PEE2V04 2019-02-12

Pulse values programmable

Type of pulses active, passive

- high voltage ranges of active pulses 2,5...3,7V

- low voltage ranges of active pulses 0 ...0,7V

- input resistance* at the bartery supply 2 MOm

- input resistance* at the main supply 10 kOm

(*Resistance of internal resistor to 3.6 V circuit)

Integrated programmable filter: programmatically

rejected input pulses, where the repetition period

is less than the stated period of the filter (2...999 ms) –for class IB only

Communication cable length between calculator

and each of the sensors (3; 5; 10; 15; 20; 40; 50) m,

Recorded errors and error duration (depending on the configuration):

- none recorded

- recorded at short circuit on line (or an impulse low level) longer than 2 s

- recorded when flow rate exceeds programmed maximum allowed value

- recorded when flow rate is under programmed minimum allowed value

- recorded when the pulse is not more than 24 hours.

Display units m3

Maximum permissible input pulse frequency and

minimal permissible pulse or pause duration,

depending on pulse type and cable length see table 2.2

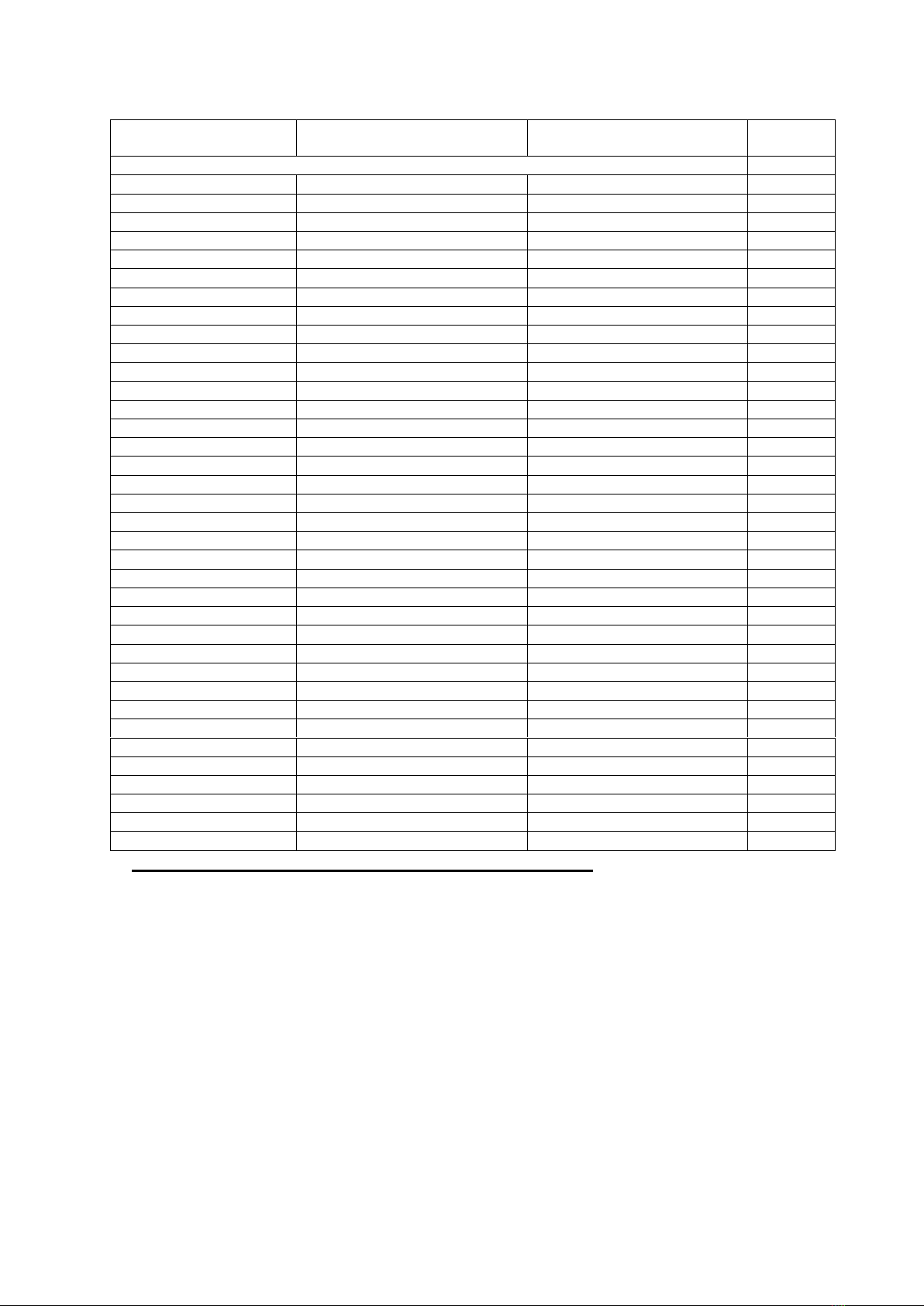

Table 2.2

Power supply of meter/

Flow pulse input type

Connection cable

length , m

Maximum

permissible pulse

frequency, Hz

Minimal permissible

pulse or pause

duration, ms

Battery supply / Active pulses

Battery supply / Passive pulses

(transistor key or mechanical contact)

Mains supply /

Active or passive pulses

* - values for pulse input device class IB are presented in brackets.

Flow rate value (for information) is calculated:

a) when the flow input pulse duration period is T 10 s - each 10 s as multiplication of flow pulse value and

flow pulse average period,

b) when the flow input pulse duration period is T =10...180 s - flow input pulse duration periodicity as

multiplication of flow pulse value and flow pulse period,

c) when the flow input pulse duration period is T 180 s - the value zero is indicated.

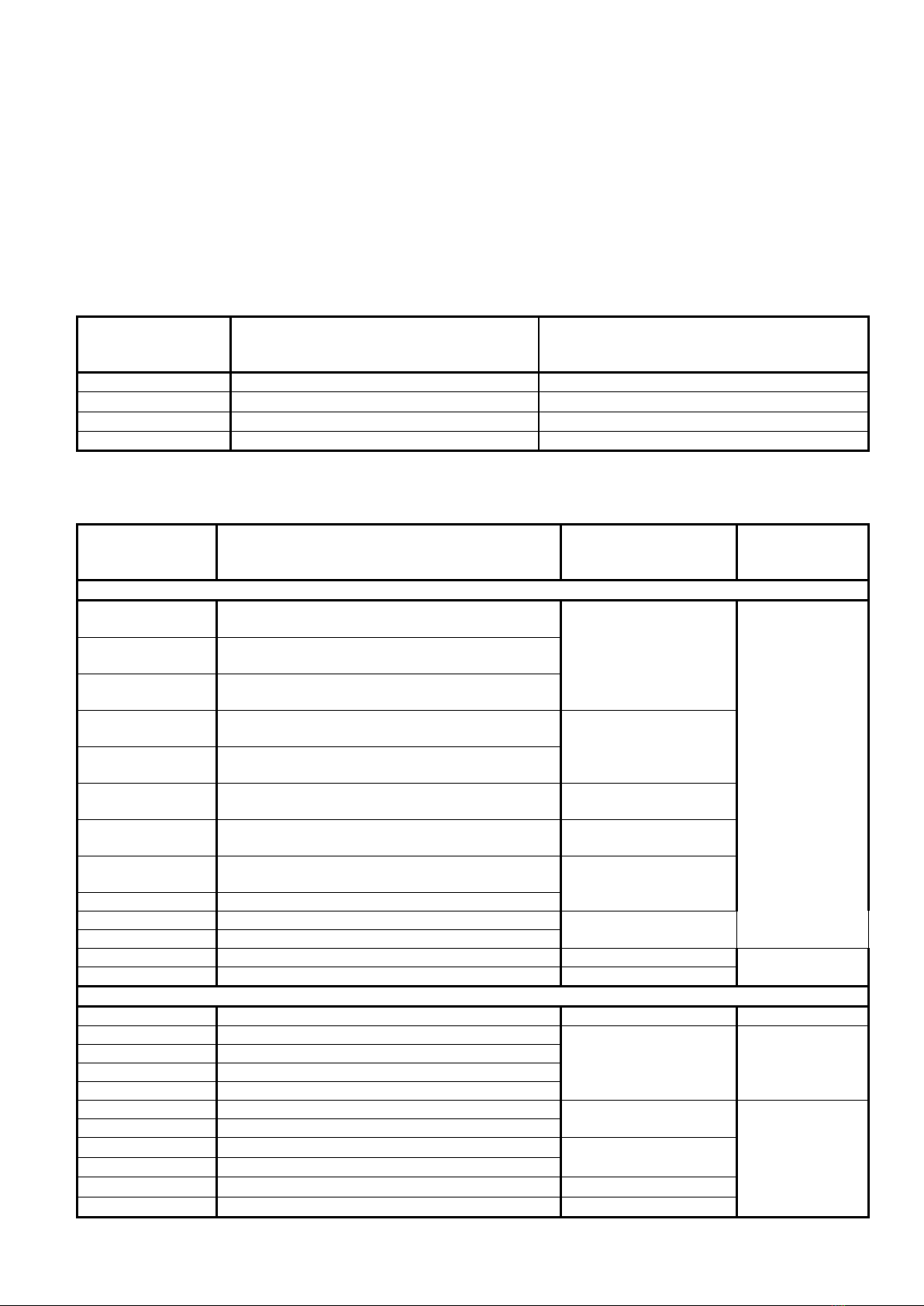

2.4. Pressure measurement

Number of pressure inputs 0...2

Display units kPa

Fiducial error not more than 0,25 of the upper limit of the

measurement range

Pressure measurement ranges:

- lower limit, programmable from 0 kPa to 2500 kPa

- upper limit, programmable from 100 kPa to 2500 kPa

Normalized input dimension current, linearly dependent on the pressure

- input current limits, programmable 0-5 mA, 0-20 mA, 4-20 mA

- input resistance 110 Om

2.5. Time measurement

Relative time measurement error not more than 0,01 %

Heat meter calculator measures:

- real time - calendar

- time, when device is powered on

- normal working hours

- failure time of additional flow sensors V3 .. V4

- time, when flow rate exceeds programmed maximum allowed value for channels V1…V4

- time, when flow rate is under programmed minimum allowed value for channels V1…V4

- time, when temperature difference Θ1-Θ2 is under programmed minimum allowed value

Display resolution:

the real time display 1 s

for operating time display 0,01 h