert Wheel Kit wheels all the way in until it stops. (See picture)

5.

Lower the Jack and repeat all of the steps for the opposite end.

6.

2/14/2017

675 N 600 W STE 2 LOGAN UT. 84321

email: [email protected] website: www.autotwirler.com

phone #: 1 (435) 752-3921

ATTENTION WITH WHEEL

KIT INSTALLED WEIGHT

LIMIT IS 1650LB

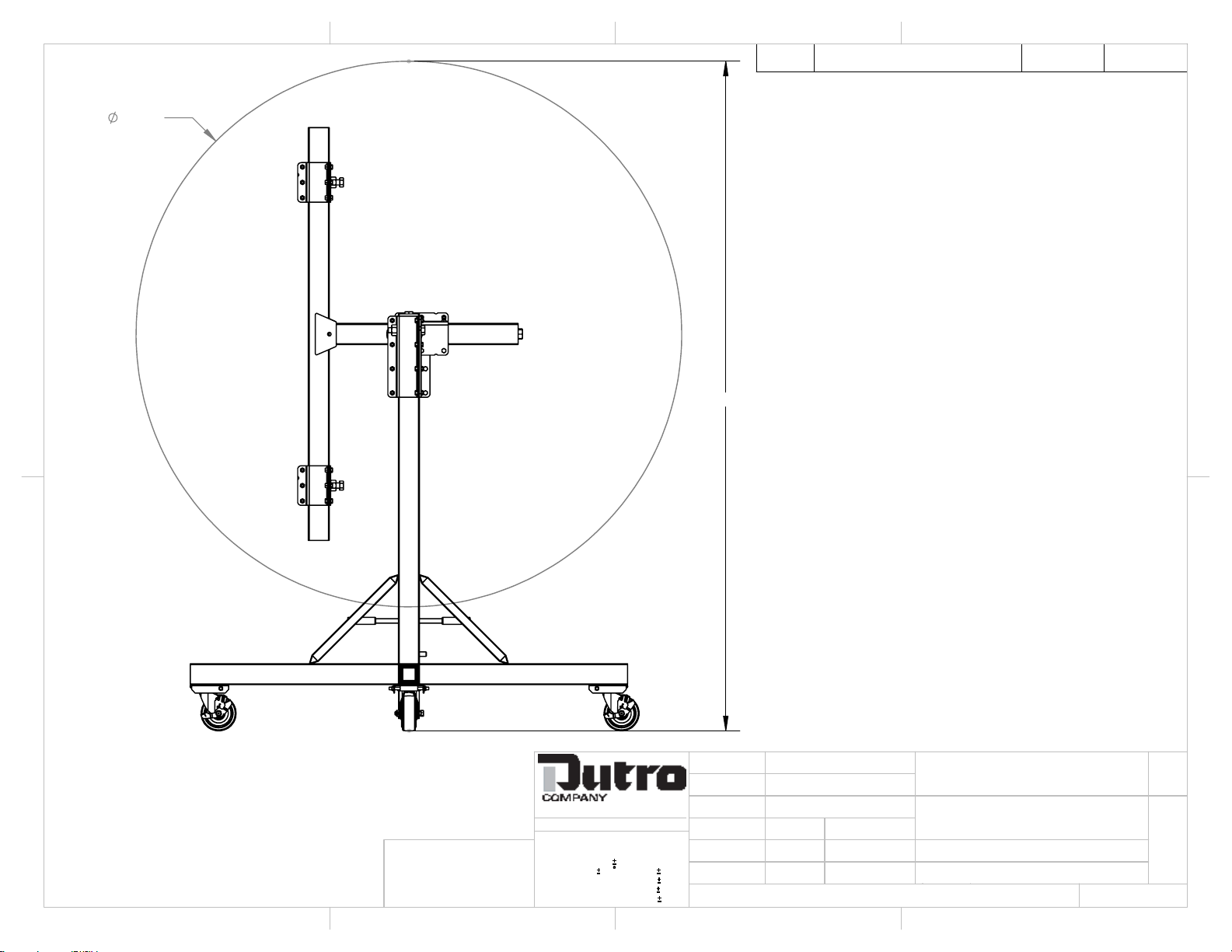

78.000

95.731

NOTE:

DIMENSIONS MAY VARY DEPENDING ON HEIGHT,

1.

WIDTH, & BALANCE CENTER OF VEHICLE.

REV.

DESCRIPTION

DATE

APPROVED

UNLESS OTHERWISE SPECIFIED:

DRAWN BY:

SIZE

CUSTOMER:

PROPRIETARY AND CONFIDENTIAL

FINISH:

DATE:

A

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL:

1/32

ANGULAR:

.5

BEND

.03

ONE PLACE DECIMAL =

.1

TWO PLACE DECIMAL =

.03

THREE PLACE DECIMAL =

.005

MATERIAL:

DIR:

CHECKED BY:

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

DUTRO CO. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF DUTRO CO.

IS PROHIBITED.

MODELED BY:

SHEET 1 OF 1

2

AUTO TWIRLER

DATE

:

DATE:

PROJECT NAME:

DWG:

AUTO TWIRLER ROTISSERIE

STANDARD COLOR

BHS

BHS

C:\CAD_FILES_VAULT\CAD FILES\AUTOTWIRLER\ROTISSERIES\

AT-PRO-90DEGREE

PRO ROTISSERIE

675 N 600W PHONE: 435-752-3921

LOGAN, UT 84321 FAX: 435-752-6360

UNLESS OTHERWISE SPECIFIED:

DRAWN BY:

SIZE

CUSTOMER:

PROPRIETARY AND CONFIDENTIAL

FINISH:

A

DIMENSIONS ARE IN INCHES

TOLERANCES:

FRACTIONAL:

1/32

ANGULAR:

.5

BEND

.03

ONE PLACE DECIMAL =

.1

TWO PLACE DECIMAL =

.03

THREE PLACE DECIMAL =

.005

MATERIAL:

DIR:

THE INFORMATION CONTAINED IN THIS

DRAWING IS THE SOLE PROPERTY OF

DUTRO CO. ANY REPRODUCTION IN

PART OR AS A WHOLE WITHOUT THE

WRITTEN PERMISSION OF DUTRO CO.

IS PROHIBITED.

MODELED BY:

SHEET 1 OF 1

B

2

DESCRIPTION:

PART#:

AT-PRO-AS

A

675 N 600W PHONE: 435-752-3921

LOGAN, UT 84321 FAX: 435-752-6360

1

1

3

4

A

3

4

B

REV

A

9/7/2017

STEEL

9/7/2017