CHAPTER 1 – Foreword

Chap. 1

- 5/14 -

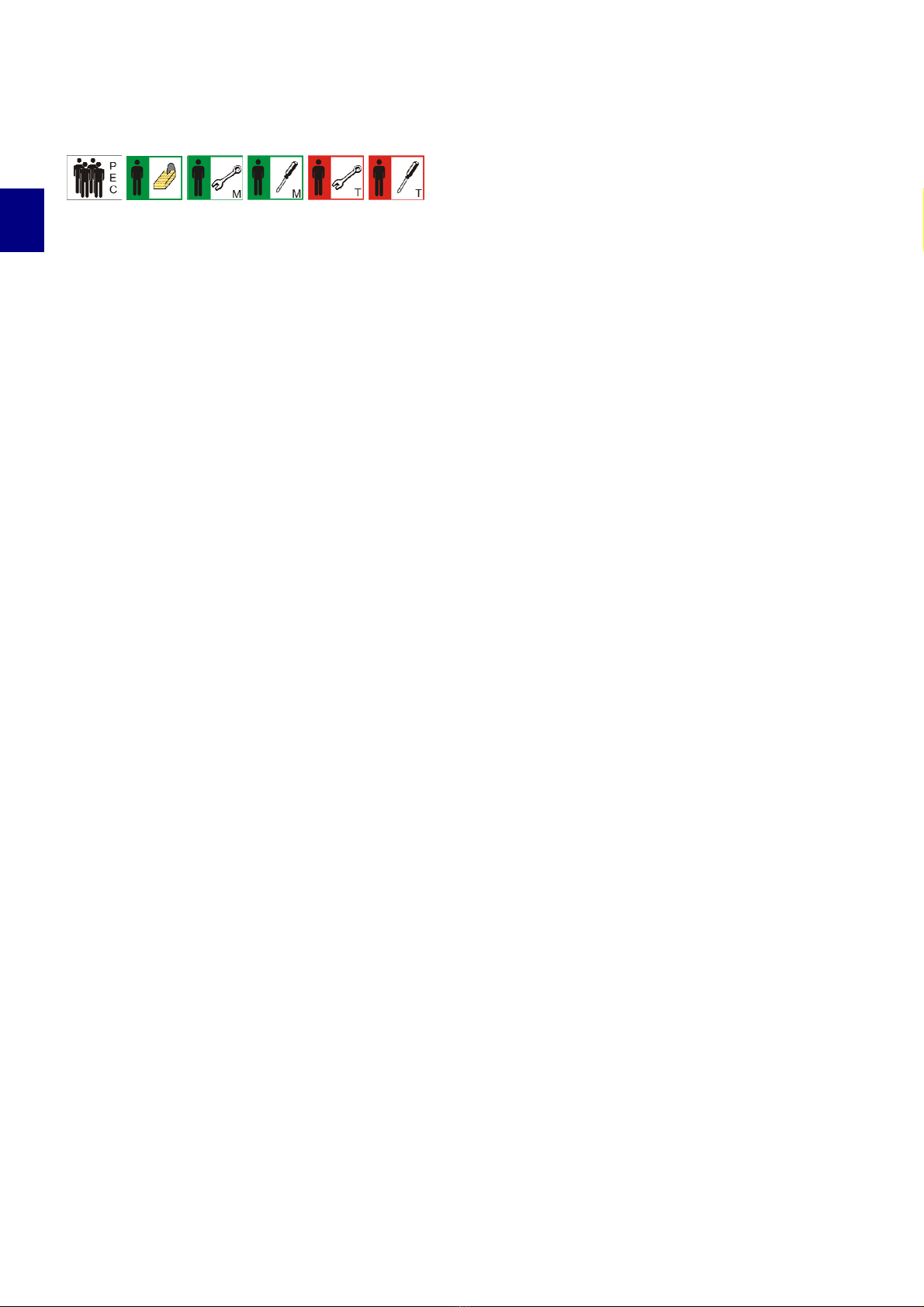

1.2 Manual addressees

All operations described will be accompanied by a symbol (pictograph) corresponding to the operator

considered more suitable for the task; the symbols at the head of each paragraph correspond to the

addresses of the information provided. Please find below the instructions necessary for the identification

of the different professional figures.

A - Operators

Personnel with no specific skills capable of performing only simple tasks, such as

operating the machine using the controls located on the pushbutton panel, loading

and unloading the materials used in production with installed and enabled

protection guards and service settings.

B - Mechanical maintenance men

Personnel with specific mechanical skills capable of carrying out the tasks of the

"operators" and work with the machine in standard operating conditions with

disabled protection guards for maintenance and/or repair work. Not authorised to

work on the electrical system.

C - Electric/electronic maintenance men

Personnel with specific electrical skills capable of carrying out the tasks of the

"operators" and work with the machine in standard operating conditions with

disabled protection guards for maintenance and/or repair work. Not authorised to

work on mechanical parts.

D - Mechanical support technicians

Qualified personnel with specific mechanical skills capable of carrying out the

tasks of item B and further, they can skilfully make any possible settings and/or

replace mechanical parts. Not authorised to work on the electrical system.

E - Electrical/electronic support technicians

Qualified personnel with specific electrical/electronic skills capable of carrying out

the tasks of item C, work with the machine in standard operating conditions with

disabled protection guards and skilfully carry out any adjustments and/or

replacements of electrical/electronic parts. Not authorised to work on mechanical

units.

F- Lifting and handling equipment operator

Operator authorised to use devices designed to lif and handle materials and

machinery (strictly following the manufacturer’s instructions), in compliance with

the regulations in force in the machine user’s country.