8

2. Device Conguration

During this time the host will set the standard PS/2 param-

eters such as scaling, resolution, stream mode; enabling

stream mode for data reports. For a list of valid PS/2 com-

mands the mouse recognizes, see Appendix G.

3. Wheel Enable (optional)

Since the wheel is not part of the standard PS/2 specica-

tion, there is a sequence of commands that enable the

wheel. Wheel-aware drivers, such as those for Microsoft

and Linux operating systems will initiate this special

sequence.

After the following sequence of commands, the wheel

report format is enabled.

0xF3, 0xC8 Set Sampling Rate 200 per second

0xF3, 0x64 Set Sampling Rate 100 per second

0xF3, 0x32 Set Sampling Rate 50 per second

0xF2, 0x03 Read Device Type returns a value of 0x03

After the Read Device Type command returns 0x03,

indicating this is a Microsoft compatible three button

wheel mouse, the wheel report format is enabled. See

Appendix G for information on PS/2 standard and wheel

reporting formats.

4. Post Start Up Operation

After the streaming mode is set and data reports are

enabled, the mouse will send button, movement, and

optionally, wheel reports back to the host. Whenever the

mouse has new data to send it will initiate a transfer to

the host.

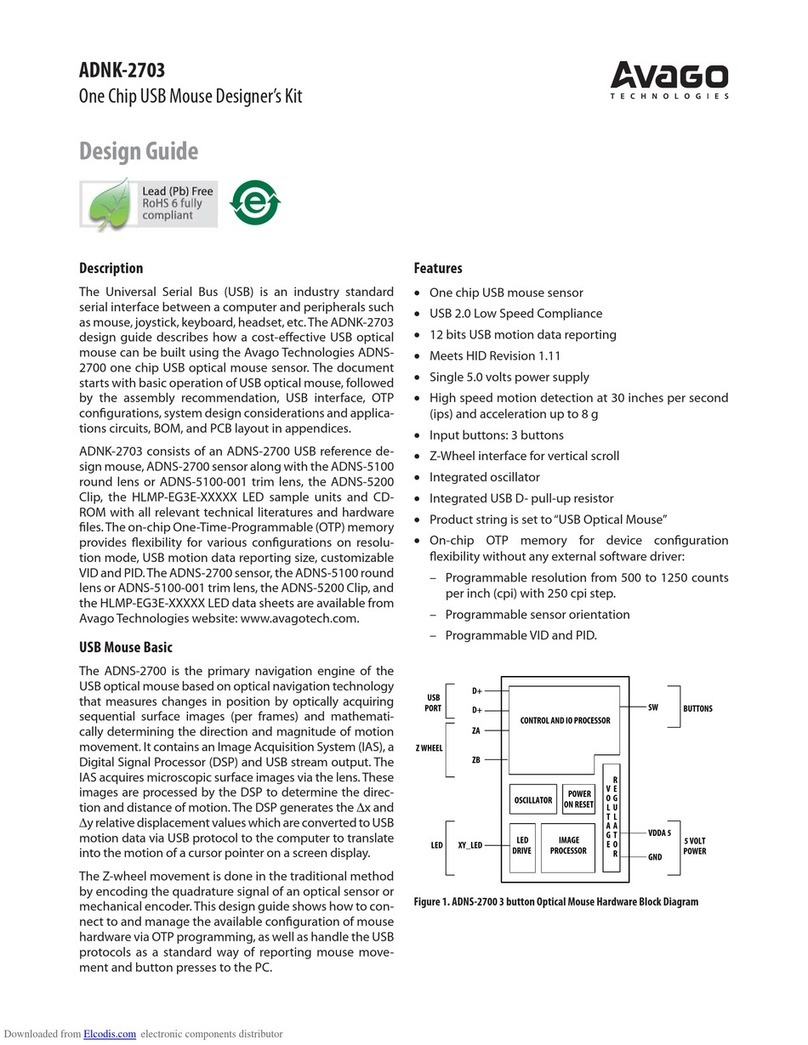

USB Firmware Description

A function call map for USB operation is shown in Figure

6. Following are descriptions of the functions in adns-

3080.asm.

Dual USB and PS2 Functions

GetMouseType – called in dualMain when the mouse is rst

plugged into the PC. This routine returns the interface of

the mouse. The following sequences are performed by

the micro-controller to determine the mouse type.

- Delay 50mS.

- Initialize the PS2 BAT delay counter.

- For a period of 2ms, poll the SCLK and SDATA lines

every 10μs. If we get 4 samples in a row with non-

zero data on either line, detect a PS2 interface. If 2mS

expires, enable the USB pull up resistor and delay

500μS.

- Poll the SCLK and SDATA lines indenitely until a non-

zero condition exists on either line. During this polling

period, we begin to count down the PS2 BAT delay.

- If SCLK(D+) is sampled high, detect a PS2 interface.

If SDATA(D-) sampled high, disable the USB connect

resistor and Delay 100μS.

- If D+ and D- are both 0, detect a USB interface, else

detect a PS2 interface.

SPIInit – This routine is called in the try_download to

enable the SPI interface. The CY7C63743-PXC is always

congured as a Master to drive the serial clock on P0.7.

The clock is set to HIGH in idle state, and the SCLK fre-

quency is set to send a bit rate of 1Mbit/s.

SensorReset – This routine resets the serial interface and

the ADNS-3080 internal registers by generating a pulse

on the RESET pin.

LoadSROM –called in try_download after the initialization of

the SPI interface. This routine is used to load the SROM

(Shadow ROM) firmware into the ADNS-3080 optical

sensor. It should be called after SensorReset.

ProcessButtons – This routine is called within the innite

loop of usbTaskLoop and ps2TaskLoop. The state of the

buttons is updated every one ms in the Dual1msTimer

Interrupt Service Routine (ISR). This routine compares the

current state of the buttons with their last state to detect

any changes in the status. If the status of these buttons

remains until the expiration of debounce timer (15ms),

the new button state is conrmed. This routine will record

the new button state in the [buttonValue] variable which

will be reported to the host in the main loop.

ReadProcessOptics – This routine returns any updates in the

X, Y and Z-wheel motion information. The motion of the

Z-wheel is detected using the traditional method by

decoding the quadrature signal generated by the pho-

totransistors. The X and Y directions of the movement

are obtained by calling the ReadDeltaX and ReadDeltaY

routines. The X, Y, and Z-wheel movement is stored in

the [xCount], [yCount], and [zCount] variables which will

be sent to the host in the main routine. The 1600cpi is

activated in this routine by writing to the Conguration

Register 0x0a with LED_MODE_1600.

ReadMotionReg – Reads the ADNS-3080 Motion register.

The data returned from this register will be used to deter-

mine if any motion has occurred or if any fault condition

exists.

ReadDeltaX – Reads the ADNS-3080 Delta_X register for the

X movement. Calls the ReadSPI routine to enable the SPI

interface and perform reading operations through the

four-wire serial interface. Any new X motion information

is added to the [xCount] variable.