Page 5For technical questions, please call 1-888-866-5797.Item 58056

RETURNS NOT ACCEPTED & WARRANTY VOID

if Spray Gun is not properly cleaned immediately after every use.

Clean Spray Gun immediately to prevent permanent damage.

SAFETYOPERATIONMAINTENANCE SETUP

Specific Safety Instructions

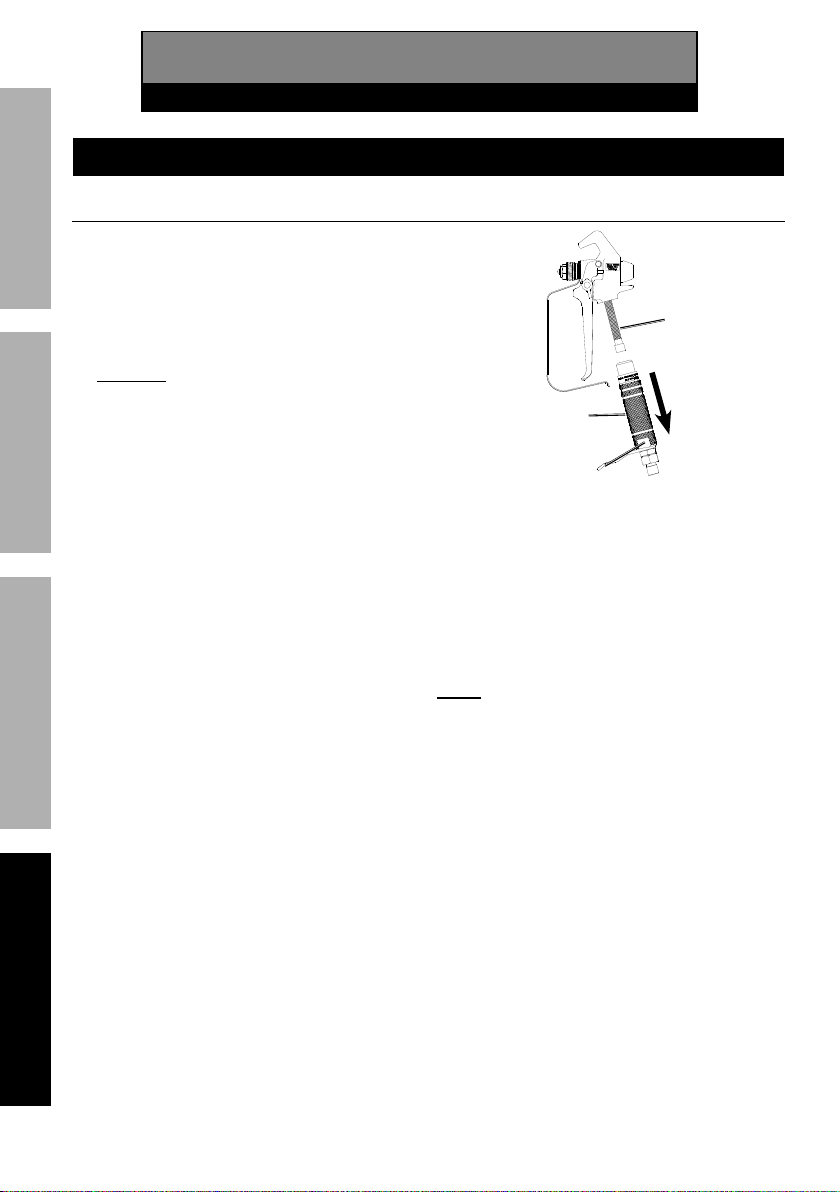

1. INJECTION HAZARD!

Although this paint gun is airless,

it still puts out paint at a very high

pressure. Through improper

use, paint can be injected through a person’s

skin, leading to serious injury, possibly

amputation. If paint is accidentally injected into

someone’s skin, contact a doctor immediately.

Do not treat an injection injury as a simple

cut. Injection can lead to amputation and

requires immediate surgical treatment.

2. Do not direct spray at people or animals. Do

not place your hand in front of Spray Gun’s

nozzle or attempt to deflect paint spray

with your hand during use. Gloves and

clothing don’t offer adequate protection

from toxic paints, sealers, or stains.

3. Do not spray flammable materials in vicinity

of open flame or near ignition sources.

Motors, electrical equipment, and controls

can cause electrical arcs that will ignite a

flammable gas or vapor. Do not store flammable

liquids or gases in vicinity of this unit.

4. Do not come into contact with a fluid stream

created by a leak in the paint hose.

5. Do not leave Paint Sprayer pressurized

while unattended.

6. Do not clean Spray Gun tip while it

is still connected to paint hose.

7. Keep the trigger and the electrical

cord plug clean and paint-free.

8. Do not use Spray Gun to spray asbestos,

metallic paints, glazes, red lead,

cement, ground chalk, abrasive grainy

paints containing lime, or bleach.

These will damage the spray gun

and void the warranty.

9. Read all of the information concerning coating

products and cleaning solvents. Do NOT use

bleach, low-flash naphthalene, acetone, alcohol or

toluene when cleaning Paint Sprayer equipment.

10. Do not use bleach or halogenated hydrocarbon

bromine, carbon tetrachloride, and ethyl iodide).

Long term exposure to many chlorinated

hydrocarbons through inhalation can result in liver

and kidney toxicity. Exposure of unprotected skin

to the solvents used can cause defatting of the

skin resulting in dermatitis. Methylene chloride

and vinyl chloride have also been shown to be

human carcinogens. Some of these solvents are

flammable. Welding operations near the these

materials can create phosgene, a highly toxic gas.

11. Many spray guns contain aluminum,

which reacts strongly to chlorinated solvents.

Contact the solvent or coating manufacturer as

needed regarding potential chemical reactions.

12. Industrial applications must follow

OSHA requirements.

13. Spraying hazardous materials may result in serious

injury or death. Do not spray pesticide, acid,

corrosive material, fertilizer, or toxic chemicals.

14. Paints and solvents may be harmful or fatal if

swallowed or inhaled. Avoid prolonged skin

contact with solvents or paints as they will

irritate skin. After any contact, immediately

wash off exposed area with hot, soapy water.

15. Use caution while spraying on windy days.

16. Do not use Spray Gun without

the nozzle guard in place.

17. Remove Spray Tip or turn to cleaning

position BEFORE cleaning or

flushing Paint Sprayer system.

18. Do not use pliers to tighten or loosen

high pressure connections.