ProScrub PG. 11

PG. 2 ProScrub

INTRODUCTION

The 20” ProScrub Automatic Scrubber is

designed to scrub floors in an indoor

environment and is not recommended for any

other use. All operators must read and

understand this manual before operating the

ProScrub.

SCRUBBER SPECIFICATIONS

L 44" W 23" 35" Wt. 325#

Solution tank capacity 12 gal.

Recovery tank capacity 15 gal.

Cleaning path 20"

Pad/brush diameter 20"

Squeegee width 30"

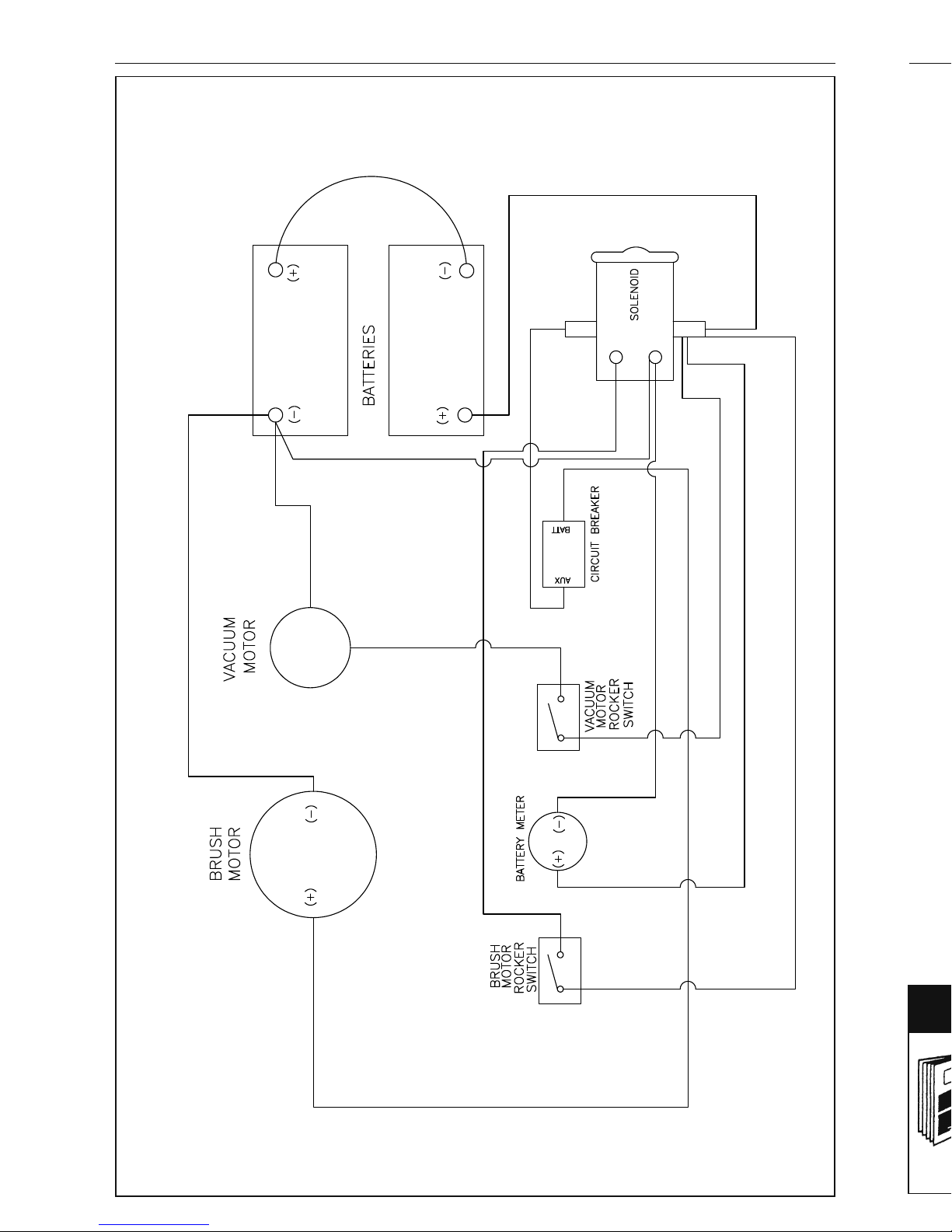

Brush Motor ¾ hp, 220 RPM

Vacuum Motor ½ hp, 2 stage, 24volt

Scrubbing pressure 65#

Batteries 2 – 130 amp/hour, 12volt

Deep cycle, lead/acid

RECOMMENDED SAFETY PROCEDURES:

1. The ProScrub should only be operated by

fully qualified maintenance personnel.

a. Do not operate, maintain, or service this

scrubber unless you are trained and

authorized.

b. Do not operate unless this manual is read

and understood.

c. Do not service or operate this scrubber if it

is not in proper operating condition.

2. Never attempt to ride on or otherwise attach

any type of rider platform to this scrubber.

3. Extreme caution should be used whenever a

ramp is used to load or unload this scrubber.

Never attempt to make turns on the ramp.

4. Do not park or leave the scrubber unattended

prior to loading or unloading.

5. Never operate this scrubber with the dash

panel removed. Always operate this scrubber

with the brush cover, battery cover, and all

side panels in the correct position.

6. Remove all loose objects from floor before

operating. Loose objects may become

dangerous projectiles when they come in

contact with revolving brushes/pads.

7. Keep scrubber moving along floor to avoid

burning or damage to floor surface.

8. Never use flammable or explosive cleaning

solutions such as gasoline, kerosene,

solvents, thinners, etc. in the solution tank in

an attempt to remove grease, oil, tar, etc.

from floors. Never operate scrubber where

flammable liquids or gases are present.

9. Always turn the master switch to the “OFF”

position whenever the scrubber is not in use.

Never leave scrubber parked on an uneven

floor. Always store scrubber safely.

10. When charging the scrubber, always

disconnect the AC plug before connecting or

disconnecting the DC plug.

11. BATTERIES ARE DANGEROUS

a. BATTERIES EMIT EXPLOSIVE GASES.

Always charge them in a well ventilated

area, keep hood open, wear eye protection

and face shield. Never smoke or use flame

or sparks around the batteries.

b. HAZARDOUS VOLTAGE! Severe shock or

electrocution can result. Always unplug

power-cord or disconnect batteries before

servicing machine.

c. BATTERY ACID CAN CAUSE BURNS.

Wear protective gloves when working with

them. Do not store them outside or let

water, chemicals, or any liquid come in

contact with them or the electrical system

of the scrubber. Damage will occur.

CHARGING BATTERIES

1. Charger Specifications

a. Output voltage – 24 volts

b. Output current – 10 to 20 amps

c. Automatic shutoff circuit

2. For deep cycle battery charging, life

expectancy of a battery is based on the

number of charges it receives. To get the

most life from your battery, recharge when

the meter drops into the red zone.

a. Do not continue to run the scrubber after

meter has gone into the red zone.

b. Do not let batteries sit uncharged for long

periods of time.

TROUBLESHOOTING

PROBLEM SYMPTOM SOLUTION

No power, nothing Batteries need charging Charge the batteries

runs Batteries faulty Replace batteries

Loose battery cable Tighten cable connection

Batteries not connected

Properly

Brush motor does Faulty brush switch Contact service center

not run Machine circuit breaker has tripped. Allow motor to cool down, breaker

will automatically reset.

Faulty wiring Contact service center

Faulty brush motor Contact service center

Carbon brushes worn Replace if worn to 3/8 or less

Faulty solenoid Contact service center

Vacuum motor does Faulty vacuum switch Contact service center

not run Faulty wiring Contact service center

Faulty vacuum motor Contact service center

Carbon brushes worn Replace if worn to 3/8 or less

Short run time Batteries not fully charged Charge batteries

Bad cell in one or more batteries Replace battery

Batteries need maintenance See “Battery Maintenance”

Faulty charger Replace charger

Little or no solution Solution flow lever is not activated Push flow lever forward

flow Solution line is clogged Remove hose and blow compressed

air through it. Then flush with

clean water

Solution valve is clogged Remove valve and clean. Do not

scratch or damage inside

Solution flow adjustment knob Turn knob down to increase flow

needs adjusting

Poor squeegee pickup Recovery tank is full Empty tank

Ball float shutoff screen is clogged Remove screen and clean

Squeegee is clogged with debris Clean squeegee

Squeegee blades are worn Replace blades

Squeegee thumbscrews are loose Tighten screws

Vacuum hose connections are loose Push hose firmly onto connections

Vacuum hose is worn or has a hole Replace

Vacuum is clogged with debris Remove debris

Tank gasket is defective Replace gasket

Recovery tank water inlet is plugged Empty recovery tank and tilt

sideways to remove clogged debris

Recovery tank lid is loose Tighten lid

Vacuum motor is loose Tighten down vacuum motor

Do not over-tighten!

Battery charge is low Do not run scrubber if meter is

in the red zone

WARNING!

!