WWW.BALTIMOREAIRCOIL.COM

2

CROSSFLOW COIL PRODUCTS

Introduction

1

Safety

Adequateprecautionsappropriatefortheinstallationandlocationoftheseproductsshould

betakentosafeguardtheequipmentandthepremisesfromdamageandthepublicfrom

possibleinjury.The procedures listed in this manual must be thoroughly reviewed prior to

rigging and assembly. Read all warnings, cautions, and notes detailed in the margins.

Whenthefanspeedoftheunitistobechangedfromthefactorysetspeed,includingthe

useofavariablespeeddevice,stepsmustbetakentoavoidoperatingatornearthefan’s

“criticalspeed”whichcouldresultinfanfailureandpossibleinjuryordamage.Consult

withyourlocalBACRepresentativeonanysuchapplications.

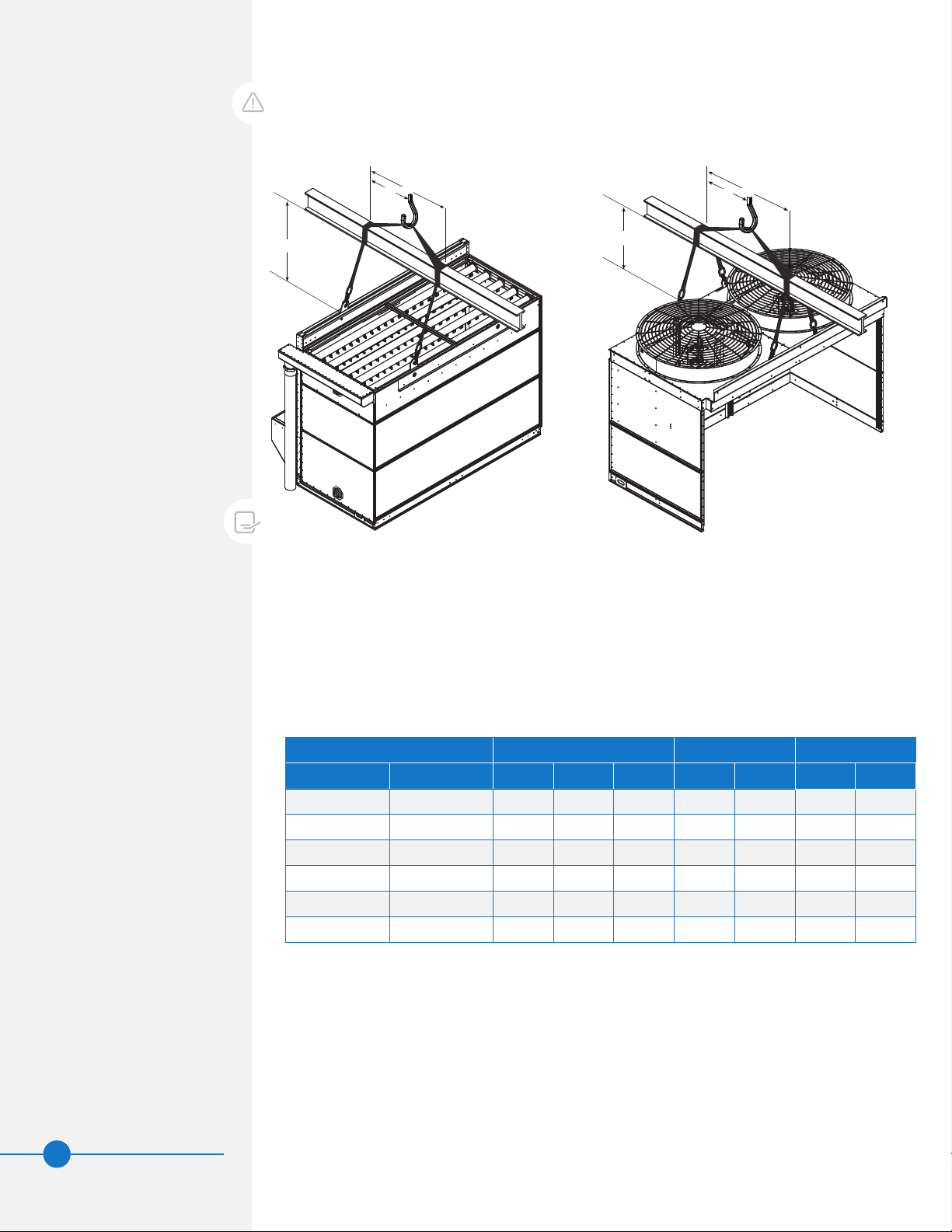

Shipping

FXV,FXV3,CXVB,andCXVTunitsarefactory-assembledtoensureuniformqualitywith

minimumeldassembly.Singleairintakemodelsshipintwosectionspercell(lowerand

upper).Dualairintakemodelsshipinfoursectionspercell(onelowerandthreeupper:

eachcoilsectionshipsseparately)tominimizeriggingandfreightcosts.Contactyourlocal

BACRepresentativeformoreinformation.Forthedimensionsandweightsofaspecicunit

orsection,refertothecertieddrawings.

Pre-Rigging Checks

Whentheunitisdeliveredtothejobsite,itshouldbecheckedthoroughlytoensureall

requireditemshavebeenreceivedandarefreeofanyshippingdamagepriortosigningthe

billoflading.

The following parts should be inspected:

SheavesandBelts

Bearings

BearingSupports

FanMotor(s)

FanGuard(s)

Fan(s)andFanShaft(s)

FloatValveAssembly(s)

WaterDistributionSystem

CoilSurface

ColdWaterBasinAccessories

InteriorSurfaces

ExteriorSurfaces

Louvers/CombinedInletShields

SprayWaterPumps

MatingSurfacesBetweenSections/

Modules

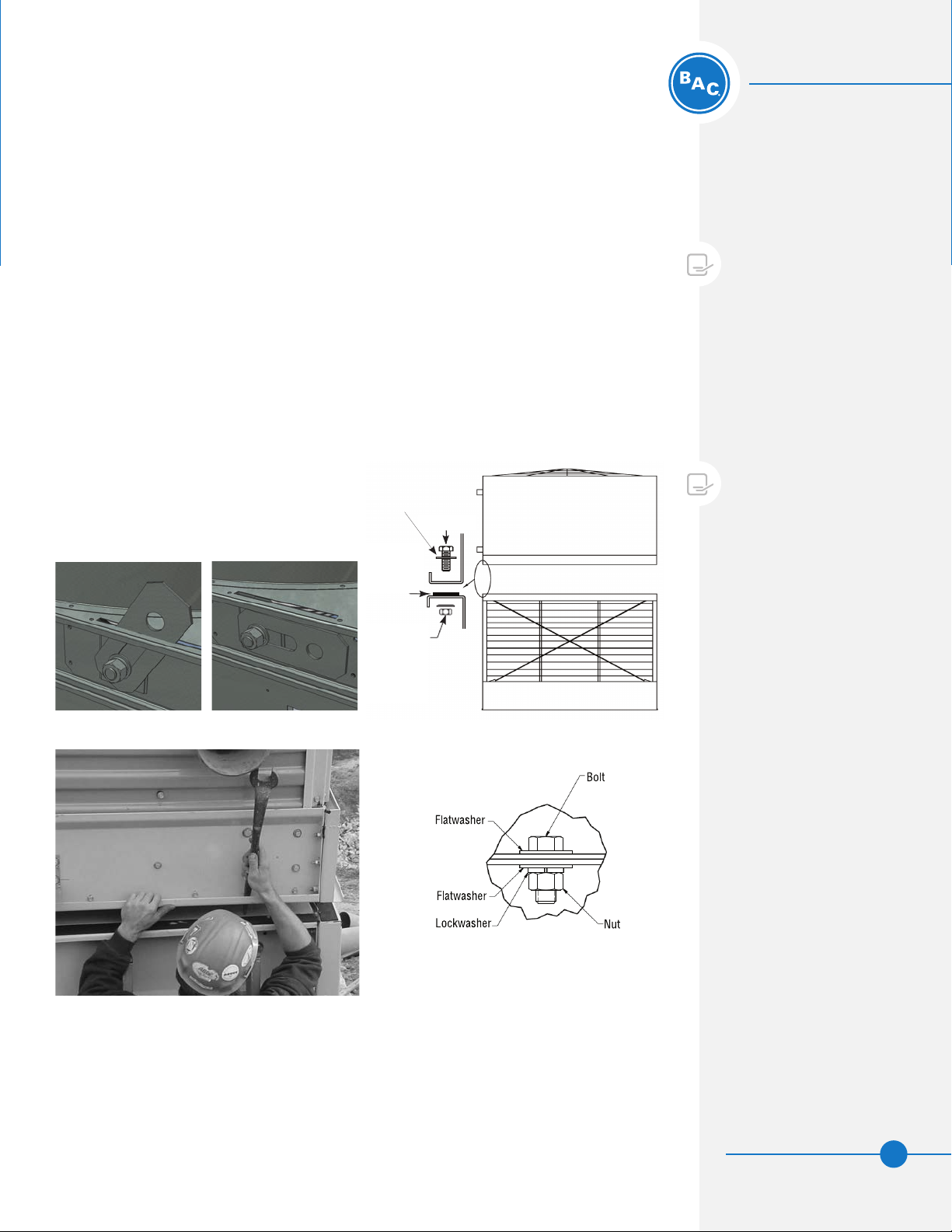

MiscellaneousItems:Allbolts,

nuts,washers,andsealertape

requiredtoassemblesectionsor

componentpartsarefurnishedby

BACandshippedwiththeunit.

Achecklistinsidetheenvelope

attachedtothesideoftheunit

marked“Contractor’sInstallation

Instructions”indicateswhat

miscellaneouspartsareincluded

withtheshipmentandwherethey

arepacked.

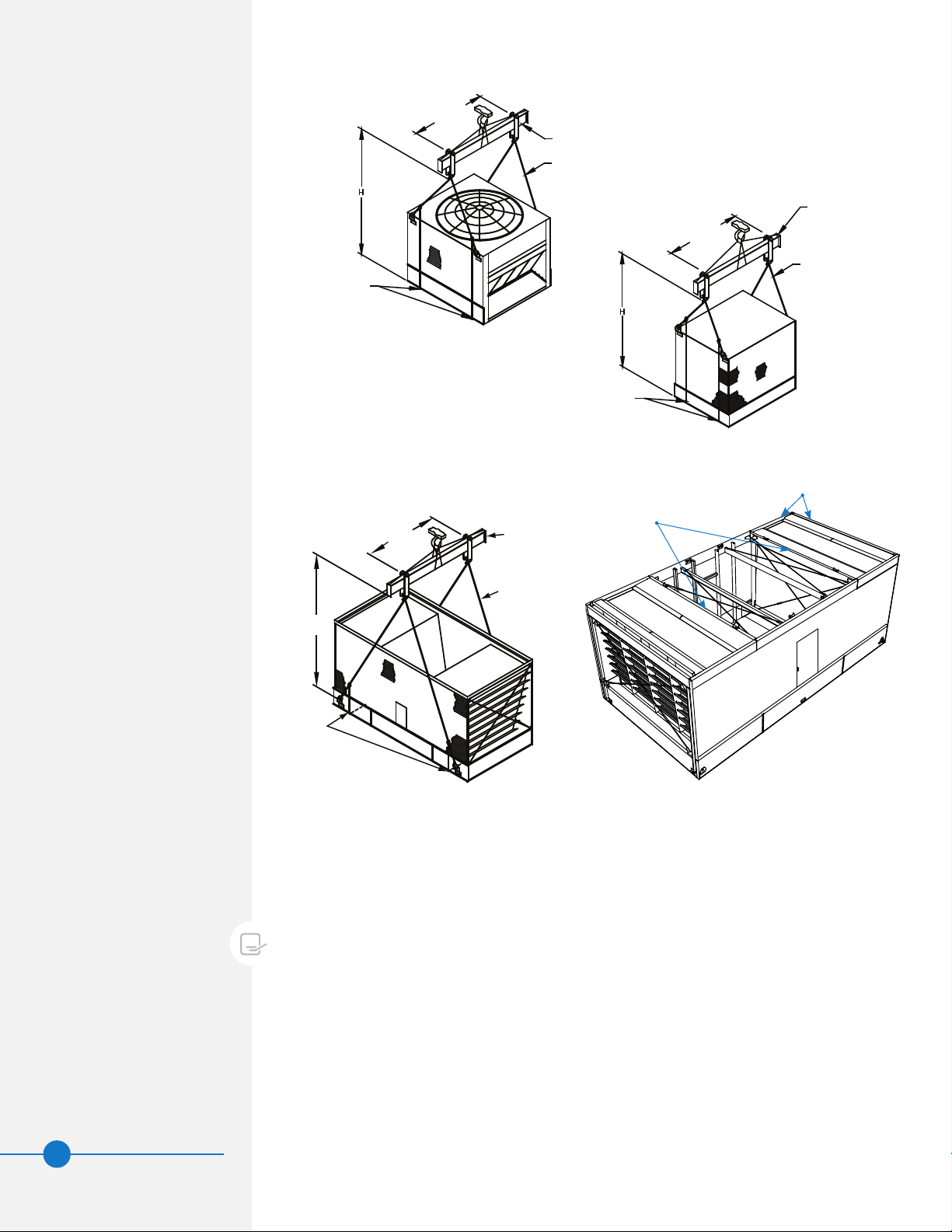

WARNING: Failure to use lifting

provisions can result in a dropped

load causing severe injury, death,

and/or property damage. Lifts

must be performed by qualified

riggers following BAC published

Rigging Instructions, and generally

accepted lifting practices. The

use of a supplemental safety

sling may also be required if the

lift circumstances warrant its

use, as determined by the rigging

contractor.

CAUTION: Only personnel qualified

to do so should undertake

operation, maintenance and repair

of this equipment. Proper care,

procedures and tools must be used

in handling, lifting, installing,

operating, maintaining and

repairing this equipment to prevent

personal injury and/or property

damage.