7 (26)

3. Safety instructions for using the attachment

Please bear in mind that safety is the result of several factors. The loader-attachment combination is highly

powerful and improper or careless use or maintenance may cause serious personal injury or property

damage. Due to this, all operators must carefully familiarise themselves about correct use and the operator's

manuals of both the loader and the attachment before starting operation. Do not use the attachment if you

have not completely familiarised yourself with its operation and the related hazards.

DANGER

Misuse, careless use, or using an attachment that is in poor condition may

cause risk of serious injuries.

Familiarise yourself with the controls of the loader,

correct coupling proc

edure, and the correct way to operate the attachment at a safe

area. Study especially how to stop the equipment in a safe manner. Read all safety

precautions carefully.

Read all safety instructions carefully before handling the attachment

WARNING

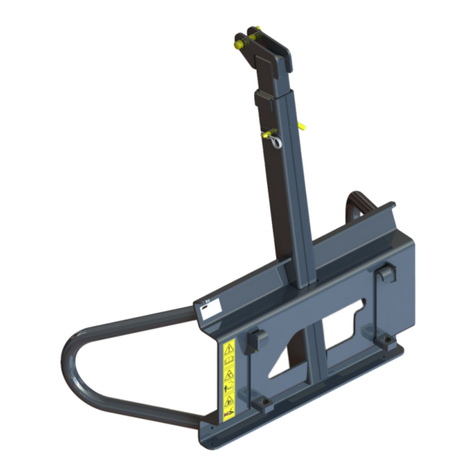

When attaching an attachment to the loader, ensure that the locking pins of the

loader's quick attach plate are in the lower position and that they have locked

the attachment to the loader. Never lift or move an unlocked attachment.

This attachment is designe

d to be used by one operator at a time. Do not let others

near the danger area of the equipment when it is in use.

Always transport the attachment as low as possible to keep the centre of gravity low,

and keep the telescopic boom retracted during driving.

Risk of crushing - Never go or allow anyone else to go under the loader boom

or attachment. The stability of the loader may change when leaving the driver’s seat,

leading to tipping over of the machine. Always remember that the boom may lower

unexpected

ly due to loss of stability, mechanical fault, or if another person operates

the controls of the loader, leading to crushing hazard. The loader is not intended to

be left to keep a load elevated for longer periods. Lower the attachment firmly on the

ground

before leaving the driver's seat and never allow anyone to be under the boom

or attachment.

Sudden movements can cause the loader to tip over - Operate the controls of

the loader in a slow and calm manner.

Be careful when lifting load to high level or

lifting load from high. Avoid sudden changes in speed or direction to maintain

balance of the loader especially when handling heavy loads. Drive slowly and

carefully especially on inclined terrain or slippery surfaces.

Risk of tipping over - Keep loads close to ground while driving. Carrying heavy

loads can shift the centre of gravity of the loader and lead to tipping over of the

loader. For the best stability always transport loads as low and close to the loader as

possible, with the telescopic boom com

pletely retracted, to keep the centre of gravity

low.

Do not connect any lifting equipment to the log grab.

Keep the loader articulation in straight position when handling heavy loads. When

turning the articulation, the loader may tilt forward.

Observe maximum load indicated in the operator’s manual of the loader. Be

especially careful when the load sensor indicator is activated, if your loader is fitted

with a load sensor system.

Make sure that the surface can bear the total load. Also follow the correct tyre

pressure settings.