3

CHECKOUT

WARNING

Explosion or Fire Hazard.

Can cause serious injury, death or property damage.

Follow instructions on opening and closing fuel

valves carefully to prevent fuel buildup and possible

fire or explosion.

After the S720B installation has been completed, make the following

checks to ensure that the system is working properly.

Ignition Spark Response Test

The flame relay should not respond (pull in) to ignition spark.

To determine flame detector sensitivity to ignition spark, per-

form the following steps:

(1) Shut off the fuel supply to both pilot and main fuel valve

manually.

(2) Start system by raising controller set point or pressing start

button.

(3) Energize the S720B Igniter so that ignition spark is pro-

duced between electrode and ground.

(4) Check to make sure that ignition has not occurred (there

should be no flame). Repeat steps 1 through 3 until there is

no flame.

(5) Check the flame relay on the burner controller or the flame

LED. If the relay has not pulled in (flame LED is off), the

system is operating properly. Restore the fuel supply and

continue the checkout with the Pilot Turndown Test.

(6) If the flame relay pulls in (flame LED is on), stop the system

as the burner controller is indicating flame regardless of the

condition of the pilot or main burner flame.

(7) If a flame rod sensor is being used, ignition interference

may be the cause of relay pull in. Ignition interference is

most easily detected by measuring the flame current with

the ignition off, then on. A difference greater than 1/2 mi-

croampere indicates the presence of ignition interference.

If ignition interference is detected, take the appropriate fol-

lowing steps:

a. Check for correct spacing of ignition electrode gap.

b. Depending upon the particular situation, rearrange the

flame electrode, ignition electrode and ground to provide

sufficient physical spacing to prevent electrical interac-

tion (interference) between these components.

c. Add more ground area in the form of a flat plate between

the flame rod and ignition electrode.

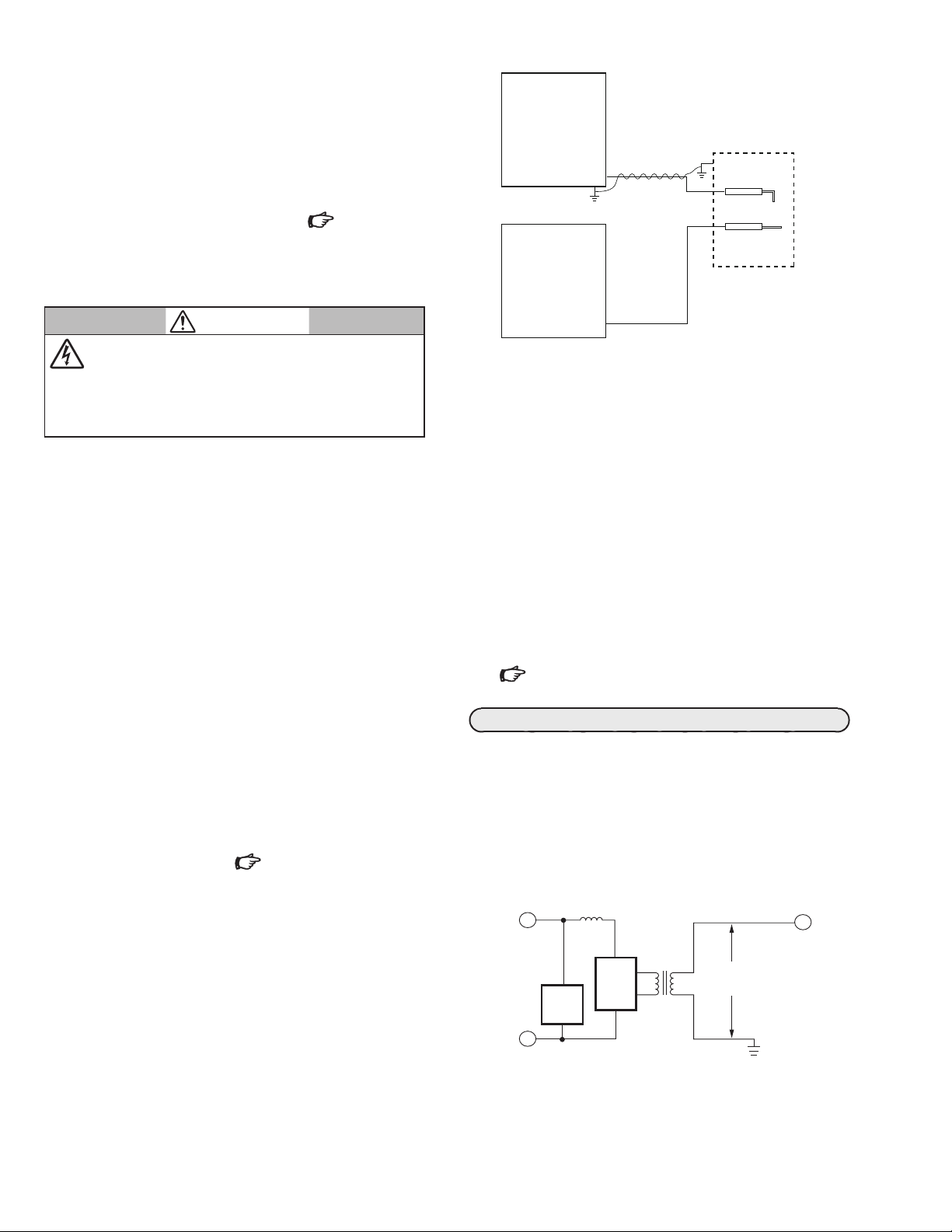

d. Try wrapping the ground lead around the igniter wire as

shown in Fig. 1, if not already done.

e. Repeat steps 1 through 6.

(8) If the flame relay pulls in (flame LED is on), replace the

burner controller.

(9) If replacing the burner controller does not eliminate flame

relay pull in (flame LED on), contact your local Azbil

branch office.

(10) If an ultraviolet (UV) flame detector is being used, the UV

detector may be responding to the UV radiation being

emitted by the electric spark. To determine whether the UV

detector is responding to the ignition spark and to eliminate

the response, try the following steps to eliminate the spark

pickup:

a. Sight the UV detector far enough out on the pilot flame

so the ignition spark is not sensed. If sensed, reverse the

S720B power leadwires.

b. Construct a barrier to block the ignition spark from the

UV detector view.

c. Reposition the ignition electrode so it is screened by the

pilot burner itself.

d. Restrict the UV detector viewing angle by using a slightly

longer sighting pipe.

e. Repeat steps 1 through 6.

(11) If the flame relay pulls in (Flame LED on), replace the

burner controller.

(12) If replacement of the burner controller does not eliminate

the relay pull in, contact your local Azbil branch office.

Pilot Turndown Test

Refer to the burner controller instructions for the exact proce-

dure to be used in performing the pilot turndown test.

Final Checkout

After other checks have been completed, restore the system to

normal operation and observe at least one complete cycle to be

sure of satisfactory burner operation.