Table of Contents

General Overview ...............................................................................................................................................................

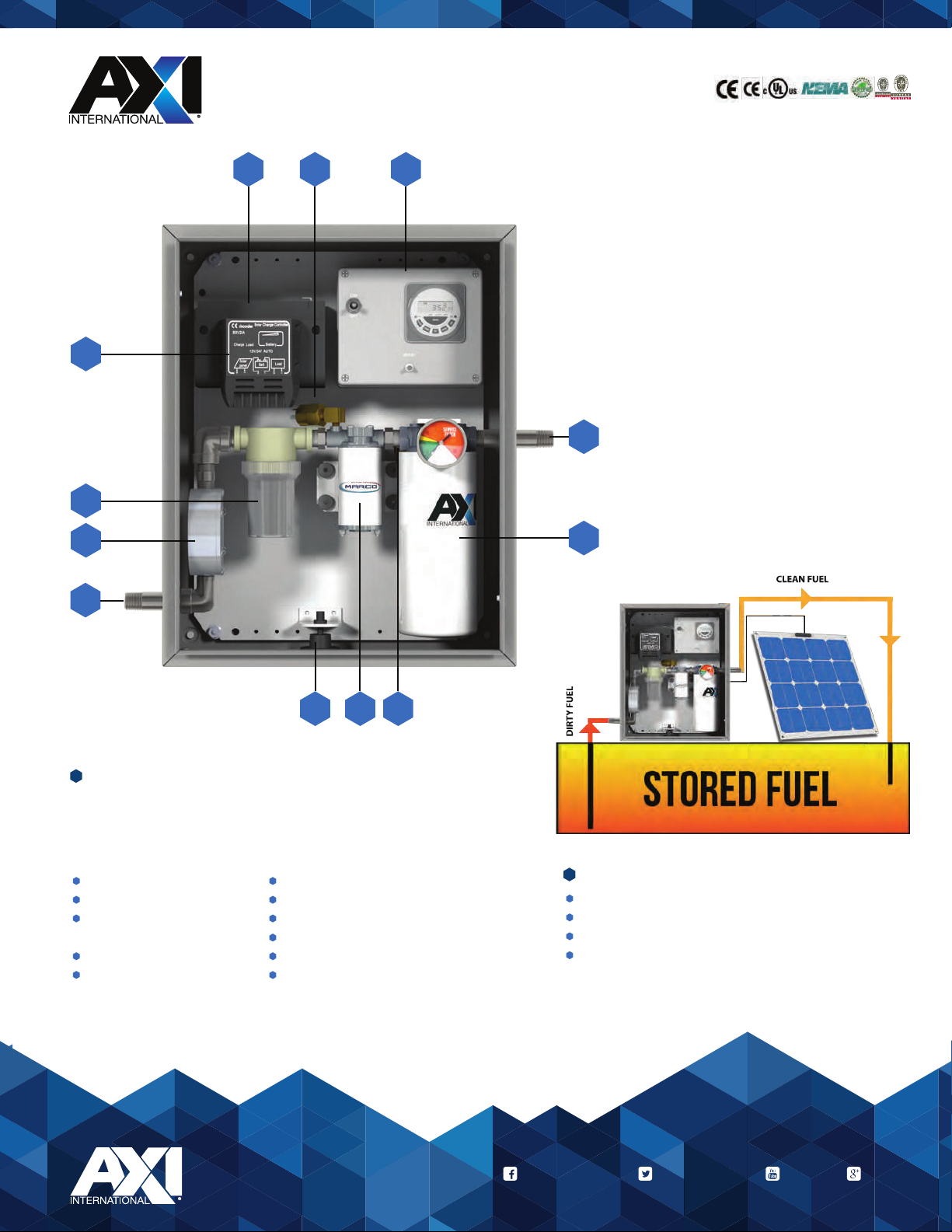

System Components .........................................................................................................................................................

Control and Safety Devices ..........................................................................................................................................

Pump / Motor .................................................................................................................................................................

Pre-Filter ........................................................................................................................................................................

Final Filter ......................................................................................................................................................................

Fuel Conditioner ............................................................................................................................................................

Plumbing ........................................................................................................................................................................

System Operation ..............................................................................................................................................................

Pump Operation ............................................................................................................................................................

Filter Congurations ......................................................................................................................................................

Alarms ............................................................................................................................................................................

Emergency Stop ............................................................................................................................................................

Primary Inspection .............................................................................................................................................................

Checklist .........................................................................................................................................................................

Installation ...........................................................................................................................................................................

Mounting ........................................................................................................................................................................

Electrical .........................................................................................................................................................................

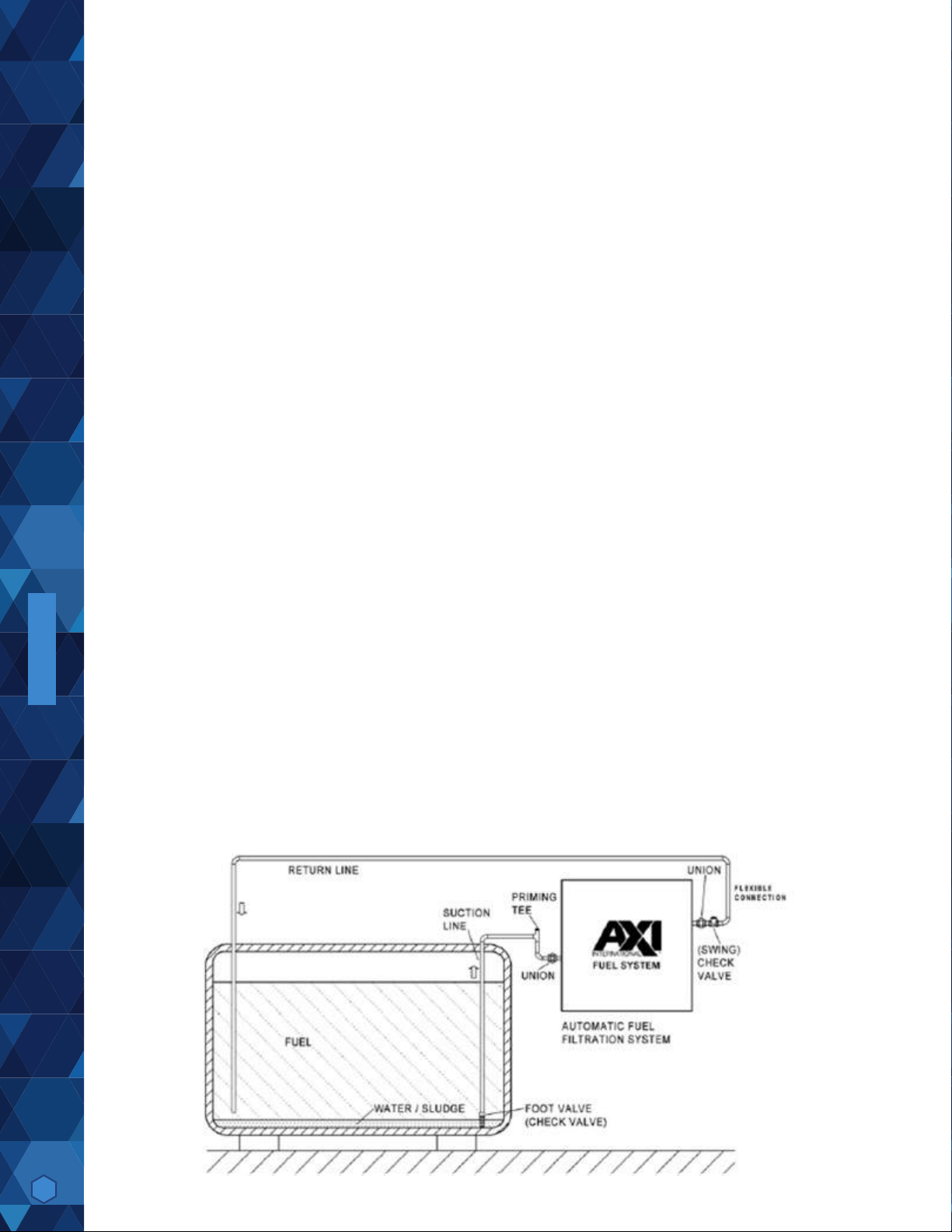

Plumbing ........................................................................................................................................................................

Typical System Installation Conguration Schematic .................................................................................................

Installation Precautions .................................................................................................................................................

Controller .............................................................................................................................................................................

Setting Date and Time ...................................................................................................................................................

Programming the Timer .................................................................................................................................................

Menu Structure ..............................................................................................................................................................

Priming the System ............................................................................................................................................................

Priming Procedure .........................................................................................................................................................

Commissioning / Initial Startup ........................................................................................................................................

Flow Switch Setting & Adjustment ................................................................................................................................

Gauge Venting & Accuracy ...........................................................................................................................................

Initial Test Procedures ...................................................................................................................................................

Maintenance ........................................................................................................................................................................

Preventative Maintenance ............................................................................................................................................

Servicing Pre-Filter ........................................................................................................................................................

Servicing Final Filter ......................................................................................................................................................

Troubleshooting .............................................................................................................................................................

Filter Chart ......................................................................................................................................................................

Warranty ...............................................................................................................................................................................

Parts / Service ......................................................................................................................................................................

5

6

6

6

6

6

6

6

7

7

7

7

7

7

8

8

8

9

9

9

10

10

11

11

11

12

12

13

13

13

14

14

15

16

16

16

16

17

17

REV03121080011217