PESDU1M02 (MID)

5

Remark: 1. LED indication begins when the button is pushed down.

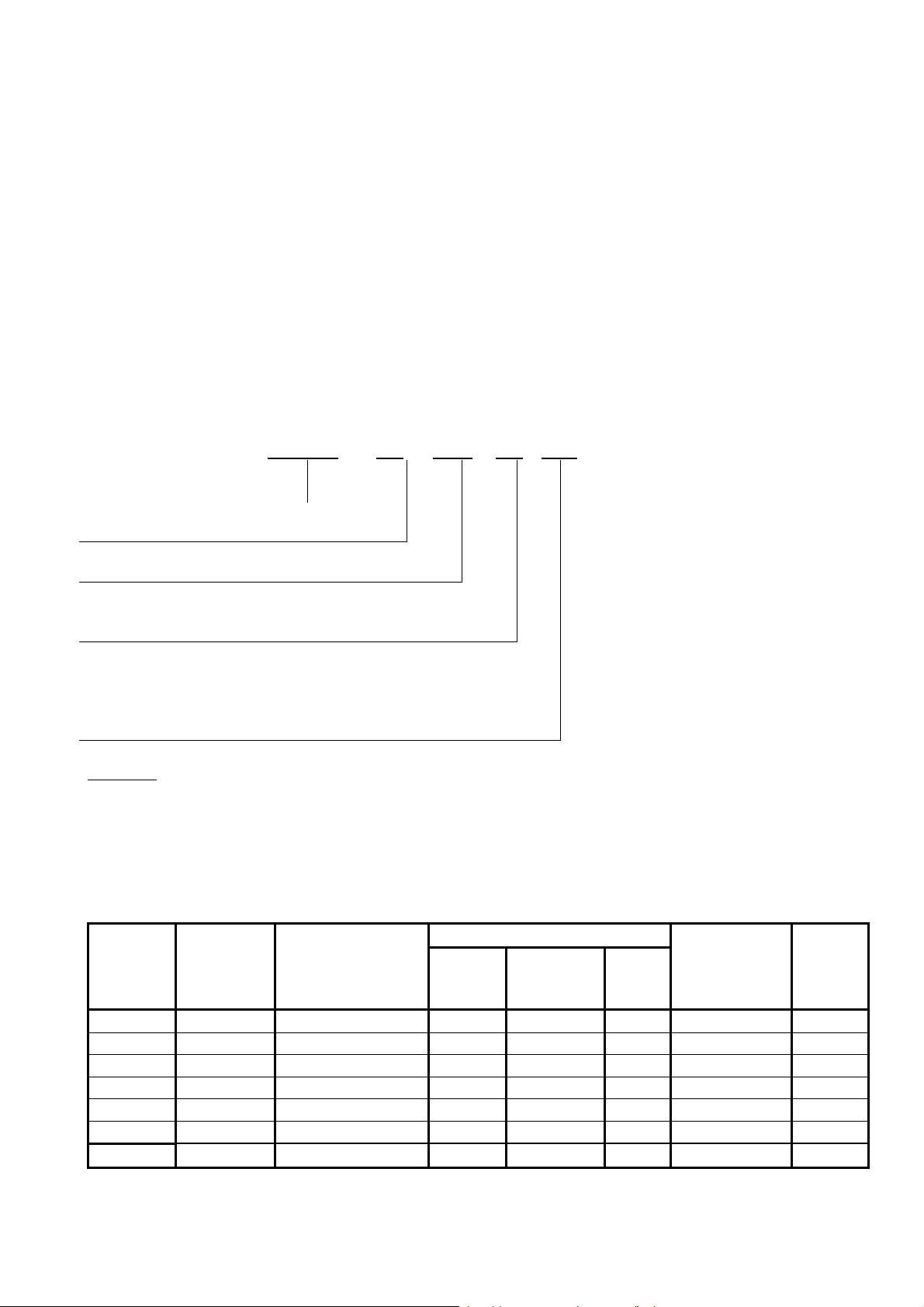

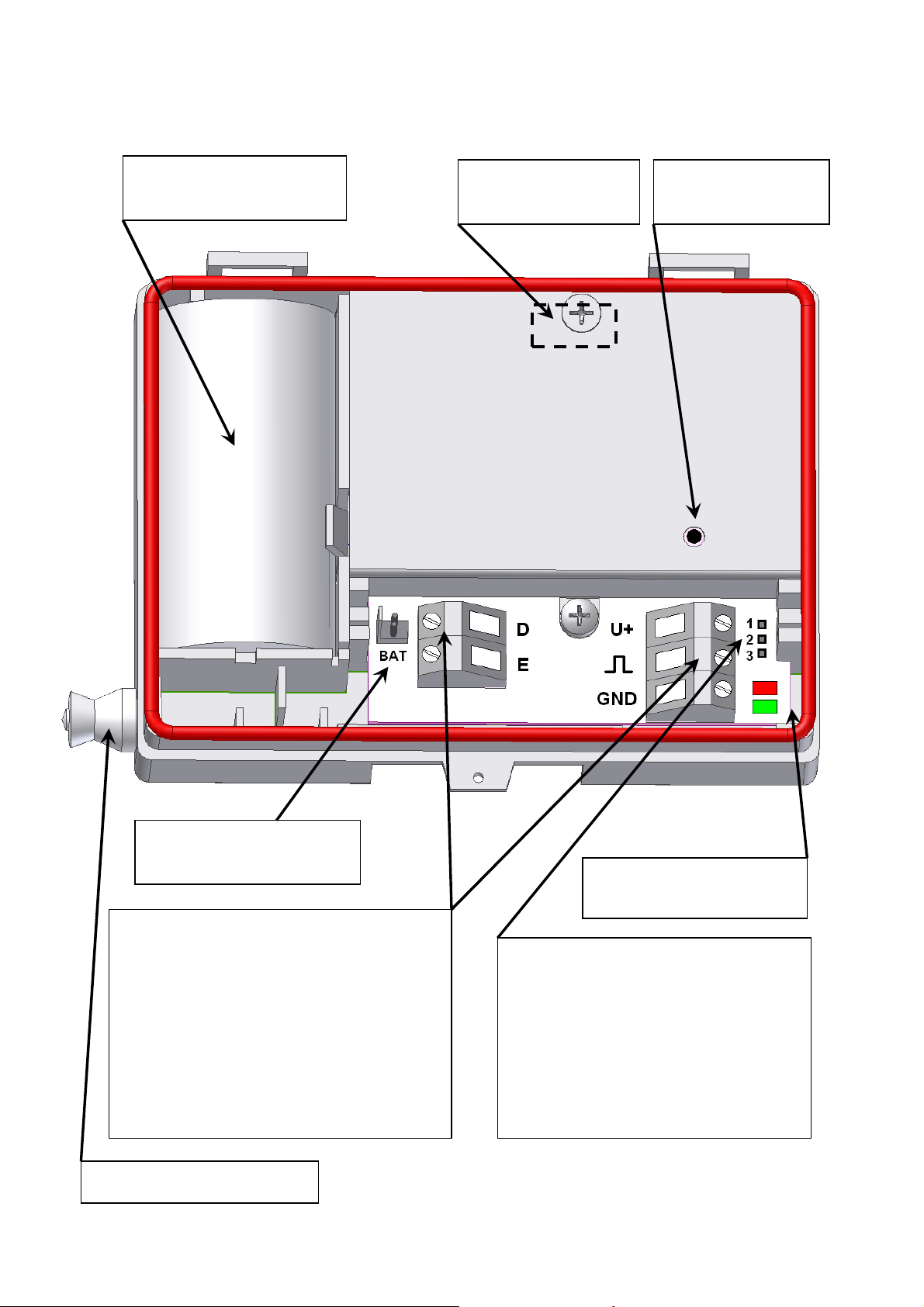

Status signals E (Error) and D (Direction) are passive signals and should be wired using the open drain

output signal connection diagram such shown in 2.6.1 p.

2.8. When the measured flow rate exceeds maximal flow q

s

per +10 %, the flow sensor transmits

the amount of pulses which corresponds to the flow rate q

s

+10 % and indicates corresponding

overflow status code.

2.9. The flow sensor is powered:

- From an external power source DC 3,6V ±0,2V (average current less than 35 µA),

or

- From internal +3.6V lithium battery, size C, with up to 12 years lifetime.

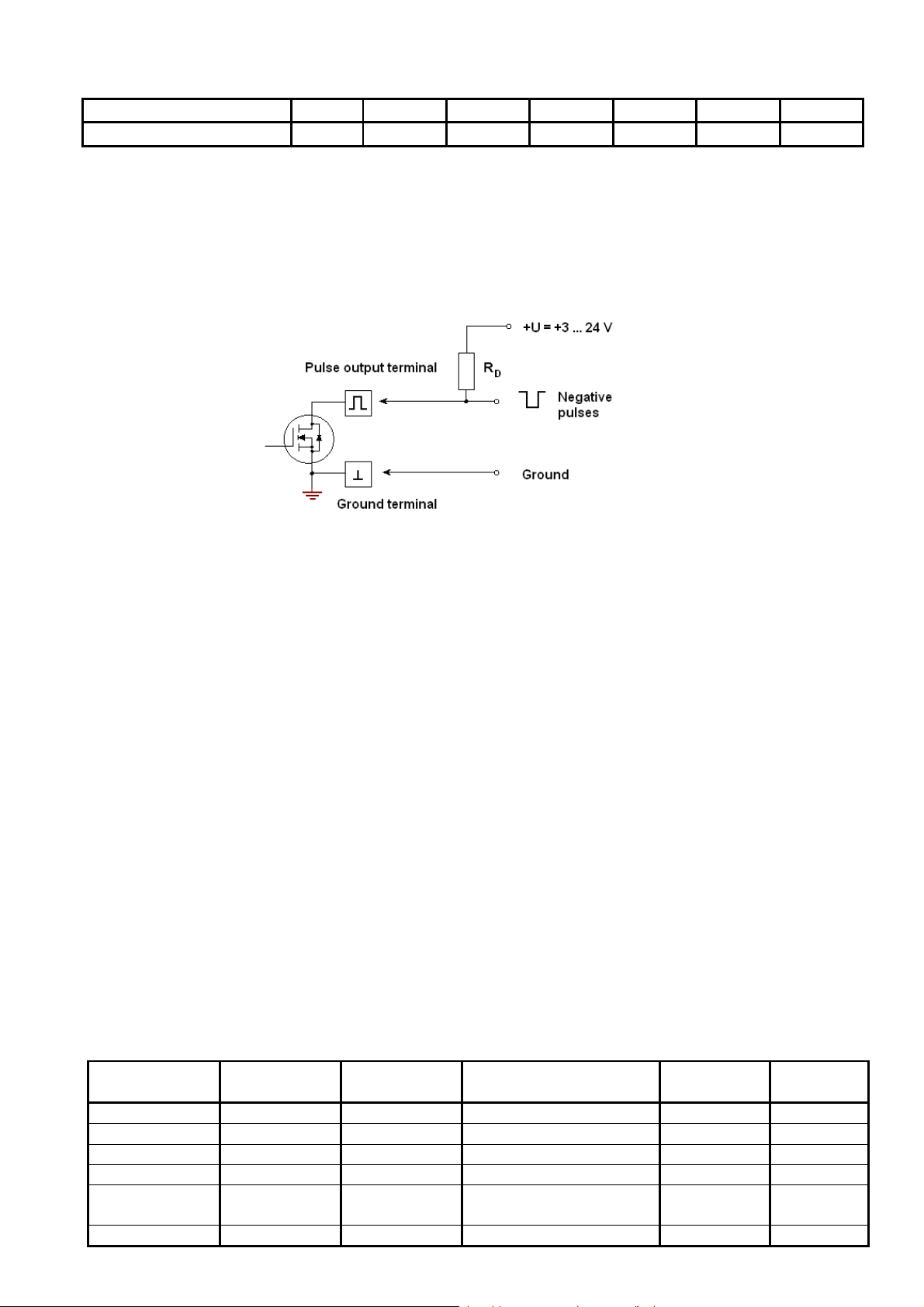

2.10. Table of flow sensor weight, corresponding with the nominal diameter:

Permanent flow q

p

, m3/h 3,5 6 10 15 25 40 60

Weight, less than, kg 3,0 3,0 3,2 6,0 10,5 13,5 14

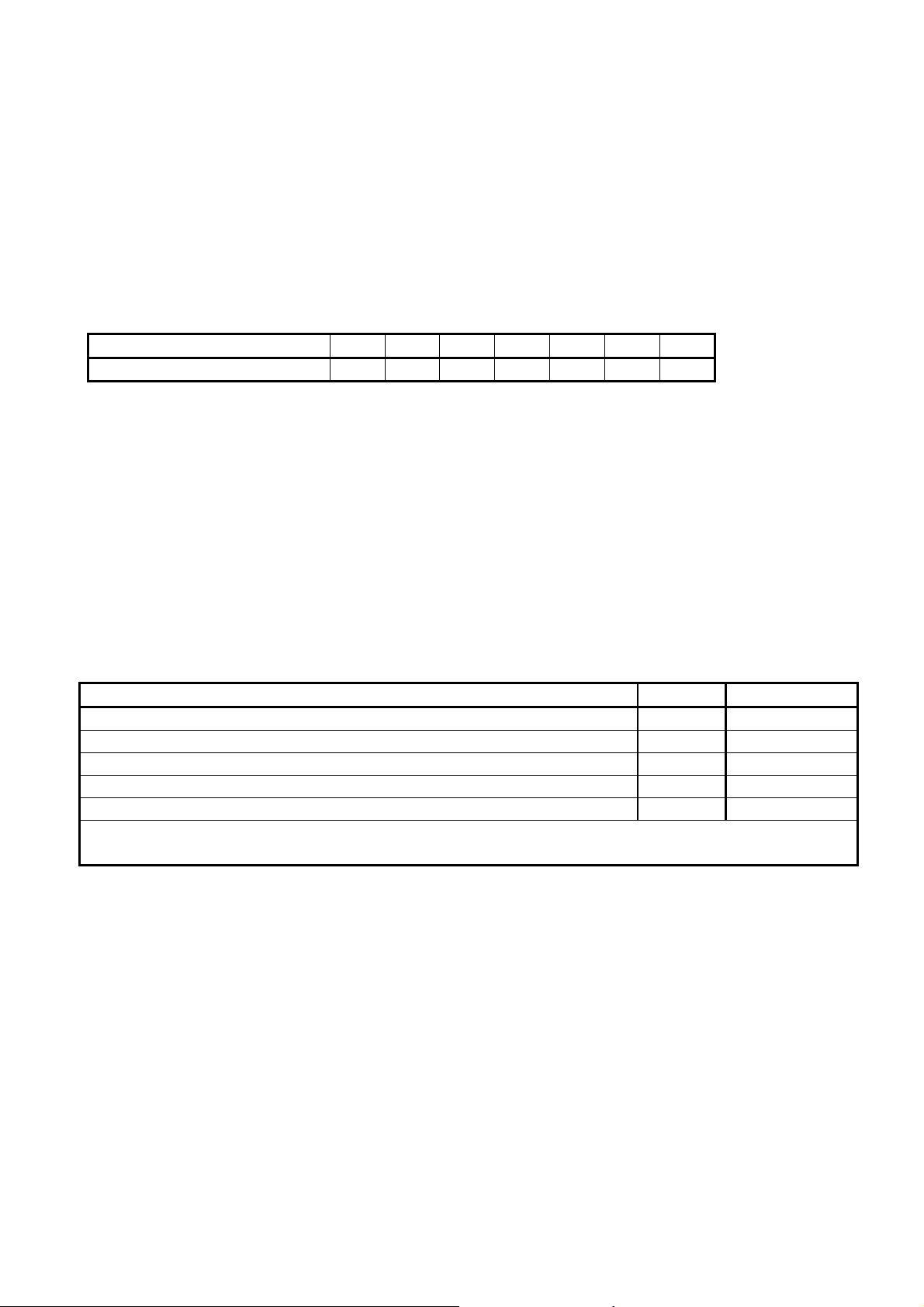

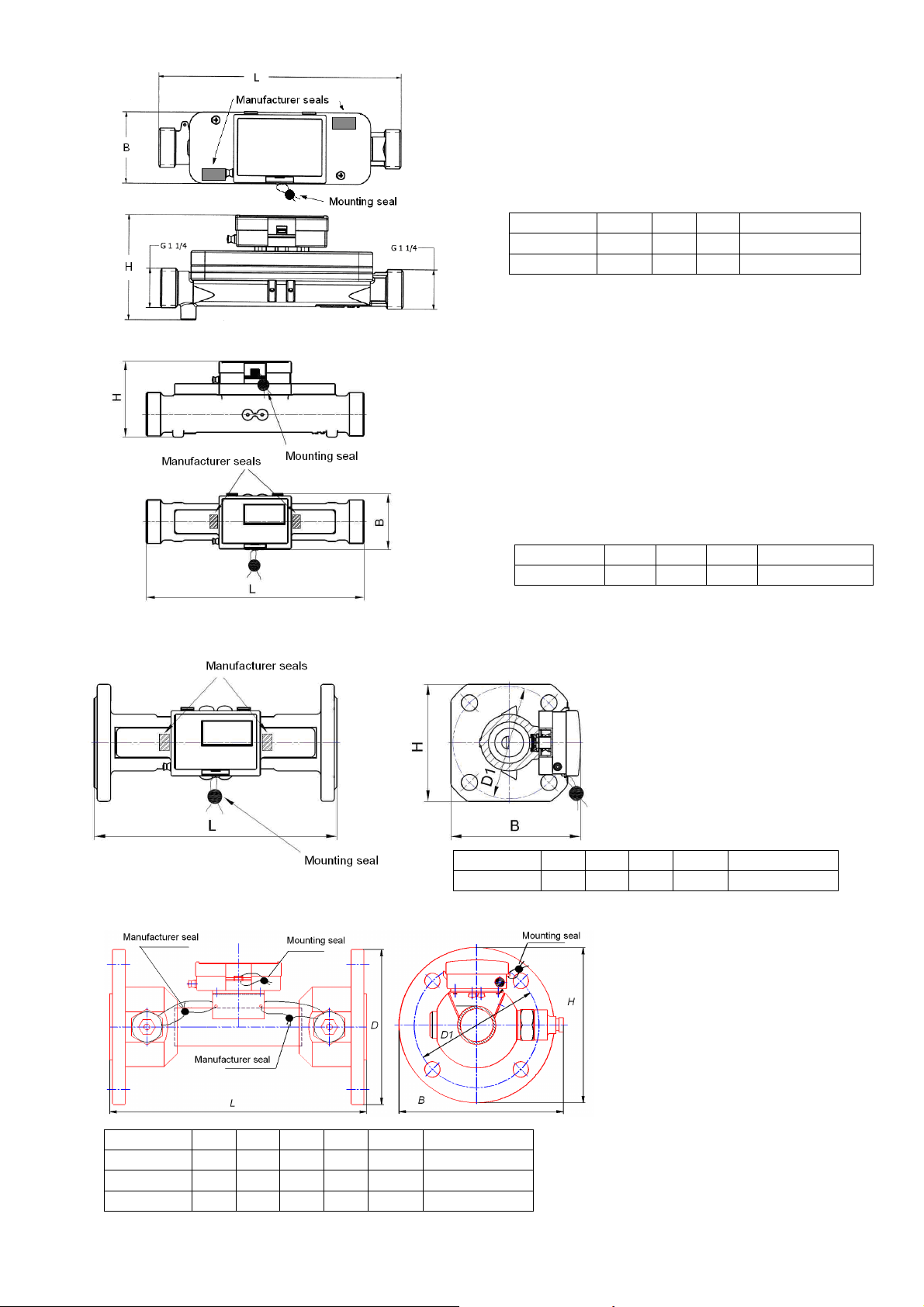

Dimensions of the flows sensors and its connection flanges is presented in the A appendix.

2.11. Environmental conditions:

- ambient temperature 5

o

C to 55

o

C,

- ambient humidity < 93 %,

- atmospheric pressure 86 kPa to 106,7 kPa,

- fluid temperature 10

o

C to 130

o

C,

- fluid pressure <1,6 MPa.

2.12. Degree of protection IP65 or IP67 (with separate order)

2.13. The flow sensor meets the requirements according to 89/336/EEC, EN50082-2, EN50081-2

3. PACKAGE CONTENT

Components included in the complete Quantity Remark

1. Flow sensor SDU-1 1

2. Set of additional connection flanges 1 *

3. Technical description, operating instruction of SDU-1 1

4. Pulse cable (length from 3 m to 200 m) 1 **

5. 3,6V lithium battery, 8Ah, size C 1 *

REMARK: * - included on demand only

** - cable length depending on the order. Standard length – 3 m.

4. OPERATING PRINCIPLE

4.1. The ultrasonic flowmeter SDU-1 is microcontroller based device that consists of flow sensor

and electronic part mounted on the flow sensor.

Flow measurement is based on the time-of flight measurement method. Fluid volume is

calculated according the formula:

V =K

H

* K

M

* (1/t

+

- 1/t

-

) *T ,

where: V - measured fluid volume, m

3

;

T – time of integration, s;

t

+

- measured upstream time of flight of ultrasonic pulse, s;

t

-

- measured downstream time of flight of ultrasonic pulse, s;

K

H

– hydrodynamic correction factor;

K

M

–coefficient that depends on the flow sensor dimensions.

Measured flow rate is converted into the pulses quantity that is transferred in output pulse terminal.