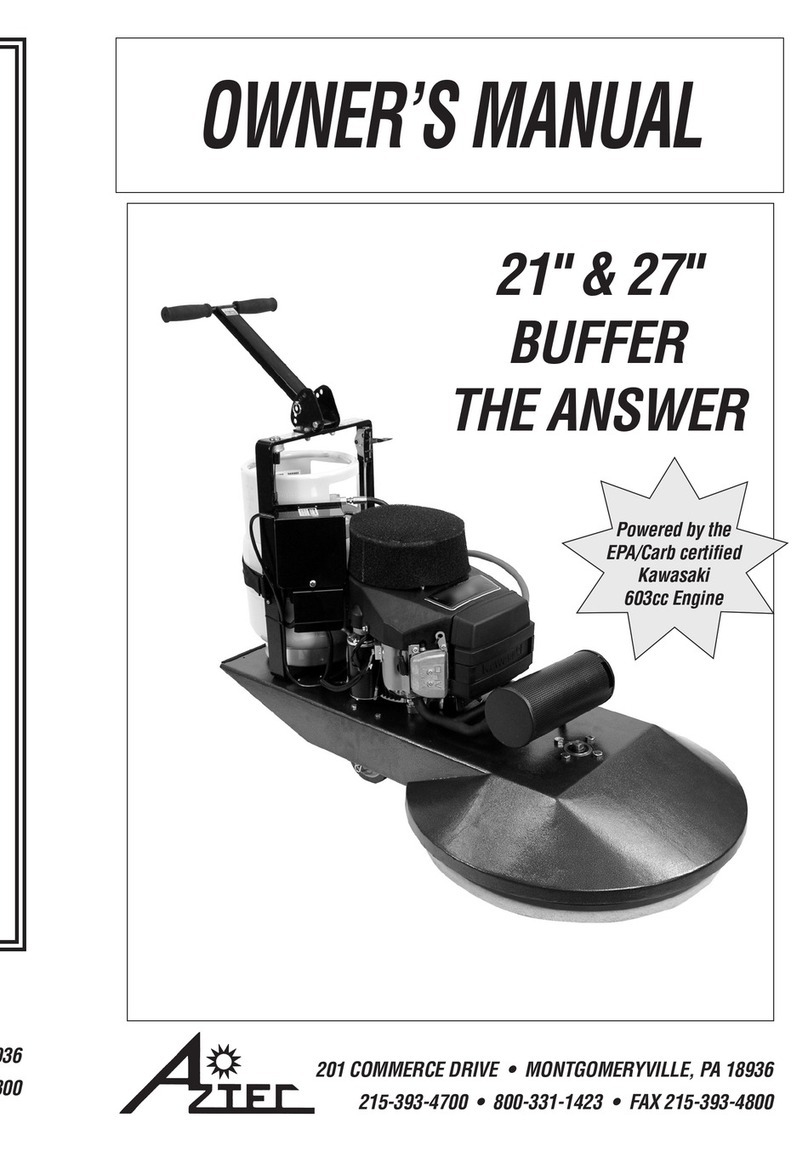

LOWRIDER OWNER’S MANUAL PAGE 5

01-2018

GENERAL OPERATION SAFETY INFORMATION

Liquefied petroleum gas (LPG or propane) is stored under pressure and must be handled in the

proper mannerto be safe. Observe the following safety messages toget the best performance, lowest

emissions, and longest life out of your equipment.

The EPA has rated the PurePower by Aztec 603cc engine cleanest in the

industry for CO (carbon monoxide) emissions. (Source: https://www.epa.gov/compliance-and-fuel-

economy-data/engine-certification-data#small-nrsi).

Because CO is always a byproduct of internal combustion engines, it is

important to know the symptoms of CO exposure, which may include

drowsiness, dizziness, nausea, vomiting, confusion, collapse, loss of

consciousness and muscle weakness. If such symptoms occur during

operation with this machine, immediately shut off the machine and go outside for fresh air. Have a

qualified service technician testthe machinefor CO emissions before using again.Call for emergency

medical attention and DO NOT operate this machine or other propane powered equipment until

cleared by a physician. For more info on CO exposure effects, see

http://www.mayoclinic.org/diseases-conditions/carbon-monoxide/basics/symptoms/con-20025444.

No smoking, no sparks, no flames near machine, engine or LPG tank. Do

not operate this machine in an environment with a potential ignition

source.

If you smell gas: immediately stop the unit, check for leaks, open

windows, don’t touch electrical switches, extinguish anyopen flames,and

contact a repair professional.

Never change or alter the propane control equipment. It is precisely tuned

to power machinery with minimal levels of carbon monoxide. Altering the

control equipment could cause dangerous levels of engine emissions.

Effective January 1, 2016, all Aztec Products, Inc. machinery is shipped

with propane tank equipped with Overfill Protection Device (OPD). If you

have an older LPG cylinder that is overfilled, always vent outdoors, away

from closed areas where gas may accumulate, and away from any fire,

flame, or spark-producing device. Use a screwdriver to vent excess propane, which escapes as a

white mist. Propane will vent clear when correct tank level has been achieved.

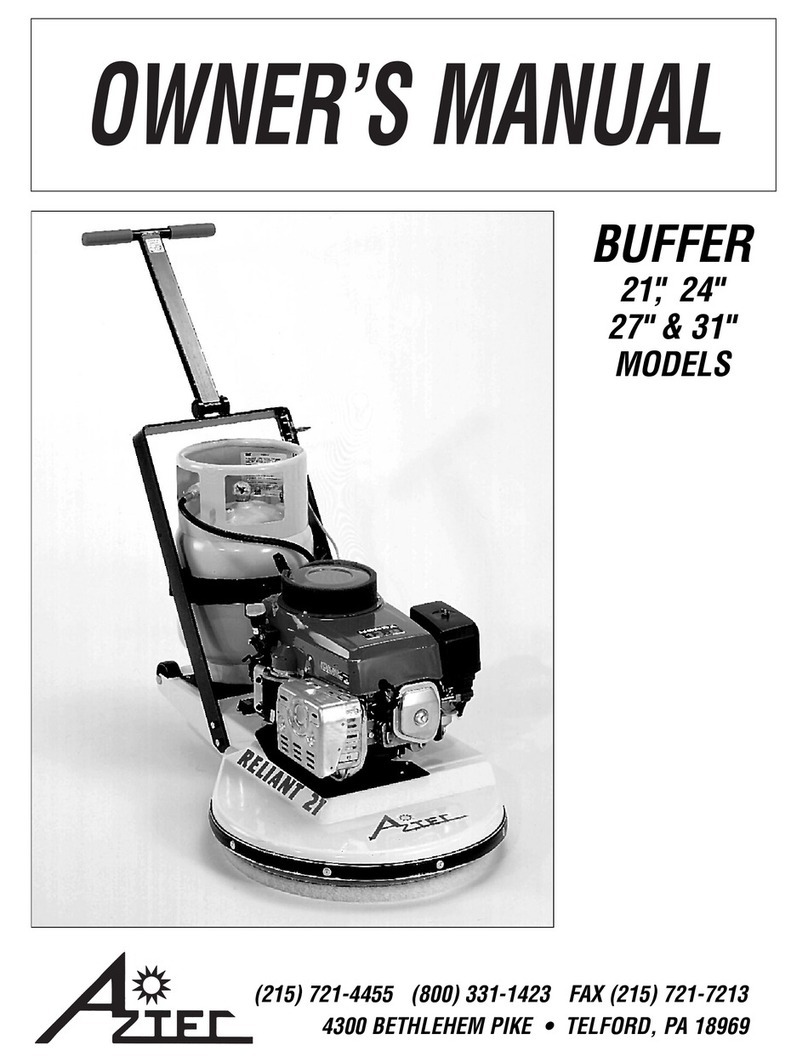

All Aztec propane powered machines are

designed specifically for use with a 20 lb

(5 gallon) vertical vapor withdrawal

propane cylinder. Use of a different

configuration cylinder or liquid withdrawal

cylinder is dangerous and could cause fire or explosion, and will void

the warranty.