3603 Burron Avenue, Saskatoon, SK S7P 0E4 Ph: (306) 651-1815

email: sales@axiomind.com website: www.axiomind.com

NT25-P18 CONDENSATE NEUTRALIZATION TANK WITH PUMP

INSTALLATION, OPERATION, AND MAINTENANCE INSTRUCTIONS

NOTE - Check with your local water authority for regulations regarding discharge of treated

condensate to the drain or sewer system.

WARNING

1. Do not use to pump flammable or explosive fluids such as gasoline, fuel oil, alcohol, etc.

2. Do not use in explosive atmospheres.

3. Do not handle pump with wet hands, when standing on a damp surface, or in water.

4. To reduce the risk of electrical shock connect pump to a properly grounded grounding type

receptacle. It is reccommended to use the pump with a GFCI (ground fault circuit interrupter).

5. Connect the pump only to the power supply specified on the nameplate of the pump.

6. In any installations where property damage and/or personal injury might result from an

inoperative pump, a backup system and/or alarm should be used.

7. Do not twist or kink the drain hose.

8. Before doing any maintenance or repairs on the pump, disconnect the pump from the power

supply to avoid electrical shock.

9. Keep children away from pump.

10. This is a non-submersible pump.

11. Every installation or after-sales service should be done by a qualified service technician.

12. If the pump runs for more than 5 minutes before shutting off check the trouble shooting

chart on page 7 for a solution.

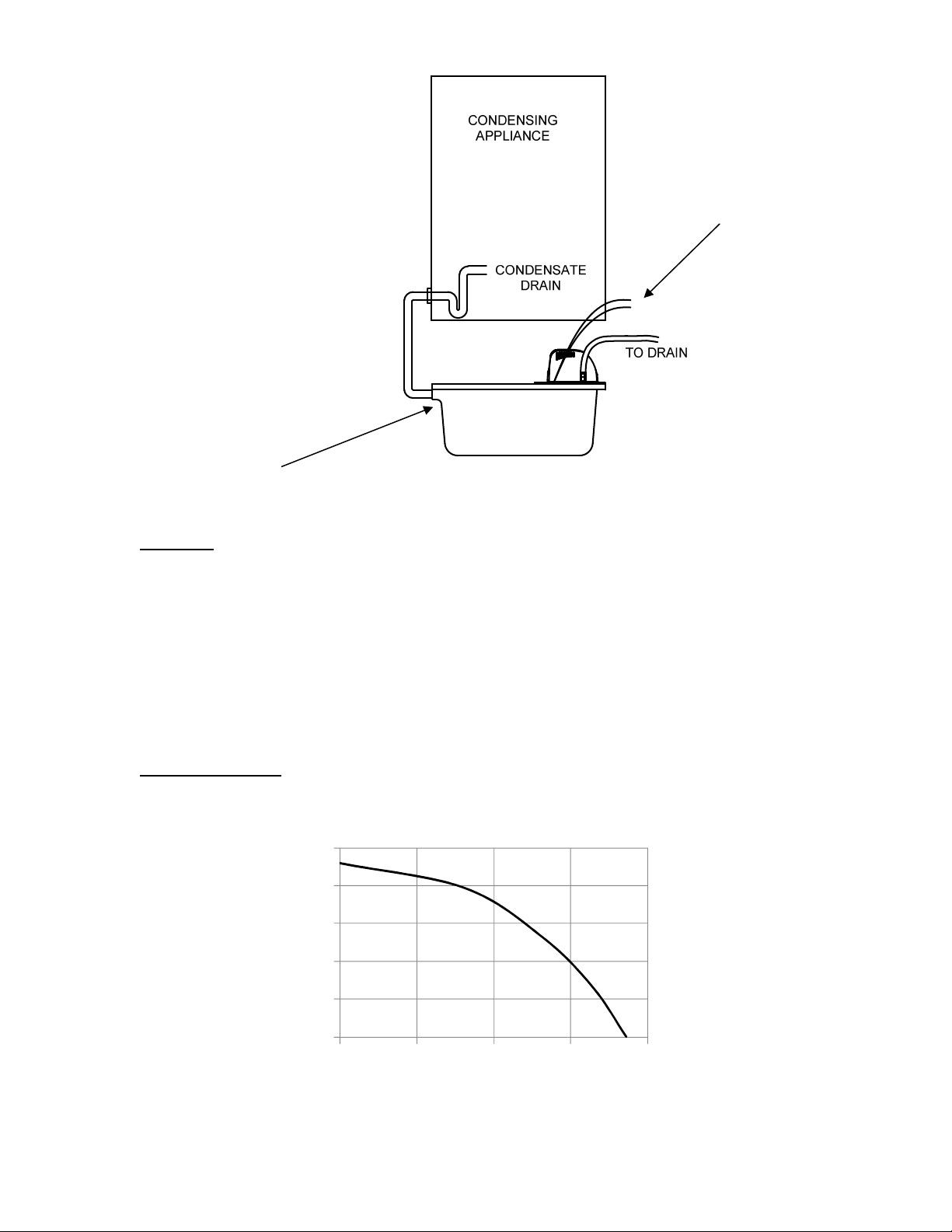

13. “Risk of damage to appliance”. The neutralization tank inlet must be at a lower elevation

than the condensate drain from appliance.

14. Do not allow exhaust flue gases to vent through the neutralization tank. All condensate

drains leading into the neutralizer must have a trap to prevent flue gas leakage. Flue gas leakage

can cause injury or death from carbon monoxide.

15. Connection to the appliance and neutralization tank must be installed to ensure that no

condensate backflow into the appliance can occur.