3

Type 8220

1. ABOUT THE OPERATING INSTRUCTIONS............................ 4

1.1. Denition of the word "device" ..................................... 4

1.2. Symbols used ................................................................ 4

2. INTENDED USE....................................................................... 5

3. BASIC SAFETY INFORMATION.............................................. 6

4. GENERAL INFORMATION ...................................................... 7

4.1. Manufacturer's address and international contacts .... 7

4.2. Warranty conditions....................................................... 7

4.3. Information on the Internet ........................................... 7

5. DESCRIPTION......................................................................... 8

5.1. Area of application......................................................... 8

5.2. Construction .................................................................. 8

5.3. Description of the name plate ...................................... 8

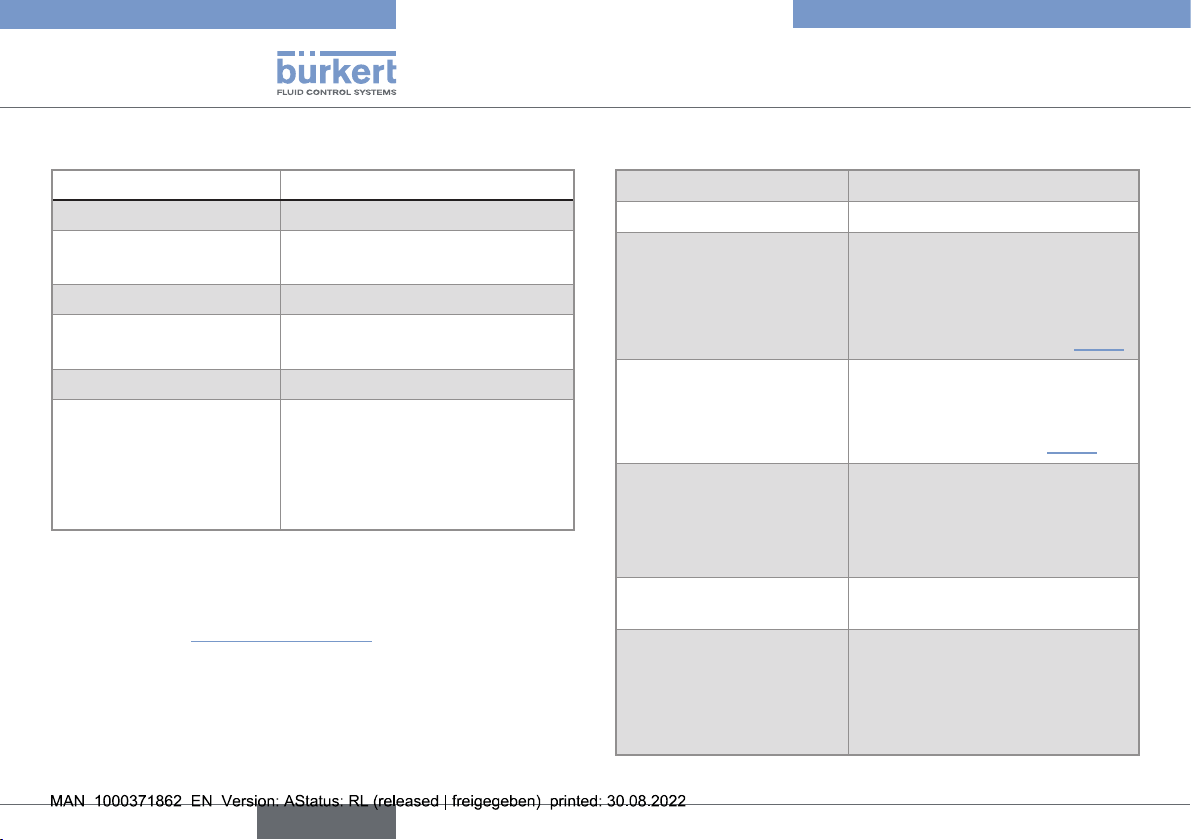

6. TECHNICAL DATA ................................................................... 9

6.1. Conditions of use........................................................... 9

6.2. Conformity to standards and directives ...................... 9

6.3. Conformity to the pressure equipment directive.......... 9

6.4. Materials....................................................................... 10

6.5. Dimensions of the device ............................................ 10

6.6. Fluid data, measurement data .................................... 10

6.7. Sensor data.................................................................. 11

7. INSTALLATION AND WIRING .............................................. 12

7.1. Safety instructions ....................................................... 12

7.2. Installation on the pipe ................................................ 13

7.3. Electrical wiring............................................................ 14

7.3.1. Safety instructions ................................................. 14

7.3.2. Technical data of the cables for the female

connectors, type2518 or type2509...................... 14

7.3.3. Assembling the female connector ......................... 15

7.3.4. Ensuring the equipotentiality of the installation ..... 15

7.3.5. Connect the device to the transmitter ................... 17

8. COMMISSIONING ................................................................. 17

9. MAINTENANCE AND TROUBLESHOOTING........................ 18

9.1. Safety instructions ....................................................... 18

9.2. Maintenance of the device and the conductivity

sensor........................................................................... 18

10. SPARE PARTS AND ACCESSORIES .................................. 19

11. TRANSPORT, STORAGE, DISPOSAL ................................. 20

English