! WARNING !

IMPORTANT SAFETY INSTRUCTION AND GUIDELINES

• This Paintball Marker is NOT A TOY. Misuse can cause serious

injury or death.

• Recommend 18 years or older to purchase this product. Person

under 18 must have adult supervision.

• Read this manual, understand and follow the manual

instructions for using this product.

• Eye and face protection specially designed for paintball use,

must be worn by user and persons within range at all times.

• Treat all paintball markers as if it were loaded and able to fire.

• Never look down the barrel or breech area of a marker.

• Always use barrel blocking device when the marker is not in use.

• Always chronograph this marker before playing paintball.

• Never shoot any marker at velocities exceeds 300 FPS (Feet

Per Second), or velocities which is greater than local fields or

national laws allow.

• Ensure all air lines and fittings are tightened and secured before

installing the air tanks.

• Do not shoot at people, animals, houses, cars or anything is not

related to the sport of paintball.

• Always keep the marker in Safe mode until ready for use.

• Fire only 0.68 caliber paintballs with this marker.

• Always make sure the bolt is in the un-cocked position when

marker is not in use.

• Any modifications or tampering of original factory parts will

cause all warranties and liabilities from Azodin.

• This owner’s manual should always accompany this marker

for reference and in the event of resale and new ownership.

! WARNING !

IMPORTANT HPA AIR TANK SAFETY INSTRUCTION AND GUIDELINES

HPA / N2 Air tanks have enough force to become a projectile and cause

serious injury or death if the regulator unscrews from the tank head.

When removing the tank from the marker, please check to see if

the regulator isunscrewing from the tank and staying on the On/Off ASA.

If the two pieces are separating contact a qualified airsmith for further

assistance.

The regulator should unscrew from the marker’s On/Off ASA (OFBA3)

when the tank is turned.

Both the regulator and tank should disconnect from the marker at

the same time.

GETTING STARTED

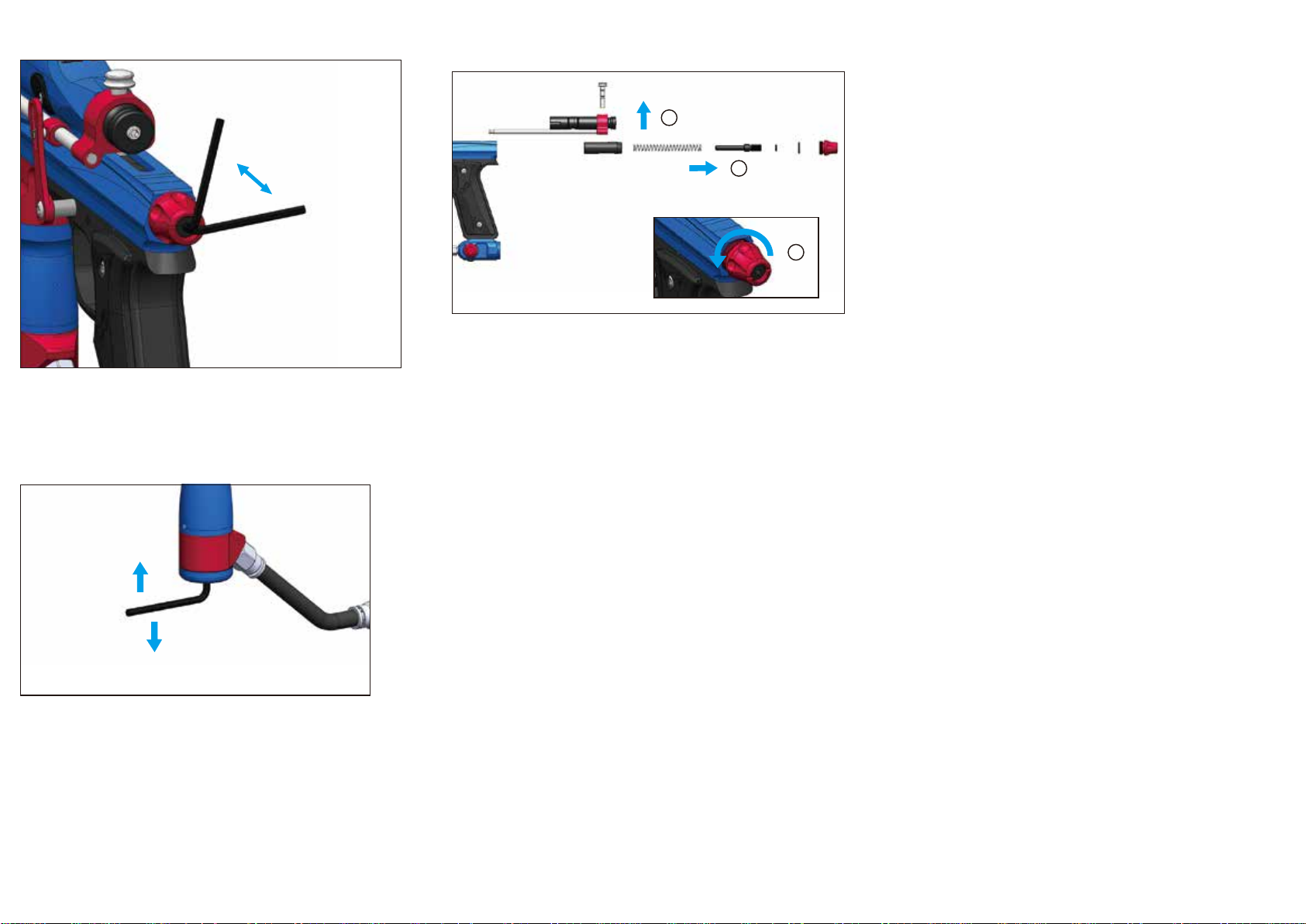

1. First, place the BARREL BLOCKING DEVICE over the barrel.

2. Always point your marker in a “SAFE” direction when not in play.

The Safety is ON when it protrudes out on the right hand side of the

grip frame. Point the marker in the safe direction before unlocking it.

To disengage the Safety, push the Safety Button so it protrudes

out on the left side of the grip frame.

3. FFirmly screw in the CO2/ HPA/ N2 air tank to the

On/Off Bottom ASA (OFBA3).

Tighten the air tank clockwise all the way in the marker’s bottom ASA.

CAUTION: Never use any hand tools to screw the air tank

into the bottom ASA.

4. Attach a paintball hopper/ loader into the marker’s feedneck.

5. Pump the handle back and pull it forward to it’s starting position.

6. Remove the barrel blocking device and disengage the safe mode.

CAUTION: Now the marker is LIVE, pulling the trigger will

fire a paintball. Only test your marker in a safe direction

or on the paintball field.

7. Push the trigger’s safety switch from right to left.

The marker’s is now ready to fire.

8. Check marker’s velocity FPS (Feet Per Second). Turning the

velocity adjuster (VA01) clockwise will increase the velocity.

Counterclockwise will decrease the velocity.

GETTING THE MARKER

READY FOR STORAGE

1. Push the tirgger’s safety switch from left to right.

This will engage the safety and not allow the trigger to fire

the marker.

2. After playing, empty out all the paintballs from the hopper.

Then detach the hopper from the marker.

CAUTION: There may be 1-2 paintballs in the breach area;

To remove the paintballs you can turn the marker upside down

or fire it into a safe area.

3. Unscrew the barrel from the marker.

4. You may now store the marker.

• Tank valves must be installed or removed by qualified personnel.

• All tanks must be retested before the expiration date.

• Improper use, filling, storage of this air tank may cause death,

serious injury and property damage.

• Air tanks must be filled only by properly trained personnel.

• Do not over pressurize. Do not expose pressurized tanks to

temperatures in excess of 130F° degrees (54°C).

• Do not expose tanks to corrosive materials and do not clean with

caustic cleaners.

• Do not alter tanks in any way.

• Tanks heated up to a temperature of 250F° degrees (54°C) or

more must be condemned or re-qualified.

• Keep air tanks out of reach of children.

• The valve should NEVER detach from the tank canister. Should

this occur, seek assistance from a qualified airsmith immediately.

• Air tanks are use for the sport of paintball only.