Tachometer Firing patterns:

P1- 1 Spark: 1RPM-Most air cooled engines.

P2- 2 Sparks: 1RPM-Specialty engines, dual

point ignition

P3- 1 Spark: 2RPMs-Engines with ignitions driven

from camshafts or distributors

• Job Timer-to erase, be in the JOB TIME function

and hold mode button down for 3 seconds.

• Service Alarm-to program a service interval be in the

SVC SET function and hold the mode button down.

Release button on the desired hour. When the SVC

TIME reaches the service interval you programmed,

the display will flash indicating service is due. This

flashing will continue until the SVC TIME is cleared.

Perform necessary service then advance to the SVC

TIME function and hold the mode button down for 3

seconds, the SVC TIME will clear and the flashing

will stop. SVC TIME will now start building back up

to the service interval you programmed in SVC SET.

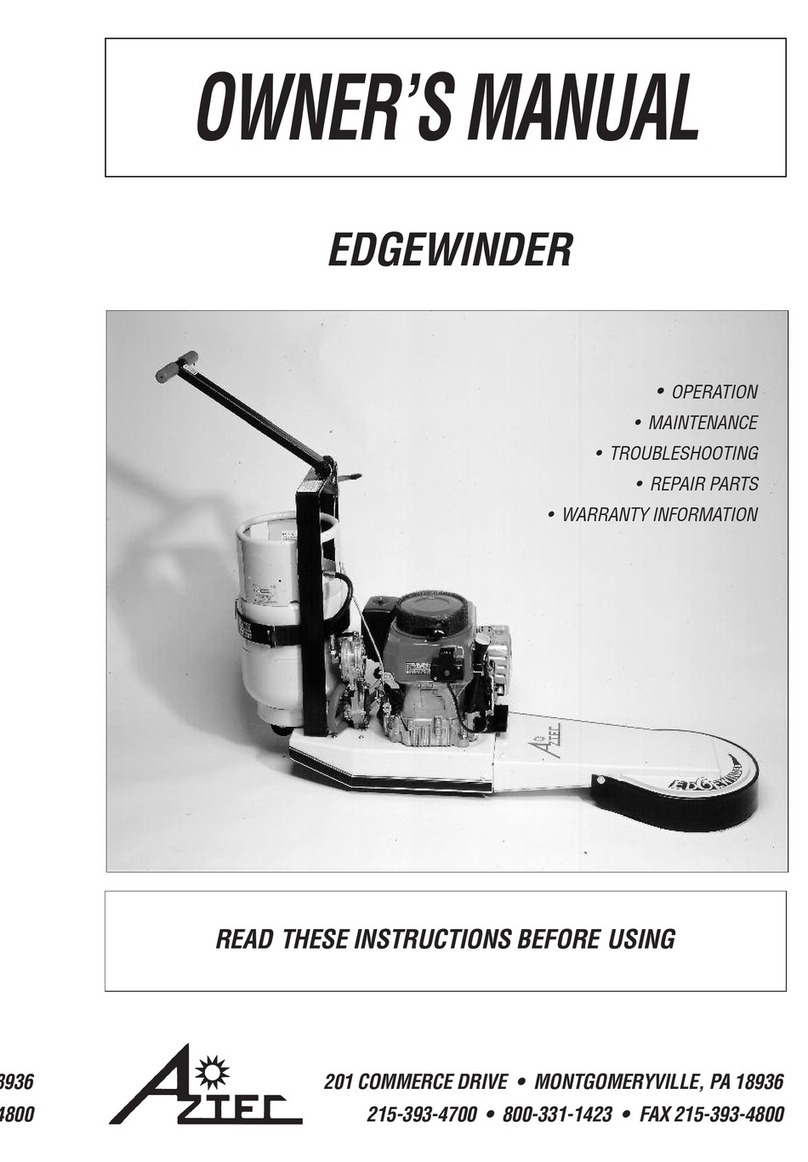

SIDEWINDER STRIPPING MACHINE

There are several factors involved in properly addressing

the surface of a floor to be stripped so that it can be

accomplished at the greatest speed with the least labor.

The design of the Sidewinder may seem complicated, yet

we assure you that its design is the reason it is so

effective. Therefore, you may want to be patient while

learning the “ins and outs” of the general maintenance

of this equipment.

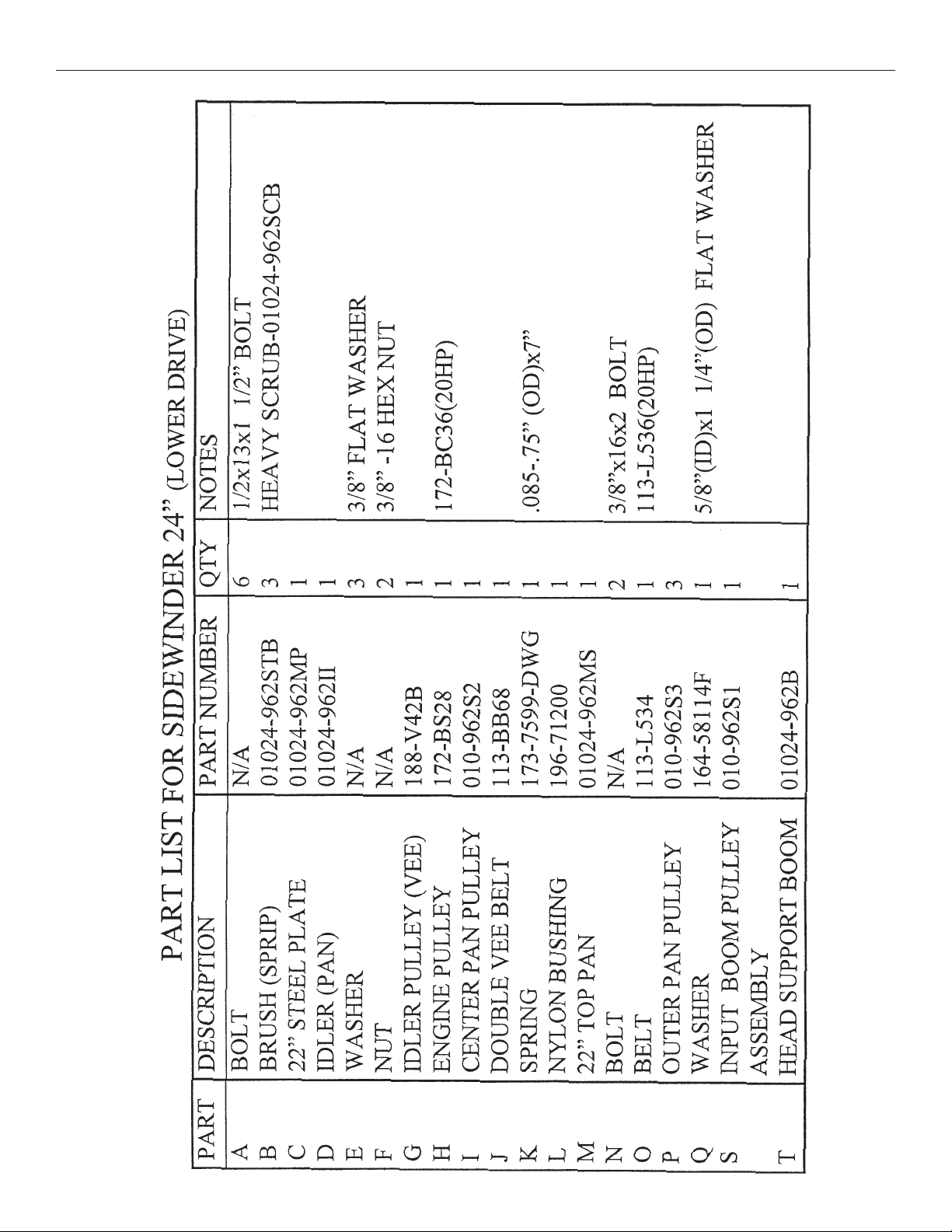

Do not remove the six (6) 3/4" head bolts from the bottom

of the machine unless you have talked to Aztec technical

support. Note: If the engine runs, but the brushes do not

engage, this is usually related to either the clutch cable or

the main drive belt. Without disassembling this machine,

you can check and fix the following:

1. Is the cable connected to the “Clutch” lever on the

handle and to the springs (2) down below? Place

machine in “tilt back” position. Go under the machine

and reach your hand up between the lower drive

assembly and the body of the machine. You will

notice the cable sticking through the wall of the

battery box, and it should be connected to one (1)

return spring (j) and one 1) clutching spring (K). If

you can reach your arm up further, you will feel the

pulley of the main drive shaft for the input boom

pulley (S) (page 19 “Upper Drive Assembly” drawing.)

By just a touch, you should be able to manipulate a

fallen belt back in place. You will do well to master the

above procedure. Such a simple problem in the hands

of inexperienced people can cost a crew much of a

night’s work.

2. The next most common problem is letting the battery

run down. What usually happens is that it takes the

crew a few jobs to get used to the whole system, so

the Sidewinder is stopped and started quite often. We

recommend that under these conditions the operator

should start the machine by hand with the recoil

starter. (Don’t forget to turn the key to the “Off”

position when finished using.)

3. To change a belt—remove three (3) bolts on right

hand side of upper deck (3/4" wrench) (page 19(0)).

Then slowly raise the front of the machine off the

floor. Notice how the belt is set in its place as this will

help you in returning the new belt to its proper place.

Remove the idler pulley only (9/16" wrench). Notice

that one side of the idler pulley hub sticks out farther

than the other side. This is very important! The side

that sticks out the most should be put on first, facing

the idler plate. If it is put on the other way, the idler

may not turn and will not line up with the drive

(engine) and lower drive assembly pulleys. This will

accelerate belt wear and increase the chance of the

belt running off one of the pulleys. Check for wear on

the springs and their catches and on the idler

mentioned rather than take a chance on stranding an

entire crew at a lock-in job with a broken machine as

they get their system coordinated. The Sidewinder

should be kept in “new” condition both physically and

mechanically to ensure a minimum down-time factor.

RETURN GOODS POLICY

As an Aztec customer, you are aware that the equipment

we design and build is both innovative and unique. Since

this is true, in order to trouble-shoot our equipment, we

rely heavily on returned defective or failed parts so that

we can examine first-hand the causes of failure. While

this may at first seem to be an inconvenience, ultimately

you benefit from safer and better designed machine

components. Please give us the opportunity to serve you

better by following these RGA (Returned Goods

Authorization) rules.

1. We maintain the serial number, date of shipment or

sale, and customer name on each piece of equipment

sold. If you were the purchaser, please reference that

SIDEWINDER PG. 4