AutoVac VACUUM IQ C2000 Series User manual

DELTA Variable Frequency Drive

40HP X 1 460V

425-11082-DELTA

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

OVERVIEW

This guide is to assist in the start up of

the C2000 series variable frequency

drives.

In Chapter 1:

The installation of the Variable Fre-

quency Drive will be covered.

In Chapter 2:

The input power to the package,

vacuum motor and pressure transdu-

cer connections will be shown.

In Chapter 3:

The operation of VFD display will be

covered.

In Chapter 4:

Will deal with electrical drawings for

different package configuration (mul-

tiple motors).

In Chapter 5:

Includes factory VFD parameters for

different package configurations.

Please take time to review this Guide

before proceeding with the installation

and testing.

QUICK START GUIDE FOR

USING THE C2000

SERIES VFD

VACUUM IQ

DANGER!

LETHAL VOLTAGES ARE PRE-

SENT Before applying power to

the variable frequency drive,

ensure that all protective covers

are on and all wiring connections

are secure. After the power has

been turned OFF, wait at least 5

minutes or until the display

indicator extinguishes complete-

ly before touching any wiring,

circuit boards or components.

02

Installation

• Please review and verify that the inverter was received free of damage and is the

correct size for the motor being used.

• To ensure personnel safety and to avoid equipment damage, follow standard

precautions and the installation procedures for mounting, wiring, and operating

environment.

Wiring

• Be sure to follow all applicable codes in make electrical connections to the motor

and input power terminals, as well as the control wiring.

• Transducer wiring should be run in a separate conduit.

• Transducer wiring should be run in a separate trench other than high voltage

wire trench if possible. Feedback errors may occur if transducer control wire is run

in the same trench with high voltage.

CHAPTER 1 -

INSTALLATION AND WIRING

NOTICE

AutoVac cannot be responsible for transducer feedback

errors due to control wire being run in the same trench

as the high voltage wire.

03

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

With power OFF, ensure the following mechanical and electrical conditions:

• Rated output current of the VFD is equal or greater than the motor FLA.

• Supply voltage, VFD rated voltage and motor voltage match.

• Power factor correctio capacitors are NOT installed between the VFD and the

motor.

• Power factor correction capacitors are NOT installed within 100m (300ft) of input

to the VFD without a line reator.

• Motor and the load rotate freely.

To connect package to the power supply, motor and

pressure transducer please refer to picture below and

Auto Cad drawings submitted in Chapter 4.

CHAPTER 2 -

INPUT POWER, MOTOR AND

PRESSURE TRANSDUCER

CONNECTIONS.

04

Input power

connection L1, L2

L3, Gnd

Transducer

Connection

Motor Connection

T1,T2, T3, Gnd

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

NOTE

For single motor configuration, input power and transducer connections are

the same. Motor connection terminals are labelled 1T1, 1T2 and 1T3.

CAUTION

To prevent an electric shock always ground the motor and VFD. Use indepen-

dent grounding method for the VFD. If independent grounding is impossible

use common grounding as shown on the figure below.

05

Inverter Inverter

Other

equipment

Other

equipment

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

VFD is supplied with KPC-CC01 keypad. Next chapter will explain basic KPC-CC01

operation.

Descriptions of keypad Functions

Key Descriptions

Start Operation Key

1. It is only valid when the source of operation command is from the keypad.

2. It can operate the AC motor drive by the function setting and the RUN

LED will be ON.

3. It can be pressed again at stop process.

KPC-CC01

Communication Interface

RJ45 (socket), RS-485 interface

Installation Method

1. Embedded type and can be put flat on the

surface of the control box. The front cover

is water proof.

2. Buy a MKC-KPPK model to do wall moun-

ting or embedded mounting. It’s protec-

tion level is IP66.

3. The maximum RJ45 extension lead is 5m

(16ft).

4. This keypad can only be uesed on Delta’s

motor drive C2000, CH2000 and CP2000.

CHAPTER 3 -

VFD DISPLAY OPERATION

06

Operation Direction Key

1. This key only controls the operation direction, and will NOT activate the

drive. FWD: forward, REV: reverse.

2. Refer to the LED descriptions for more details.

ENTER Key

Press ENTER and go to the next level. If it is the last level then press ENTER to

execute the command.

a. Because the condition which triggers the fault is not cleared. When

the condition is cleared, the fault can be reset.

b. Because it’s the fault status checking when power-on. When the

condition is cleared, re-power again, and the fault can be reset.

RUN

STOP

RESET

FWD

REV

ENTER

Stop Command Key. This key has the highest priority in any situation.

1. When it receives STOP command, no matter if the AC motor drive is in

operation or stop status, the AC motor drive needs to execute “STOP”

command.

2. The RESET key can be used to reset the drive after the fault occurs.

3. The reasons why the error cannot be reset:

F1 F2 F3 F4

ESC MENU

HAND AUTO

ENTER

RUN FWD

REV

STOP

RESET

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

07

ESC Key

ESC Key function is to leave current menu and return to the last menu. It also

functions as a return key or cancel key in the sub-menu.

Key Descriptions

Press menu to return to main menu.

Menu content:

Function Key

1. The function keys have factory settings and can be defined by users. The

factory settings of F1 and F4 work with the function list below. For exam-

ple, F1 is JOG function, F4 is a speed setting key for adding/deleting user

defined parameters.

2. Other functions must be defined by TPEditor firts (please use version 1.60

or above). TPEditor software can be download at:

Direction: Left / Right / Up / Down

1. In the numeric value setting mode, it is used to move the cursor and

change the numeric value.

2. In the menu/text selection mode, it is used for item selection.

1. Parameter Setup

2. Quick Start

3. Application Selection List

4. Changed List

5. Copy Parameter

6. Fault Record

7.

8.

9.

10.

11.

12.

Language Setup

Time Setup

Keypad Locked

PLC Function

Copy PLC

Display Setup

13.

14.

15.

16.

Startup Menu

Main Page

PC Link

Start Wizard

HAND Key

1. This key is executed by the parameter settings of the source of Hand

frequency and hand operation. The factory settings of both of Hand

frequency and hand operation are the digital keypad.

2. Press HAND key at stop status, the setting will switch to hand frequency

source and hand operation source. Press HAND key at operation status, it

stops the AC motor drive first (diplay AHSP warning), and switch to hand

frequency source and hand operation source.

3. KPC-CC01 display HAND mode on the screen.

AUTO Key

1. This key is executed by the parameter settings of the source of AUTO

frequency and AUTO operation. The factory setting is the external terminal

(source of operation is 4˜20mA).

2. Press Auto key at stop status, the setting will switch to hand frequency

source and hand operation source. Press Auto key at operation status, it

stops the AC motor drive first (diplay AHSP warning), and switch to auto

frequency source and auto operation source.

3. KPC-CC01 display AUTO mode on the screen.

ESC

MENU

HAND

AUTO

F1 F2

F3 F4

http://www.deltaww.com/services/DownloadCenter2.aspx?secI-

D=8&pid=2&tid=0&CID=060302&typeID=1&downloadID=,&tittle=--Selec

Product Series --&dataType=8;&check=1&hl=en-US

Please refer to instruction for TPEditor in Chapter 10-3.

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

08

Descriptions of keypad Functions

Function of Digital Keypad KPC-CC01

POWER ON

LED Descriptions

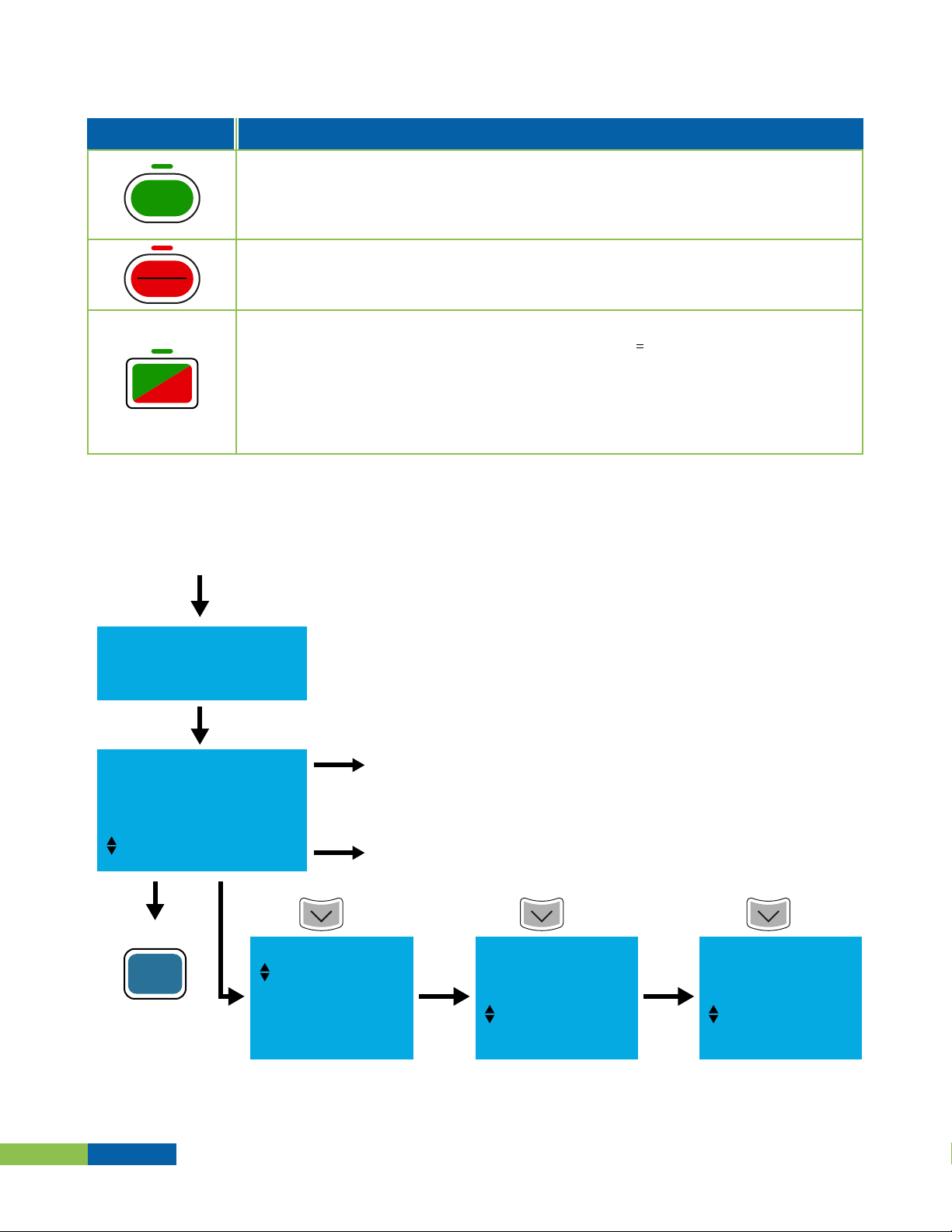

Steady ON: operation indicator of the AC motor drive, including DC brake, zero

speed, standby, restart after fault and speed search.

Blinking: drive us decelerating to stop or in the status of base block.

Steady OFF: drive doesn’t execute the operation command.

Steady ON: stop indicator of the AC motor drive.

Blinking: drive is in the standby status.

Steady OFF: drive doesn’t execute “STOP” command.

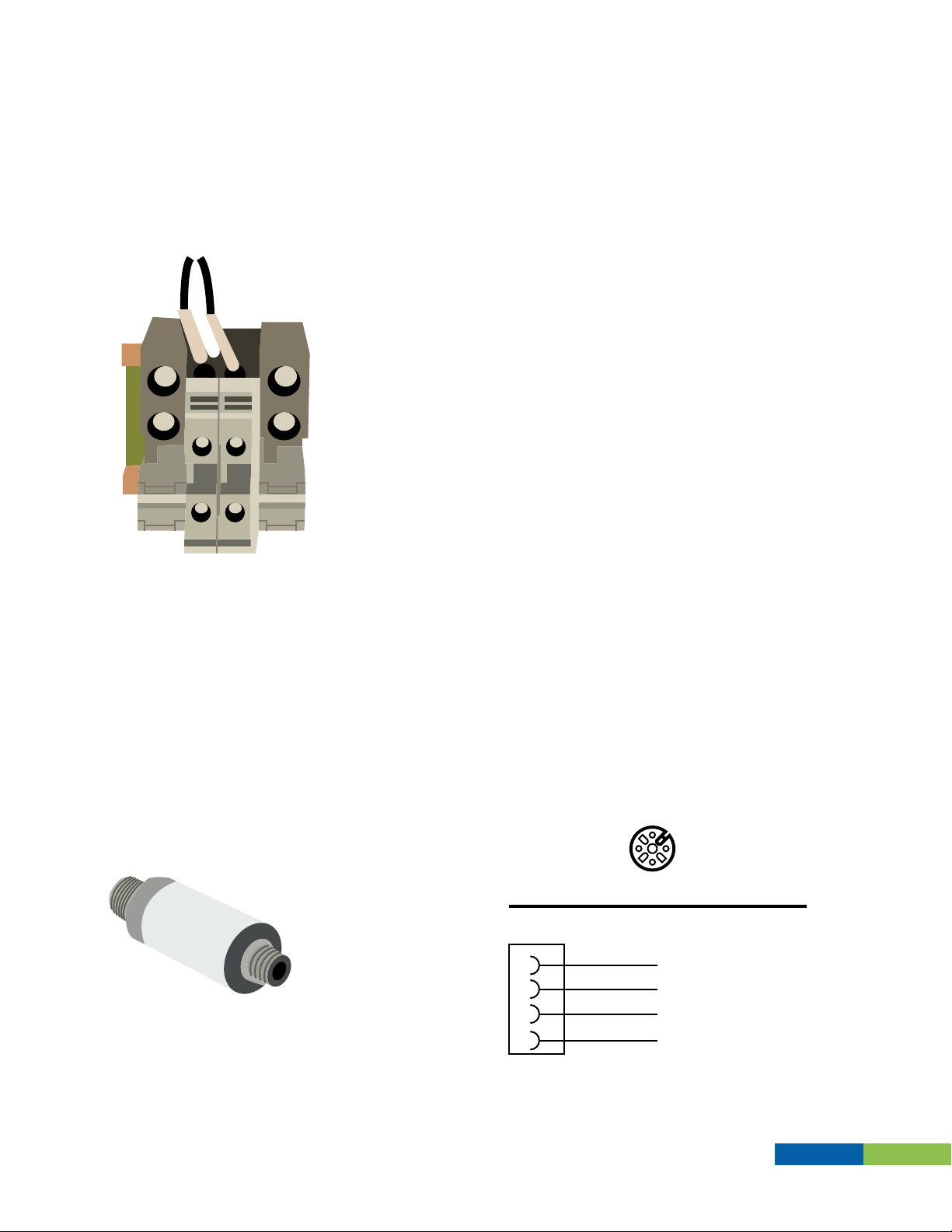

1. The default Start-up page is Delta Logo. (Default 1

and 2).

2. User can customize their start-up page through the

edited function. (Need to purchase the optional

accesories).

The top line of LCD display the status of drive.

After main menu is selected, the start-up page will

display in the format user defined. The page sjown

on the left is displayed as Delta default setting.

The bottom line of LCD display time and JOG.

Operation Direction LED under Torque Mode

1. Green light is ON: when the torque command >0, and the motor is

running forward.

2. Red light is ON: when the torque command < 0, and the motor is running

backward.

3. Twinkling light: when the torque command < 0, and the motor is running

forward.

Start-up

Skip to main page

after 3 sec.

60.00 Hz

0.00 Hz

540.0 Vdc

JOG 14:35:56

AUTO

F

H

V

60.00 Hz

0.00 Hz

540.0 Vdc

JOG 14:35:56

Press once

Press

F

H

V

60.00 Hz

0.00 Hz

540.0 Vdc

JOG 14:35:56

AUTO

F

H

V

0.00 Hz

540.00 Vdc

0.0 Amp

JOG 14:35:56

AUTO

H

V

A

MENU

Press again Press again

RUN

STOP

RESET

FWD

REV

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

09

Display Icon

Display Item

Parameter Setup

Press

For example: Setup source of master frequency command.

Once in the Group 00 Motor Drive

Parameter, use Up/Down key to select

parameter 20: Auto Frequency Com-

mand.

to select.

1: Pr Setup

2: Quick Start

3: App Sel List

MENU

MENU

1: Parameter Setup

2: Quick Start

3: Application

Selection List

4. Changed List

5: Copy Parameter

6: Fault Record

7: Language Setup

8: Time Setup

9: Keypad Locked

10: PLC Function

11: Copy PLC

12: Display Setup

13: Startup Menu

14: Main Page

15: PC Link

16: Start Wizard

1: Pr Setup

2: Quick Start

3: App Sel List

MENU

MENU

1: Parameter Setup

2: Quick Start

3: Application

Selection List

4. Changed List

5: Copy Parameter

6: Fault Record

7: Language Setup

8: Time Setup

9: Keypad Locked

10: PLC Function

11: Copy PLC

12: Display Setup

13: Startup Menu

14: Main Page

15: PC Link

16: Start Wizard

1: Default 1

2: Default 2

3: User define

Start-up

00: SYSTEM PAR

01: BASIC PARA

02: DIGITAL IN/

Pr Setup

00: SYSTEM PAR

01: BASIC PARA

02: DIGITAL IN/

Pr Setup

00: Identity Co

01: Rated Curren

02: Parameter Re

00-SYSTEM PARAME

When this parameter is selected, pres

ENTER key to go to this parameter’s

setting menu.

20: Source of F

21: Source of OP

22: Stop Methods

00-SYSTEM PARAME

Use Up/Down key to choose a setting.

For example: Choose “2 Analogue

input”, the press the ENTER key.

2

Analog input

0˜8ADD

00-20

: present setting

: roll down the page for more options

: show complete sentence

Press for more options

Press

Once a parameter group is

selected,

to select a parameter

group.

Press for complete information

ENTER

Press to go into that

group.

ENTER

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

10

Language Setup

Language setting option is displayed in the language of the

user’s choice. Language setting options:

Use Up/Down key to select

language, than press ENTER.

English

繁体中文

1.

2.

简体中文

Türkçe

3.

4.

Русский

Español

Português5.

6. Français

7.

8.

After pressing the ENTER key, a END

will be displayed which means that

the parameter setting is done.

NOTE: When parameter

lock/password protection function is

enabled, it will display “Pr. lock” on the

right-up corner of the keypad.

The parameter cannot be written or is

protected by the password under this

circumstances.

END

Analog input

00-20

2

Analog input

00-20 Pr. lock

0˜8ADD

1: English

Language

2: 繁体中文

3:简体中文

Language Setup

Use Left/Right key to select

Year, Month, Day, Hour, Minute

or Second to set up

Use Up/Down key to

set up Year

Use Up/Down key to

set up Month

Use Up/Down key to

set up Day

2009/01/01

_ _ : _ _ : _ _

Time setup

2014/01/01

00 : 00 : 00

Time setup

2014/01/01

00 : 00 : 00

Time setup

2014/01/01

00 : 00 : 00

Time setup

Use Up/Down key to

set up Hour

2014/01/01

21 : 00 : 00

Time setup

Use Up/Down key to

set up Minute

2014/01/01

21 : 12 : 00

Time setup

Use Up/Down key to

set up Second

2014/01/01

21 : 12 : 14

Time setup

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

11

NOTE:

Limitation: The charging process of the super capacitor will

finish in about 6 minutes. When the digital keypad is

removed, the time setting will be in stanby status for 7

days. After this period, the time need to be reset.

After setting up, press ENTER to

confirm the setup.

END

Time setup

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

12

CHAPTER 4 -

AutoCad DRAWINGS

TERMINAL CONNECTION

Case 1 - Single motor

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

13

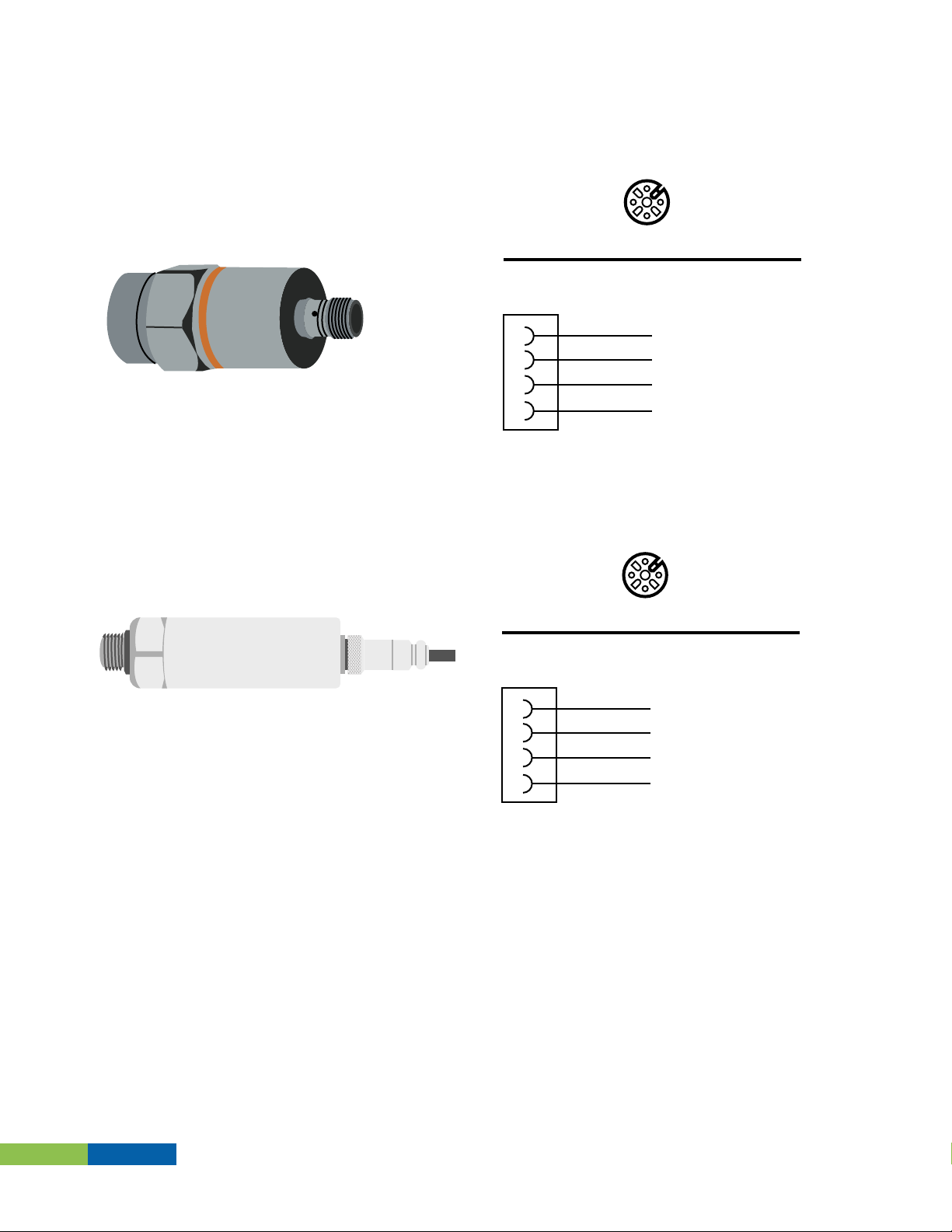

In this page you can view the wiring connections for the four possible options of

pressure transducer sensor.

Please follow the pictures to ensure a proper connection.

Transducer sensor wiring connections

Cordset Wiring

Brand: Turck

Part No.: PT01VR-11-LI3-H1131

Turck Sensor Connector A

Circuit Diagram VFD TERMINAL

1

2

3

4

Brown +10V

N.C.

AV1

N.C.

White

Blue

Black

1

3

24

The enclosure has a dedicated terminal block to

wire the transducer sensor; please look up for the

terminal block aside of the Motor Connection

Terminal Block.

Terminal Block

There are two wires: brown and white; brown is

for the transducer power supply (+10V) and the

white is the Analog Input to the VFD (AV1).

Delta VFD Enclosure

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

14

Cordset Wiring

Connector A

Circuit Diagram VFD TERMINAL

1

2

3

4

Brown +10V

AV1

N.C.

N.C.

White

Blue

Black

1

3

24

Brand: IFM

Part No.: PA3029

Brand: LEFOO

Part No.: LFT2010

Connector A

Circuit Diagram VFD TERMINAL

1

2

3

4

Brown +10V

N.C.

AV1

N.C.

White

Blue

Black

1

3

24

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

15

CHAPTER 5 -

VFD Parameter Settings

5.1 - VFD Parameter Settings for Single motor configuration

The Variable Frequency Drives are shipped with the parameter values shown in

Parameter Tables and no further programming should be necessary. However, if

additional fine tuning is required please refer to Chapter 3, VFD Display Opera-

tion.

Autovac Settings - Single VFD

Parameter Parameter Description Setting

Maximum frequency 60 Hz

35 Hz

30 sec

30 sec

0

1

52

3599

2

33.8

2

01-00

01-07

01-12

01-13

00-22

03-00

05-01

05-03

05-04

05-05

07-06

Minimum frequency

Acceleration time

Deceleration time

Stop selection

Analog input selection (AVI)

Full-load current for induction motor 1 (A)

Rated speed for induction motor 1 (rpm)

Number of poles for induction motor 1

No-load current for induction motor 1 (A)

Restart after momentary power loss

AutoVac - DELTA Variable Frequency Drive 40HP X 1 460V

DELTA Variable Frequency Drive

40HP X 1 460V

425-11082-DELTA

Table of contents

Other AutoVac Servo Drive manuals

Popular Servo Drive manuals by other brands

Danfoss

Danfoss VLT AQUA Drive FC 200 Programming guide

GEZE

GEZE E 170/230 V AC Wiring diagram

Stober

Stober SC6 Series operating manual

Lenze

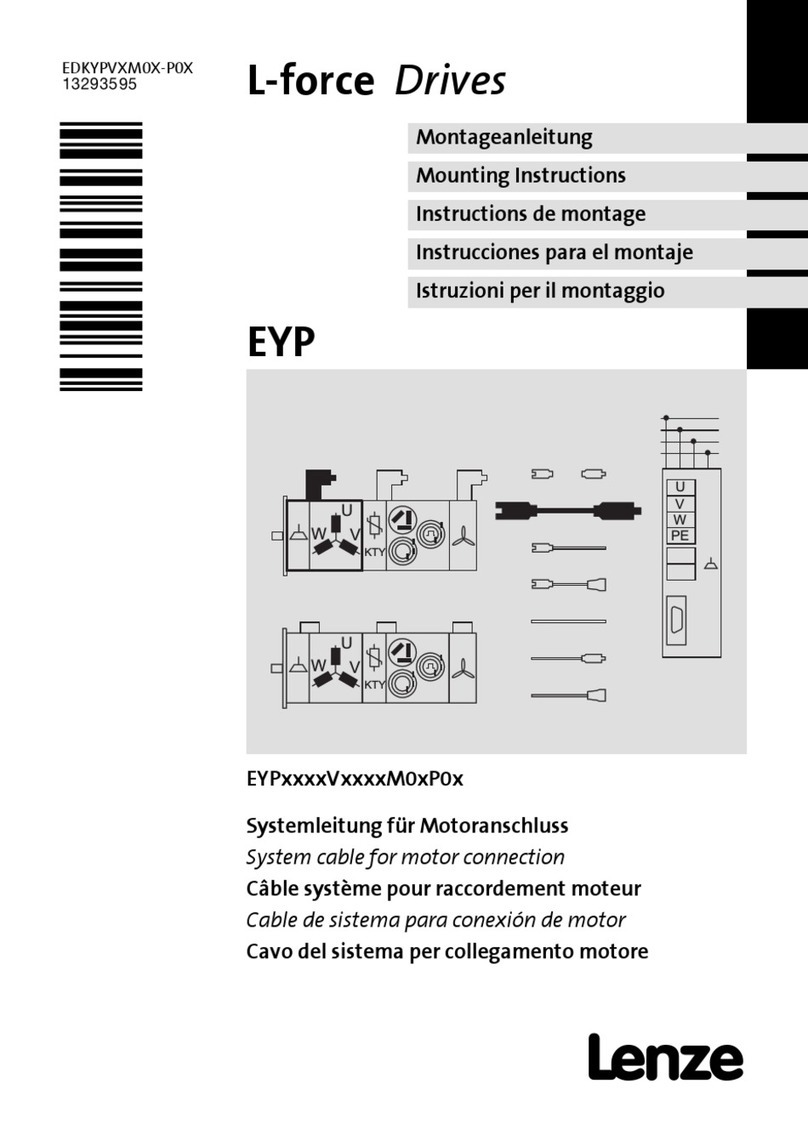

Lenze L-force EYP Series Mounting instructions

LAFERT

LAFERT ATE ZONE 2-22 operating instructions

Rockwell Automation

Rockwell Automation Allen-Bradley Kinetix 3 2071-AP0 user manual