25

Delta P stop: this parameter sets the positive pressure delta compared to Pmax for immediate

shutdown of the pump. During normal operation, when the valves close, the pump stops after a

time set in the parameter "stop delay". In any case, if the system pressure exceeds the Pmax value

of a delta greater than that set in this parameter, the pump will stop immediately to avoid

overpressure which may damage the system.

Unit of measurement: select the unit of measurement in BAR or PSI

Imax: this parameter enables entry of the maximum current absorbed by the electric pump in

routine conditions, to enable shut-down of the motor in the event of excessive absorption. The

motor is also shut down if the current read during operation is below 0.5 A following interruption

of the connection between the motor and Sirio. The trip time of the current overload safety device

is inversely proportional to the entity of the overload in progress; therefore a slight overload will

lead to a more delayed trip time while a more significant overload will accelerate the trip time. On activation of the device, if

the Imax parameter is set at 0.5 A (factory setting), the display automatically shows the settings page of the maximum current

and no action is permitted until the absorption limit value is set.

Rotation direction (only for three-phase pump version): this screen enables the user to invert

the direction of rotation of the electric pump without modification to the electric motor wiring. To

modify the direction of rotation of the motor, use buttons "+" and "-"; the direction indicated by

the arrow has a purely indicative value and does not reflect the actual sense of rotation which must

be verified by the installer.

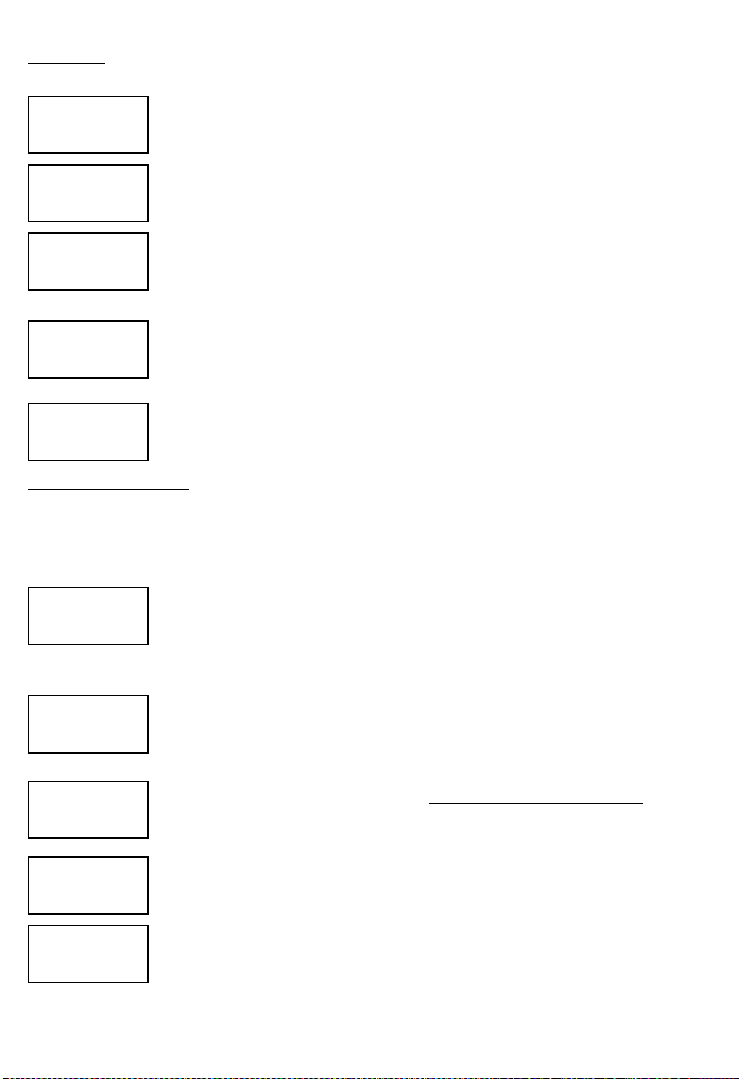

ADVANCED PARAMETERS:

The advanced parameters are accessible only to the technical assistance service. For access to these parameters, it is necessary

to contact the re-seller, a technical assistance centre or the manufacturer.

The following table lists the advanced parameters for reference when technical assistance is required.

REF. PARAMETER DESCRIPTION

1.2

Minimum frequency

Minimum motor start-up frequency

1.3

Stop frequency

Motor shutdown frequency

1.4

Nominal motor frequency

Maximum nominal motor frequency

1.5

Switching frequency

PWM Switching frequency

1.6

Frequency correction

Maximum frequency correction

1.7

Soft-start

Soft-start activation/deactivation

2.0

Flow switch activation

Flow switch activation or deactivation

2.1

Command source

Source of manual or automatic command

2.2

Auxiliary contact function

Selection of auxiliary contact function

2.3

I/O board input function

Function of I/O auxiliary board input contact

2.4

I/O board output function

Function of I/O auxiliary board output contact

2.5

Delay on stop

Delay on shutdown after closure of utilities

2.6

Autoreset interval

Time interval between autoreset attempts

2.7

No. autoreset tests

Number of autoreset attempts

2.8

Total automatic reset

Enabling of overall reset of all alarms

3.0 Pressure calibration 0.0 Bar To carry out calibration of the pressure sensor at 0 Bar

3.1 Pressure calibration 5.0 Bar To carry out calibration of the pressure sensor at 5 Bar

3.2 Flow sensor calibration To carry out calibration of the flow sensor

3.3 Pressure test Current pressure test signal

3.4 Flow switch test Flow switch test signal

3.5 Software Release Release of software

3.6 Power supply timing Inverter power supply timer

3.7 Pump timing Electric pump operational timer

3.8 Last error Last error occurred log

3.9 Start-up Pump start-up counter

4.0 Vboost Voltage boost at 0Hz

4.1 Dry run Time delay before activation of the protection due to no water

4.2 Protection starts per hour Activation or deactivation of the control on the number of start-ups per hour

(leak checks)

4.3 Anti-blockage protection Activation or deactivation of a function that automatically starts up the pump

after 24 hours of disuse

4.4 Dead time PWM Dead time PWM setting

4.5 Ki PID controller integral constant

4.6 Kp PID controller proportional constant

4.7 Boost time Boost time at maximum frequency with soft start disabled