RADIO C

ONTROL

SYSTEM

A 2-channel

dogotal

proportional radio is

requored

to opperate

an

RC car. Any standard system can

be

used. how

eve

r

,a3

-8 channel system

may

not

be

applocable

depending

on

the

receover

soze.

Rechargeable nickel-cadium batteroes (no-cads). are highly

effiCient

and can

be

u

sed

as

many

as

300

tomes

or

more.

There are two

basoc

types of battery chargers. The more c

ommon

of

the two is a low rate

or

tnckle charg

er

wh

ich opperates off n

ormal

household currenl {1 10 volts) and

requores

approxoma

tely 15 hours to fully charge the system. A

quoc

k charger

os

also

availa

bl

e.

requ

or111g

only

15

monu

tes to fully charge the system.

Thos

typo

of

char

ge

r opperates off a 12 volt

po

wer source such as

an

a

ut

omobile or moto

rcy

cle

ba

tter

y.

'

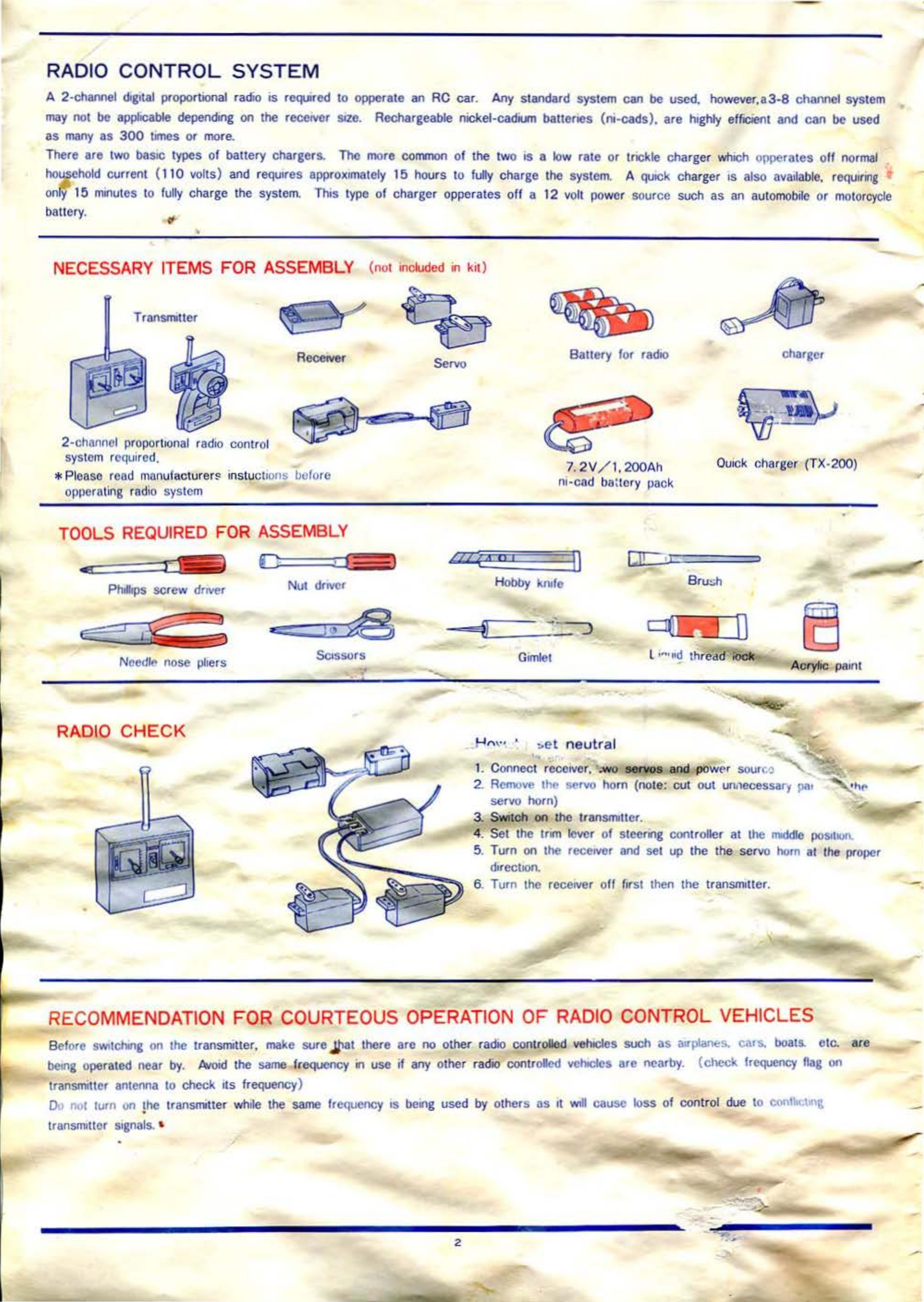

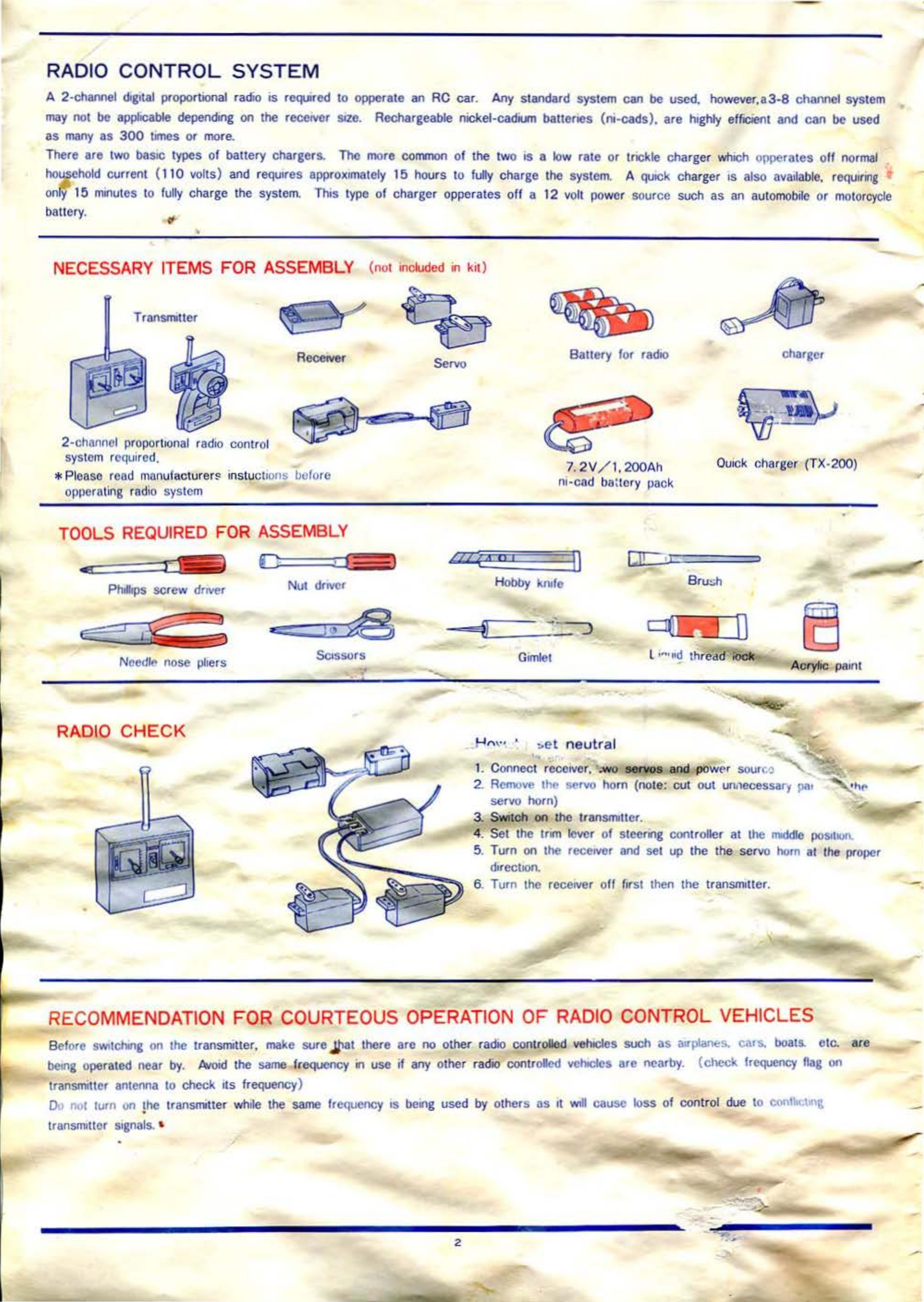

NECESSARY ITEMS FOR ASSEMBLY {not

in

cluded in kit)

Transmotter

2-

channel pro

porto

ona

l radio control

syst

em

requir

ed.

Receover

*Please read

ma

nu

f

acturer~

i

ns

tuc

to

ons before

opperating ra

di

o system

TOOLS

REQ

UI

RED FOR ASSEMBLY

r "

Pholtops

screw driver Nut

drover

I

N

eed

lf' nose

phers

"'

"'*

=:

::::

:Jill"~>t3

Scossors

RADIO

CHECK

Servo Battery for radio

7.

2V

/ 1.

200

Ah

ni-cad ba:tery pack

charger

Qui

ck charger (TX-2

00

)

•

L

IZ

(a

u 1 D

CJ!

;

Hobby

knofe

B

ru

sh

c::JGLn

j 0

-

Gim

let Acrylic

pe

on

t

..

~m

·

•

.

•

..

et

ne

utral

'

1. Connect r

eceiv

er. •

wo

~

and

po

wPr sour

coJ

'-

...._-

:.;:o

2.

Remove

thP servo horn (note: cut out un

.1

ecessa

ry

pa•

servo horn)

_,.

3. S

Wi

tch

on

the tr

ansmotter.

4. Set

the

trom

lever

of

steerong

controller at the

mddle

posotl<ll\

5. Turn

on

the

receover

and

set up the the se

rvo

hom

at t

he

proper

dorect1on.

6. Turn

the

r

eceover

o

ff

first

then

the transmotter.

RECOMMENDATION FOR COURTEOUS OPERATION

OF

RADIO

CONTROL VEHICLES

Before s

wuchlng

on

the

transmiuer.

make

suro

Jll

at

there are

no

ot

her r

adio

controlled

ve

hiCles

such

as atrplanes. car

s.

boats.

etc.

are

betng

oper

at

ed

near by.

Av

oid the

same

frequency

on

use

if

any

other rad'

10

controlled

vehiCles

are nearby. {check frcqocncy

flag

on

transrmtter

antenna

to check

its

frequency)

Do

not turn

on

the

transmitter while

the

same

frequency

IS

beong

used by others as ot

Will

cause loss of co

ntr

ol

due to

contl><;t«~l\

•

transmlltor

sognals.

•

2 •

-

~

-

...

-

-•

-

-