300S Series ow to work safely

5

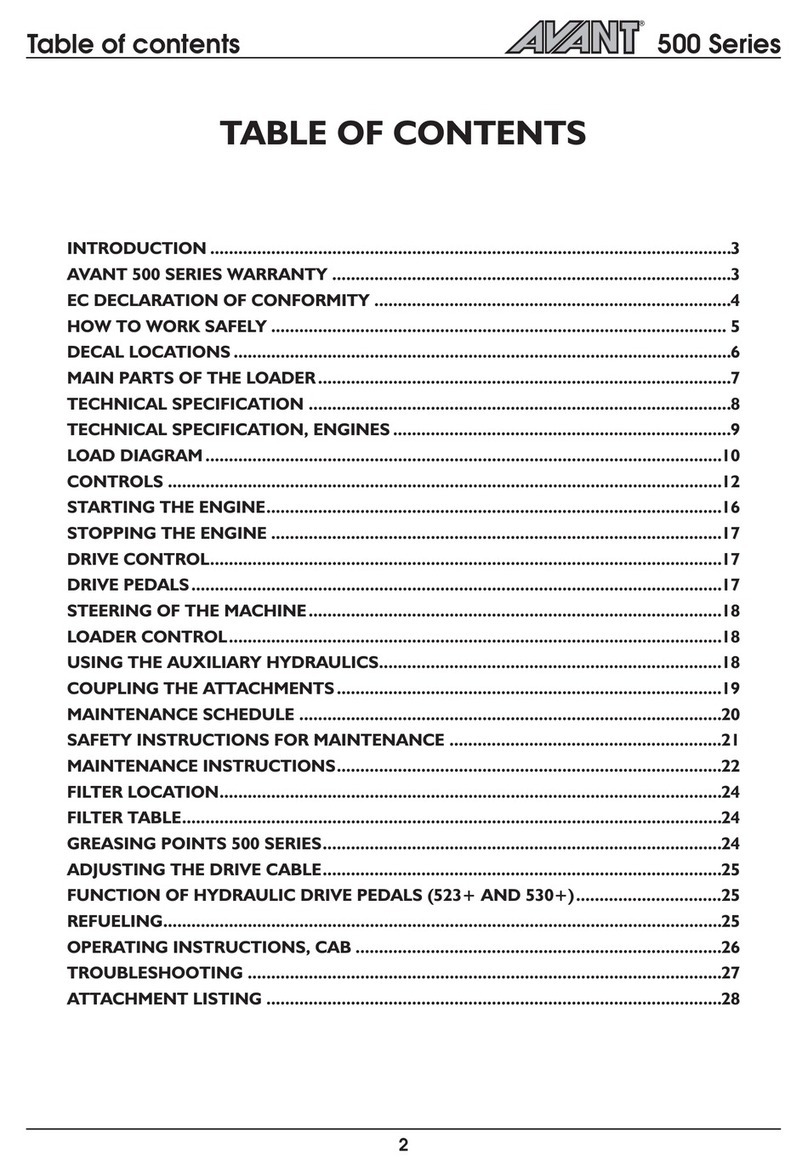

HOW TO WORK SAFELY

An incorrect or careless operation of the loader may

be the origin of a serious accident. Before putting the

machine into operation, familiarise yourself with the

use of the machine and read and understand this

Operators Manual as well as the safety instructions.

THIS SYMBOL INDICATES

THE IMPORTANT

SAFETY FACTORS.

Understand the limitations of speed, braking, steering

and stability as well as loading capacity of the machine

before starting operation.

If you have no previous experience of the machine,

make sure to do all testing at a safe and open place

with no persons in the area of operation.

SAFETY INSTRUCTIONS

Never use the loader without instructions. Read loader

signs (decals), and this manual.

Start the operation slowly and carefully.

Do not wear loose clothing, long uncovered hair or

jewelry near machine.

When driving be comfortably seated in the driver´s

seat, keep your feet in their proper place in the footwell

and both hands on the control levers.

Operate the control levers and the lever of auxiliary

hydraulics only when sitting in the driver´s seat.

Operate the control levers with ease and without

hesitation.

When coupling the attachment, make sure that the

locking pins lock in positively.

Never put any part of the body or let anyone go under

the lifted boom.

Do not transport persons in the bucket. The machine

is not designed to lift or to transport persons.

Keep hands, feet and clothing away from any moving

part and/or hydraulic cylinder.

Never carry passengers. Keep other bystanders away

from the work area.

Drive slowly on uneven terrains. Watch out for ditches,

manholes and steep gradients.

Do not drive on too steep a gradient. Load, unload, and

turn on flat level ground.

Make sure that the ventilation is sufficient when working

indoors or otherwise confined area.

Do not use loader in an atmosphere with explosive dust

or gases or where exhaust can contact flammable

material, explosion or fire can result.

Do not transport the load with the boom lifted.

Always carry bucket or attachment as low as possible,

and put the load down whenever you leave the machine.

When lifting or lowering the load, do not operate the

boom control lever abruptly. Turn the lever smoothly

and with care.

Do not exceed rated operating capacity - follow the

load diagrams.

Do not park the machine on a surface with a gradient.

Should this be necessary, use the parking brake and

preferably turn the machine sideways and put down

the bucket. If needed, use chocks behind the wheels.

Before leaving driver´s seat:

- Lower the loader boom

- Place attachment flat on ground

- Stop the engine, remove the key

- Engage the parking brake

Never perform any maintenance or repair operation

when the engine is running.

Stop and cool the engine before adding fuel.

Never use ether or starting fluid on diesel engines with

glow plugs. Use only starting aids as approved by engine

manufacturer.

Keep the engine area clean of flammable materials.

Wear eye protection when servicing, and hard hat or

other protective equipment as needed.

When connecting a booster battery for "jump" start,

always make last connection (negative cable) to engine,

never at battery. When removing the "jump" start cable,

always remove the negative cable (-) from engine first.

Never charge a frozen battery.

Lead acid batteries produce flammable and explosive

gases. Keep arcs, sparks, flames and lighted tobacco

away from battery.

Battery acid causes severe burns. In case of acid contact,

wash immediately with water for several minutes and

get medical attention in case of eye contact.

Use a piece of cardboard to check for hydraulic leaks.

Leaking fluids under pressure can enter the skin and

cause serious injury. Medical attention is required if

hydraulic or other fluids contact skin.

Never modify the loader or add attachments not

approved by AVA NT Tecno Oy.

Do not smoke during refueling or driving.

Read this Operator's Manual carefully, especially if you

are unfamiliar with the safe use and operation of the

machine.