PAGE 4TABLE OF CONTENTS

Introduction & Important Info.................1

Safety Precautions.....................................2

Features & Specifications........................5

Installation Options...................................5

Heating Specifications...............................5

Dimensions.............................................5

Fuel, Emissions, Electrical..........................5

Stove Installation

Installation Preparation.............................6

Items Required for Installation....................6

Packing Lists..........................................6

Order of Installation .................................6

Door Removal ........................................6

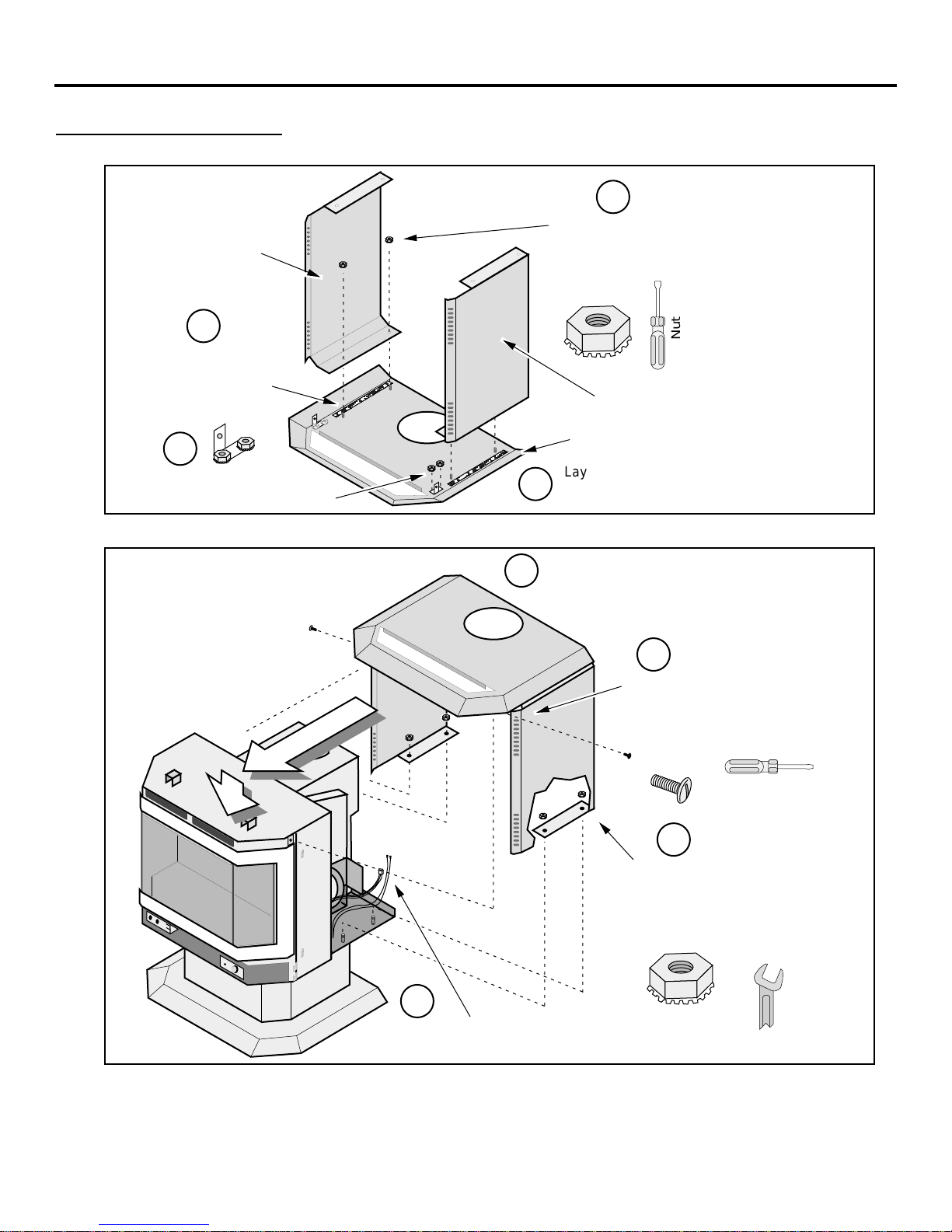

Pedestal Attachment................................6

Stove Shell Assembly...............................7

Gas Inlet Installation ................................9

Floor Protection Requirements...................10

Stove Placement Requirements .................10

Gas Line Installation ................................11

Vent Requirements..................................12

Approved Vent Configurations....................13

Restrictor Position .............................13

Elbows............................................13

How to Measure Vent Lengths .............13

Approved Vent Config's with No Elbows

or Two 45°Offsets (Vertical Term.) .......14

Approved Vent Config's with a

Horizontal Termination........................15

Approved Vent Config's with a Vertical

Termination and Two 90°Elbows..........16

Horizontal Vent Termination Requirements...17

Vertical Vent Termination Requirements ......17

Electrical Connection ...............................17

Insert Installation

Installation Preparation.............................18

Items Required for Installation....................18

Packing Lists..........................................18

Order of Installation .................................18

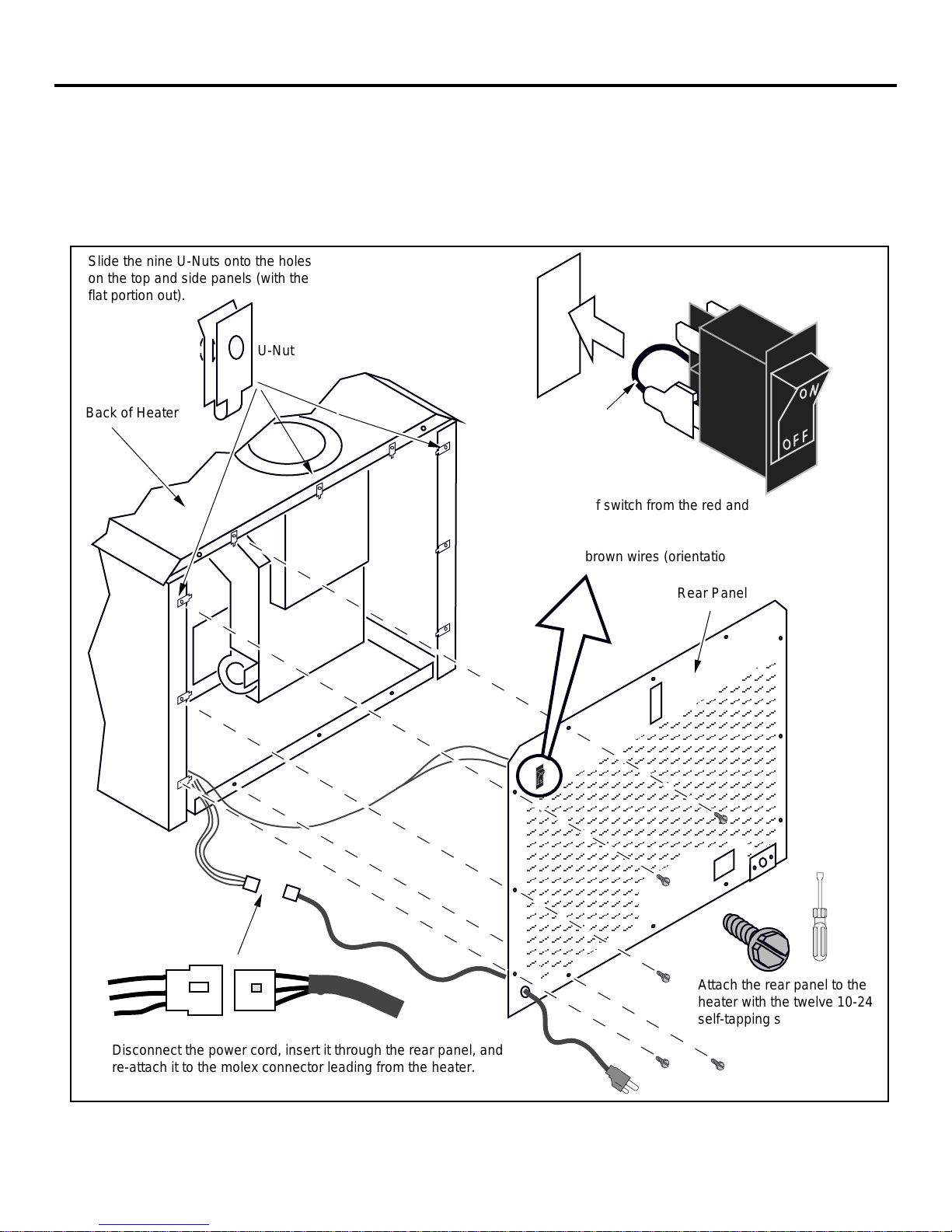

Installing the Power Cord..........................19

Insert Placement.....................................20

Floor Protection ......................................20

Gas Line Install.......................................21

Vent Requirements..................................22

Approved Vent Configurations....................23

Electrical Connection ...............................23

Surround Panel Installation........................24

Insert Shell Installation .............................25

Finalizing the Installation

1 Door Opening ......................................26

2 Log, Twig, and Ember Installation.............27

3 Glass Installation ..................................28

4 Purge and Leak Test the Gas Line ...........28

5 Pilot Flame Inspection............................28

6 Air Shutter Adjustment...........................29

7 Flame Inspection ..................................29

8 Explain Heater Operation to Owner ..........29

Operating Your Heater

Before You Begin....................................30

Location of Controls.................................30

Starting The Pilot Flame ...........................31

Starting the Stove for the First Time ............32

Turning the Stove On and Off ....................32

Adjusting the Flame Height........................32

Adjusting the Blower Speed.......................33

Normal Operating Sounds.........................33

Maintaining Your Stove

Maintaining Your Stove's Appearance..........34

Cleaning Your Stove................................34

Yearly Service Procedure..........................34

Troubleshooting

Troubleshooting Table..............................35

How this Stove Works ..............................36

Wiring Diagram.......................................37

Warranty.....................................................38

Listing Information ..................................39

Optional Equipment

Propane (LP) Conversion Kit .....................40

Thermostat ............................................44

Remote Control Thermostat.......................45

Gold Trim Kit..........................................46

Addendum

Altitude Considerations.............................47

Class A Chimney Conversion Kit ................47

Interior Masonry Chimney Conversions........47

Index 48

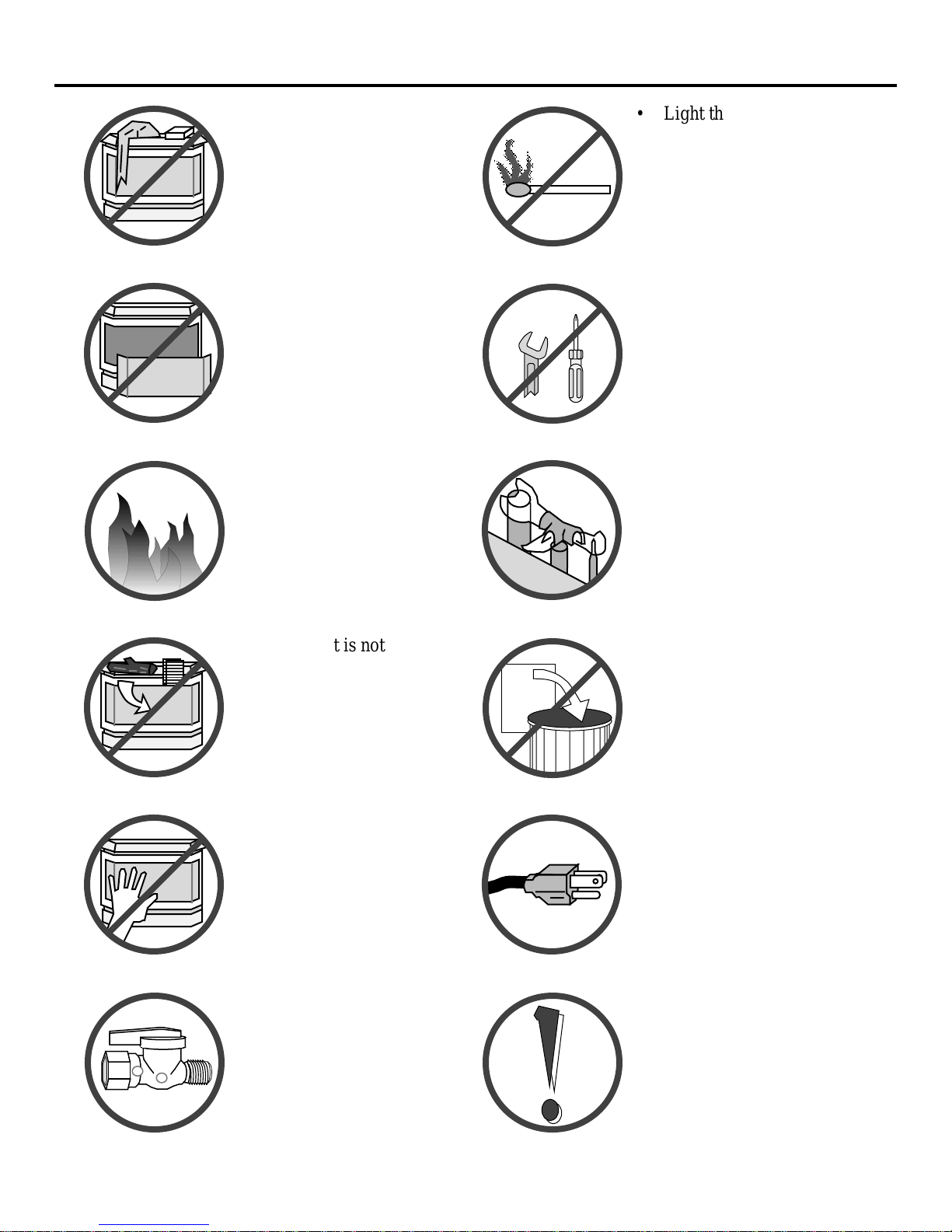

Symbols Used in this Manual

The illustration below details what the symbols used along the left margin indicate.

Requirement

•1!?+

Hint

NoteWarningStep