2 EC-30 | 1.01.00 www.mc-techgroup.com

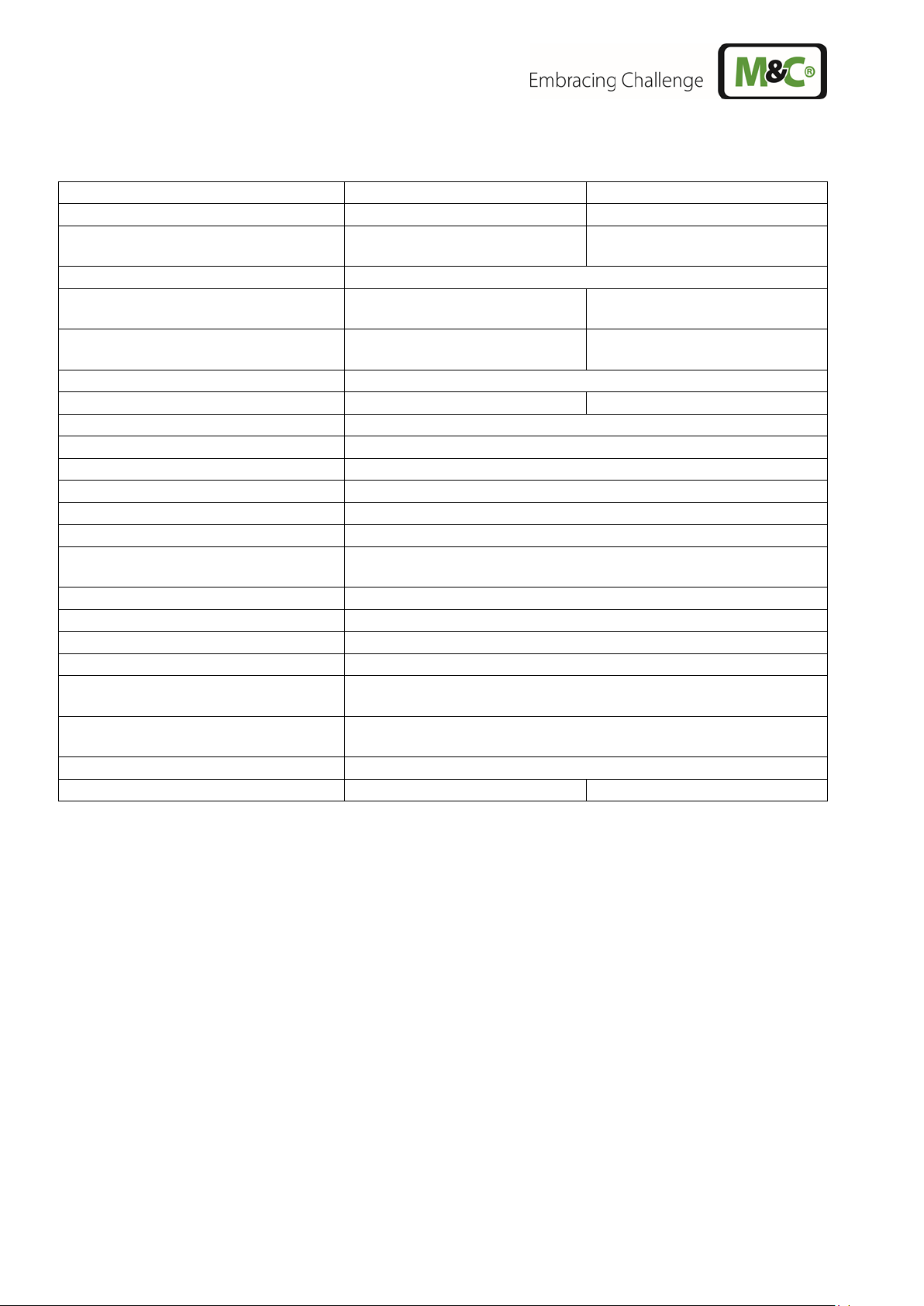

Content

1General information................................................................................................................5

2Declaration of conformity....................................................................................................... 5

3Safety instructions.................................................................................................................. 6

4Warranty ..................................................................................................................................6

5Used terms and signal indications.........................................................................................7

6Introduction............................................................................................................................. 8

6.1 Serial number........................................................................................................................8

7Application............................................................................................................................... 9

8Technical data....................................................................................................................... 10

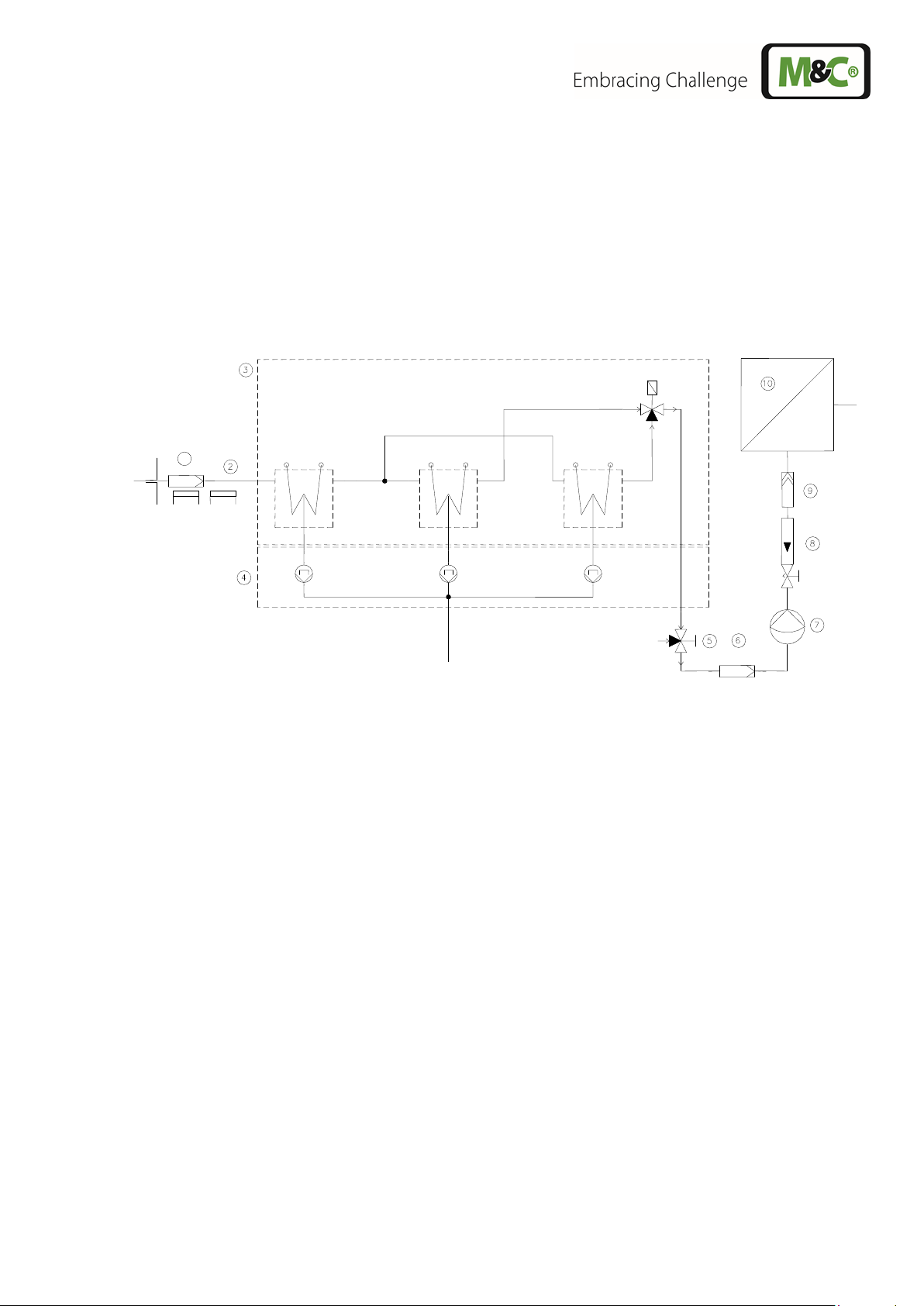

9Description ............................................................................................................................ 10

9.1 Assembly............................................................................................................................. 11

10 Function................................................................................................................................. 12

11 Reception and storage.......................................................................................................... 14

12 Installation instructions........................................................................................................ 15

13 Supply connections.............................................................................................................. 15

13.1 Hose connections................................................................................................................ 15

13.2 Electrical connections.......................................................................................................... 16

14 Start-up.................................................................................................................................. 18

14.1 Function sequence and LED function display...................................................................... 18

15 Closing down......................................................................................................................... 20

16 Maintenance .......................................................................................................................... 20

16.1 Maintenance of the peristaltic pumps type SR25.1 of the EC-30/FD.................................... 21

16.1.1 Change of the pump tube...............................................................................................21

16.1.2 Change of contact pulleys and springs........................................................................... 22

16.1.3 Cleaning the pump head................................................................................................22

16.2 Replacing the heat exchangers ...........................................................................................23

17 Trouble shooting................................................................................................................... 24

18 EC automatic control board.................................................................................................. 26

18.1 Connecting the cooling compressor..................................................................................... 27

18.2 Temperature setting for the cooler....................................................................................... 28

19 temperature sensors............................................................................................................. 28

19.1 Checking the temperature sensor of the pre-cooling stage.................................................. 28

19.2 Checking the temperature sensor of the deep cooling stage................................................29

20 EC control board................................................................................................................... 31

20.1 Function sequence of the EC30 control electronics ............................................................. 32

21 Spare parts list ...................................................................................................................... 34

22 Appendix................................................................................................................................ 35