Avery Dennison ST9500 Operating manual

1

ST9

ST9ST9

ST95

55

500™

00™00™

00™

Plastic Staple

Plastic StaplePlastic Staple

Plastic Staple

®

®®

®

Attacher

AttacherAttacher

Attacher

Item # 15000™

Operator and

Operator andOperator and

Operator and

Service Manual

Service ManualService Manual

Service Manual

©

©©

©

Part No. 3-05-0100-01 Rev. 1

Patent(s) Pending

2

IMPORTANT NOTICE: PLEASE READ CAREFULLY THE TERMS AND CONDITIONS OF THIS END-USER LICENSE AGREEMENT

(“AGREEMENT”) BEFORE BREAKING THIS SEAL AND OPENING THIS PACKAGE CONTAINING THE ST9500™ PLASTIC

STAPLE® ATTACHER (THE “PRODUCT”). AVERY DENNISON CORPORATION AND/OR ANY OF ITS SUBSIDIARIES (“AVERY”) IS

WILLING TO LICENSE TO YOU (“YOU” OR “YOUR”) THE RIGHT TO USE THE PRODUCT ONLY ON THE CONDITION THAT YOU

ACCEPT ALL OF THE TERMS AND CONDITIONS OF THIS AGREEMENT. BY OPENING THIS PACKAGE, YOU AGREE TO THE

TERMS AND CONDITIONS OF THIS AGREEMENT. IF YOU DO NOT AGREE TO THESE TERMS AND CONDITIONS, PLEASE DO

NOT OPEN THIS PACKAGE AND CONTACT AVERY CUSTOMER SERVICE FOR INFORMATION ON HOW TO OBTAIN A REFUND

OF THE MONEY YOU PAID, IF ANY, FOR THE PRODUCT (LESS SHIPPING, HANDLING, AND ANY APPLICABLE TAXES) AT ANY

TIME DURING THE NINETY (90) DAY PERIOD FOLLOWING THE DATE OF PURCHASE.

PATENT AND COPYRIGHT NOTICE: THE PRODUCT IS COVERED BY U.S. PATENT NO. 5,433,366 (THE “PATENT”) AND/OR

CERTAIN PATENTS APPLIED FOR. THE PRODUCT ALSO CONTAINS SOFTWARE PROTECTED BY COPYRIGHT.

1. License. Subject to the terms and conditions of this Agreement, Avery grants to You a limited, personal, non-exclusive license to use the

Product.

2. NOTICE--Third Party Fasteners. The Product was designed to operate with original Avery plastic fasteners. Use of third-party plastic

fasteners may result in Product performance problems and/or quality risks in resulting byproducts. Accordingly, unless otherwise authorized by

Avery in writing, THE LIMITED WARRANTY OFFERED IN SECTION 3 BELOW WILL NOT APPLY TO THE EXTENT THAT YOU USE

THE PRODUCT WITH THIRD-PARTY FASTENERS.

3. Limited Warranty. Avery warrants that the Product will be free from defects in material and workmanship for a period of ninety (90) days

(or the period stated on the specific product information literature in effect at time of delivery, if longer) after the date of shipment. It is expressly

understood and agreed that Avery's sole obligation and Your exclusive remedy under this warranty, under any other warranty (if applicable),

express or implied, or otherwise, shall be limited to, at Avery’s discretion: (i) the replacement of the defective Product, at no additional cost to you;

(ii) the repair of the defective Product, which repair will be made at Avery’s own facility or at the location of the Product, at no additional cost to

You; or (iii) if Avery determines that replacement or repair is not commercially practical, a reasonable credit in light of the defect in the Product,

which credit shall in no event exceed the purchase price You paid for the Product.

4. Limitation of Liability. SOME STATES AND COUNTRIES DO NOT ALLOW THE LIMITATION OR EXCLUSION OF LIABILITY

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES, SO THE LIMITATIONS OR EXCLUSIONS SET FORTH BELOW MAY NOT

APPLY TO YOU.

TO THE MAXIMUM EXTENT PERMITTED BY APPLICABLE LAW AND REGARDLESS OF WHETHER ANY REMEDY SET FORTH

HEREIN FAILS OF ITS ESSENTIAL PURPOSE, IN NO EVENT WILL AVERY BE LIABLE TO YOU FOR ANY SPECIAL,

CONSEQUENTIAL, INDIRECT, OR SIMILAR DAMAGES, INCLUDING ANY LOST PROFITS, ARISING OUT OF THE USE OR

INABILITY TO USE THE PRODUCT, EVEN IF AVERY HAS BEEN ADVISED OF THE POSSIBILITY OF SUCH DAMAGES. IN NO

EVENT SHALL AVERY'S LIABILITY EXCEED THE PURCHASE PRICE PAID FOR THE PRODUCT, IF ANY.

AVERY’S AGGREGATE LIABILITY UNDER OR IN CONNECTION WITH THIS AGREEMENT SHALL BE LIMITED TO THE AMOUNT

PAID FOR THE PRODUCT, IF ANY.

5. Governing Law.This Agreement shall be governed by and construed in accordance with the substantive laws in force in the State of

California if You purchased the Product in the United States. This Agreement will not be governed by the conflict of law rules of any jurisdiction

or the United Nations Convention on Contracts for the International Sale of Goods, the application of which is expressly excluded.

6. General Provisions.If any part of this Agreement is found void and unenforceable, it will not affect the validity of the balance of this

Agreement, which shall remain valid and enforceable according to its terms. This Agreement may only be modified by a writing signed by

an authorized officer of Avery. This is the entire agreement between Avery and You relating to the Product and it supersedes any prior

representations, discussions, undertakings, communications or advertising relating to the Product.

3

This manual is copyrighted with all rights reserved and may not be copied, in part or in whole, without the written consent

of Avery Dennison Corporation. Avery Dennison makes no warranty, express or implied, as to its accuracy and assumes no

liability arising out of its use by others.

The descriptions and specifications contained in this manual were in effect at the time the manual was approved for

printing. Avery Dennison, whose policy is one of continuous improvement, reserves the right to discontinue models at

any time or change specifications or design, without notice and without incurring obligations or liability.

Copyright (c) 2008 Avery Dennison Corporation. All rights reserved. Avery Dennison and all other Avery Dennison

brands, product names and codes are trademarks of Avery Dennison Corporation.

Avery Dennison Corporation

Fastener Division

224 Industrial Road

Fitchburg, MA 01420 Printed in China

Visit us on the web at

www.fastener.averydennison.com

4

Contents

Important Safety Instructions

Chapter 1 Introduction

Chapter 2 Installation

Unpacking the ST9500

TM

……………………………………………… ..............................9

Mounting the ST9500

TM

………………………………………………...............................10

Setting Up the ST9500

TM

………………………………………………. .............................11

Chapter 3 Operation

Operating the Front Panel……………………………………………….............................14

Adjusting Needle Spacing………………………………………………............................18

Double Shot Mode and Single Shot Mode Switch………………..…….............................19

Loading Fasteners………………………………………………………. ...........................20

Adjusting the Fastener Cut ………........................................................................ ..............22

Inserting a Fastener into a Garment ……………………………… ……………………….23

Inspecting the Fastener Cut............................................................ ......................................24

Chapter 4 Theory of Operation

Electric Schematic Block……………………………………………. ...............................26

The ST9500

TM

Cycle …………………………………………………. .............................27

Chapter 5 Parts Replacement

Removing the Enclosure…………………………………………………..........................30

Replacing the Door Needle Guard ………………………………………..........................31

Replacing the Needle Guard………………………………………………........................32

Replacing the Needles……………………………………………………..........................33

Replacing the Ejector Rods………………………………………………..........................34

Replacing the Knife ………………………………………………………........................35

Replacing the Feed Wheel………………………………………………….......................36

Removing the Head Assembly …………………………………………….......................38

Removing the Ejector Slide ………………………………………………........................40

Replacing the Knife Lever …………………………………………………......................41

Replacing and Aligning the Gears …………………………………………......................42

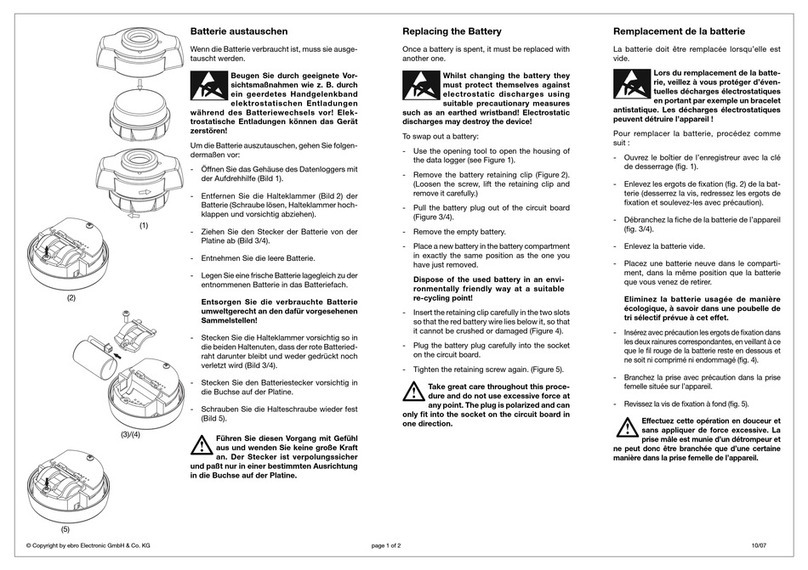

Replacing the Circuit Board ……………………………………………….......................44

Replacing the Capacitor ………………………………………………….. ......................45

Replacing the Motor, Coupling, and Crank Arm Assembly ……………...........................46

5

Replacing the Crank Arm ………………………………………………… ......................48

Replacing the Coupling………………………………………………..…….................... 49

Chapter 6 Troubleshooting

ST9500

TM

Doesn’t Actuate or Actuates Abnormally…………………. ...........................51

Panel Doesn’t Display or Works Abnormally…………………. ......................................51

Host Software Application Doesn’t Function Properly………………..............................52

Fastener Problems …………………………………………………………......................52

Ejection Problems ………………………………………………………….. ...................53

Chapter 7 Routine Maintenance and Lubrication

Daily Maintenance …………………………………………………………. ...................54

Lubrication ………………………………………………………………….. ..................55

Chapter 8 Parts List ………………………………………………………………...….. ..................57

Chapter 9 Contact Information………………………………………………. ……….. .................79

6

Important Safety Instructions

The needles are extremely sharp and can cause serious injury. Keep hands and personal

clothing clear of needles during operation.

Do not remove the needle guards and do not operate the machine without needle guards

in place.

Disconnect power to the machine before replacing needles.

Do not attempt to remove the cover, or service or disassemble any component while the

ST9500 is connected to a power source. Disconnect the power cord before attempting to

replace any component.

Do not operate the ST9500 with the cover removed or make any attempt to defeat the

cover interlock switch. Moving parts and shock hazard can cause serious personal injury.

CAUTION Improper use of lubricants can cause machine failure and/or damage

to the garment.

Do not use any type of lubricant on the fastener path use only compressed air to

clean it.

Do not use any solvents on the ST9500.

WARNING For your safety the information in this manual must be followed to

prevent personal injury or loss of life

7

Chapter 1

Introduction

This manual provides all of the information required to install, operate, troubleshoot, and service the

Avery Dennison ST9500

TM

Plastic Staple®Attacher.

The ST9500 fastens garment size,

pricing, and brand-

name tags to fabrics by

inserting Plastic Staple

®

fasteners through

the tag and the underlying fabric.

Tag

Fabric

Fastener

8

Chapter 2

Installation

The chapter describes how to install the ST9500.

□

Unpacking the ST9500

□

Mounting the ST9500

□

Setting up the ST9500 for operation

9

Unpacking the ST9500

TM

1. Check the contents of the shipping box. It should contain the following:

1 ST9500

TM

Plastic Staple Attacher

1 Operator and Service Manual

3 Power cords

1 Programming cable

2. Remove the ST9500.

3. Remove the power cords, select the appropriate cord, and discard the unneeded cords.

□

For 220/240 VAC, UL/CSA

□

For 240 VAC, CE

□

For 110 VAC, UL/CSA

4. Visually inspect the ST9500 and the shipping materials for damage.

□

If the ST9500 is damaged, notify Avery Dennison immediately.

□

If the shipping box is also damaged, notify the freight carrier as well as Avery Dennison,

and save the shipping materials for the carrier to inspect.

10

Mounting the ST9500

TM

.

WARNING With the base rotated, the ST9500 will not stand unsupported

without tipping.

2. Position the ST9500 on the work surface and mark the location of the four

mounting holes in the base.

3. Drill four mounting holes in the work surface for the mounting bolts.

4. Bolt the ST9500 to the work surface.

1. Decide how to mount the ST9500. The

ST9500 must be bolted to a stable, heavy work

surface. When shipped from the factory, it is set

up as shown to the right.

If you require more clearance between the

ST9500 and the mounting surface, you can rotate

the base 180 degrees for

overhanging edge of bench operation. To reverse

the base, remove the four bolts from the bottom

of the base, rotate the base and replace the bolts.

11

Setting Up the ST9500

TM

1. Open the front door.

2. Remove the shipping restraint screw.

NOTE Keep the shipping restraint screw. If you need to ship the unit,

you must use this screw to lock the head in mid-cycle, as

follows:

Lower the head by actuating the machine and opening the door

before the machine can complete one cycle. Manually raise the

head of the unit so you can thread the screw into the tapped

hole and then tighten the screw.

3. Make sure the power switch is in the OFF position (0), then plug the power cord

into the power cord receptacle on the ST9500.

Power cord receptacle

on the left

Foot switch

receptacle

12

4. Plug the foot switch cord into the foot switch receptacle.

5. Connect the power cord to an electrical outlet and turn the ST9500 power

switch from OFF (0) to ON (1).

13

Chapter 3

Operation

The chapter explains how to operate the Avery Dennison ST9500.

□

Operating the front panel

□

Adjusting needle spacing

□

Double shot mode and single shot mode switch

□

Loading fasteners

□

Adjusting the fastener cut

□

Inserting a fastener into a garment

□

Inspecting the fastener cut

14

Operating the Front Panel

1. Panel General Description

ST9500 panel consists of a digital display with blue backlight and white fore-colored letters

and 5 membrane buttons for changing parameter settings. The 5 buttons are numbered as 1, 2, 3,

4 and 5, and their marks in the buttons are named as SPEED, INTERVAL, MODE, COUNT

/RESET and SAVE.

2. Display Functions: Each line displays 16 letters (or digits)

Position I in first line (e.g. 0.25S): This indicates the cycle speed. The range is from

0.25 second/cycle to 0.6 second/cycle. Speeds are 0.25s, 0.28s, 0.30s, 0.32s, 0.35s,

0.40s, 0.45s, 050s, 0.55s, and 0.60s.

Position II in first line (e.g. 0.8s): This indicates the interval time between the beginning

of one cycle and the next in Continuous Cycle Mode or multiple. This value ranges from

0.0 second to 1.0 second in increments of 0.1 seconds.

Position III in first line (e.g. C_): This indicates the Cycle Mode. The values may be 1

through 10 and C_. If the value is 1, it means the machine will run 1 cycle at a press of

foot switch, and likewise, 2 for 2 cycles per press, 3 for 3 cycles per press… while if the

value is C_, it means the machine will keep running after you press of foot switch and

stops if you press it again.

Position in second line (e.g. Count: 13,000): This line can display the values of two

different counters. One counter can be reset, while another cannot be reset but it records

the accumulated cycles all through its lifetime. “COUNTER:” means the counter that

can be reset and “LIFE” means the counter that cannot be reset. Both counters can count

and display up to 12 digits up to 999,999,999,999 and it will begin from 0 when it is

greater than this quantity.

3. Button Functions:

Membrane buttons are used to change the parameters displayed in the panel when the

parameter setting function is activated.

Button “1” (“SPEED”): This is to change the cycle speed. With each press the display

will change to the next value of “…, 0.25s, 0.28s, 0.30s, 0.32s, 0.35s, 0.40s, 0.45s, 050s,

15

0.55s, 0.60s, 0.25, 0.28 …” and it will then repeat.

Button “2” (“INTERVAL”): This is to change the interval. With each press the display

will change to the next value of “…, 0s, 0.1s, 0.2s, 0.3s, 0.4s, 0.5s, 0.6s, 0.7s, 0.8s, 0.9s,

1.0s, 0s…” which forms a loop.

Button “3” (“MODE”): This is to change the Cycle Mode. With each press the display

will change to the next value of “…, C_, 1, 2, 3, 4, 5, 6, 7, 8, 9, 10, C_, 1, 2 …” which

forms a loop.

Button “4” (“COUNT/RESET”): This is to switch the display between the

aforementioned two different counters and to reset the counter that can be reset.

With each “short press” (keep pressing the button less than 2 seconds) the display

will switch between “CTR” and “LIFE”.

With each “long press” (keep pressing the button longer than 2 seconds) the counter

that can be reset will be reset

Button “5” (“SAVE”):

With each “short press” to save the settings you just made to the RAM in the

machine, so that this setting can be activated when you power on the machine next

time.

With each “long press”, the panel will display a password entering dialogue and you

can switch the machine between Password Enable and Disable modes.

4. Password Enable and Disable Functions:

To use the password Enable and Disable function is for better management of the privileges

in changing machine parameters. The machine reserves the availability to switch from Password

Enabled Mode to Password Disabled Mode and vice versa. In the former mode, the user need to

enter a valid password before he can change the motor parameters, then need press the button

“5” (SAVE) to save it after changing the motor parameters; while in the latter mode, the user can

change the parameters without any password and it can save the parameters real time.

The machine will be set to Password Disabled Mode when it is shipped from the factory.

4.1 Switch between Password Enabled Status and Password Disabled Status:

a). Long press (keep pressing over 2 seconds) the Button “5” at any time when the machine is

powered on, and the display will show a indication as “XXX” for the user to enter a password.

After a valid password, the machine will be switched from Password Disabled Status to

Password Enabled Status or reverse.

b). When you want to enter a password, you will use the buttons described as below:

Press “1” to change the display of the first digit of the three. With each press the first

digit will change to the next value of “…0, 1, 2, 3, 4, 5, 6, 7, 8, 9, 0, 1…” and then it

repeats.

Press “2” to change the display of the second digit and pressing “3” to changes the

display of the third digit.

Press “5” as confirmation key to confirm the password you just enter.

If the password is invalid, the display will show “XXX” again; Then please try to

enter a valid password by the abovementioned procedure;

If the password is valid, the display will show “Enable” or “Disable”; then press “1”

button to switch between the two, and then press “5” to confirm.

16

4.2. Operations in Password Enabled Mode:

a). Press any of the three Buttons of “1”, “2” and “3” at any time in Password Enabled Status,

and the display will show a indication as “XXX” for the user to enter a password. After a valid

password, the user can change the Speed, Interval and Mode parameters, and then press “5” to

confirm.

b). Follow the same procedure as 4.1. b) to enter password.

c). Change the parameters as described in above “3. Button Functions” In this step the settings

will be activated at once after each press of the button and user may run the machine to test the

settings and may change them if necessary. But in this step the settings are not saved to the Flash

Memory and therefore if the power fails at this time, the settings will not be saved.

d). Press Button “5” to save the parameter settings to the flash memory and the machine will

return to Normal Working Status. Note: if the Button “5” is not pressed the machine will not save

the parameters or return to Normal Working Status and the user may continue to change the

parameters.

e). If you need change the parameter next time, repeat operations from step “a)”to step “d)”.

4.3. Operations in Password Enabled Mode:

User can press the four buttons to change the parameters settings as described in above section

3. “Button Functions”.

4.4. Super Administrator Password:

If you forgot the password, please contact Avery Dennison.

4.5 Password Change: You may change the password by following the display

instructions.

17

5. Panel Operation Flow Chart:

18

Adjusting Needle Spacing

1. Open the front door.

2. Turn the Knob and adjust the space between the two needles. When you adjust the needle spacing,

please make sure that the Ejector Rods move according to the needles, if the Ejector Rods do not

move then there might be some friction with the Ejector Rod guide at the top. Please use your finger

to help it move if necessary.

3. The adjustable range of needle spacing is 6~12 mm, you may read the data from the scale at the plate.

Knob for adjusting

needle spacing

Ejector Rod Guide

19

Double Shot Mode and Single Shot Mode Switch

1. Open the front door.

2. Use a screw driver to loose the Mode Switch Knob;

3. Use the Mode Switch Knob to switch the shot mode between double shot and single shot. In double

shot mode, the machine feeds two pieces of staples at a cycle, while in single shot mode the machine

feeds one piece of staple at a cycle.

4. When the arrow in the picture below points to “I” the machine works on single shot mode, while the

arrow points to “II” the machine works on double shot mode.

5. Tighten the screw of Mode Switch Knob after switching.

Mode Switch Knob

20

Loading Fasteners

1. Turn the power switch to OFF (0).

2. Open the front door of the ST9500.

3.

Place a reel of fasteners on the reel support with the fasteners coming off the

top of the reel. Check that the reel rotates freely.

4. Cut the end of fasteners

half way between two rungs.

5. Feed the fasteners through the upper slot on the front of the ST9500 (refer to

the fastener feed diagram inside the front door, if necessary).

Table of contents

Other Avery Dennison Power Tools manuals