UMAX0608XX‐1000.Tri‐AxialJ1939CANInclinometer.Version9B iii

TABLE OF CONTENTS

1INTRODUCTION ................................................................................................................. 5

2INCLINOMETER DESCRIPTION ........................................................................................ 6

2.1Theory of Operation ..................................................................................................... 6

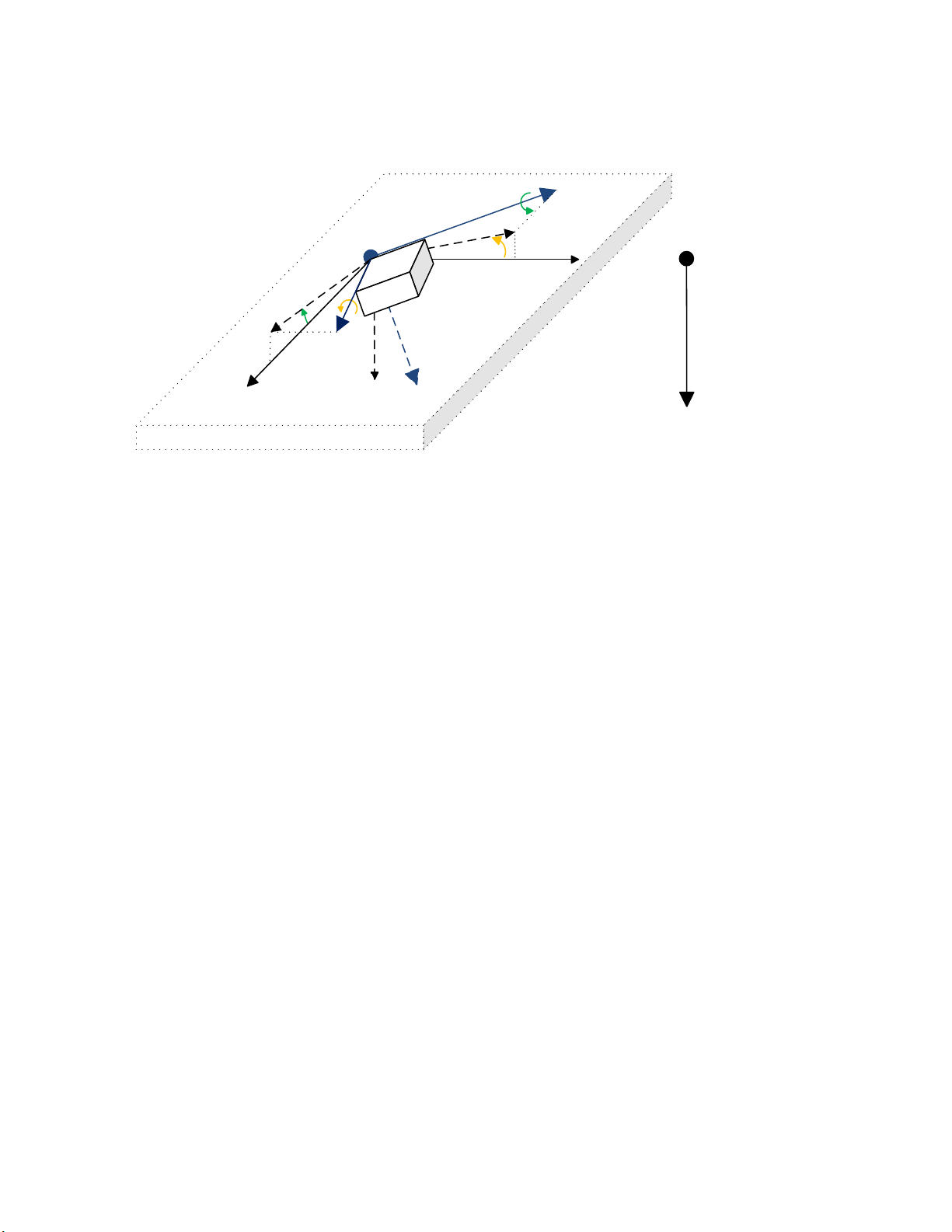

2.1.1Unit Coordinate System ........................................................................................ 6

2.1.2Unit Reference Frames ......................................................................................... 6

2.1.3Angle measurements ............................................................................................ 7

2.1.3.1Tilt Angles ......................................................................................................... 8

2.1.3.2Rotation Angles ................................................................................................. 9

2.1.3.2.1Unit Rotation Angles ................................................................................. 10

2.1.3.2.2Euler Angles ............................................................................................. 11

2.1.3.2.3Gimbal Lock .............................................................................................. 12

2.1.3.3Maximum Gravity Acceleration Error ............................................................... 13

2.1.3.4Practical Recommendations ............................................................................ 13

2.1.3.5Default Settings ............................................................................................... 15

2.2Hardware Block Diagram ........................................................................................... 16

2.3Software Organization ............................................................................................... 16

2.4CAN Interface ............................................................................................................ 17

2.4.1CAN Baud Rate .................................................................................................. 18

2.4.2J1939 Name and Address .................................................................................. 18

2.4.3Slew Rate Control ............................................................................................... 19

2.4.4Network Bus Terminating Resistors .................................................................... 19

2.5Default Settings .......................................................................................................... 19

2.5.1CAN Interface ..................................................................................................... 19

2.5.1.1PGN 61459, Slope Sensor Information, SSI ................................................... 19

2.5.1.2PGN 61481, Slope Sensor Information 2, SSI2 .............................................. 21

2.5.1.3PGN 65256, Vehicle Direction/Speed, VDS .................................................... 22

2.5.1.4PGN 64905, Vehicle Direction/Speed 2, VDS2 ............................................... 23

2.5.2Analog Outputs ................................................................................................... 24

3INCLINOMETER LOGICAL STRUCTURE ....................................................................... 25

3.1Function Block Signals ............................................................................................... 26

3.1.1Undefined Signal ................................................................................................ 26

3.1.2Discrete Signal .................................................................................................... 26

3.1.3Continuous Signal ............................................................................................... 26

3.1.4Signal Type Conversion ...................................................................................... 27

3.1.4.1Discrete to Continuous Conversion ................................................................. 27

3.1.4.2Continuous to Discrete Conversion ................................................................. 27

3.1.4.3Undefined Signal Conversion .......................................................................... 27

3.2Accelerometer ............................................................................................................ 27

3.3Angle Measurement ................................................................................................... 28

3.4Unit Installation .......................................................................................................... 29

3.4.1.1Unit Frame Orientation Examples ................................................................... 30

3.5Sensor Calibration ..................................................................................................... 32

3.6Binary Functions ........................................................................................................ 32

3.7Analog Signal Outputs ............................................................................................... 34

3.8Global Parameters ..................................................................................................... 36

3.9J1939 Network ........................................................................................................... 36

3.9.1ECU Network Parameters ................................................................................... 37