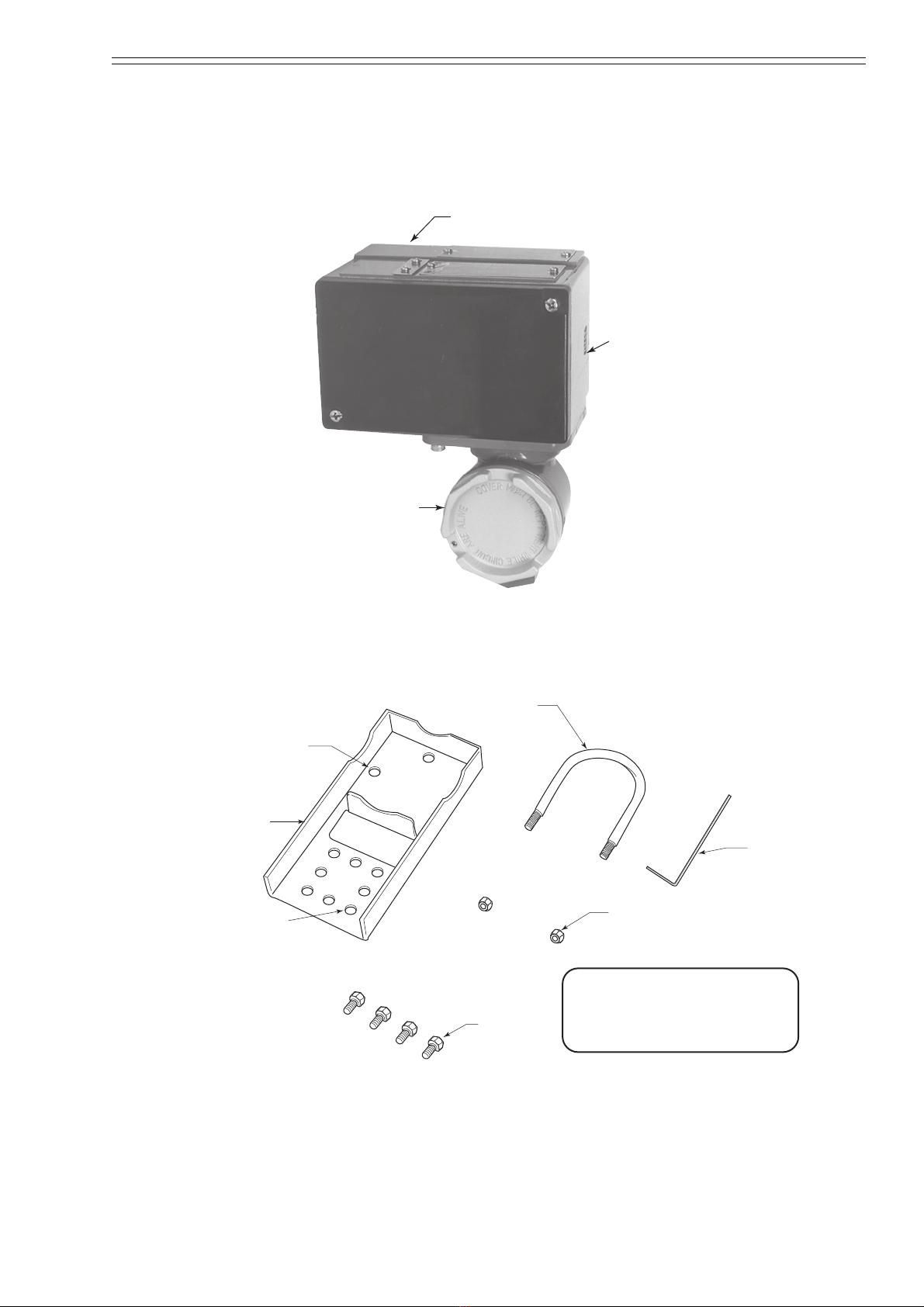

KUX113 - Field-Type I/P Converter 2-1

Azbil Corporation

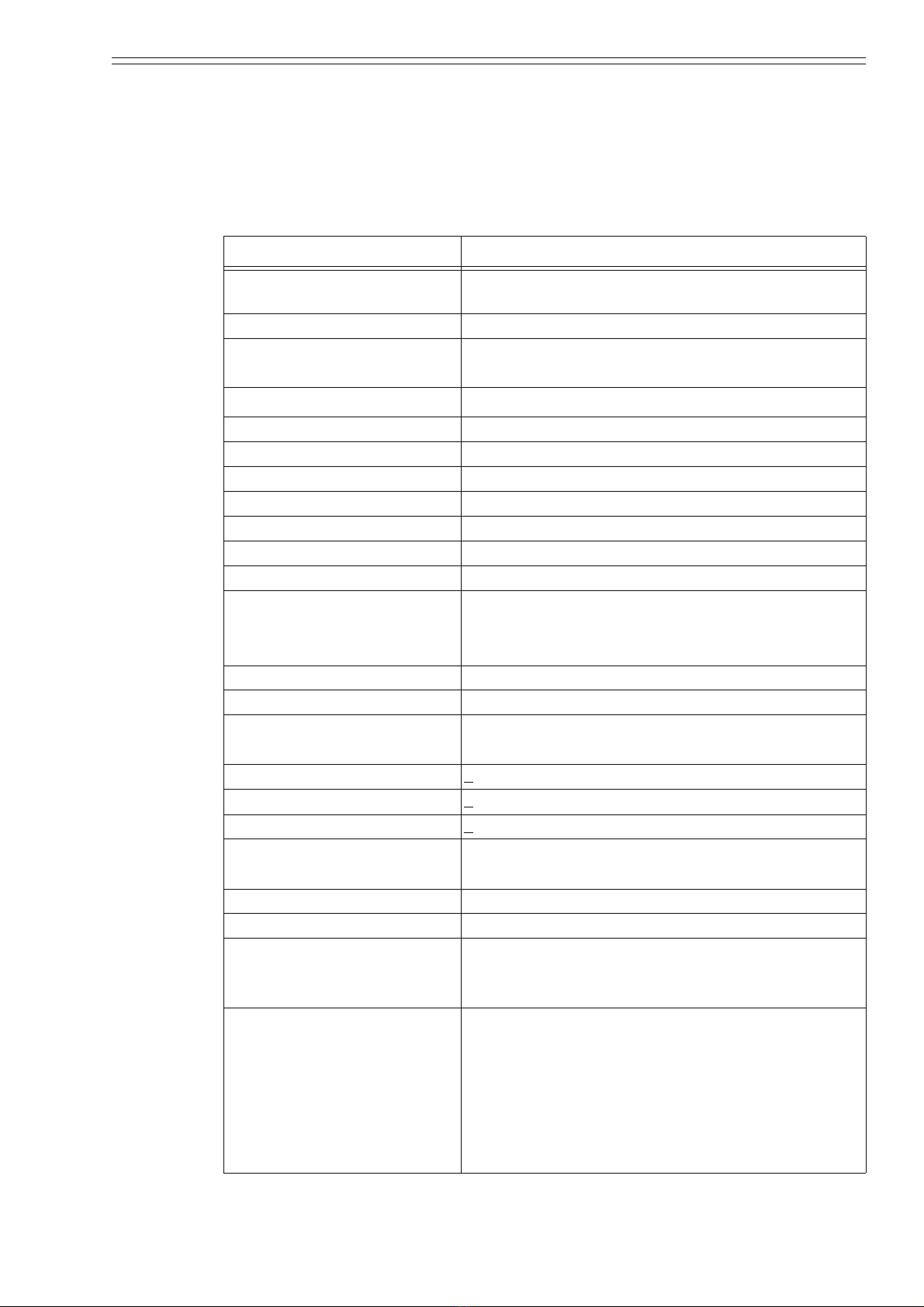

Chapter 2 : Specifications

2-1 : Performance Specifications

Table 2-1 Performance specifications

Item Specifications

Input signal 4 to 20mA DC (Maximum allowable current approx.

30mA.)

Input resistance 250 ohms maximum

Output signal 20 to 100 kPa, 3 to 15 psi, 0.2 to 1.0 bar, 0.2 to 1.0 kgf/cm2

(Maximum allowable pressure 200kPa)

Air supply pressure 140 kPa {1.4 kgf/cm2} ±10%

Air consumption 4 "/min(N) (With output 50% balanced)

Maximum air supply capacity 110 "/min(N)

Maximum air exhaust capacity 110 "/min(N)

Minimum load capacity I.D. 4 mm copper tube × 3 m + 20 cc

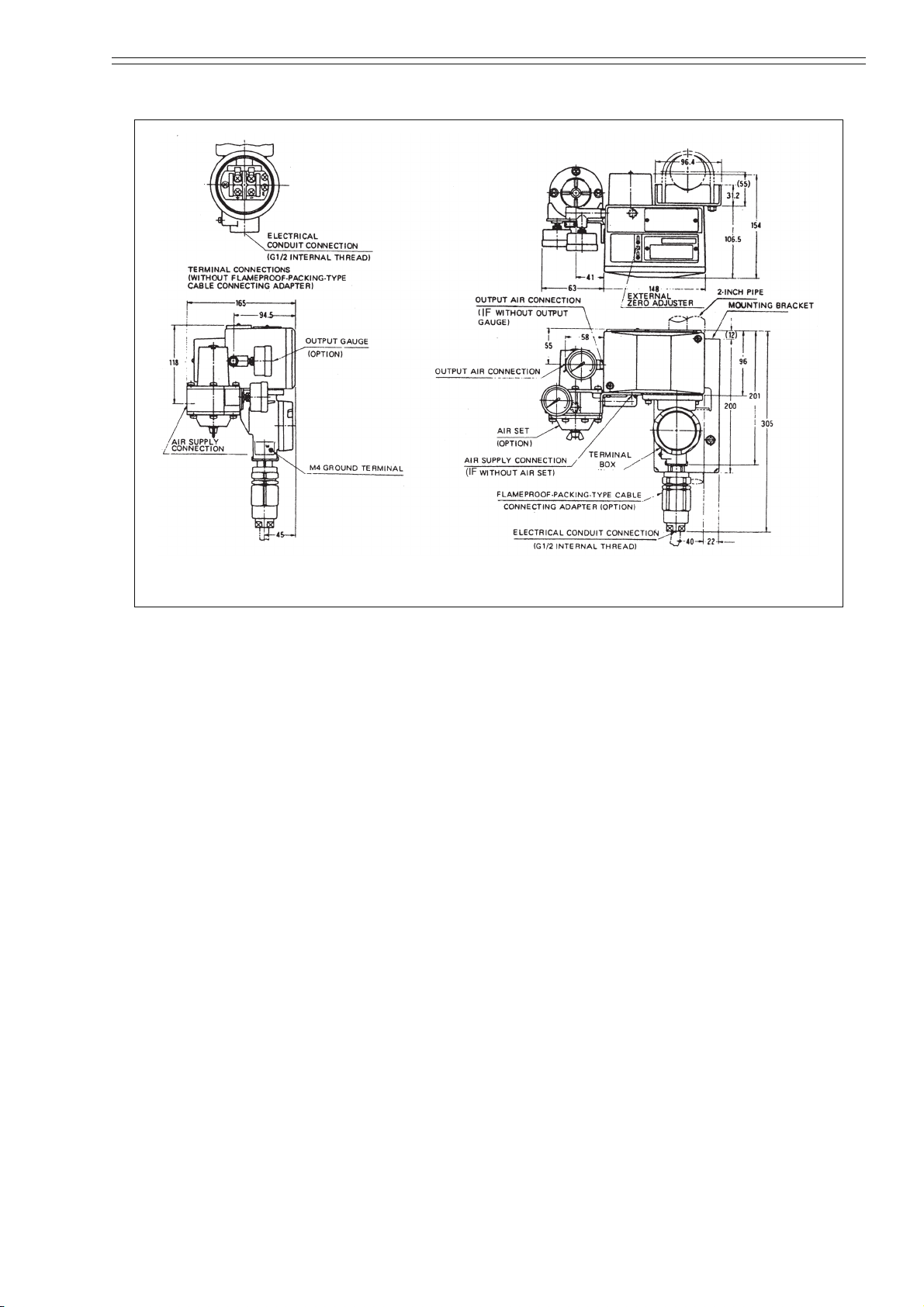

AIr piping connections Rc1/4, 1/4NPT internal thread

Electrical conduit connection G1/2 internal thread

Material of major components Aluminum alloy

Operating temperature range Waterproof, dust proof type: -30 to +80°C

Flame-proof type explosionproof type: -10 to +70°C

Intrinsic-safety explosionproof type: -10 to +60°C

Operating humidity range 10 to 90% RH

Accuracy ± 0.5% F.S.

Linearity

(with reference to zero)

± 0.2% F.S.

Hysteresis error <0.5% F.S.

Reproducibility <0.4% F.S.

Dead band <0.05% F.S.

Temperature effect Zero shift: ±3% F.S. /30°C (Maximum)

Span shift: ±2% F.S. /30°C (Maximum)

Mounting 2-inch pipe (Horizontal of vertical)

Net weight Approx. 3 kg

Finish and color Finish: Acrylic baked finish

Color: Case; Dark beige, Cover; Black PPS resin, Termi-

nal box cover; Light beige

Construction Waterproof, dust proof type: JIS C 0920 Watertight, JIS F

8001 Class 3 Splashproof

Flame-proof type explosionproof type: JIS C 0903, d2G4

(Operating temperature -10 to +70°C)

Intrinsic-safety explosionproof type: JIS C 0903, i3aG5

(Operating temperature: -10 to +60°C, signal power sup-

ply: 23 to 27.5V DC)