NSK MEGATORQUE MOTOR Series User manual

MEGATORQUE MOTORTM SYSTEM

(Driver Model EGA)

User’s Manual

NSK Ltd.

Document Number: C20191-03

M-E099GA0C2-191

Copyright 2022 by NSK Ltd., Tokyo, Japan

All rights reserved.

No part of this publication may be reproduced in any

form or by any means without permission in writing

from NSK Ltd.

NSK Ltd. reserves the right to make changes to any

products herein to improve reliability, function or design

without prior notice and without any obligation.

NSK Ltd. does not assume any liability arising out of the

application or use of any product described herein;

neither does it convey any license under its present

patent nor the rights of others.

Revision History

3rd Edition

■

Chapter 3

●

Added "If dust or oil mist is present" to the precautions for the converter.

■

Chapter 9

●

Revised standards conformity and test standards.

●

Added explanation about converter protection grade and polution level.

●

Added cautions and warnings.

2nd Edition

■

All chapters

●

Added motors M-PB3030JN001 and M-PB3060JN001.

●

Added driver M-EGA-30A2301.

●

Added motor cable M-CAxxxA101.

●

Added converter cable M-CCxxxA101.

●

Added outline drawings.

●

Method of usage modified to set JRAT1 value.

●

Added supplementary items for usage.

■

Chapter 2

●

Corrected values of circuit power for output signal of general output.

Incorrect: 24-15 [VDC] →Correct: 24 [VDC]

■

Chapter 3

●

Added content and location of serial number of drivers.

●

Deleted items about dummy inertia.

●

Added items about cables (for motors and converters).

■

Chapter 4

●

Signal names and their function of CN1 modified to be factory default settings.

●

Added examples of wiring between CN1 and host unit.

●

Equivalent products added to model number of recommended ferrules.

■

Chapter 5

●

Magnetic Pole Position Estimation status added to driver status display.

●

While Magnetic Pole Position Estimation Ready (CSETRDY) and Magnetic Pole Position

Estimation Completion (CSETCMP) added to signals of Group A.

■

Chapter 6

●

Flowchart of auto-tuning characteristic selection modified to set JRAT1 value.

■

Chapter 7

●

Magnetic Pole Position Estimation status added to driver status display.

■

Chapter 8

●

Added items about magnetic pole position estimation error (AL. 44).

■

Chapter 9

●

Added motor outline drawings.

●

Added converter outline drawings.

●

Added outline drawing and pin allocation of motor cable.

●

Added outline drawing and pin allocation of converter cable.

●

Added pin allocation of PC communication cable.

●

Added supplementary items for usage.

Safety precautions Please fully observe

i

The following signs are used to indicate safety precaution in this instruction manual.

Please fully observe the precautions as important contents included in the descriptions.

■Safety precautions and the signs

Safety precautions Signs

Danger Indicates an imminently hazardous situation which, if

incorrectly operated, will result in death or serious injury.

Danger, injury

Electrical shock

Warning

Indicates a potentially hazardous situation that, if incorrectly

operated, may result in minor or moderate injury, or property

damage only. Even those hazardous indicated with this sign

may lead to a serious accident.

Warning

Fire

Burn injury

Prohibition

Indicates actions that must not be allowed.

Prohibition

Disassembly

prohibited

Mandatory

Indicates actions that must be carried out (mandatory

actions).

Mandatory

■Danger

Do not use the system in explosive atmospheres.

Injuries and fire may occur.

Do not perform wiring, maintenance, and inspection with power distributed. Make sure to start

performing any tasks surely 15 minutes or more after power shutdown.

Electrical shock may occur.

Make sure to ground the driver protective grounding terminal “”tothe machine or control cabinet.

Electrical shock may occur.

Never touch inside of driver.

Electrical shock may occur.

Safety precautions Please fully observe

ii

Only qualified personnel who have electrical knowledge should conduct maintenance and inspection.

Electrical shock, injuries, and fire may occur.

Do not damage, apply excessive stresses, put heavy things on, and tuck down cables.

Electrical shock may occur.

Perform wiring in accordance with wiring diagram and the instruction manual.

Electrical shock and fire may occur.

Never approach or touch terminals and connectors while power is being distributed.

Electrical shock may occur.

Never touch rotating part of motor during operation.

Injuries may occur.

Never remove terminals and connectors while power is being distributed.

Electrical shock may occur.

Safety precautions Please fully observe

iii

■Warning

Unpack after checking upside and downside.

Injuries may occur.

Verify no discrepancies between the product you received and the product you ordered. Installing

incorrect product can result in injuries and damages.

Injuries and failures may occur.

Make sure to read the instruction manual and observe the instructions before inspection, operation,

maintenance, and inspection.

Electrical shock, injuries and fire may occur.

Do not use faulty, damaged, and burnt-out driver, motor and converter.

Injuries and fire may occur.

Please be aware that temperatures on driver, motor and peripheral equipment become high.

Fire may occur.

Do not use driver, motor and converter outside the scope of the specification.

Electrical shock, injuries and failures may occur.

Use the specified combination of motor and converter.

This can result in fire and failures.

For driver and motor, do not perform measurement of insulation resistance and dielectric strength

voltage.

Failures may occur.

Correctly and properly perform wiring.

Injuries may occur.

Safety precautions Please fully observe

iv

Do not put heavy things on, or climb on the system.

Injuries may occur.

Make sure to observe the specified installation direction.

This can result in fire and failures.

Do not apply high impacts.

This can result in failures.

Never install the system in the area where it may be exposed to water, near corrosive/ flammable

gaseous, or by combustible material.

This can result in fire and failures.

Do not apply static electrical charge and high voltage to motor resolver cable and converter connectors.

This can result in failures.

Perform wiring in accordance with electrical installation technical standards and internal wiring standards.

Burnout or fire may occur.

Do not block and let any foreign materials into inlet/outlet.

Fire may occur.

Maintain the specified distances for layout inside of driver control cabinet.

This can result in fire and failures.

It is very dangerous to carry the system, so carefully carry the system as not to fall and roll over.

Injuries may occur.

Safety precautions Please fully observe

v

Install the system in incombustible material, such as metal.

Fire may occur.

No protective equipments are supplied with motor. Protect the system with overcurrent protective device,

earth leakage circuit breaker, overtemperature thermostat, and emergency stop equipment.

Injuries and fire may occur.

Do not touch heat releasing fin and regenerative resistor of driver and motor while power being

distributed or after a while power is turned off, as the temperatures on them become high.

Burn injuries may occur.

Stop operation immediately when any abnormality occurred.

Electrical shock, injuries, and fire may occur.

Never make excessive adjustment change as operation becomes unstable.

Injuries may occur.

Perform test operation by fixing motor with motor separated from mechanical systems, and then install

the motor after performing the operation check.

Injuries may occur.

When alarm activated, eliminate the cause, secure the safety, reset the alarm, and then re-start

operation.

Injuries may occur.

Confirm that input power voltage is within the specification.

This can result in failures.

Safety precautions Please fully observe

vi

Do not approach equipments after restoration from instantaneous interruption of service, as sudden

re-start can occur.

(Design the machine so as to ensure safety even sudden re-start occurs.)

Injuries may occur.

Do not externally and continuously rotate motor during servo-off with standard speciation driver with

dynamic brake, as the dynamic brake will generate heat and this will cause dangers.

Fire and burn injuries may occur.

Carefully perform maintenance and inspection as temperature on driver frame becomes high.

Burn injuries may occur.

Please contact us to repair. Disassembly can cause inoperative.

This can result in failures.

It is very dangerous to carry the system, so carefully carry the system as not to fall and roll over.

Injuries may occur.

Do not hold cables and motor rotating part to carry the system.

Failures and injuries may occur.

Dispose any driver, motor and converter properly as general industrial wastes.

Safety precautions Please fully observe

vii

For repairing, if any, contact us. Any insulation failure in the motor and/or short-circuited or broken wires

in any cables may occur depending on the motor operating environments or conditions. If you keep on

using the system without repairing the faulty conditions, the motor becomes unable to demonstrate the

original performance, the driver becomes damaged or other trouble may occur.

This can result in failures.

Use the specified combination of motor and converter.

This can result in failures.

Remember to make a note of parameters.

This can result in failures.

Never attempt to modify any cables.

This can result in failures.

Tightly lock the connectors and make sure that the screws are securely tightened without any loosening.

This can result in failures.

Make proper service parts available (drivers, motors, converters, cables, etc. for replacement).

This can result in failures.

For cleaning, do not use any thinner but use alcohol.

This can result in failures.

The motor produces regenerative electric power when reducing a large load moment of inertia. The

regenerative electric power is normally charged in the capacitor in the driver. However, in case where

higher regenerative electric power is continuously generated, it fails to be fully stored in the capacitor and

the motor becomes shut down.

Change the operating conditions (speed, acceleration/deceleration, operating duty) otherwise

make proper regenerative resistor available externally.

Safety precautions Please fully observe

viii

In the applications involving repeated operations through an angle of within 45 [°], be sure to perform the

angular movement at an angle exceeding 90 [°] at least once a day.

This can result in failures.

Where rotation supporting parts (bearings, ball screws, etc.) are to be additionally installed outside the

motor, be sure to complete the center alignment properly (within a runout of 0.01 [mm]). Remember that

any excessive offset loads or excessive loads can cause abnormality in the bearings in the motor.

This can result in failures.

Ensurethat the bending radius of motor cable lead wire (7) and resolver cable lead wire (7) becomes larger

than R30[mm].

This can result in failures.

Never attempt to use any motor cable lead wire and resolver cable lead wire in any moving parts.

This can result in failures.

Ensure that the connections between lead wires and connectors are free from exposure to any stress (tension,

vibration, etc.) to avoid possible broken wire and/or poor contact.

This can result in failures.

Ensure that the bending radius of motor cable (8) is larger than R43 [mm] and be sure to tightly secure

the motor cable.

This can result in failures.

Install the power system (AC supply source, motor cable) and the signal system properly by separating

them from each other. Never attempt to bundle the systems nor pass them through any same duct.

This can result in failures.

In any possible case where cables may be exposed to severe vibration, secure the cables next to the

connectors to protect the connectors from exposure to stresses.

This can result in failures.

Safety precautions Please fully observe

ix

■Prohibition

Never expose the motor, driver and converter to any water and oil. Do not store nor operate the system in

the area where it may be exposed to rain and water drops, or toxic gasses or liquids exist.

This can result in failures.

Do not perform overhaul.

This can result in fire and electrical shock.

Do not remove nameplate.

Never cut any cables into segments for extension, shortening or splicing.

This can result in failures.

Never attempt to overhaul the motor body.

This can result in failures.

Do not remove the casings from driver and converter.

This can result in failures.

Do not impact the motor directly with a hammer or other tools.

Direct impact on the sides of motor or the parts installed on the motor can cause degraded accuracy of

internal detector.

This can result in failures.

The specifications of dynamic brake include limitations on allowable load and rotational speed.

In the operation of position alignment, limit the operating actions to 360[°] within the allowable load of

inertial moment.

This can result in failures.

Safety precautions Please fully observe

x

■Mandatory

Store the system within the specified temperature and humidity “-20°C to 65°C, 90%RH or less(no

condensation)”away from direct sunlight.

Driver and converter

Temperature -20[°C] to 65[°C]

Humidity 90[%RH] or less (No condensation)

Motor

Temperature 0[°C] to 40[°C]

Humidity 20 to 80[%RH] (No condensation)

This can result in failures.

Place emergency stop circuit outside the product so that operation can be stopped and power supply can

be shut down instantaneously. Place a safeguard circuit outside driver so as to shut off main circuit power

supply when alarm activated.

Going out of control, injuries, burnout, fire, and secondary damages can occur.

Following the power-on sequence, remember to complete the estimation of magnetic pole position.

In the estimation of magnetic pole position, the rotational part of motor moves through the maximum

angle of ±18 [°].

Going out of control, injuries, burnout, fire, and secondary damages can occur.

Please operate within the specified range of temperature and humidity.

Driver and converter

Temperature: 0[C] to 55[C]

Humidity: 90%RH or less (No condensation)

Motor

Temperature: 0[C] to 40[C]

Humidity: 20 to 80[%RH] (No condensation)

This can result in burnout and failures.

Do not overload the products which may cause collapses.

Injuries may occur.

Allowable momentum load, allowable axial load, and allowable radial load vary depending on the size of

individual motors. Make sure your operating conditions are suitable the allowable loads.

This can result in failures.

Safety precautions Please fully observe

xi

Any excessive offset loads or excessive loads can cause permanently deformed rotors and/or faulty

bearings in the motor. Remember to prevent the motors from possible falling and exposure to any impact

during the installation of motors, and also to protect the motors against possible impact due to external

interference during the transportation.

This can result in failures.

Install every motor on the surface of flatness of 0.02 [mm] or less.

This can result in failures.

Use driver software with version A or later for motor M-PB3030JN001 and converter

M-ECC-PB3030GA201.

Alarm will be output and cannot operate the motor.

Table of contents

xii

1. Preface.............................................................................................................................................................. 1

1.1 Illustration of system components...................................................................................................................1-1

1.2 Coding for reference number of individual parts..............................................................................................1-2

1) Reference number of driver.....................................................................................................................1-2

2) Reference number of motor.....................................................................................................................1-2

3) Reference number of converter ...............................................................................................................1-3

4) Reference number of motor.....................................................................................................................1-3

5) Reference number of converter cable......................................................................................................1-3

1.3 Part names......................................................................................................................................................1-4

1) Driver.......................................................................................................................................................1-4

2) Motor........................................................................................................................................................1-5

3) Converter.................................................................................................................................................1-5

2. Specifications................................................................................................................................................... 2

2.1 Motor...............................................................................................................................................................2-1

1) Motor specifications................................................................................................................................. 2-1

2) Load on the motor....................................................................................................................................2-2

3) Direction of rotation of motor.................................................................................................................... 2-2

2.2 Driver ..............................................................................................................................................................2-3

1) Specifications of driver.............................................................................................................................2-3

2) Input command, position feedback signal output, general input, general output......................................2-4

2.3 Power supply ..................................................................................................................................................2-6

1) Main circuit power supply capacity, control power supply capacity..........................................................2-6

2) Incoming current, leakage current............................................................................................................2-6

2.4 Position feedback signal .................................................................................................................................2-7

1) Position feedback signal output ...............................................................................................................2-7

2.5 Specifications for analog monitor....................................................................................................................2-8

1) Monitor output..........................................................................................................................................2-8

2) Monitor for velocity, torque, and position deviation ..................................................................................2-9

2.6 Specifications for dynamic brake...................................................................................................................2-10

1) Allowable frequency, instantaneous tolerance, decreasing the rotation angle of the dynamic brake.....2-10

2.7 Regenerative control..................................................................................................................................... 2-11

2.8 Converter......................................................................................................................................................2-12

1) Specifications of converter.....................................................................................................................2-12

3. Installation........................................................................................................................................................ 3

3.1 Driver ..............................................................................................................................................................3-1

1) Precautions..............................................................................................................................................3-1

2) Unpacking................................................................................................................................................3-2

Table of contents

xiii

3) Mounting direction and location...............................................................................................................3-3

4) Control arrangement within the machine .................................................................................................3-3

3.2 Motor...............................................................................................................................................................3-4

1) Precautions..............................................................................................................................................3-4

2) Unpacking................................................................................................................................................3-4

3) Installation................................................................................................................................................3-4

4) Motor mounting method...........................................................................................................................3-5

3.3 Converter........................................................................................................................................................3-7

1) Precautions..............................................................................................................................................3-7

2) Unpacking................................................................................................................................................3-8

3) Installation................................................................................................................................................3-8

3.4 Cable (motor and converter)...........................................................................................................................3-9

1) Precautions..............................................................................................................................................3-9

4. Wiring................................................................................................................................................................ 4

4.1 Wiring for main circuit power supply, control power, regenerative resistance, and protective grounding........4-1

1) Part name and function............................................................................................................................4-1

2) Wire .........................................................................................................................................................4-1

3) Wire diameter-allowable current ..............................................................................................................4-2

4) Recommended wire diameter..................................................................................................................4-2

5) Crimping of wires.....................................................................................................................................4-3

6) High voltage circuit terminal; tightening torque ........................................................................................4-3

4.2 Wiring with Host Unit.......................................................................................................................................4-4

1) CN1 signal and pin number (wiring with host unit)...................................................................................4-4

2) CN1 connector disposition.......................................................................................................................4-5

3) Signal name and its function....................................................................................................................4-5

4) Terminal connection circuit.......................................................................................................................4-6

5) Example of wiring with CN1................................................................................................................... 4-12

4.3 Peripheral equipments.................................................................................................................................. 4-13

1) Power supply capacity and peripherals list............................................................................................4-13

5. Operation.......................................................................................................................................................... 5

5.1 System parameters.........................................................................................................................................5-1

1) Confirmation of specifications..................................................................................................................5-1

2) System parameters list ............................................................................................................................5-3

3) Confirmation and settings of system parameters.....................................................................................5-3

4) Confirmation and settings of the system parameters (settings for encoder specification)........................5-5

5)Factory default setting values..................................................................................................................5-5

5.2 Test operation .................................................................................................................................................5-6

Table of contents

xiv

1) Confirmation of installation and wiring .....................................................................................................5-6

2) Confirmation of movement....................................................................................................................... 5-6

3) Confirmation of I/O signal ........................................................................................................................5-7

4) Confirmation of device operation .............................................................................................................5-9

5.3 Driver status display......................................................................................................................................5-10

1) Default display.......................................................................................................................................5-10

2) Alarm display.........................................................................................................................................5-10

5.4 Operation sequence...................................................................................................................................... 5-11

1) Operation sequence from power turn on to power shut off at the standard shipment setting ................ 5-11

2) Stop sequence at alarm.........................................................................................................................5-13

3) Sequence of alarm reset........................................................................................................................5-15

4) Sequence when power is turned OFF during operation (During servo ON)...........................................5-16

5.5 Monitor function ............................................................................................................................................ 5-17

1) Monitor function .....................................................................................................................................5-17

2) Description of monitor............................................................................................................................5-18

5.6 Analog monitor and digital monitor................................................................................................................5-22

5.7 Setting parameters........................................................................................................................................5-23

1) Parameters list.......................................................................................................................................5-23

5.8 Parameter functions......................................................................................................................................5-30

5.9 Control block diagram...................................................................................................................................5-80

5.10 SEMI F47 supporting function.......................................................................................................................5-83

1) Parameter setting General parameters Group8 “Control system”.....................................................5-83

2) Operational sequence............................................................................................................................5-83

3) Notes .....................................................................................................................................................5-83

6. Adjustments ..................................................................................................................................................... 6

6.1 Servo tuning functions and basic adjustment procedure.................................................................................6-1

1) Servo tuning functions .............................................................................................................................6-1

2) Tuning method selection procedure.........................................................................................................6-2

6.2 Automatic tuning.............................................................................................................................................6-3

1) Use the following parameters for automatic tuning..................................................................................6-3

2) Automatically adjusted parameters in auto-tuning ...................................................................................6-6

3) Adjustable parameters during auto-tuning...............................................................................................6-6

4) Unstable functions during auto-tuning......................................................................................................6-7

5) Auto-tuning characteristic selection flowchart..........................................................................................6-8

6) Adjustment method for auto-tuning..........................................................................................................6-9

7) Monitoring servo gain adjustment parameters.......................................................................................6-10

8) Manual tuning method using auto-tuning results....................................................................................6-10

6.3 Automatic tuning of notch filter...................................................................................................................... 6-11

Table of contents

xv

1) Operation method.................................................................................................................................. 6-11

2) Setting parameters................................................................................................................................. 6-11

6.4 Automatic tuning of FF vibration suppression frequency...............................................................................6-12

1) Operation method..................................................................................................................................6-12

2) Setting parameters.................................................................................................................................6-12

6.5 Using manual tuning.....................................................................................................................................6-13

1) Servo system configuration and servo adjustment parameters .............................................................6-13

2) Basic manual tuning method for velocity control....................................................................................6-15

3) Basic manual tuning method for position control ...................................................................................6-15

6.6 Model following control..................................................................................................................................6-16

1) Automatic tuning method for model following control.............................................................................6-16

2) Manual tuning method for model following control.................................................................................6-17

6.7 Tuning to suppress vibration.........................................................................................................................6-18

1) FF vibration suppression control............................................................................................................6-18

2) Model following vibration suppression control........................................................................................6-18

3) Tuning methods.....................................................................................................................................6-20

6.8 Using disturbance observer function.............................................................................................................6-21

7. Digital Operator................................................................................................................................................ 7

7.1 Digital Operator names and functions.............................................................................................................7-1

7.2 Modes.............................................................................................................................................................7-1

1) Changing modes......................................................................................................................................7-1

2) Mode contents .........................................................................................................................................7-2

7.3 Setting and display range................................................................................................................................7-3

7.4 Status display mode........................................................................................................................................7-4

1) Driver status display.................................................................................................................................7-4

2) Over-travel status display ........................................................................................................................7-4

3) Status display of regenerative overload warning, and overload warning..................................................7-4

4) Alarm code and driver status code when alarm occurs............................................................................7-4

5) Alarm reset when alarm activated............................................................................................................7-5

6) How to check the software version of driver ............................................................................................7-5

7) How to check Information 1, Information 2 (driver information), and Information 3 (Motor Code)............7-6

8) How to set pass ward...............................................................................................................................7-7

9) How to cancel password..........................................................................................................................7-7

7.5 Editing parameters..........................................................................................................................................7-8

1) Basic parameters, editing system parameters......................................................................................... 7-8

2) Editing general parameters......................................................................................................................7-9

7.6 How to tune automatic notch frequency........................................................................................................ 7-11

7.7 How to tune automatic FF vibration suppression frequency..........................................................................7-12

Table of contents

xvi

7.8 Velocity-controlled JOG Operation................................................................................................................7-13

7.9 Automatic tuning result writing......................................................................................................................7-14

7.10 Automatic setting of motor parameter...........................................................................................................7-15

7.11 Alarm history display.....................................................................................................................................7-15

7.12 How to clear alarm history.............................................................................................................................7-16

7.13 Monitor display..............................................................................................................................................7-16

7.14 Fixed monitor display....................................................................................................................................7-17

7.15 Motor code-setting of motor used ................................................................................................................. 7-17

8. Maintenance..................................................................................................................................................... 8

8.1 Trouble shooting .............................................................................................................................................8-1

8.2 List of warning and alarm................................................................................................................................8-3

1) Warning List.............................................................................................................................................8-3

2) Alarm List.................................................................................................................................................8-4

8.3 Trouble shooting when alarm activated...........................................................................................................8-7

1) Alarm display...........................................................................................................................................8-7

2) Corrective action for alarm.......................................................................................................................8-7

8.4 Inspection......................................................................................................................................................8-26

9. Appendix........................................................................................................................................................... 9

9.1 Standards conformity......................................................................................................................................9-1

1) Standards conformity...............................................................................................................................9-1

2) Over-voltage category, protection grade, pollution level ..........................................................................9-2

3) Connection and installation......................................................................................................................9-2

4) UL file number..........................................................................................................................................9-2

9.2 Compliance with EN Directives.......................................................................................................................9-3

1) Conformity verification test.......................................................................................................................9-3

2) Requirements for driver installation to achieve the EMC certification ......................................................9-4

3) Requirements for converter installation to achieve the EMC certification ................................................9-5

9.3 Outline drawing...............................................................................................................................................9-6

1) Motor........................................................................................................................................................9-6

2) Driver.......................................................................................................................................................9-8

3) Converter.................................................................................................................................................9-9

4) Motor cable..............................................................................................................................................9-9

5) Converter Cable.....................................................................................................................................9-10

9.4 Optional parts................................................................................................................................................ 9-11

1) Connectors ............................................................................................................................................ 9-11

2) Mounting bracket ................................................................................................................................... 9-11

3) Setup software and serial communication .............................................................................................9-12

This manual suits for next models

3

Table of contents

Other NSK Servo Drive manuals

Popular Servo Drive manuals by other brands

Moog

Moog DS2020 Maintenance and user manual

Mitsubishi Electric

Mitsubishi Electric Melservo-J3 Series MR-J3-B manual

YASKAWA

YASKAWA SERVOPACK Sigma 7S Series Supplementary manual

SEW-Eurodrive

SEW-Eurodrive CMP ELVCD operating instructions

Hiwin

Hiwin E1 Series Operation Procedure

Kinco

Kinco FD3 User Guidance Manual

INGENIA

INGENIA Triton Go product manual

Mitsubishi Electric

Mitsubishi Electric MR-J5 Series user manual

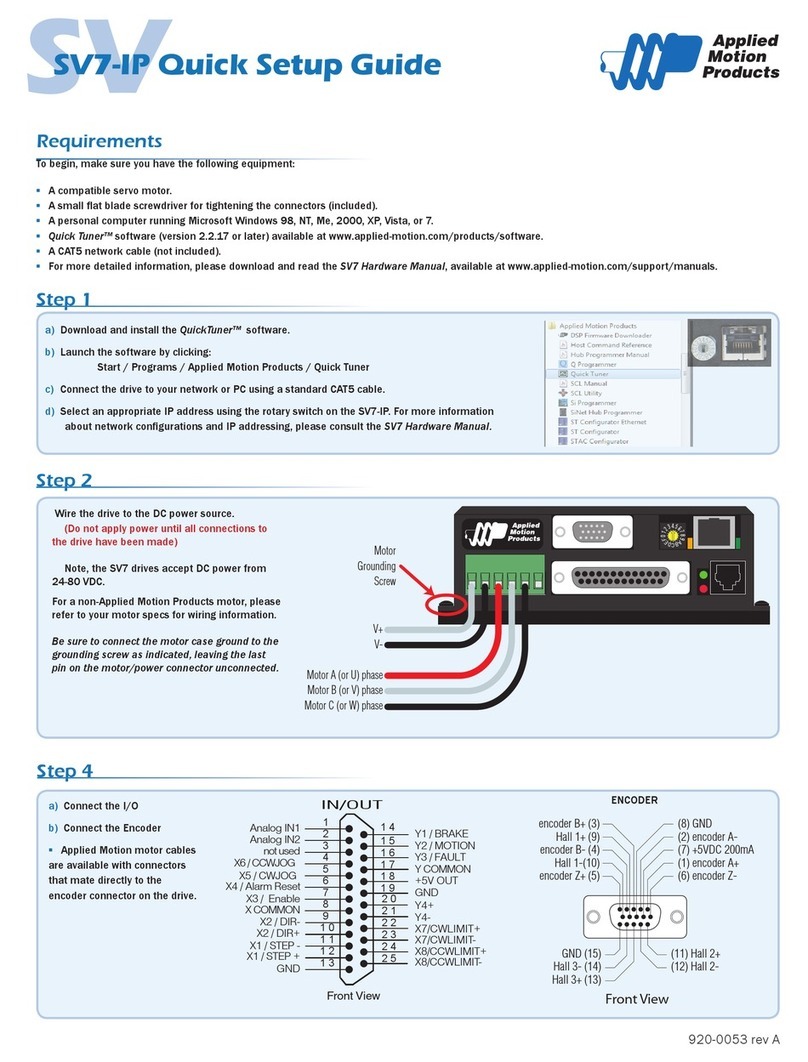

Applied Motion Products

Applied Motion Products SV7-IP Quick setup guide

LinMot

LinMot C1400-CI-VS-0S-YYY installation guide

Festo

Festo CMMT-AS-S1 Series manual

Metronix

Metronix DIS-2 48/10 FB FS STO Mounting instructions