3

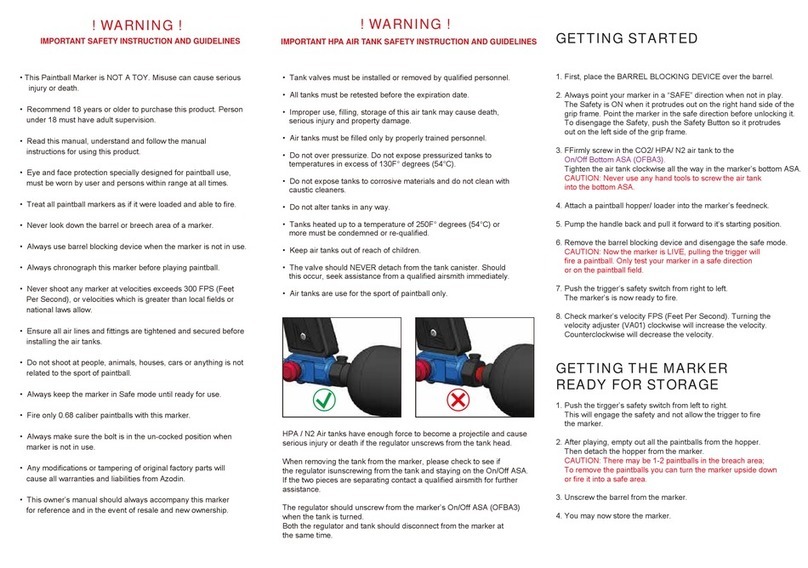

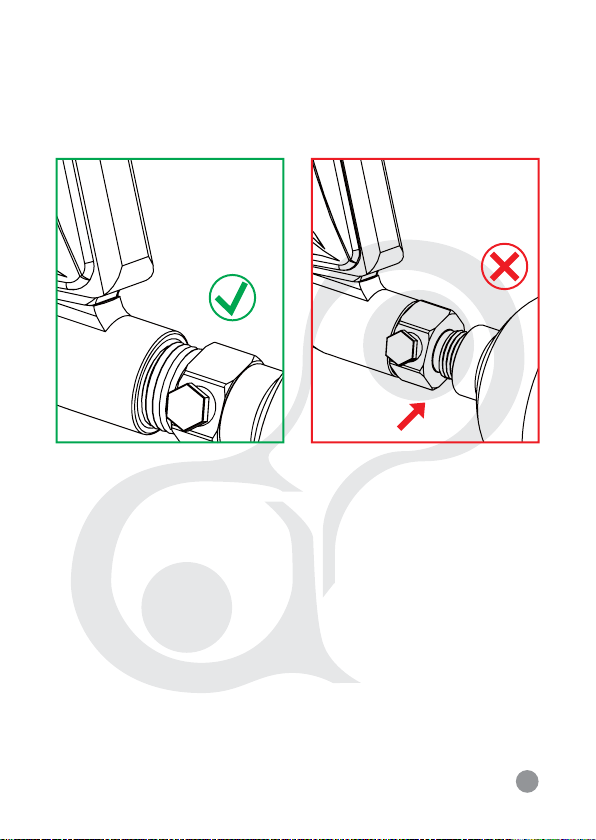

Tank valves must be installed or removed by qualified personnel.

All tanks must be retested before the expiration date.

Improper use, filling, storage of this air tank may cause death,

serious injury and property damage.

Air tanks must be filled only by properly trained personnel.

Do not over pressurize. Do not expose pressurized tanks to

temperatures in excess of 130F° degrees (54°C).

Do not expose tanks to corrosive materials and do not clean with

caustic cleaners.

Do not alter tanks in any way.

Tanks heated up to a temperature of 250F° degrees (54°C) or

more must be condemned or re-qualified.

Keep air tanks out of reach of children.

The valve should NEVER detach from the tank canister. Should

this occur, seek assistance from a qualified airsmith immediately.

Air tanks are use for the sport of paintball only.

•

•

•

•

•

•

•

•

•

•

•

! WARNING !

IMPORTANT CO2/ HPA AIR TANK SAFETY INSTRUCTION

AND GUIDELINES