Bacharach MGS-410 User manual

Other Bacharach Gas Detector manuals

Bacharach

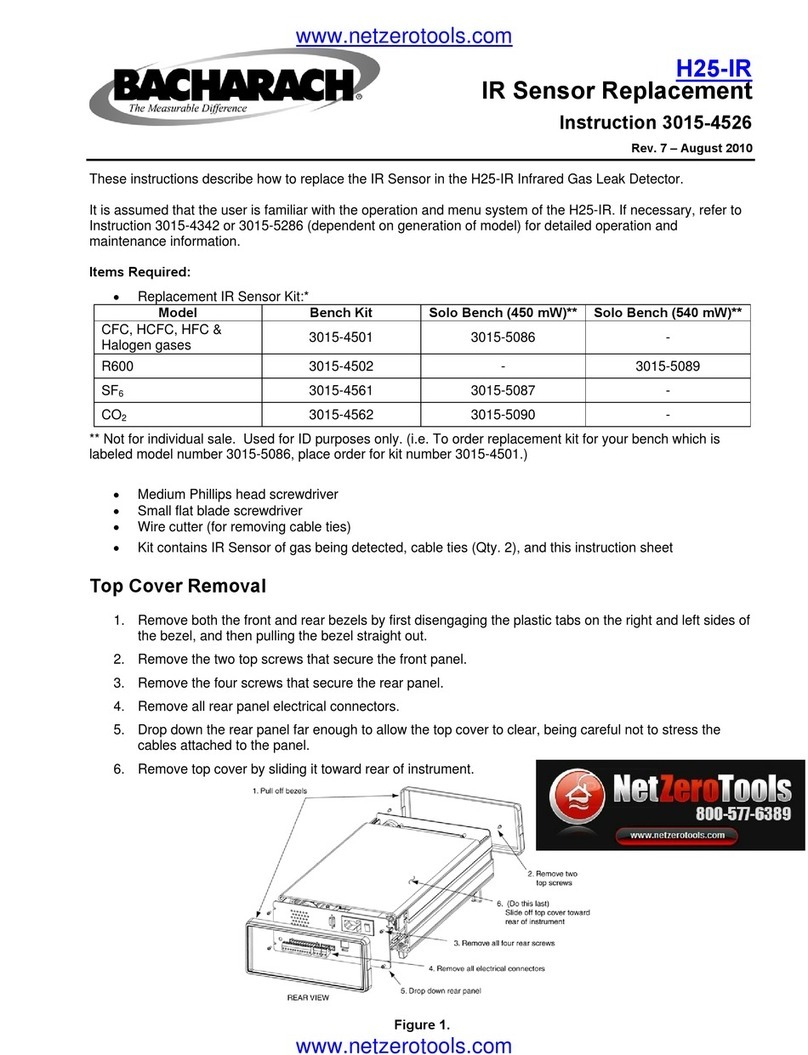

Bacharach H25-IR User manual

Bacharach

Bacharach MVR-300 User manual

Bacharach

Bacharach MGS-350 User manual

Bacharach

Bacharach Leakator 10 User manual

Bacharach

Bacharach MGS 550 User manual

Bacharach

Bacharach MGS-460 User manual

Bacharach

Bacharach Leakator 10 User manual

Bacharach

Bacharach MGS-400 User manual

Bacharach

Bacharach IAM-100 User manual

Bacharach

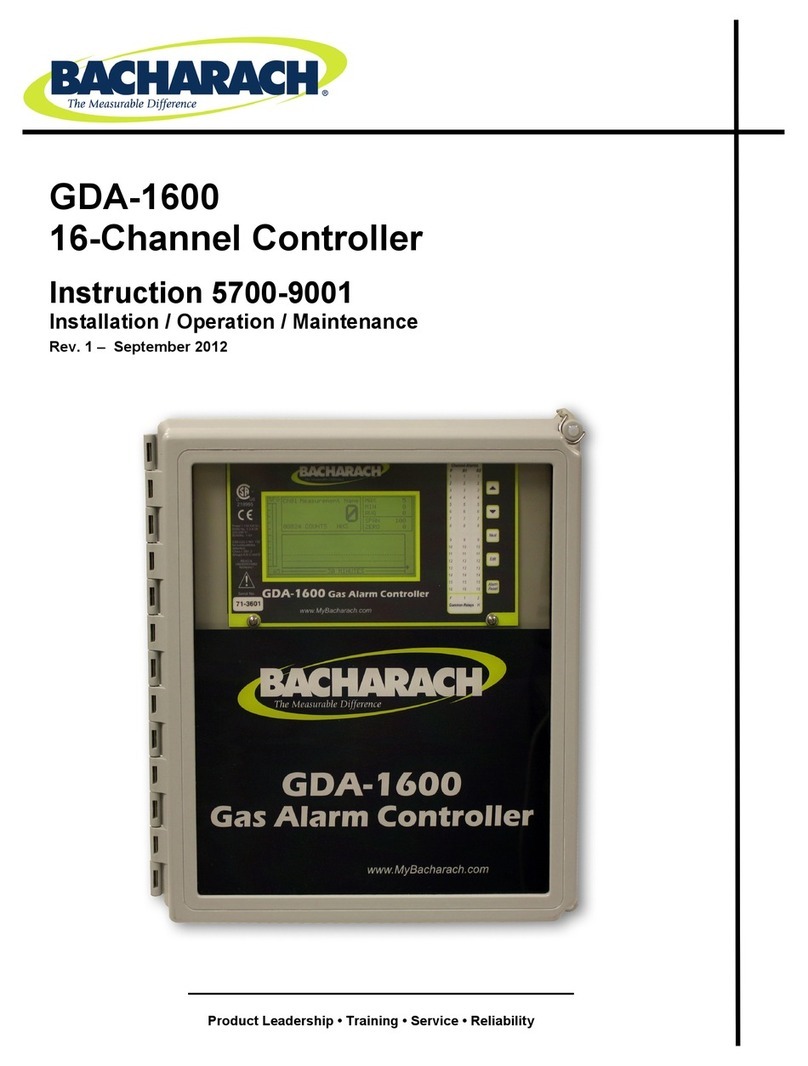

Bacharach GDA-1600 User manual

Popular Gas Detector manuals by other brands

Macurco

Macurco GD-6 Operation manual

Evikon

Evikon E2632 user manual

Critical Environment Technologies

Critical Environment Technologies CGAS-A Series Installation & operation manual

MSA

MSA altair 5 operating manual

DOD Technologies

DOD Technologies ChemLogic CL96 operating manual

DEGA

DEGA NS III LCD Series instruction manual