B-I Inductrial BI-SM2004 User manual

SMOKE DENSITY

INDICATOR

MODEL : BI-SM2004

B-I INDUSTRIAL CO., LTD.

OFFICE : 3F, OSAN B/D, 237-3, HANGNAG-RO 1 GA,

YONGSAN-GU, SEOUL, KOREA

TEL : (82-2) 795-3077 (REP) FAX : (82-2) 795-3076

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

REVISION RECORD

Description Of Change Pages

Table of contents --------------------------------------------------------- 3~4

BI-SM2004 Information---------------------------------------------- 5~6

Introduction --------------------------------------------------------------------- 7

General Information ------------------------------------------------------ 7

Specifications ------------------------------------------------------------------- 8

Operation --------------------------------------------------------------------- 9~17

Installation ----------------------------------------------------------------- 18~22

Electrical connections --------------------------------------------- 23~24

Installation Drawing------------------------------------------------- 25~34

BI-SM2004.doc 2/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

TABLE OF CONTENTS

INDEX PAGES

CHAPTER 1

1-1 BI-SM Information

1-1-1 General View……….…………………..………………………………………................5

1-1-2 Technical Specification…………………..…..…….………………………….…….........6

1-2 Introduction…………………………………..……………………….…….…….….............7

1-3 General Information………………………...………………….……….….………...........7

1-4 Specifications

1-4-1 Control Unit.…...................……………………………………………................................8

1-4-2 Projector/Receiver Units………….………………..……......................................................8

CHAPTER 2

2-1 Operation And Setting

2-1-1 Preliminary Operation……………………..………………………….…….….…................9

2-1-2 Operation…………………………..……………………………....................................9~10

2-1-3 Setting Value…………………………..……………………………………………...........10

2-1-4 Setting…………………………….……………………………..........................................11

Alarm……………………………………………………………..……...….......................12

High Level …………………………..……………………………...................................12

High High Level…………………………....……………………………...........................13

Delay Time……………...……………..……………………………..................................13

Filter…………………...…………..…………………………............................................14

Zero & Span ………...…………………..………………………….............................14~15

4-20mA………………………..…..……………………………...................................15~16

2-1-5 Trouble Shooting………………….……………………………………………………..17

CHAPTER 3

3-1 Preliminary Instructions…………………….……..………………………........................18

3-2 Installation - Projector & Receiver Units

3-2-1General…………………………..…………………………….………...............................19

Typical Installation…………………..…………………………………….…....................19

3-2-2Location…………………………..…………………………..............................................19

3-2-3Temperature………………………..………………............................................................19

3-2-4 Accessibility………………………..…………………........................................................19

3-2-5 Scanning Distance………………………..……………………...........................................20

3-2-6Stratification………………………..……………………....................................................20

3-2-7 suunight……………………………………….....................................................................20

3-2-8 Mounting Optical Units………………..…………………..................................................21

3-2-9 Positive Pressure Application………………………….……………………......................22

3-2-10 sealing air…………………………..………………………..............................................22

BI-SM2004.doc 3/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

CHAPTER 4

4-1 Electrical Connections

4-1-1Optical Units…………………………..………….………..................................................23

wiring diagram…………..………………..…………………………..................................23

4-1-2Mains Connection…………………………..………………….…………..........................24

4-1-3Alarm Relays………………..…………..………………………….....................................24

4-1-4Analogue Output………...………………..…………………....…………..........................24

CHAPTER 5

5-1 Installation drawing

5-1-1Cover For Installation Drawing…….………..………….…….…………...........................25

5-1-2Contorl Panel Dimension

Disclose, Type (A).….…………..………………..……………………...........................26

Inside Installation, Type (B)……………………..………………………...........................27

5-1-3Projector And Receiver assembly………………….…..………………..............................28

5-1-4Stack and intermediate adaptor..………………….……………………………..................29

5-1-5Smoke Stack Installation……..……………………..…..…………………….....................30

5-1-6Sensor assembly……………………………….…..……………………………….............31

5-1-7Wiring Diagram

Power Source…….………...……………….….……………………………......................32

Connection Dia. For Control Panel………….……………………...………......................33

List of spare part…………….……………………………………………………………..34

BI-SM2004.doc 4/34

1-1 BI-SM2004 Information

1-1-1 General View

SMOKE DENSITY INDICATOR

Model No. BI-SM2004

ControlPanelforDiscloseType

Projector Receiver Intermediate Adaptor Stack Adaptor

The Unit has been designed to enable Industry to comply with the Clean Air Act and worldwide ships to comply with Canadian

Shipping Air Pollution CRC, Vol. XV, C. 1404 and Alaska – 18 AAC 50.070, Marine Vessel Visible Emission Standards.

The product consists of Control Panel, Light Beam Projector, Photocell Receiver, Stack Adapter and the Intermediate Adaptor

that clean air is supplied for Glass Cleaning

There are two type of Control Panel, one is disclose type for the application of exposure area, the other type is for inside

installation of Boiler Panel and any other Control Panel.

The Projector and Receiver connected to intermediate Adaptor are mounted on opposite side of the chimney or flue preferably

where a negative pressure exists thus reducing the necessity of frequent cleaning of the optical system.

The presence of smoke in the flue or chimney will cause changed electrical signal between the Projector and Photecell Receiver.

The changed signal is analyzed by Control Panel and give the information on the Digital Display. The Preset Alarm, Low and

High alarm, can be adjusted easily to meet the regulation required per country.

Key Features

DigitalDisplay 0.1%Resolution AdjustableTimeDelay

Easy Installatjion Easy Cleaning and Removing Low maintenance cost

T

E

L

:

(

8

2

-

2

)

7

9

5

-

3

0

7

7

h

t

t

:

/

/

w

w

w

.

b

-

i

.

c

o

.

k

r

1-1-2 Technical Specification

Technical Specification Model: BI-SM2004

Measuring Range 0.0% - 100% Smoke Density for Black & White Smoke

Power Supply AC110 & AC 220 to 240 V, 50/60Hz

Dimension of Control Panel 290mm x 240mm x 120mm for Disclose Type

Weight of Control Panel 5.5kgs

Signal Output 4-20mA able to connect to ECR directly

Adjustable Time Delay Adjustable between 0 - 60 Seconds, Factory Set 15 Seconds

Protection Designed to IP65

Accuracy -/+2%fullscaledetection(FSD)

Resolution 0.1%SmokeDensity.

Alarm Setting AdjustableLow&HighAlarm

FactoryLowSetting:40%SmokeDensity.

Zero Stability Manual zero by one push button

Relative Humidity 0 to 95% non condensing

TemperatureLimts -10 ~ 60 ℃Ambient

Optional Recorder, Digital/Analog Indicator

Date Logger System to follow the measured smoke density

Alarm Repeater

Easy Cleaning Procedure

1. Remove Projector / Receiver from intermediate Adaptor

2. Fit Blind Flange to Intermediate adaptor (Because the leakage of Exhaust Gas)

3. Cleaned the Glass and Reassembled.

Typical Installation

Head Office : 3F, OSAN B/D, 237-3, Hangang-Ro 1 Ga, Yongsan-Gu, SEOUL, KOREA

TEL : (82) 2 795-3077 (REP) FAX : (82) 2 795-3076 Home page add. : http://www.b-i.co.kr

As an ISO 9001 approved company, B-I Industrial Co., Ltd’s quality assurance programmes

demand the continuous assessment and improvement of all B-I products.

PROJECTOR RECEIVER

BOILER

SMOKE

STACK

CONTROL PANEL

BUZZER

SIGNAL OUT

4~20mA

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

1-2 INTRODUCTION

The environments is high on the political agenda at the moment and Pollution is still very

much a live issue. Accordingly, we have developed this system to meet requirements for the

Air Pollution Control Act, etc enable to measure and acknowledge the quantity of gas emitted

in order for the prompt response against the status of smoke.

The regulations relevant Air Pollution from ships are as follows;

Canada Shipping Act : Air Pollution Regulations – CRC, Vol. XV, c.1404

SIP – ALASKA – 18AAC 50.700

ETC.

The main purpose of our smoke density indicator is to prevent Air Pollution by installation on

smoke stack on vessels and Chimney on industries.

1-3 GENERAL INFORMATION

Our System consists of Control Panel, Light Beam Projector, Photocell Receiver, Stack

Adaptor and Intermediate Adaptor.

When Smoke is present in the Flue or Chimney, it will obsure the light beam and casue a

change in the electrical signal on the receiver cell.

This change is recognized by the control which displays the information on the panel meter

and the control panel digitalize the electric signal and display the value of 0~100 on the

monitor.

Project is used with High-Brightness LED. The life time of this LED is semipermanent and

light intensity is maintained regularly.

Receiver is equipped with CDS Cell which has characteristics of long life time and liner to

detect light in comparison with other sensors.

The materials of Projector and Receiver is light-weight and anti-corrosion Aluminum so it is

easy for users to replace spares and maintenace.

There are two Relays for high and high high on Main Panel. Accordingly, the efficency of

compatibility with othe instruments is improved.

Operator can see the status of Smoke by observation of the value on the monitor. Our system

is easily operated by beginner.

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

1-4 SPECIFICATIONS

1-4-1 Control Unit

Power Requirement : 240 or 110Vac, 60 Hz

Obscuration Range : 0% to 100%

Analogue Output : 4 to 20 mA for 0% to 100% obscuration

Alarms : Two SPCO, each rated at 5A, 250V.A.C.

Keyboard : Touch membrane

Display : 5 FND DIGITAL

Calibration : Automatic zero and span

Temperature Limits : -10oC to 60oC Ambient

Panel Cut-Out A Type 240mm x 290mm x 120mm

Dimensions(H x W x D) : B Type 97mm x 97mm x 140mm

Weight(A type/Btype): 4.9Kg/0.3Kg

1-4-2 Projector/Receiver Units

Projector - Lamp : 5 V.D.C. HIGH BEAM LED

Receiver

Cell : CDS cell

Scanning Distance : 300 to 5000 mm (standard unit)

Flanges : 115 mm x 49 mm x 12Ø X 4 HOLE

Mounting Tube : Optional Extra

Inject air connection : 10mm BSP Standard Connection 0.5 BAR

Max. Temperature : 70oC

Weight : Projector 0.4Kg, Receiver 0.4Kg

Miniclean Adapter 2.3Kg, Stack Adapter 2.1Kg

BI-SM2004.doc 8/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

CHAPTER 2

2-1 OPERATION AND SETTING

2-1-1 Preliminary Operation

a. Check the connection of terminal block, ect inside control panel

b. Check the power connection AC110/220V and PCB socket status according to the

POWER AC110/220V

c. If all connection is setup properly, please power on and check the monitor

d. After booting complection, Indication will be displayed accroding to stack status

e. If necessary, carry out Calibration. Refer to 13 page, setup Zero & Span(chapter 2 on)

our manual

2-1-2 Operation

Power On

Switch the power on at the ac inlet. The FMD on the front panel illuminates, it remains

illuminated while the ac power is connected to the unit and switched on. The Smoke Density

Indicator enters its warm-up, this takes approximately 60 seconds to complete. During

warm-up the following screens appear on the display.

START WARM-UP

DISPLAY THE SOFTWARE VERSION

CHECKING SMOKE SENSOR

COMPLETED WARM-UP AND NORMAL OPERATING

DISPLAY

BI-SM2004.doc 9/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

The instrument is operated via 4 button belows.

The explanation how to operate button and it’s functions is belows.

- Escape from manu selection

- Alarm reset, Zero setting (press for 5 seconds)

- Reading of AD value

- Selection main manu

- Adjust setting value

- Light Beam on/off

– Into main manu(Press for 5 seconds)

- Into setup & Input setting value

☞. AD VALUE

The value of signal comes from Projector to Receiver. The value is to be changed depending

on distance between Projector and Receiver and the status of Somke Stack.

After initial installation, you can detect the status of Receiver / Projector and damage of

Glass, if you compare the reading of AD Value when Zero & Span is 100% to the value after

long hours of operation.

AD – The signal of analog is digitalized

☞. When Setting 4-20mA

if you push button simultaneously, the value is decreased.

2-1-2 Setting Value

You can configure below value by means of using above 4 buttons.

Factory default setting

ALARM : 20%

HIGH LEVEL : 20%

HIGH HIGH LEVEL : 40%

BI-SM2004.doc 10/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

DELAY : 15 SECONDS, Set by 0~60 sec. range and 5sec.

(after detection of smoke, Delay when Ararm, High & High High signal output)

FILTER : 1, Select proper value among 0~9.(Sensitivity of smoke sensor)

ZERO : Setting is configured when delivered but reconfiguration is recommended after

installation.

SPAN : 100% SPAN, Setting is configured when delivered but reconfiguration is

recommended after installation.

4-20mA : Signal output to ECR. (It is not necessary to reconfigure after installation)

2-1-4 Setting

If you press for 5 seconds, Setup Menu is displayed. By means of button, you can

move to another menu. The sequence of Setup menu display is as follows:

You can start to set up, if you press button

BI-SM2004.doc 11/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

☞. Alarm Setting

Press , Displayed ALARM value

By Pressing button, Adjust ALARM value(0~100%)

Press , Diplayed

Completed Alarm setup

☞. High Level Setting

Press , Displayed HIGH value

By Pressing button, Adjust HIGH value(0~100%)

Press , Diplayed

Completed High level setup

BI-SM2004.doc 12/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

☞. High High Level Setting

Press , Displayed HIGH HIGH value

By Pressing button, Adjust HIGH HIGH value(0~100%)

Press , Diplayed

Completed High High level setup

☞. Delay Time Setting

Press , Displayed DELAY TIME

By Pressing button, Adjust DELAY TIME (0~60sec.)

Press , Diplayed

Completed Delay Time setup

BI-SM2004.doc 13/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

☞. Filter Setting

Press , Displayed FILTER LEVEL value

By Pressing button, Adjust FILTER LEVEL value(0~9)

Press , Diplayed

Completed Filter Level setup

☞. Span Setting : Zero

Press , Displayed Zero & Reading AD value

AND

AD Value become steady (about 2 min. Later), Press , Displayed

Completed Zero Setup. And Light Beam will be switched off and converted to Span 100%

Setting Mode.

BI-SM2004.doc 14/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

☞. Span Setting : 100%

Displayed 100% span & Reading AD value

AND

AD Value become steady (about 2 min. Later), Press , Displayed

Completed Span 100% Setup

☞. 4-20mA Setting : 4mA

Connect ampere meter to terminal of Signal Output on Terminal Board inside Control Unit.

If you press button simultaneously, the value will be decreased.

Press , Displayed 4mA & Reading AD value

AND

By Press button, Adjust the AD value until Ampere Meter read out 4mA

Press , Displayed

Completed 4mA Signal Output setup, and dissplay converts to 20mA Setting Mode.

BI-SM2004.doc 15/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

☞. 4-20mA Setting : 20mA

Press , Displayed 20mA & Reading AD value

AND

By Press button, Adjust the AD value until Ampere Meter read out 20mA

Press , Displayed

Completed 20mA Signal Output setup

※※※ CAUTION ※※※

Please note that 4-20mA is factory default thus re-setting is not necessary and

it should not be changed by users.

If the re-setting is to be indispensable, please contact our Technical

Department.

BI-SM2004.doc 16/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

2-1-5 Trouble Shooting

Condition Cause Action Remarks

SEnS &

Error Disconnection of

electric cable Check cable connection between

control panel & receiver

UndEr Sensor fail Zero resetting & calibration

ouEr Sensor fail 100% span resetting & calibration

Power fail Check the power source

Break down fuse Replace fuse with new one

System reset(power off & on)

Program damaged Contact our engineering dapartment

Display board damaged Replace display board with new one

Main board damaged Replace main board with new one

Display error

20p cable damaged Replace 20p cable with new one

Zero resetting & calibration

Sensor fail 100% span resetting & calibration

Glass was dirty Cleaned glass

Cleaned stack adaptor

Abnormal

indication

Stack adaptor

is Clogged Check sealing air line

BI-SM2004.doc 17/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

CHAPTER 3

3-1 Preliminary Instructions

A. This equipment comprised :

A.1 Light Beam Projector

This consists of two parts, a tube housing a solid state light source and optical system and a

flange casting which is mounted onto the flue or stack. The flanged casting should be

insulated against the flue or ducting by an asbestos gasket to reduce conduction of heat into

the projector and receiver units.

A.2 CDS cell Receiver

This has a casting for mounting on the flue or stack similar to the projector unit. A second

tube houses a photocell, and optical system which should be cleaned at regular intervals in

order to prevent soot deposits causing incorrect operation. The cell should not be subjected

to an ambient temperature in excess of 70 deg Centigrade.

A.3 Control Unit

This is contained in a robust housing suitable for panel or wall mounting. Wiring should be

carried out in accordance with the diagram.

B. The following points should be carefully observed before installation:

B.1 Optical units must be rigidly mounted and properly aligned.

B.2 Avoid temperature extremes at the projector, receiver and cable junctions i.e. direct

sunlight, hot stack etc. Max. temperature 70°C.

B.3 Prevent external light sources affecting the optics i.e. install away from duct or flue exit.

B.4 The optical units should be installed after possible pipe connection to an inert gas

system.

BI-SM2004.doc 18/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

3-2 Installation - Projector and Receiver Units

3-2-1 General

To avoid possible errors in obscuration readings due to infiltration of air the optical units

should be located away from the flame area and downstream of any flue gas sampling points.

Typical Installation

3-2-2 Location

These units must be rigidly mounted in the horizontal plane on opposite sides of the stack or

duct so that the projector light beam is at right angles to the flow of flue gases and gives

unrestricted illumination of the receiver CDS cell. The following considerations should be

taken into account when choosing a suitable location.

3-2-3 Temperature

Radiated heat, which has the greater effect on the units, can be effectively reduced by

suitable lagging of adjacent hot surfaces. Normally sufficient cooling effect is provided by air

purging. The temperature of the Projector / Receiver units should not exceed 70°C.

3-2-4 Accessibility

Optical units must be located such that they are readily accessible for lens cleaning, routine

maintenance and servicing.

BI-SM2004.doc 19/34

B-I INDUSTRIAL CO., LTD.

SMOKE DENSITY INDICATOR

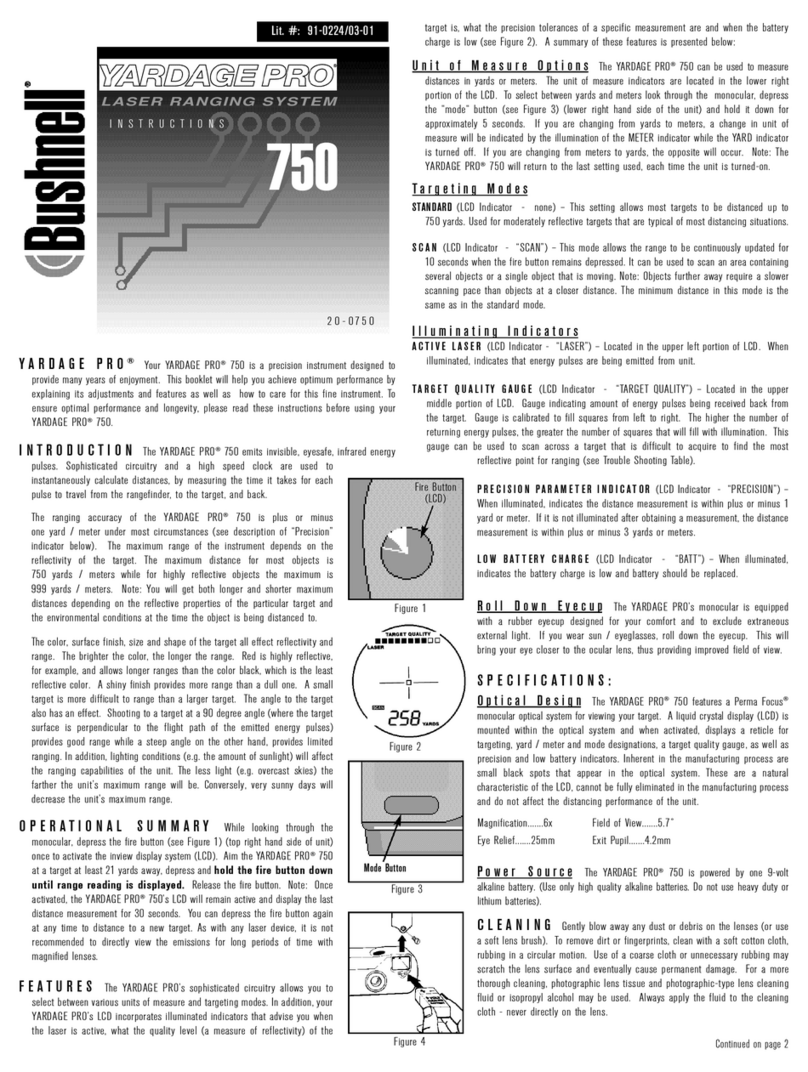

RECEIVER PROJECTOR

SUN

Whilst the optical units will function correctly at temperatures up to 70°C, locations of high

ambient temperature should be avoided as far as possible so that routine maintenance and

service can be carried out whilst the plant is in operation.

3-2-5 Scanning Distance

It is recommended that the scanning distance be kept within the limits 300 mm to 5000 mm.

Where the distance between the duct walls is greater the mounting tubes may be extended

into the duct to reduce the scanning distance, Scanning distances less than 300 mm should

be avoided if possible.

3-2-6 Stratification

To ensure that the smoke or dust measured by the instrument is representative of that emitted,

the influence of dampers, bends, tees, obstructions and draught balance doors should be

considered when selecting a suitable position. Location of the units close to bends in the flue

should also be avoided as the momentum of the flue gases may deposit dust on the lenses.

3-2-7 Sunlight

The optical units should not be

installed at the flue opening to

atmosphere as ambient light may

affect the stability of readings.

3-2-8 Mounting Optical Units

The diagram below indicates the method of mounting to optical units on a steel duct or

chimney. Mounting tubes are normally supplied and fitted by the steel fabricator and must

always be installed in the horizontal plane.

The mounting tubes should be fabricated from 50A, Schedule 80 pipe and special flange O.D

115 mm X I.D 50mm X 15T

BI-SM2004.doc 20/34

Table of contents

Popular Measuring Instrument manuals by other brands

TFA

TFA 30.5019 instruction manual

Endress+Hauser

Endress+Hauser Soliphant T FTM20 technical information

3B Elettronica

3B Elettronica 8110-AIR5 user manual

Sper scientific

Sper scientific 300033 instruction manual

R.M. Young

R.M. Young 52202 instruction sheet

Hanna Instruments

Hanna Instruments HI96786C instruction manual