Avid Power ACD306-N User manual

12V CORDLESS DRILL/DRIVER

SAVE THIS MANUAL

You will need this manual for safety instructions, operating procedures and warranty.

Put this manual and the original sales receipt in a safe dry place for future reference.

Operator's Manual

MODEL: ACD306-N/

ACD306-P

1

IMPORTANT SAFETY INSTRUCTIONS-------------------------------------------P.2

PRECAUTIONS FOR BATTERY CHARGER ------------------------------------P.6

SAFETY PRECAUTIONS FOR DRIL---------------------------------------------- P.7

PRODUCT SPECIFICATION----------------------------------------------------------P.8

CONPONENTS --------------------------------------------------------------------------P.9

PACKAGE INCLUDED ----------------------------------------------------------------P.9

OPERATION ------------------------------------------------------------------------------P.10

ADJUSTMENT ---------------------------------------------------------------------------P.14

MAINTENANCE -------------------------------------------------------------------------P.17

PART LIST --------------------------------------------------------------------------------P.18

SCHEMATIC DRAWING --------------------------------------------------------------P.19

TABLE OF CONTENTS

2

IMPORTANT SAFETY INSTRUCTIONS

1. KEEP THE WORK AREA CLEAN. Clean areas prevent injuries.

2. CONSIDER THE WORK AREA ENVIRONMENT. Don’t use power tools in

damp, wet, or poorly lit locations. Don’t expose your tool to the rain. Keep

the work area well lit. Don’t use tools in the presence of flammable gases or

liquids.

3. KEEP CHILDREN AWAY. All children should be kept away from the work

area. Don’t let them handle machines, tools and extensions cords.

4. STORE UNUSED EQUIPMENT. Store equipment in a dry area to inhibit

rust. The equipment also should be in a high location or locked up to keep

out of the reach of children.

5. DON’T FORCE THE TOOL. It will do the job better and more safely at the

rate for which it was intended.

6. USE THE RIGHT TOOL. Don’t force a small tool or attachment to do the

work of a larger industrial tool. Don’t use a tool for a purpose for which it

was not intended.

WARNING: When using electric tools, machines or equipment, basic safety

precautions should always be followed to reduce the risk of fire, electric shock, and

personal injury. The warnings, cautions, and instructions detailed in this manual

cannot cover all possible conditions and situations that occur.

3

IMPORTANT SAFETY INSTRUCTIONS

7. DRESS PROPERLY. Don’t wear loose clothing or jewelry, they can get

caught in moving parts. Protective, non-electrically conductive gloves and

non-skid footwear are recommended when working. Wear protective hair

covering to contain long hair and keep it from harm.

8. USE EYE PROTECTION. Use a full face mask if the work you’re doing

produces metal filings, dust or wood chips. Goggles are acceptable in other

situations. Wear a clean dust mask if the work involves creating a lot of fine

or coarse dust.

9. DO NOT TOUCH BITS OR BLADES WITH HANDS AFTER USE. They can

become extremely hot after the job is completed.

10. SECURE WORK. Use clamps or a vise to hold the work if possible. It’s

safer than using your hands and it frees both hands to operate the tool.

11. DON’T OVERREACH. Keep proper footing and balance at all times. Do

not reach over or across machines that are running.

12. MAINTAIN TOOLS WITH CARE. Keep tools sharp and clean for better

and safer performance.

13. Follow instructions for lubricating and safe performance. Follow

instructions for lubricating and changing accessories. Keep handles dry,

clean and free from oil and grease.

14. REMOVE ALL ADJUSTING KEYS AND WRENCHES. Make it a habit to

check that keys and adjusting wrenches are removed from any rotating tool

4

before using it.

15. AVOID UNINTENTIONAL STARTING. Don’t carry tools with a finger on

the switch. Be sure the direction switch is in the STOP position when not in

use or when changing attachments.

16. STAY ALERT. Watch what you are doing & use common sense. Don’t

operate any tool when you are tired.

17. CHECK FOR DAMAGED PARTS.

1) Before using the tool, any part that is damaged should be carefully

checked to determine that it will operate properly and perform its intended

function.

2) Check for alignment of moving parts, binding of moving parts, breakage

of parts, mountings, and other conditions that may affect its operation.

3) Check bits and blades to make sure they are sharp and not chipped.

Inspect screws and tighten any ones that are loose.

4) Any part that is damaged should be properly repaired or replaced by an

authorized service center unless otherwise indicated elsewhere in the

instruction manual. Have defective switches replaced by an authorized

service center? Don’t use the tool if the switch does not turn on and off

properly.

18. GUARD AGAINST ELECTRIC SHOCK. Prevent body contact with

grounded surfaces such as pipes, radiators ranges, and refrigerator

5

PRECAUTIONS FOR BATTERY CHARGER

enclosures. When drilling or cutting into walls, floors, or wherever “live”

electrical wires may be, try to ascertain whether there is a danger of shock.

19. REPLACEMENT PARTS. When servicing, use only identical replacement

parts.

CHARGE BATTERY AT LEAST 6 HOURS before initial use.

1. CHARGE AT ROOM TEMPERATURE. The room temperature must be

higher than 32°F and lower than 104°F.

2. DO NOT CHARGE IF THE CHARGER’S CORD OR PLUG IS DAMAGED.

Charging with a damaged cord may result in a fire or electrical shock. If the

charger is damaged in any way, have it repaired by a qualified serviceman.

3. USE WITH CAUTION, when coming into contact with items that can cause

an electrical short, such as paper clips, nails, the sides of a metal toolbox.

4. DO NOT INCINERATE THE BATTERY. This product has been carefully

engineered and manufactured to give you dependable operation. Please

read this manual thoroughly before operating your new product, as it

contains the information you need to become familiar with its features and

obtain the performance that will bring you continued use for many years.

1. Wear ear protectors when impact drilling. Exposure to noise can cause

SAFETY PRECAUTIONS FOR 12V DRILL

6

hearing loss.

2. Hold power tool by insulated gripping surfaces, when performing an

operation where the cutting accessory may contact hidden wiring.

3. Special Safety Instructions for Battery Pack and Charger. If under extreme

conditions any electrolyte should escape from the battery, it's essential to

avoid contact with skin. If electrolyte does come into contact with your skin,

rinse it off with water. In the event of electrolyte contact with your eyes, it's

essential to consult a doctor.

4. Before the use of the charger and the battery pack, read the instruction

manual for it carefully.

5. During the charging process, the current used should correspond to the

current of the battery charger.

6. Never let moisture, rain or splashed water reach the charging location. The

ambient temperature must not exceed 40℃.

7. Battery packs, which are defective or damaged or can no longer be

recharged, must be disposed of as hazardous waste. Hand them over at a

special collection point. Never harm our environment. Do not throw

unusable battery pack away into the domestic waste, into fire or into water.

8. If the electrical cable is damaged, the wire may only be replaced by the

supplier or by his repair workshop. Have repairs carried out only by an

authorized specialist.

7

9. Use only the battery pack, which has been produced by the original

manufacturer.

10. Always keep the surface of the charger free from dust and dirt.

11. Insert the battery pack into the charger. Follow the guidelines provided

concerning polarity.

12. Always remove battery pack before working on the machine.

13. When the battery pack is outside the drill, cover the contacts to avoid

short circuits (e.g. from tools).

14. Do not throw Li-ion batteries into water or fire, risk of explosion!

15. Protect the battery pack from impacts, and don't open it.

16. Never discharge the battery pack completely and recharge occasionally if

not used for a prolonged period.

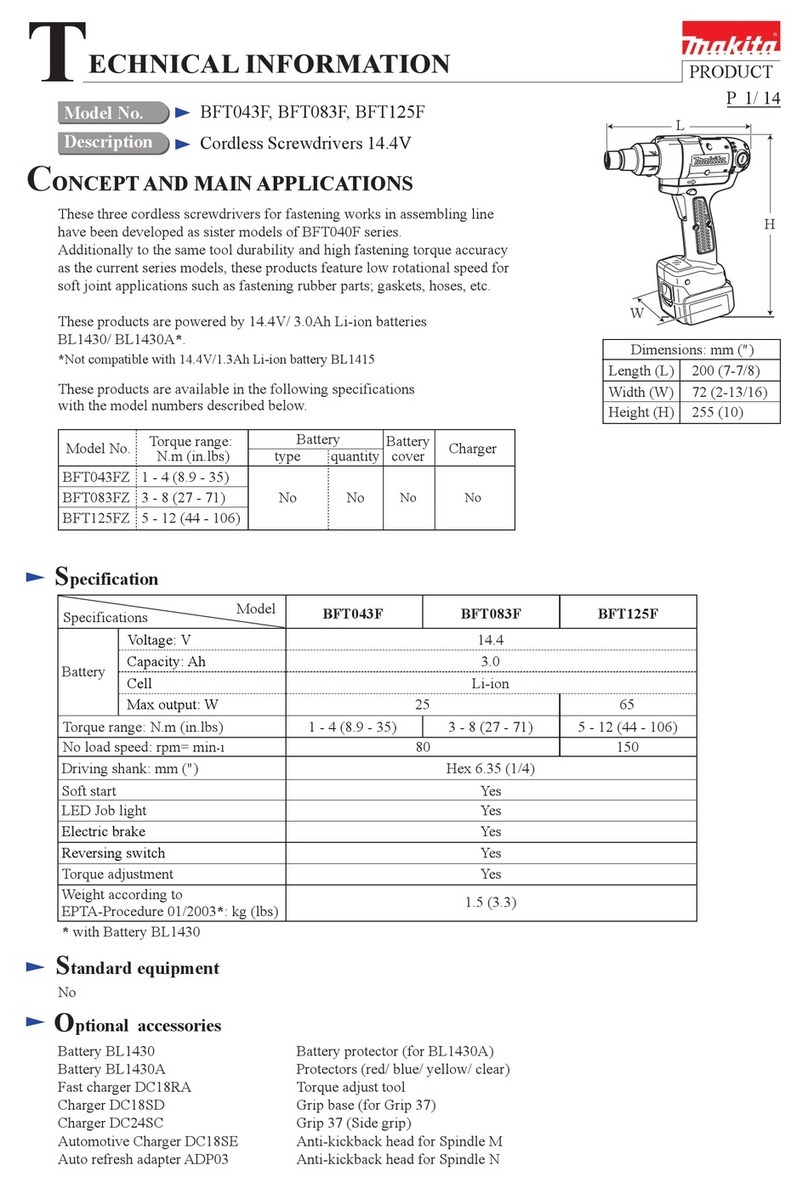

Model ACD306

Voltage 12V

Charge Time

Battery Capacity 1.3Ah

Keyless chuck 3/8’’(10mm)

Adjustable Torque Setting 15+1

No Load Speed 0-350RPM/0-1250 RPM

Weight 3.1pounds

Product Dimensions 9.2 x 8.9 x 2.9 inches

PRODUCT SPECIFICATION

3 - 5 Hours

8

1. Keyless chuck

2. Torque settings

3. Variable speed trigger switch

4. Trigger lock

5. Build in work light

6. Gear shifter

7. Rubberized grip

8. Battery pack

9. Battery release tags

A. Charger

B. Charger stand

C. Flexible shaft

D. Extended bar

E. 10pcs drill bits

F. 10pcs driver bit

PACKAGE INCLUDED

TOOL CONPONENTS

9

How to install/remove the battery pack

1. Release battery pack from tool by pressing on both sides of the battery

release tabs and pull downward (Fig.2).

2. To insert battery, align battery and slide battery pack into tool until it locks

into position. Do not force.

(Note: If battery release tabs are cracked or damaged, do not insert into tool.

Battery can fall out during operation.)

1. Cordless drill 3. Release button

2. Battery pack

OPERATION

10

CAUTION: Fully charge battery before first use. The battery will reach full

capacity after being charged and discharged several times.

CAUTION: Avoid short periods of charging. Only charge the battery pack when

completely empty.

CAUTION: Adaptor, charger and battery pack will be warm when charging.

How to charge the battery pack (Fig.3)

1. Insert the AC/DC adaptor into the household current receptacle. The green

light is on. The green light is the power indicator.

2. Properly insert the battery pack into the charging stand. Make sure it is

placed correctly(+ and -). The red light is on. The red light is the charge

indicator.

3. Normal charging time is 3-5 hours. When the battery is fully charged, the

red light will turn off.

4. When charging more than one battery pack in succession, allow 15

minutes between charges.

OPERATION

11

METHOD 1 (Fig.4)

To install the driver bit/drill bit:

Step 1: Rotate the chuck (A) anticlockwise by hand to open the chuck jaws. (If

A was screwed too tight, please rotate it with more force).

Step 2: Place the driver/drill bit in the chuck as far as it will go.

Step 3: Then rotate the chuck (A) clockwise by hand to tighten the chuck

jaws.

Do it in reverse to remove the driver bit/drill bit.

OPERATION

12

METHOD 2(Fig.5 Fig.6 Fig.7)

To install the driver bit/drill bit:

Step 1: Open the chuck jaws: move the forward/reverse button to the right

side of the tool to make it do reverse rotation.

Step 2: Hold the keyless chuck with one hand and squeeze the trigger with

the other hand to open the chuck jaws.

Fig.5

Fig.6

OPERATION

13

Step 3: Carefully center the driver bit/drill bit between the jaws.

Step 4: Move the forward/reverse button to the left side, it will do forward

rotation.

Step 5: Hold the keyless chuck with one hand and squeeze the trigger slowly

until it is locked in place.

Do it in reverse to remove the driver bit/drill bit.

NOTE: This drill is compatible with the accessories of other brands. However,

since the drill chuck is 3/8 inch, the diameter of drill bits/driver bits you

purchase cannot exceed 3/8 inch.

REVERSING SWITCH (Fig.8)

1. The reversing switch determines the rotational direction of the tool and also

ADJUSTMENT

Close

Fig.7

Open

14

serves as a lock-off button. You can choose between clockwise and

anticlockwise rotation. To avoid causing damage to the gearing it is

advisable to change the direction of rotation only when the tool is at a

standstill.

2. To select forward rotation, release the trigger switch and depress the

forward/reverse control button on the right side of the tool.

3. To select reverse rotation, depress the forward/reverse control button on

the left side of the tool.

NOTE: The first time the tool is run after changing the direction of rotation, you

may hear a click on start up. This and the impacting noise that the tool makes is

normal and does not indicate a problem.

GEAR SHIFTING (Fig.9)

The tool is equipped with two separate gear ranges, low gear, and high

gear. Low gear provides high-torque and slower drilling speeds for

heavy-duty work or for driving screws. High gear provides faster speeds

15

for drilling lighter work.

A) Select LOW speed for applications requiring higher power and torque.

B) Select HIGH speed for fast drilling, drilling or driving applications.

NOTE: Never change speeds while the tool is running. Failure to obey this caution

could result in serious damage to the drill.

NOTE: If you have difficulty changing from one gear range to the other, turn the

chuck by hand until the gears engage.

Torque adjustment collar(Fig.1)

The torque can be adjusted in 0-15 graduation by turning the adjusting

collar. Circling the collar are numbers and a drill bit symbol. These

numbers are used to set the clutch to deliver a torque range. The higher

the number on the collar, the higher the torque and the larger the fastener

ADJUSTMENT

16

which can be driven. To select any of the numbers, rotate until the desired

number aligns with the arrow.

NOTE: Before the actual operation, drive a trial screw into your material or a

piece of duplicate material to determine which torque level is required for a

particular application.

Trigger Switch (Fig.10)

To turn the tool on, squeeze the trigger switch . To turn the tool off, release

the trigger switch. The chuck will stop as soon as the trigger switch is fully

released. The variable speed switch enables you to select the best speed

for a particular application. The more you squeeze the trigger, the faster

the tool will operate. Use lower speeds for starting holes without a center

punch, drilling in metals or plastics, or driving screws. For maximum tool

life, use variable speed only for starting holes or fasteners.

Trigger

Fig.10

17

ATTENTION: Always remove the battery before carrying out any work on the

machine.

1. To clean, always use a dry or moist, but not wet towel. Many cleaning

agents contain chemical substances which may cause damage to the plastic

parts of the machine. Therefore do not use any strong or flammable cleaners

such as gas, paint thinner, turpentine or similar cleaning agents.

2. Always keep air ventilation holes free of dust deposits to prevent overheating.

3. Keep the vents clear of dust and debris. This will help prevent possible

electrical shorts and ensure proper cooling.

4. Keep the tool housing and handle clean and free of oil and grease by using

mild soap and a damp (not wet) cloth.

5. Avoid overloading your drill. It will become hot and lose efficiency. Running it

free of load for a minute or two will allow it to cool itself to normal temperature.

6. Inspect the cord regularly and have it replaced by an authorized repair

facility if it is damaged.

7. Lubrication for this tool is done at the factory and should not be necessary

again under normal use.

8. An authorized repair center should do any repairs, modification, or

maintenance that involves disassembling the grinder.

9. Any damage to the tool should be corrected at an authorized repair center.

MAINTENANCE

18

NO.

DESCRIPTION

NO.

DESCRIPTION

1

Shift button

24

Steel pillar

2

Spring

25

Washer

3

Housing

26

Gear ring

4

Plate spring

27

Ring

5

LED light

28

Steel ball

6

F/R button

29

Shaft

7

Trigger switch

30

Sleeve

8

Motor

31

Screw

9

Gear

32

Keyless chuck

10

Cover

33

Torque setting ring

11

Screw

34

Screw

12

Washer

35

Front cover

13

Inner gear

36

Press ring

14

Planet gear

37

Spring

15

Gear holder

38

Cir clip

16

Planet gear

39

Washer

17

Gear holder

40

Steel ball

18

Gear ring

41

Spring washer

19

Ring

42

Pin

20

Pin

43

Screw

21

Planet gear

44

U clip

22

Gear holder

45

Battery connector

23

Spindle lock block

46

Battery pack

PART LIST

19

SCHEMATIC DRAWING

This manual suits for next models

1

Table of contents

Other Avid Power Power Screwdriver manuals