Cleral Pro Series User manual

1

User Manual

SENTINEL

PS2

Wireless, Pro Series

rev #3 Oct 2012

Warning 4

Version and Revision 4

Weigh bridge (certified) 4

Pneumatic connections 4

Lift Axles 4

Fuel 4

Air Leaks 4

Recalibration 4

Batteries (2 X AA) 4

Technical Support 4

Warranty 4

Manufacturer 4

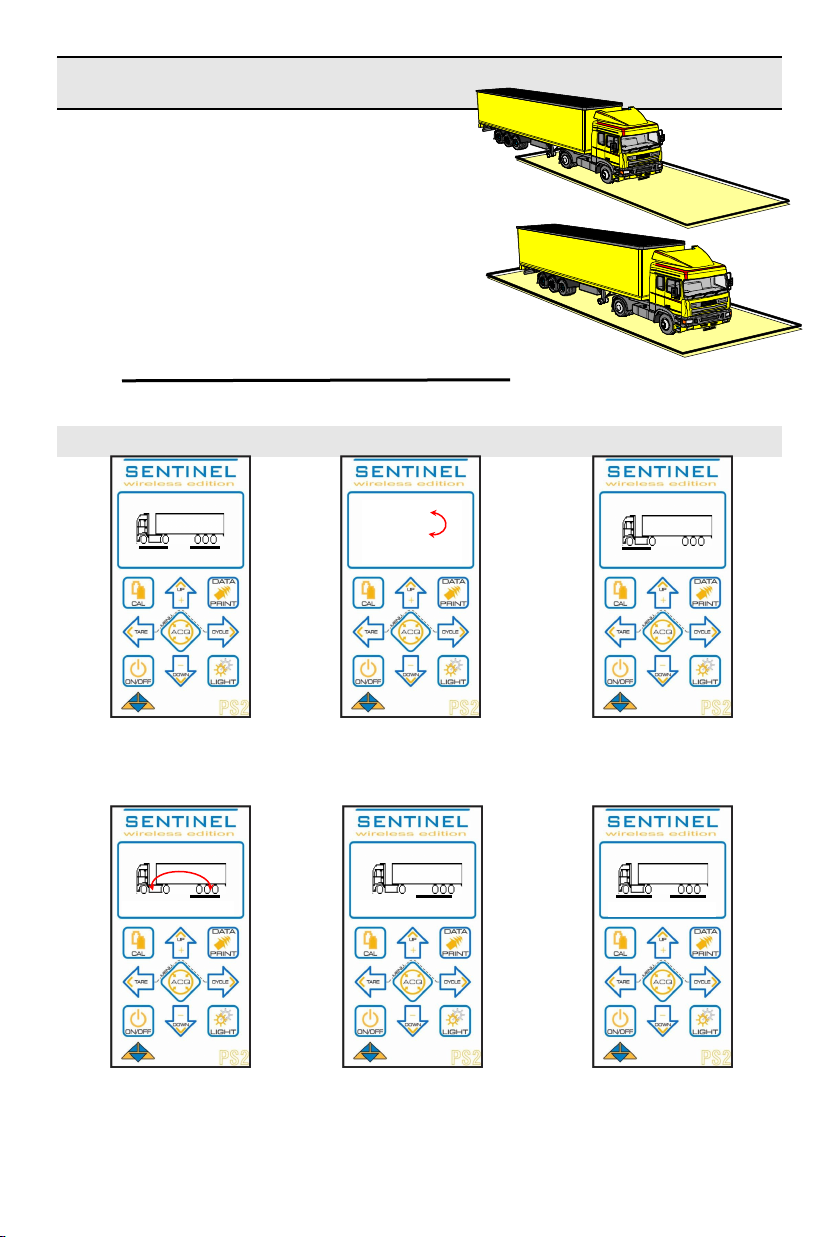

Keypad description 5

Sentinel PS2 Flow chart 5

Navigating in the menus 6

Communication Address 6

Automatic sensor acquiring 7

Selecting and Validating the channel 7

Changing channel 8

Releasing a channel 8

Exiting the Acquire mode 8

WIFi Ch Config 9

Manual sensor acquiring 10

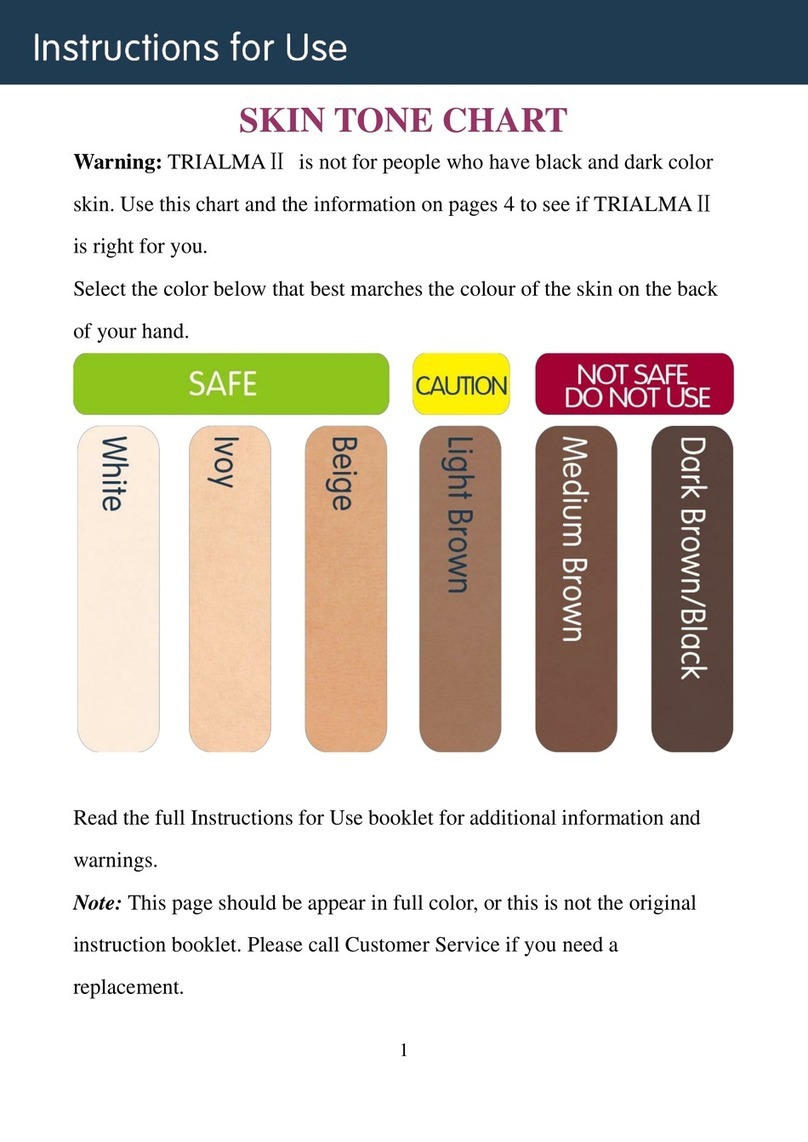

Acquiring weights for straight body trucks 11

Acquiring trailer weights 11

Acquiring tractor and semi-trailer weights 12

Acquiring additional semi-trailer weights 12

Acquiring steering axle weights 12

Calibration Empty 13

Calibration Full 14

Multi-calibration 15

Slide FW 17

Net / Gross Weight 18

Language 18

Units 18

Increment 18

Displaying in tons 19

Number of decimals 19

Cycle time 19

Auto Zero 19

Pause Option 20

Battery saver 21

Auto Shut off 21

2

Shut off time 21

RS 232 21

No N/A 22

Controller 22

Choose truck 23

Steering axle 24

Nb channel 24

Suspension Configuration 25

TAG Axle (AUTO MODE) 27

TAG Axle (MAN MODE) 27

No Air limit 28

Hide No Air 28

Safety Menu 29

Printer address 31

SensorAdd 33

Sensor Name 34

MulConfiguration 34

PS2 Name 35

Date and Time 36

Technical information and trouble shooting 37

ERREUR Codes 37

Positioning wireless devices 39

Air connections 39

Recommended power supply 40

Batteries (2 X AA) Hand held 40

Wire connections 40

Pressure Stress 41

Zeros 42

Factors 43

Multi-point Factor 44

Errors Register 44

Err Cal 45

Europe EMC 45

LevelNoise 45

Mem Flags 46

Version 46

Revision 46

Factory reset 47

Precision problems? 48

Data before calling 49

3

Warning

Your Cleral onboard weighing system is a

tool. Learning to work with it can only make

it more efficient. Read this manual before

using your Sentinel PS2.

Version and Revision

Some functions described in this manual

may not be present in your PS2. This will

depend on the version and revision of your

device.

Weigh bridge (certified)

Acquire the weights needed to calibrate

using a certified weigh bridge (Platform

scale). Whenever possible, record the

weights while sitting on the weigh bridge.

Pneumatic connections

Make sure that all air connections be made

according to the installation diagrams.

Lift Axles

Lift axles should always be in the UP

position while acquiring and recording the

weights in the PS2. If the vehicle is

equipped with an automatic lift axle

activation device, then you must acquire

and record the weights while the lift axle is

engaged (touching the ground) for both

empty and heavy calibration. And use the

system with lift axle down.

Fuel

To enhance the performance, fuel tanks

must be full to acquire and record the

weights.

Air Leaks

Leaks in the pneumatic system can

cause erratic and false weight readings.

Recalibration

Recalibration is necessary if you have

adjusted or replaced a leveling valve or if

you’ve replaced a mechanical sensor, air

transducer, or flexmeters.

Slopes

A slightly sloped terrain will not affect the

accuracy of your scale, but the bigger the

inclination the higher the error margin.

Learning to work with your Cleral system

will ultimately give you better precision in

these conditions.

Batteries (2 X AA)

Do not invert battery position. CLERAL

recommends the following batteries:

Duracell : Power Pix ™

Energizer: Ultimate Lithium ™

Technical Support

For technical help, consult your local

authorized Cleral dealer.

Warranty

Cleral products are warranted against

defects in workmanship for a period of one

year from the original date of purchase.

The defective covered product will be

repaired or replaced by the manufacturer.

The defective product needs to be sent by

your local dealer to Cleral with proof of

purchase. This warranty does not cover

injury or damages caused by the use of

this product. It also does not cover all costs

connected with the replacement part

(labor, shipping and handling or other).

Cleral will not be liable for fines issued for

overweight violations while using its

products.

Contact your local Cleral dealer for repairs

and replacement parts.

Thank you for choosing and trusting

CLÉRAL CANADA

Manufacturer

CLÉRAL INC.

90, des Distributeurs

Val-d’or (Quebec) Canada

J9P 6Y1

Tel: (819) 825-5553

fax: (819) 825-5556

email: [email protected]

Web: www.cleral.com

4

Keypad description

On/Off

Access calibration mode.

Confirm or advance in

menus.

Tare when empty.

Back one step.

Decrease.

Scroll down.

Increase.

Scroll up

Change channel.

Advance in the menu

Back light On/Off

Print.

Transmit data.

Acquiring sensors.

Simultaneously to

access menu.

Simultaneously to Freeze

or Pause.

Sentinel PS2 Flow chart

On/Off

Weights Display

Calibration

Empty

Full

Multi Cal 00

Acquire

Acquire

Manual Mode

Wifi Channel configuration

Options

FW Slide

Net weight

Language

MeasureUnits

Increment

TonDisplay

Nb Decimal

Cycle Time

Auto Zero

Opt Pause

EnergySave

AutoShutOf

ShutOffTim

RS232

No N/A

Controller

Configuration

Choose Truck

Nb channel

SuspensionCfg

Tag Axle

Adjust Tag

NoAirLimit

Hide NoAir

Safety Menu

Sensor add

Sensor Name

Mul Config

Printer add

Nom PS2

Time and date

RS232 add

Technician

Pressure Stress

Zeros

Factors

Errors Register

Err Cal

Europe Wifi

LevelNoise

Mem Flags

Version

Revision

5

!

Navigating in the menus

Sentinel PS2 allows easy access to

menus and sub-menus. Refer to the

flow chart on previous page.

Being familiar with the flow chart will

facilitate the navigation and make your

system comprehension better. Here is

the principal behind the PS2

navigation.

To enter the menu, press Tare and

Cycle simultaneously.

You will see:

The curser indicates the position. The

arrows are used to scroll

down or up as well as decreasing or

increasing a given value.

The right arrow is used to enter

(move forward) in the menu and the

left arrow to move one step

backward.

➔Acquire

!Options

!Configuration

!Technician

Communication Address

Every PS2, and wireless components,

have a unique communication

address. This «ID» is indicated on the

sticker on the back of your PS2 hand

held unit.

The air transducer «ID» is located on

the sticker that is on top of the

devices.

PN: SA-W04-PS CH: A B C D

SN: S24-0906 ID: 403DC11A

CLERAL Onboard Scales/Pesages

embarquées

90 Des Distributeurs,Val-d’Or, Quebec, Canada, J9P 6Y1

The multiplexer «ID» is also found on

the sticker on top of the device.

PN: MST-W05-PS2

SN: CS-590-3216

ID: 403D813E

CLERAL

Onboard Scales-Pesages embarquées

90 Des Distributeurs

Val-d’Or, Quebec, Canada

J9P 6Y1

819 825-5553

www.cleral.com

MADE IN CANADA

FABRIQUE AU CANADA

CLERAL Onboard Scales/Pesages embarquées

90 Des Distributeurs,Val-d’Or, Quebec, Canada, J9P 6Y1

819 825-5553 www.cleral.com

PN: TMA-W04-PS SN: 4MQ-MS-5906

ID: 403FB2DE

MADE IN CANADA

FABRIQUE AU CANADA

B

INPUT

A

INPUT

INPUT

C

INPUT

D

6

Automatic sensor acquiring

Before calibrating, each activated

channel needs to be associated with a

sensor (s). To do so you need to

acquire the sensors or multiplexers

that are connected to that specific

vehicle. Each device has a unique

address.

Automatic Acquiring

Press ACQ

!

.

The PS2 will display «Search».

Here is an example of what the PS2

will have found. The curser points to

the first device found. Displayed is the

type of device (Air-mechanical-or

flexmeter), the «ID» and the channel

associated with the given device.

Explanation:

Sensor channel (a/b/c/d/e/f/g/h/x)

Sensor «ID»

Curser

Type of sensor(Air/Mec/Flx)

➔1: Air 01872F B

Order of reception

Note!

If the PS2 displays «None» this

means that it has not found any

device. If this happens, try an

automatic acquiring again. If this fails,

try a manual acquiring. In case nothing

➔1: Air 4BCE56 A

2: Mec 4A11F8 C

3: Flx DD1258 X

has changed, refer to the Acquiring

problems section.

Important!

If a sensor is Fixed on a channel, it

does not appear in the search results

when acquiring. To see if your channel

is fixed, refer to the section Fixing a

channel.

Acquiring procedures:

↳Validate and anchor the channel

↳Changing the channel

↳Exit

Selecting and Validating the

channel

Use the Down and Up

arrows to select all the sensors that

are associated to the appropriate

channels, press the right arrow to

hi-light them.

➔1: Air 4BCE56 A

2: Mec 4A11F8 C

3: Flx DD1258 X

➔1: Air 4BCE56 A

2: Mec 4A11F8 C

3: Flx DD1258 X

7

Changing channel

If a sensor is not associated to the

correct channel, bring the curser to

select it and press Data/Print until

the channel is correct. Then press the

right arrow to hi-light it.

Note!

When pressing Data/Print , you will

only see the possible channels

according to your configuration (A B C

D E F G H X), can be displayed. The X

means that it is not associated to any

channel.

Important!

A configuration cannot have duplicated

channels. The PS2 will not allow you

to do so. In the example below, it is not

possible to anchor the second sensor

Air in A because channel A is already

associated to a sensor. Every other

channel is possible except channel A.

Note that sensor can be identified to a

channel that is already associated to a

sensor, but that is only displayed, it

cannot be high lighted, thus it cannot

be acquired.

1: Air 4BCE56 A

➔2: Mec 4A11F8 C

3: Flx DD1258 X

1: Air 4BCE56 A

➔2: Air 4A11F8 C

3: Air DD1258 A

Releasing a channel

If you have mistakenly anchored a

channel, you can release while you

still in the menu. Replace the curser

on the channel to be released and

press Cycle to release the

channel. The address is no longer

highlighted. Presser repeatedly on

Data to select the appropriate

channel and Cycle to anchor the

new channel. Press to go to the

next address.

Exiting the Acquire mode

Once you have selected and hi-lighted

the appropriate sensors, press ACQ

!

.

If you have made a mistake or you are

not sure that you selected the correct

sensors, press Tare «Cancel».

will be displayed and will take you

back to the screen without validating

any sensors.

Once you press the Acquire button,

the PS2 searches for the sensors and

will display «anchor data» indicating

that it has loaded the sensors with the

corresponding addresses and

channels.

8

WIFi Ch Config

To set an address in memory to a

given channel. Setting a channel

where the address is permanent. This

can be done for two channels

maximum. This feature is mostly

useful for two cases:

CASE 1- When the hand held is

always dedicated to the same two

sensors on a vehicle (channel A & B).

CASE 2- For tractor-trailer fleets, we

usually fix the tractor and leave the

semi-trailers free for multiple swapping

possibilities. The fleets of tractor-

trailer, tractor sets the sensor (Channel

A) and left the other free channels for

frequent switching trailers.

IMPORTANT !

To fix a sensor it must previously be

acquired.

With the curser on Wifi Ch Config

press Cycle to enter the menu.

The following appears showing the

channels that are free.

To fix the channel, press Cycle ,

Free will change to Fix.

Acquire

Manual Mode

➔Wifi Ch Config

➔A: 4BCE56 Fix

➔B: 4A11F8 Free

Press to go to B and t o

come back to A.

IMPORTANT !

The fixed channels will not appear

when acquiring. If you need to see the

fixed sensors, you need to change

them to Free.T

Acquiring in Fleet mode

When acquiring in the presence of

multiple instrumented tractors with

fixed sensors, only the semi-trailers

with free sensors will appear. You only

need to select the desired semi and

anchor it.

Use to select the desired

semi to anchor. Use to high light

and , ACQ

!

to confirm and exit.

IMPORTANT !

It is not possible to anchor a sensor on

a fixed channel.

9

Manual sensor acquiring

To manually acquire a sensor, press

Tare and Cycle simultaneously

to access the menu. Scroll to select

Acquire. Press Cycle to enter.

Use the Up or Down arrow to

select Manual Mode. Press Cycle

to enter.

This screen will appear.

The address that needs to be entered

is located on the sticker that is on the

device. This number is preceded by

«ID». The curser points to the first digit

that you may have to change. Using

the Down and Up arrows ,

select the desired digit then using the

Left and Right arrows, move

to the next digit.

➔Acquire

Options

Configuration

Technician

Acquire

➔Manual Mode

Wifi Ch Config

Enter Address

40000000

↑

Enter address

Once the last digit entered make sure

to press the right arrow or

!

acquire. The PS2 will «Search» and

then will indicate «Found 1» if it has

found it and the device «ID» will be

displayed.

To change the channel press Data .

Once the device has the correct

channel, press Cycle to hi-light

and confirm. Then press ACQ

!

to

validate.

If no device is found, try again. If still

no success, you may have entered the

wrong «ID». There can also be no or

not enough power to the device.

Check trouble shooting section.

Enter Address

403D817E

↑

➔1: Air 3D817E A

➔1: Air 3D817E B

➔1: Air 3D817E B

10

Acquiring weights for straight body trucks

The first step in calibrating your PS2 is getting the weight information for each

axle groups. Get the steer axle weight for channel A and then weigh the entire

vehicle and subtract the channel A weight from the total weight to get the channel

B weight.

Acquiring trailer weights

Once the weights of the tractor are taken, the next step is to acquire the trailer

axle group weights. Weigh the whole tractor and then the rear axle group

(channel D) and subtract D from the whole trailer weight to get channel C weight.

If the trailer has central axles, as illustrated below, just acquire the whole axle

group weight only.

11

Weigh bridgeWeigh bridge

Weigh bridge

Weigh bridge Weigh bridge

Weigh bridge

Channel «A» Channel «B»

Total

(-) Channel A

= Channel B

C+D

(-) Channel D

= Channel C

Weigh

Weigh bridge

Channel Channel«D»

Weigh bridge

Channel

Acquiring tractor and semi-trailer weights

Weigh the tractor only (Channel A) then weigh the whole rig (Total). Subtract the

tractor weight from the Total weight to determine the weight of the semi-trailer

(Channel B).

Acquiring additional semi-trailer weights

Any additional axle groups should be weighed individually.

Acquiring steering axle weights

In the case where the steering weight is required, acquire by making sure that

only the steer axle is on the weigh bridge. To acquire the drive axle weight, weigh

the whole tractor and subtract the steer axle weight.

If the steer axle is instrumented : Channel A B C

If the steer axle is not instrumented (Virtual): Channel S A B

12

Weigh

bridge

Weigh bridge Weigh

Channel «B» or «A» Channel «C» or «B»

Channel «A» or «S»

Weigh bridge Weigh bridge

Channel «B»

Channel «A»

Weigh bridge

Channel

Empty

Calibration Empty

Acquire vehicle weights

Advance the empty tractor only on the weigh

bridge. Make sure that the semi-trailer wheels

are not on the weigh bridge.

Note the tractor empty weight:__________Kg

Advance the entire rig on the weigh bridge.

Total Empty weight :_________kg

Tractor Empty weight (-) :_________kg

Note the semi-trailer empty weight :_________kg

Recording the empty weights

13

Press Cal to enter the

Calibration menu Use down or up arrow to

record channel A weight

13000

Empty T:16000 Kg

With the curser pointing

Empty, press the right

arrow

3000 3000

GWT T: 6000 Kg ➔Empty

Full

Multi Cal 00

☞

☞

☞

13000 3000

Empty T:16000 Kg

Press the right arrow

to change channel Use down or up arrow

to record channel B

weight

Press right arrow to exit

7500

Empty T:20500 Kg

13000 7500

GWT T: 20500Kg

☞

☞

☞

⑥⑤④

③②①

Ex: 13000

Ex: 20500

Ex: 13000

Ex: 7500

EMPTY

Calibration Full

Acquire vehicle weights

Advance the Full tractor only on the weigh bridge.

Make sure that the semi-trailer wheels are not on

the weigh bridge.

Note the tractor empty weight:__________Kg

Advance the entire rig on the weigh bridge.

Total Full weight :_________kg

Tractor Full weight (-) :_________kg

Note the semi-trailer Full weight :_________kg

Recording Full weights

14

Ex: 57000

Ex: 23000

Ex: 24000

Ex: 23000

Full

Full

13000 7500

GWT T: 20500 Kg ➔Empty

➔Full

Multi Cal 23000

Full T: 30500 Kg

23000 7500

Full T: 30500 Kg

24000

Full T: 57000 Kg

23000 24000

GWT T: 57000 Kg

Press Cal to enter the

Calibration menu Use down arrow to move the

curser to Full

Press Right arrow

Use down or up arrow to

record channel A weight

Press right arrow to

change channel Press right arrow to exit

Use down or up arrow to

record channel B weight

☞

☞

☞

☞

☞

❶

❷

① ② ③

④⑤ ⑥

☞

☞

Multi-calibration

When the suspension has a nonlinear

effect Multi-calibration function is used.

The algorithm of this function

increases the accuracy.

Press CAL to enter the calibration

menu. Press to select Multi Cal.

Vide

Plein

➔Multi Cal 0 0

With the curser on Multi Cal, press

Cycle . The first letter blinks.

Press to change the 0 (non

activated) to channel A (activated

Multi-Cal on this channel).

➔Multi Cal A0

Press Cycle to go to the next

channel and press to change the

0 to channel B. Only the activated

channels will appear.

➔Multi Cal A B

To exit, press to stop the blinking

and press ACQ

!

to exit.

Determining the calibration points

This feature forces you to make three

full calibration points instead of one.

Here is the method for determining the

optimal multi-curve calibration.

First, determine the average weight

that you carry on the channel to be

calibrated (Fa2 = 14000kg). Then

determine the average weight greater

than the weight that will never be

exceeded (F3 = 17000kg). Finally,

determine the weight lower than

average weight in which you do not

carry (Fa1 = 11000kg). Thereafter it is

necessary to calibrate these three

points.

Note!

You must respect the legal weight

limits at any time.

FYI

In the case of our example, the curve

Cs suspension illustrates the

deformation of the suspension by

weight. The segment Dp1 represents

the calibration curve at a single point.

As can be seen, there are differences

in weight between this line and the

curve Dp1 Cs. Cp3 curve is the curve

of multi-calibration. We note that the

differences are significantly reduced.

Weight

STRESS

Fa3

Fa2

Fa1

Cp3

Dp1

Cs

15

Multi-Cal 3 Point Calibration

Following the determination of the 3-

point loading, load and calibrate point

1, 2 and 3. It important to follow the

progress of loading the lightest to the

heaviest.

Channel A Example

Loading Point 1 : 11000 kg

Press to enter the calibration

menu. Press , to bring curser to

Full.

Empty

➔Full

Multi Cal 00

With the curser on the desired

channel, use the arrows to record the

weight of point 1.

Total : 31000

111000 20000

The display shows, at the bottom left

corner, the point of calibration that you

are recording.

Repeat these steps for Point 2 and 3.

Load Point 2 : 14000 kg

Total : 34000

214000 20000

Load Point 3 : 17000 kg

Total : 37000

317000 20000

Important!

If your calibration is not good, you

must repeat the entire calibration of

the three calibration points.

Important!

If you disabled the Multi-Cal, the factor

will that will be used is Point 2, it is

determined by the maximum legal

weight.

16

Slide FW

This option lets you see the live

distribution of weight of channel A or S

when moving the fifth wheel position.

This allows weight distribution without

having to recalibrate the system.

This option will only be available if you

you chose a truck configuration with

virtual steer weight. (S).

How to use this function:

Access Options and select SlideFW.

➔SlideFW

Net weight Non

Language Eng

MesureUnit lbs ↓

Press Cycle .

Note:

For optimum precision, stay on flat

ground.

SVI

A

B

↓↑

S

Cal to set

Steer Drive

5000 18000

Once on flat ground, press Cycle

to start load distribution. The following

will be displayed.

At this point you can start moving the

fifth wheel forward or backward.

When moving the tractor under the

fifth wheel, the weights of both

channels will change live.

Once satisfied with the load transfer,

press Cycle to exit.

Cycle if OK

Steer Drive

5000 18000

Flat ground

Cycle if OK

Steer Drive

6200 16800

17

Net / Gross Weight !

Net weight is the weight of the load

only. The gross weight is the weight of

the vehicle and the load together.

Note!

You can change from gross weight to

net weight without the need to

recalibrate.

➔Net weight Off

Language Eng

Unit Measure lbs

Increment 10↓

When the curser is on Net weight,

press Cycle to select On or Off.

Press ACQ

!

exit.

Language

IN this section, you can choose the

language you want to work in. English,

French, or Spanish.

Net weight Off

➔Language Eng

Unit Measure lbs

Increment 10↓

When the curser is on Language

press Cycle to select the

language Fr, Eng or Esp. Press ACQ

!

to exit.

Units

You can work in either pound (lbs) or

kilograms (kg).

Net weight Off

Language Eng

➔UnitMeasure lbs

Increment 10↓

When the curser is on MesureUnit

press Cycle to select lbs for

pounds or kg for kilograms. Press

ACQ

!

to exit.

Increment

You can work either in increments of

tens (10) or hundreds (100).

Net weight Off

Language Eng

Unit Measure lbs

➔Increment 10↓

When the curser is on Increment

press Cycle to select the 10 (tens)

or 100 (hundreds). Press ACQ

!

to

exit.

18

Displaying in tons

Weight can be displayed in Metric ton

(1000 kg) tmet or Imperial ton (2000

lbs). timp

➔TonDisplay Off↑

Nb Decimal 2

Cycle time 2

Auto Zero On↓

When the curser is on TonDisplay,

press Cycle to select Off, tmet

(metric) or imp (imperial). Press ACQ

!

to exit.

Note!

Even if you chose to display in tons,

you will need to calibrate in pounds

(lbs) or kilograms (kg). TM or TM will

be displayed on the main screen

where kg or lbs would be.

Number of decimals

Choose the number of decimals that

will be seen when you choose to

display in tons. (0-1-2).

TonDisplay Off↑

➔Nb decimal 2

Cycle Time 2

Auto Zero On↓

When the curser is on Nb decimal

press Cycle to select the number

of decimals you want displayed 0, 1 or

2. Press ACQ

!

to exit.

Cycle time

Select how long you want the different

channel weights will be displayed

when in Cycle.

TonDisplay Off↑

Nb Decimal 2

➔Cycle time 2

Auto Zero Oui↓

When the curser is on Cycle time,

press Cycle select between 1 and

15 seconds. Press ACQ

!

to exit.

Auto Zero

When performing an empty Cal, a zero

must be done before recording the

weights. This function will perform an

automatic zero if the empty weight is

changed.

TonDisplay Off↑

Nb Decimal 2

Cycle Time 2

➔Auto Zero On↓

When the curser is on Auto Zero

press Cycle to turn auto zero On

or Off. Press ACQ

!

to exit.

19

Pause Option

This function freezes the weights

between the activation point and the

deactivation point. If you activate

Pause at 30000 lbs, whenever you

deactivate the Pause, say the next

morning, the weight will remain at

30000 no matter what, even if there

has been temperature changes or

other reasons that the weight should

have changed..

➔Opt Pause Off↑

EnergySave Off

AutoShutof On

ShutoffTim 5↓

When the curser is on Opt Pause,

press Cycle to turn ON or Off

Press ACQ

!

to exit.

How to use this function:

Step : 1

Place your vehicle on flat ground.

Step : 2

While on main screen, press Up and

Down simultaneously and

hold for 5 seconds. Pause will be

displayed. The weights are frozen.

Step : 3

You can move your vehicle. The

weight will not change.

Step : 4

Before deactivating Pause, place your

vehicle on flat ground. press Up

andDown simultaneously and

hold until Pause shuts off. The weight

displayed will be the same as when it

was frozen and are now live.

NOTE!

It is important to follow each step to

prevent the need to recalibrate.

Tip!

If the Gage reading of pressure or

stress (GA) is not equal to the sum of

all the sensors on that channel,

divided by the number of sensors, you

need to perform an empty tare (Zero).

PAUSE T : 43000 kg

13000 30000

PAUSE T : 43000 kg

13000 30000

20

This manual suits for next models

1

Table of contents

Other Cleral Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Ecolab

Ecolab EMP Kompakt II Operating instruction

Elgas

Elgas TRZ Installation and operating instructions

Safety Vision

Safety Vision SV-IR-THRM user guide

Medical International Research

Medical International Research spirodoc user manual

Campbell

Campbell CR850 Operator's manual

Movacolor

Movacolor MC-BALANCE user manual