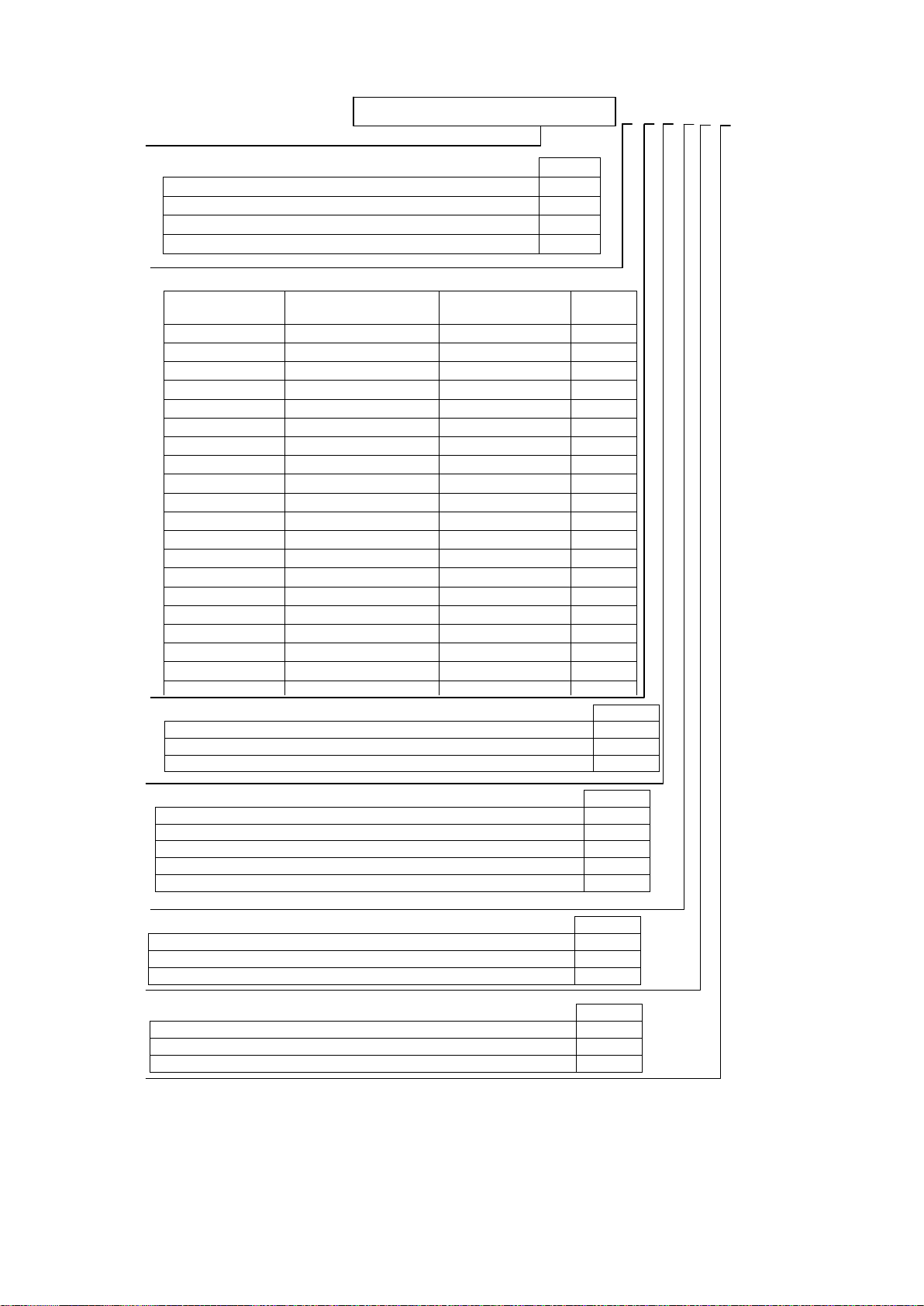

PL WQ1_180829

Volume measurement unit’s m3

Resolution of a displaying device 0,001 m3

Displaying range 999999,999 m3

The maximum permissible error (MPE), on volumes delivered at flow rate between the transitional flow rate Q2

(included) and the overload flow rate Q4(included) is:

- When water temperature ≤ +30 ºC 2 %

- When water temperature > +30 ºC 3 %

The maximum permissible error (MPE), on volumes delivered at flow rate between the minimum flow rate Q1

(included) and the transitional flow rate Q2(excluded) for water having any temperature is: 5%

If the flow-rate exceeds the maximum value Q4:

–when the flow-rate Q ≤ 1,2Q4, the flow-rate measurement and calculations are continued;

–when the flow-rate Q > 1,2Q4, calculations are performed using flow-rate value 1.2∙ Q4, the

info code “ Maximum allowable value of flow rate is exceeded ” is recorded and the duration of that status is

calculated.

Display (LCD)

The device is equipped with 2- lines LCD (Liquid Crystal Display):

Upper line - 9-digits for displaying measured volume of water:

Readings in normal mode: m3( three digits after decimal point).

Readings in verification (TEST) mode: m3( six digits after decimal point).

Lower line - 5-digits for displaying current flow rate, m3/h, and special symbols for displaying

operation modes

In the case of battery discharge, all integral readings and archive data shall be saved for at least 16

years and can be accessed by connecting a power battery in the operating condition.

Data recording and storage

In its memory, the meter accumulates an archive of hourly, daily, and monthly-measured parameters.

Archive data can be read only by remote data reading means (see Paragraph 6.5). The monthly data archive

parameters which are also additionally showed on the display are specified in Paragraph 6.3.1.

The following parameters of each hour, day, and month are accumulated in the memory of the meter:

Integral volume of water in the forward direction

Integral volume of water in the reverse direction

Maximum flow rate value and date

Operating time without error

Data logger capacity:

up to 1480 h –for hourly records.

up to 1130 days - for daily records,

up to 36 last months - for monthly records,

Archive data storage time not less than 36 months

Storage time of measured integrated parameters even if device is disconnected from power supply

not less than 16 years.

External communication modules and interfaces

Integrated in meter:

Optical interface

It is intended for data reading via Mbus protocol, parameterizing of meter, and for outputting optical

pulses in the test (verification) mode. It is activated by sending 1 s. pulse sequence (5 minutes after the end of

communication is automatically deactivated).

NFC (Near-field communication interface)

It is intended for data reading.

Ordered interface (to be specified when ordering the meter; one options can be selected only):

- RF 868 MHz