3 OPERATING PRINCIPLE

The flow-rate is measured on the basis of the ultrasonic measurement principle. The ultrasonic

signal is sent along the flow sensor upstream and downstream between the ultrasonic sensors, which

alternately perform transmitter and receiver functions. The flow rate is calculated on the basis of the

measured propagation time difference (downstream and upstream).

The temperature differential between the supply and return flows is measured by resistive

temperature sensors. The electronic unit calculates the amount of consumed heat energy by integrating over

time the difference of the enthalpies of supply and return heat carrier and provides the data on the display.

Energy calculation formulas:

–when the flow sensor is in the supply line

Q = Vρ1(hT1-hT2)

–when the flow sensor is in the return line

Q = V ρ2(hT1-hT2)

Where: Q –heat energy;

V –the volume of water passing through the meter, m3;

ρ1, ρ2 –the water density corresponding to the supply and return heat carrier temperatures

Θ1 and Θ2 measured by the supply and return water temperature sensors T1 and T2;

hT1, hT2 –the calculated specific enthalpy of the heat carrier for the temperatures Θ1 – Θ2.

When the cooling energy tariff function is activated, in case of a negative temperature differential, energy will

be accumulated in the additional tariff register Q☼. In this case, energy values are calculated according to the

following formulas:

–when the flow sensor is in the supply line

when Θ1 > Θ2: Q = V1(hT1-hT2), Q☼= 0

when Θ1 < Θ2: Q☼= V1(hT2-hT1), Q = 0

–when the flow sensor is in the return line

when Θ1 > Θ2: Q = V2(hT1-hT2), Q☼= 0

when Θ1< Θ2: Q☼= V2(hT2-hT1), Q = 0

The electronic unit of the heat meter performs all necessary measurement and data storage functions:

- measurement and collection of thermal energy consumption and heat transfer medium volume,

- accumulation of instantaneous, average, maximum and minimum values of heat flow and temperatures,

- measure and accumulation of volumes according to the received pulses at the two pulse inputs,

- generates energy and volume pulses at two pulse outputs,

- performs automatic diagnostics of the meter and accumulation of operating and measuring errors,

- displays measured and stored data and transmits via telemetry interfaces,

- store the values of thermal energy in separate registers,

- ensures accelerated detection of measurement errors in test and adjustment modes.

4 MARKING AND SEALING

4.1. Marking

The following is indicated on the front panel of the electronic unit of the meter: the manufacturer’s

trade mark, type and the type code of the meter, EU –type examination certificate number, factory number,

year of manufacture, temperature measurement range, temperature difference measurement range,

accuracy, environmental class according to LST EN1434-1, electromagnetic and mechanical environment

class, flow measurement range (qi, qp, qs), temperature range, type of temperature range, maximum

allowable working pressure and the distributor’s mark (if applicable), types of communication interfaces

(excluding optical ones), and supply voltage (in the case of external power supply).

The following is indicated on the housing of the flow sensor:

–the type of connection (thread or relative diameter);

–the flow direction.

Destination of wire communication interfaces , additional inputs and outputs, and wires of external

power cables is marked with the colour of the cable wires and an additional label on the cable indicating the

destination.

The temperature sensor intended for mounting in the higher-temperature pipeline is marked with a red

marking pipeline sign; that intended for mounting in the lower-temperature pipeline is marked with a blue

pipeline sign.

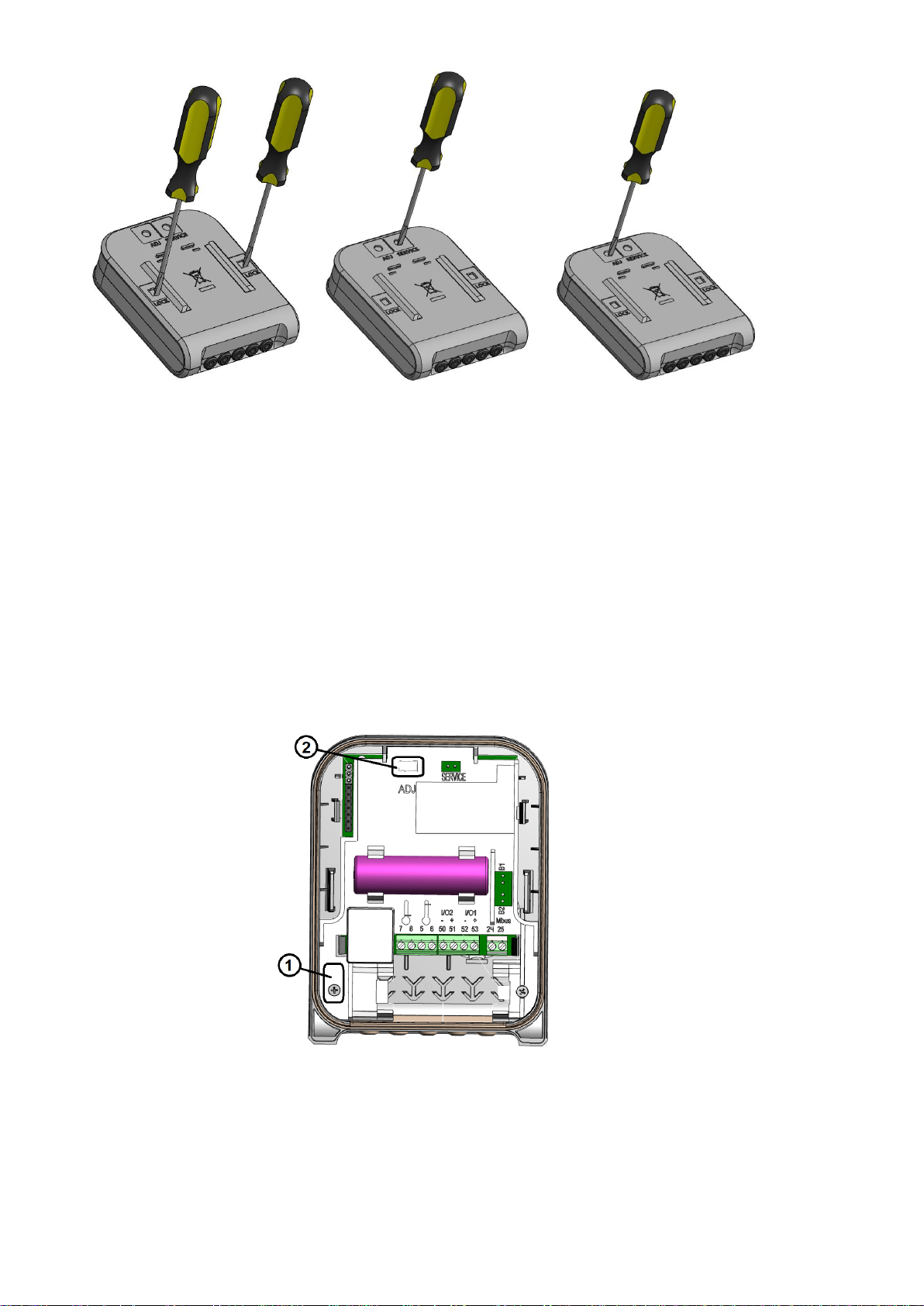

4.2. Sealing of the meter (Annex C)

4.2.1. Sealing of the calculator of the heat meter

Access to the opening elements of the box, the configuration change activation contacts and the

adjustment data change activation contacts is protected by special partitions that can be easily broken with a

tool (such as a universal flat-blade screwdriver) (Fig.4.1).