5 (36)

2. Designed purpose of use

The AVANT Pallet fork with hydraulic side shift is an attachment that is suitable for use with AVANT multi

purpose loaders that are shown in Table 1. The pallet fork is an excellent tool for handling standard sized

pallets. The pallet fork is an useful attachment all year round for example on construction sites, farms, and

especially at outdoor material handling jobs, where conventional fork-lift trucks may be impracticable. When

operating with the pallet forks, the performance and stability limits of the loader must be observed, especially

when working on inclined terrains.

With the fork side shift mechanism, different pallet sizes can be transported easily and stacked precisely. The

side shift feature is controlled by the auxiliary hydraulic output of the loader, and the operating mode, side shift

or fork width, is chosen by an electric switch. A foldable load backrest extension is fitted as standard, which

must be used when handling loose materials that could fall from a pallet. If lifting and load handling tasks are

frequent, equipping the loader with the boom self levelling and the electric joystick will make repeated lifting

tasks easier.

The maximum load is different for each pallet fork model. Never handle loads that are heavier than the

declared maximum load. The actual operating capacity of the loader equipped with pallet forks depends on

the loader model, and various environmental factors, as shown in this manual. Refer to the operator's manual

of your loader for information about the lift capacity of your loader. In this manual there are load charts that

apply for loaders that are manufactured in 2018 or later.

When operating with the pallet forks, the performance and stability limits of the loader must be observed,

especially when working on inclined terrains. The pallet forks must not be used for lifting persons and it is

prohibited to use the pallet forks as any kind of access platform. The Pallet forks are not designed for any

other use than what is specified in this manual and must not be used for any other purposes than intended.

Using the pallet forks for other purposes than lifting of loads on pallets, or other unit loads that are intended to

be lifted with forks, can damage the fork arms or the frame of the pallet forks. Hanging of loads from the pallet

forks is prohibited. The fork arms must no be used to, for example, wedging of large rocks, or similar tasks

where fork arms are subject to high loads, bending, or impact. The fork arms must also not be bent, heated, or

straightened after damage.

The attachment has been designed to require as little maintenance as possible. The operator can perform

regular maintenance tasks. All repair work can’t be performed by the operator, and demanding repair and

maintenance operations are to be left for professional maintenance. All maintenance work must be done using

proper safety equipment. Spare parts must be identical with original specifications, which can be ensured by

using only original spare parts. A separate spare parts catalogue may be available, consult your Avant dealer.

Familiarise yourself with the manual's instructions regarding service and maintenance. Please contact your

AVANT retailer if you have additional questions about the operation or maintenance of the equipment, or if

you require spare parts or maintenance services.

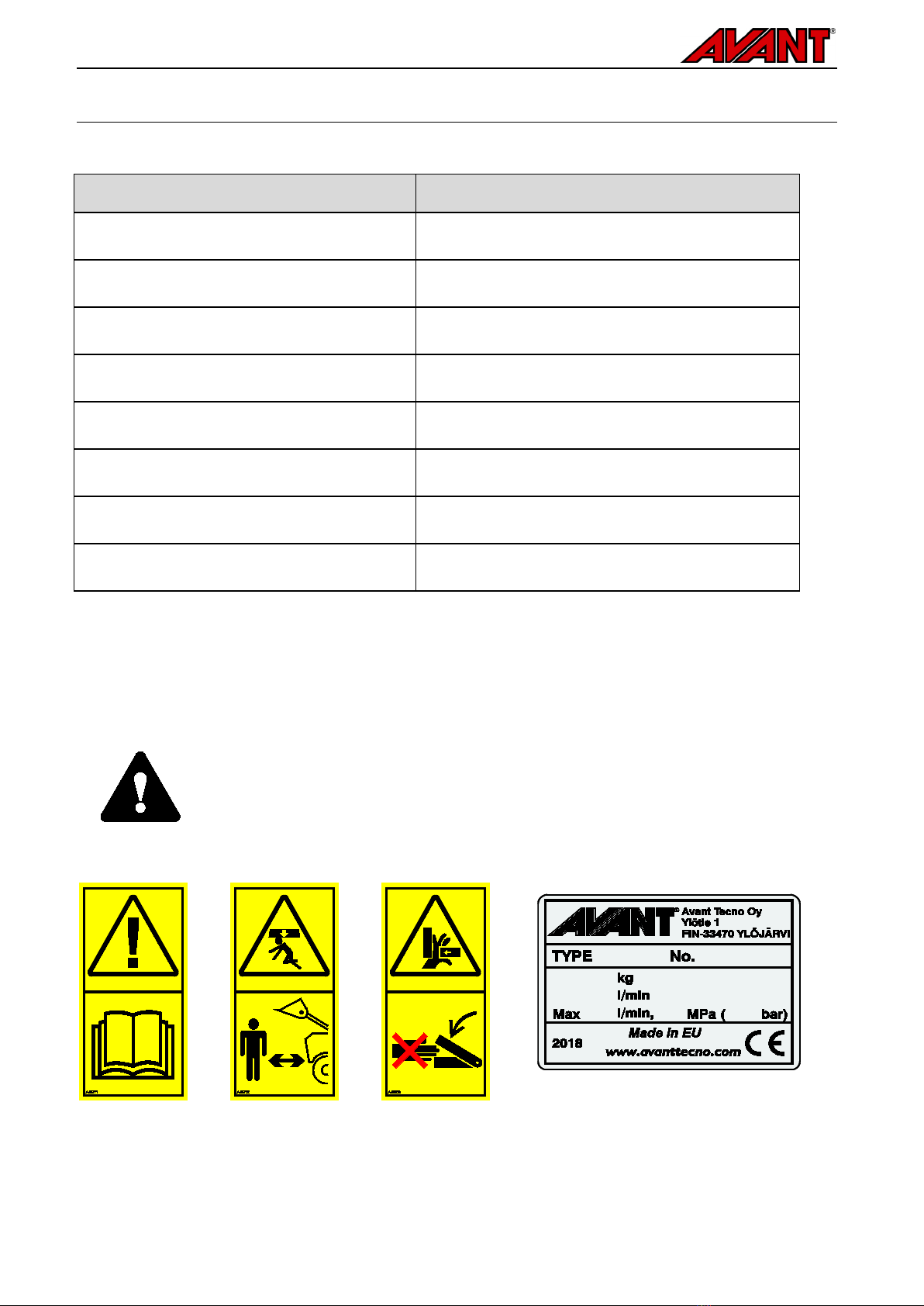

Table 1 - Pallet fork with side shift - Compatibility with Avant loaders

Avant 220 series 2

225

225 LPG

313S

320S

420

423

520

523

R20

525LPG

R28

528

530

e5

e6

630

R35

635

640

745

750

755i

760i

850

860i

A36279 1100 mm - - ••••••

The compatibility recommendations are based on the width of the loader, lifting capacity, and adequate

breakout force. The operating capacity of the loader can be determined by using the information shown in this

manual and the load diagram shown in the operator's manual of the loader. Depending on operating

conditions additional counterweights may also be required. For compatibility information with a model not

shown in table above, contact your Avant dealer.