Baby Lock BL3-407 User manual

Other Baby Lock Sewing Machine manuals

Baby Lock

Baby Lock Flourish BLMFO User manual

Baby Lock

Baby Lock Tempo BLTP User manual

Baby Lock

Baby Lock Acclaim BLES4 Technical manual

Baby Lock

Baby Lock Quilter's Choice BLQC2 Technical manual

Baby Lock

Baby Lock imagine wave BLE3ATW Technical manual

Baby Lock

Baby Lock esante BLN User manual

Baby Lock

Baby Lock Jazz BLMJZ Technical manual

Baby Lock

Baby Lock Spirit BLPY User manual

Baby Lock

Baby Lock Gallant XL Technical manual

Baby Lock

Baby Lock ellegante 2 BLG2 User manual

Baby Lock

Baby Lock Triumph BLETS8 Technical manual

Baby Lock

Baby Lock Ovation User manual

Baby Lock

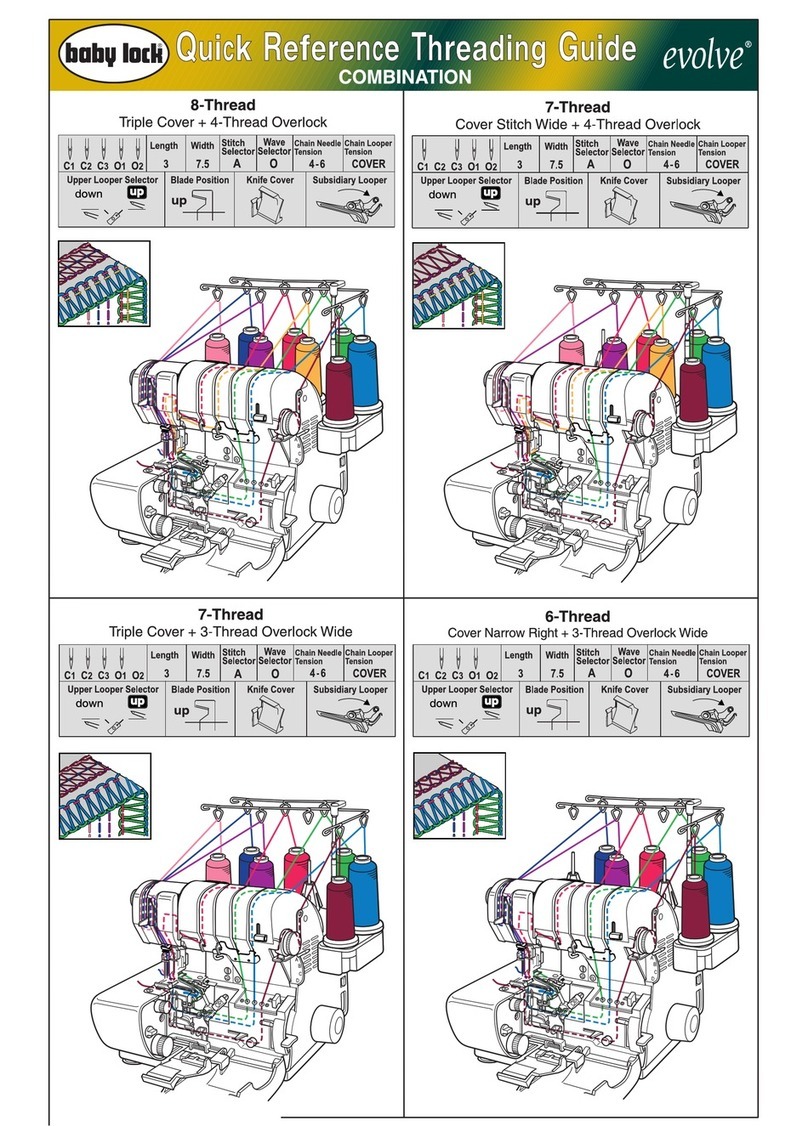

Baby Lock evolve User manual

Baby Lock

Baby Lock Amelia BL100A Technical manual

Baby Lock

Baby Lock Endurance II BND9-2 User manual

Baby Lock

Baby Lock Regent BLRT18 Technical manual

Baby Lock

Baby Lock Pro Line BL4-838D User manual

Baby Lock

Baby Lock Capella Technical manual

Baby Lock

Baby Lock Elissimo & Elissimo GOLD BLSO-BF2 User manual

Baby Lock

Baby Lock Ellure PLUS BLR3 Technical manual