WWW.BALTIMOREAIRCOIL.COM

8

• Remove excess and loose sealer tape from valves and connections, including flume

connections.

• Turn the water supply on.

• Set the make-up float valve so the water shuts off at the operating level, see Table 2

on page 22 and Figure 17 on page 23.

• Ensure proper water treatment. Refer to page 30 for details.

• Verify the voltage stated in the submittal package matches the incoming power at the

job site.

• Verify that the supply power is connected to the iPilot® Control System.

• Verify that Building Management System (BMS) interface is correctly wired to the

iPilot® Control System.

• Turn on all breakers inside the iPilot® Control System.

• Close the iPilot®Control System panel and ensure that all the locks have been fully

engaged and secured by rotating them 90° with a flathead screwdriver or coin.

• Turn on the main power supply to the unit.

• Verify wiring from each component to the iPilot® Control System.

• Verify component operation by entering the Main Menu of the user interface, select

Point Overview, and change Manual Mode to On. Refer to the “iPilot® Control System

Appendix” on page 45.

• On units that are powered with 230/460V three phase, the power must be connected

properly to ensure that the pumps rotate clockwise. The wiring should be installed to

have incoming power U phase connected to panel L1, V phase to L2, W phase to L2,

and E phase to ground. It is recommended that a rotation meter be used to confirm

the power is connected to allow clockwise operation. Failure to ensure correct phase

wiring will result in reduced spray pump water flow, reduced thermal performance, and

possible excessive scale buildup.

• Verify that fan(s) are rotating in the correct direction (clockwise when looking into the

unit from the outside) by operating each component in “Manual mode”.

• Check for unusual noise or vibration.

• To flush dirt, debris, and oils from the basin and from the heat exchanger exterior,

operate the fans at 350 rpm, per the instructions in Appendix screen V10, and

operate the pumps, per the instructions in Appendix screen V04.

• After verifying component operation, re-enter the Main Menu and change Manual

Mode to Off and ensure that operational system value (OSV) is Off so that the iPilot

Control System can cycle fans and pumps appropriately.

Start-Up

• For initial start-up, clean the conductivity sensor after two weeks of service.

• Ensure that main disconnect switch on the iPilot®Control System is turned On.

The iPilot® Control System will arrive onsite preconfigured with factory default values and

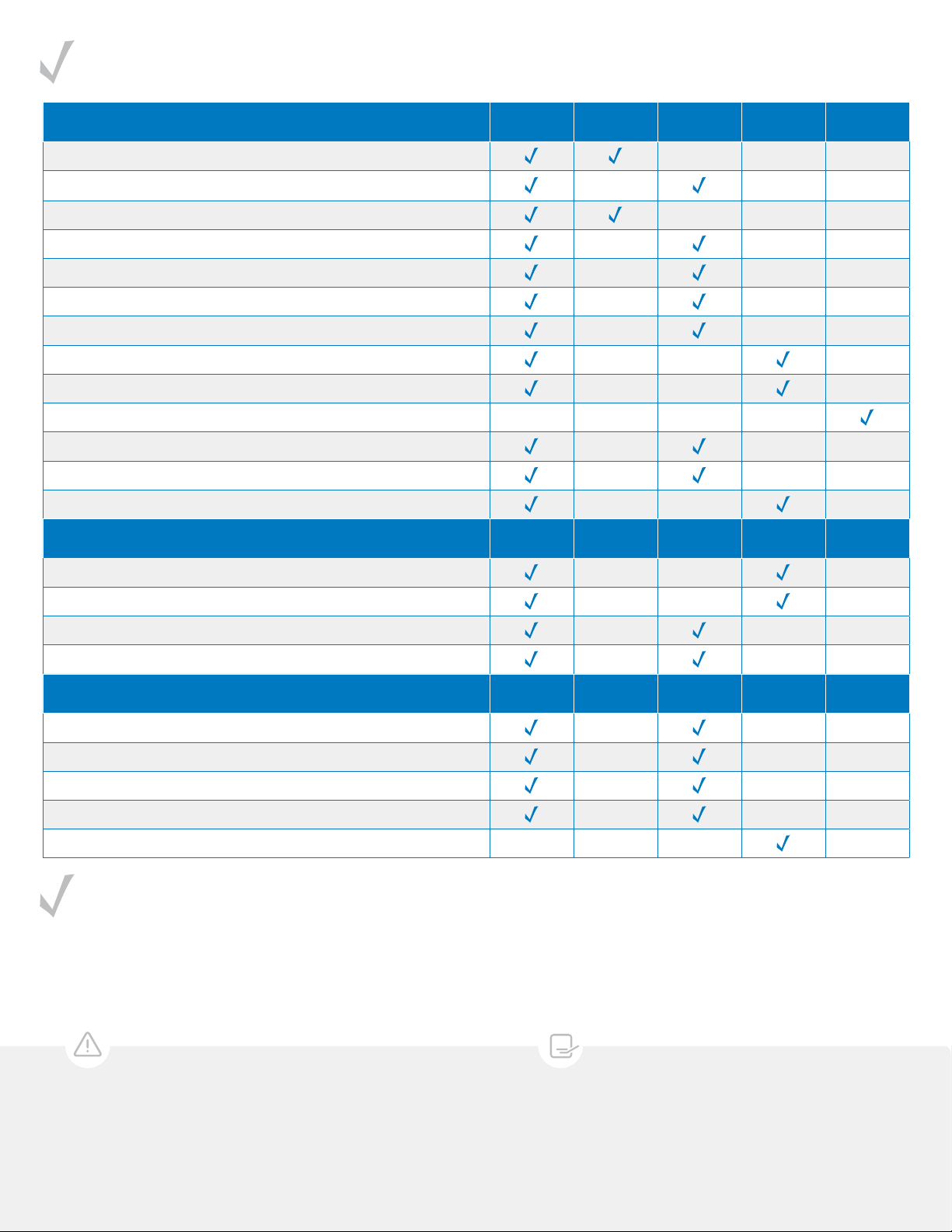

requires field setup. There are three methods of equipment control:

1. Local control without a Building Management System (BMS) interface

2. Local control with a BMS interface (See Table 15 on page 57 for the BMS

data points).

3. Customer Input: Control using analog input (0-10 VDC, 10-0 VDC,

or 4-20 mA) by others.

DANGER: Rotating equipment

will cause severe personal injury

or death to persons who come in

contact. Do not perform any service,

maintenance, or inspection on or

near the fans, motors, or inside

the unit without first ensuring

that the fans and pump motors

are disconnected, locked out, and

tagged out.

WARNING: Dangerous voltages

are present in this equipment.

Disconnect the electrical service

of the source and tag the circuit

out before servicing or replacing

components.