User manual Drive unit DAE-01 CL

10

5. Configuration menu

The Configuration menu allows the individually adaptation of the drive

unit to the requirements of the platter.

For the correct speed, the relationship between the pulley and the platter

must be considered very carefully. It is also very important to optimize

acceleration and braking forces in order to match the material properties

of the drive belt and the mass of the platter.

This allows the drive unit to be optimally adjusted to the pairing with the

platter and adapted to actual conditions.

The channels are not numbered consecutively, they are organized in mea-

ningful categories:

• Channels below 100 are intended for the general channels „Dimmer“,

„Key Delay“ and „Pickup“.

• Channels 100 ... 123 concern the „Set“

• Channel 999 is for reset to factory defaults

„Gaps“ in channel numbering during selection therefore are completely

normal.

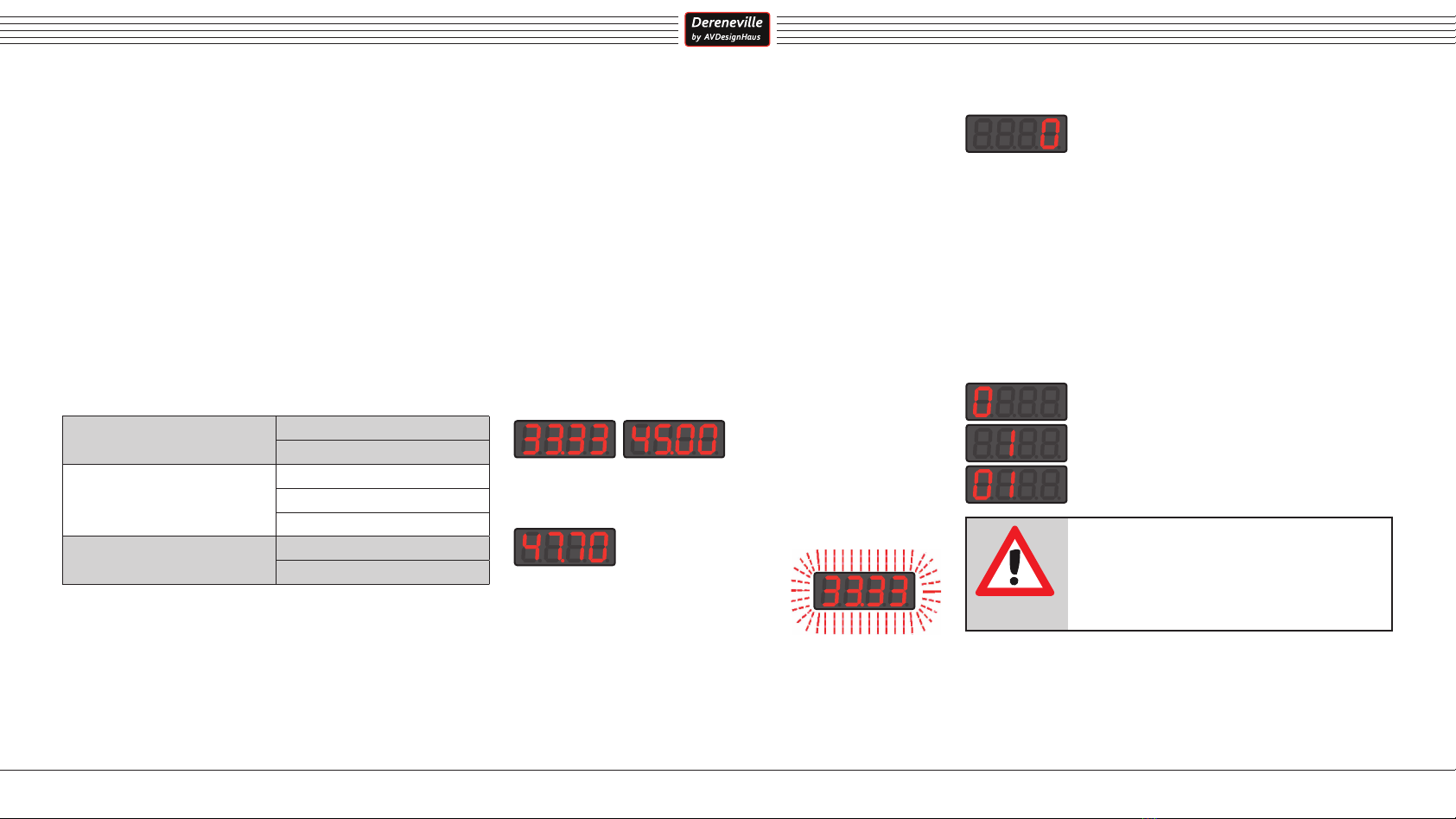

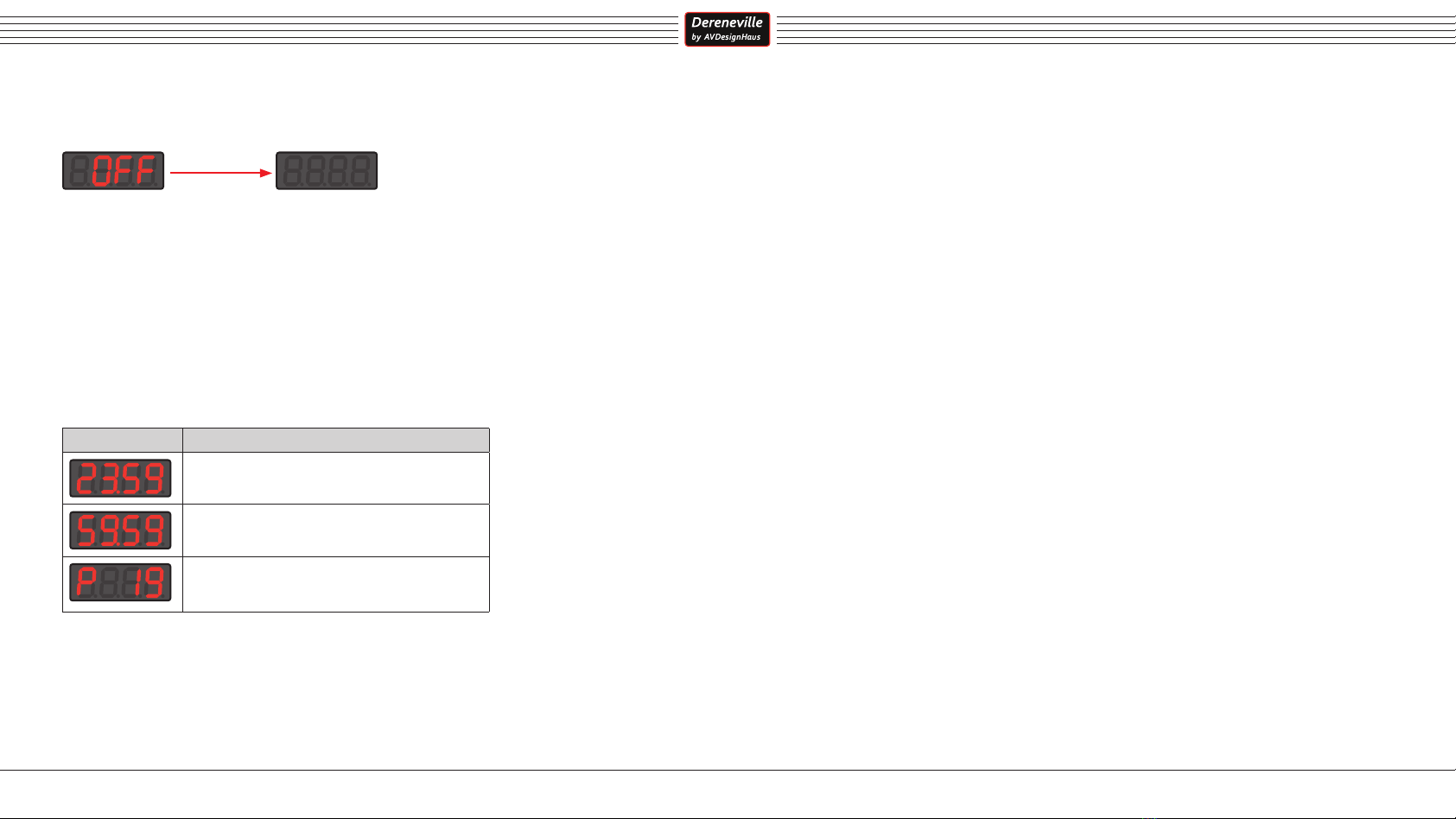

5.1 Call up Configuration menu

► Press and hold the [On Off] key and then briefly press the [-] key to

enter the Configuration menu.

The display changes to the channel display („c“ and channel number):

Function ►Display

Congurationmenu

+

► Press [On Off] to exit the Configuration menu.

5.2 Channel selection

► Press [+] to increase channel number.

► Press [-] to decrease channel number.

After selecting the channel to be edited, the channel number and the cur-

rent value for this channel are displayed alternately.

channel valuechannel number

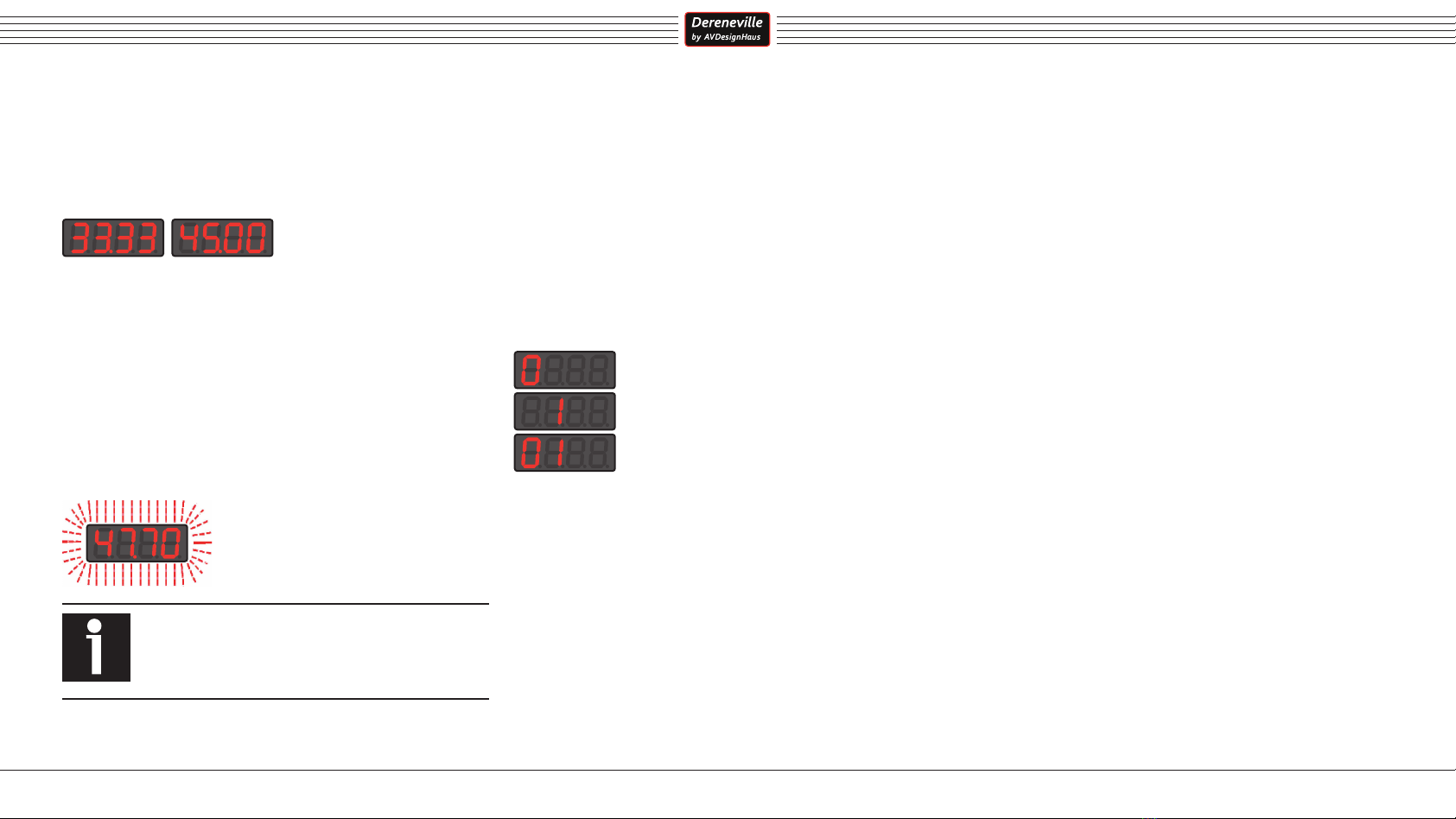

5.3 Changing channel value

► Press and hold the [33 45] key and then briefly press the [+] key to

increase channel value.

► Press and hold the [33 45] key and then briefly press the [-] key to

decrease channel value.

Pressing and holding the buttons [+] / [-] for a longer time will change the

channel value continuously, whereby the step size of the change of the

channel value increases by the duration of the button operation.

► Press and hold the [33 45] and [On Off] key to restore the original

channel value („Undo“).

While the channel value is changed, only the channel value is shown in the

display.

The effect of change a channel value is immediate, if possible. For exam-

ple, the speed settings are directly passed on to the motor with each chan-

nel value change, so that the resulting changes can be checked directly.

If the value of a channel is not changed for a certain time, the current value

for this channel and the channel number is displayed alternately again.

When you exit the Configuration menu by pressing the [On Off] key,

changed channel values are stored in the non-volatile memory and thus

remain safely stored until any later changes are made, even in the event

of a power failure.

Some channels are used only to display actual values.

A change of these channel values therefore is not possible.

There is no need to hurry while changing values in the Con-

figuration menu.

The Configuration menu will not be exited until the [On Off]

key has been pressed.