TC-Standard (+)

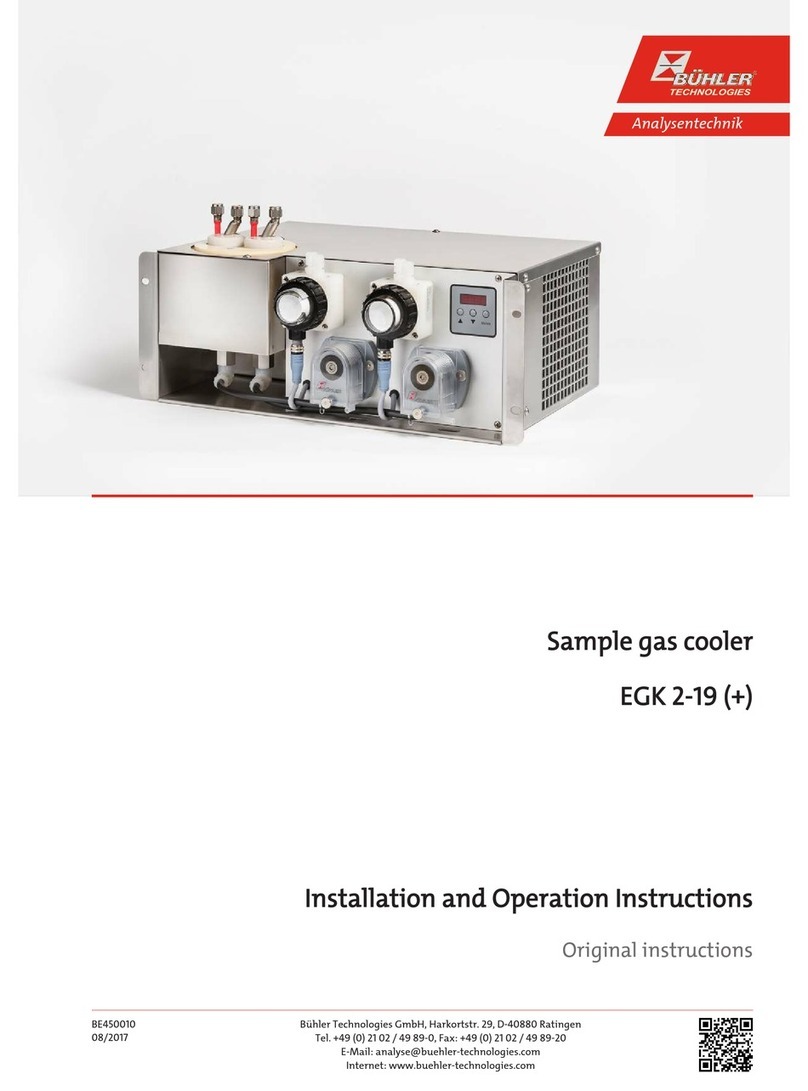

Contents

1 Introduction..................................................................................................................................................................................................................... 3

1.1 Intended use .........................................................................................................................................................................................................3

1.2 Overview ................................................................................................................................................................................................................ 3

1.3 Type plate .............................................................................................................................................................................................................. 3

1.4 Scope of delivery.................................................................................................................................................................................................. 3

1.5 Ordering instructions ........................................................................................................................................................................................4

1.5.1 Gas cooler models with one heat exchanger .............................................................................................................................. 4

1.5.2 Gas cooler models with two heat exchangers .............................................................................................................................5

1.5.3 Gas cooler model with two heat exchangers in series ............................................................................................................. 6

2 Safety instructions......................................................................................................................................................................................................... 7

2.1 Important advice................................................................................................................................................................................................. 7

2.2 General hazard warnings .................................................................................................................................................................................8

3 Transport and storage ..................................................................................................................................................................................................9

4 Installation and connection ...................................................................................................................................................................................... 10

4.1 Installation site requirements....................................................................................................................................................................... 10

4.2 Installation ..........................................................................................................................................................................................................10

4.2.1 Connecting the filter gas connections (optional) .....................................................................................................................10

4.2.2 Flow adapter connection (optional)..............................................................................................................................................10

4.2.3 Connecting the moisture detector (option).................................................................................................................................11

4.2.4 Peristaltic pump connector (optional) ..........................................................................................................................................11

4.2.5 Connecting the heat exchanger......................................................................................................................................................11

4.3 Electrical connections ...................................................................................................................................................................................... 12

4.4 Signal outputs.....................................................................................................................................................................................................13

5 Operation and control .................................................................................................................................................................................................15

5.1 Description of functions...................................................................................................................................................................................15

5.2 Delta T control option .......................................................................................................................................................................................15

5.3 Use of menu functions .................................................................................................................................................................................... 16

5.3.1 Lock Menu.............................................................................................................................................................................................16

5.3.2 Menu navigation overview.............................................................................................................................................................. 17

5.4 Description of menu functions ..................................................................................................................................................................... 19

5.4.1 Display menu.......................................................................................................................................................................................19

5.4.2 Main menu...........................................................................................................................................................................................19

5.4.3 Submenu 1 ...........................................................................................................................................................................................20

5.4.4 Submenu 1 (global settings) ............................................................................................................................................................ 21

5.4.5 Set favourite menu ........................................................................................................................................................................... 24

6 Maintenance.................................................................................................................................................................................................................. 25

7 Service and repair.........................................................................................................................................................................................................26

7.1 Troubleshooting ................................................................................................................................................................................................26

7.1.1 Error messages on the display........................................................................................................................................................27

7.2 Safety instructions............................................................................................................................................................................................28

7.3 Cleaning and removal of the heat exchanger...........................................................................................................................................29

7.4 Replacing the hoses of the peristaltic pump (option) ............................................................................................................................29

7.5 Replacing the filter element (option)..........................................................................................................................................................29

7.6 Drying of the moisture detector (option)...................................................................................................................................................30

7.7 Calibration of the moisture detector (option)..........................................................................................................................................30

7.8 Replacing the base unit...................................................................................................................................................................................30

7.9 Spare parts and accessories ............................................................................................................................................................................31

7.9.1 Consumables and accessories ........................................................................................................................................................ 31

8 Disposal........................................................................................................................................................................................................................... 32

9 Appendices..................................................................................................................................................................................................................... 33

9.1 Gas cooler technical data................................................................................................................................................................................ 33

9.2 Technical Data - Options .................................................................................................................................................................................34

9.3 Flow diagrams.................................................................................................................................................................................................... 35

iBühler Technologies GmbHBE440026 ◦ 12/2020